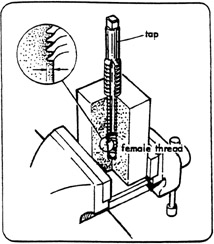

Taps

A tap cuts an internal (female) thread, either left or right handed.

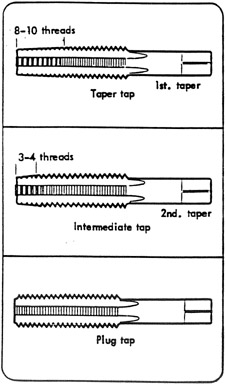

Set of Taps

Taps are usually made in sets of three: a taper tap, an intermediate tap, and a plug tap.

Safety: Beware of cutting edges when handling!

Taper Tap

This tap is tapered off for 8 to 10 threads, and is used first, cutting to the full thread gradually.

Intermediate Tap

This tap usually has three or four threads chamfered. The second tap can finish a through hole.

Plug Tap

This tap has a full sized, untapered thread to the end, and is the main finishing tap. In the case of a blind hole, a plug tap must be used.

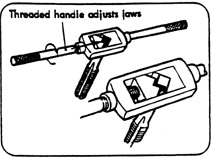

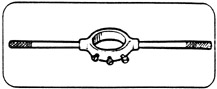

The Wrench

The appropriate sized wrench should always be used for a given tap to ensure that the jaws fit correctly.

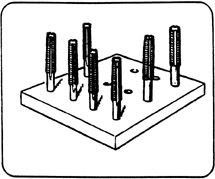

Care of Taps

Care must be taken not to damage the cutting edges. A chipped tap must never be used. When not in use, taps should be kept clean and stored in a rack.

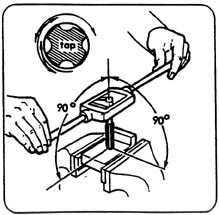

Using Taps

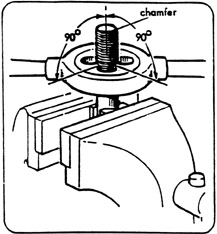

A hole must be drilled to the tapping size for the thread. The workpiece must be securely supported. When starting the cutting, the tap must be perpendicular in all planes to the work. Excessive force must not be used, as this will result in breaking the tap. Cutting fluid should be used. The threads must be cleared as often as is necessary to prevent the flutes from clogging.

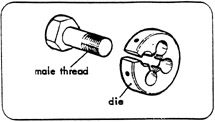

Dies

A die cuts external (male) threads, which may be right or left handed. A dies is made of high quality tool steel, suitably heat treated.

Stock

A die is held in and turned by a stock.

Types of Dies

There are button dies, half dies, and solid die nuts.

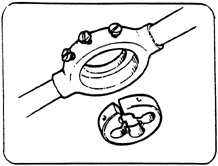

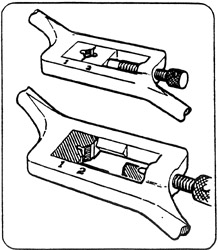

The Button Die

The button or split die allows a limited amount of adjustment in the depth it will cut, by means of screws in the stock which spring it open or shut. It should be fully open for the first cut and then gradually reduced to finished size. It must be checked against an existing thread or die nut of correct size.

Half Dies

Half dies have the advantage of taking smaller cuts to reach correct size, so the amount of material taken off can be controlled. Half dies are in matched pairs, and should always be used together.

Using Dies

The work should be chamfered for ease of starting. The workpiece must be securely supported and vertical in the vise. Great care must be taken to start the thread true to the axis of the bar. Lubricant should be used. The threads must be cleaned as often as is necessary.

Drill Size Table

This table gives the sizes for drills required for machining metric threads. Click the thumbnail for a larger image.