Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

1/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

Organization

: EDF/EP/AMV

Manual of Reference

R5.06 booklet: Dynamics in modal base

Document: R5.06.05

Forces of fluid blade in transitory calculation on basis

modal

Summary:

This document presents a numerical modeling of the forces of fluid blade which exist when two

mechanical systems, plunged in a fluid, vibrate with weak plays between them.

These non-linear forces comprise terms of acceleration which require a particular processing for

conventional explicit diagrams of integration.

An iterative diagram of type not fixes is proposed. It makes it possible to preserve the architecture of the explicit diagrams of

Code_Aster. These forces are established in the operator

DYNA_TRAN_MODAL

[U4.54.03].

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

2/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

Contents

1 Introduction ............................................................................................................................................ 3

2 analytical Expression of the forces of fluid blade in a simple geometrical configuration ............. 4

2.1 Geometrical configuration .............................................................................................................. 4

2.2 Equations governing the behavior of the fluid .............................................................................. 4

2.3 Resolution of the fluid flow of blade with uniform profile ..................................................... 5

2.4 Resolution of the fluid flow of blade with parabolic profile ................................................. 6

3 Study of the dynamic behavior of a system to a degree of freedom in the presence of a blade

fluid ...................................................................................................................................................... 8

3.1 To launch of a mass slowed down by fluid blade with uniform profile ................................................... 8

3.2 To launch of a mass slowed down by fluid blade with parabolic profile ............................................ 10

4 Calculation of a system multi degrees of freedom locally subjected to forces of fluid blade ............. 13

5 Establishment of the non-linear forces of fluid blade ........................................................................... 15

5.1 Specific integration for the forces of fluid blade .................................................................... 15

5.2 Use of the forces of fluid blade in DYNA_TRAN_MODAL ............................................... 15

6 Model of fluid transition blade - shock ............................................................................................... 16

7 Conclusion ........................................................................................................................................... 17

8 Bibliography ........................................................................................................................................ 18

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

3/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

1 Introduction

In the primary education circuit of the power stations ITEM the mechanical components are immersed in a fluid.

For some of this hardware, put in vibrations by the excitation of the primary education fluid, the presence of plays

relatively reduced leads to a more or less important closing of these plays even to contacts

in fluid environment. Numerical work was undertaken in Code_Aster to modelize the contact

dryness between mechanical structures. This work was established in a transitory operator of calculation

by modal recombination [bib3] and were validated by comparison with tests carried out on

model SOLID MASS [bib4].

The vibrations with contact in fluid environment show characteristics different from those

observed in air. When the play is filled, it creates a all the more important fluid flow as it

play is weak. This flow is at the origin of compressive forces acting on the structures

antagonists. Contrary to the configuration in air, where the structures interact by forces of

contact, only when the play is filled; in fluid environment this interaction is permanent and

depends in a non-linear way of the values on the play, normal speed of the structures and of their

acceleration. One will qualify the fluid locked up in the reduced type font of fluid blade; forces resulting from

compression of the fluid will be the forces of fluid blade.

For hardware like the fuel assemblies or the pencils of the bunches of

order these forces of fluid blade induce an amendment of the mechanical characteristics of

structure in air (mass, damping). The damping induced by the fluid blade can be

considerable, and it seems interesting to take it into account in a modeling of this hardware.

We present, in this report/ratio, a simple geometrical configuration, where one can integrate

the flow in the fluid blade realizing certain assumptions on the profile of the flow and them

losses of load at the edges. We determine thus the compressive forces exerted by the fluid on

structure and let us release a general form of their expression according to the play, speed and of

acceleration relative normals between the structures.

We build case-tests of reference on a system to a degree of freedom which illustrate it

behavior of a mechanical system subjected to a force of fluid blade.

The numerical establishment of these non-linear forces in Code_Aster is then detailed. It

require the use of a fixed algorithm of point to find accelerations generalized.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

4/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

2

Analytical expression of the forces of fluid blade in one

simple geometrical configuration

One proposes to determine in an analytical way here the forces being exerted on a structure vibrating

in an incompressible fluid in the vicinity of a motionless wall.

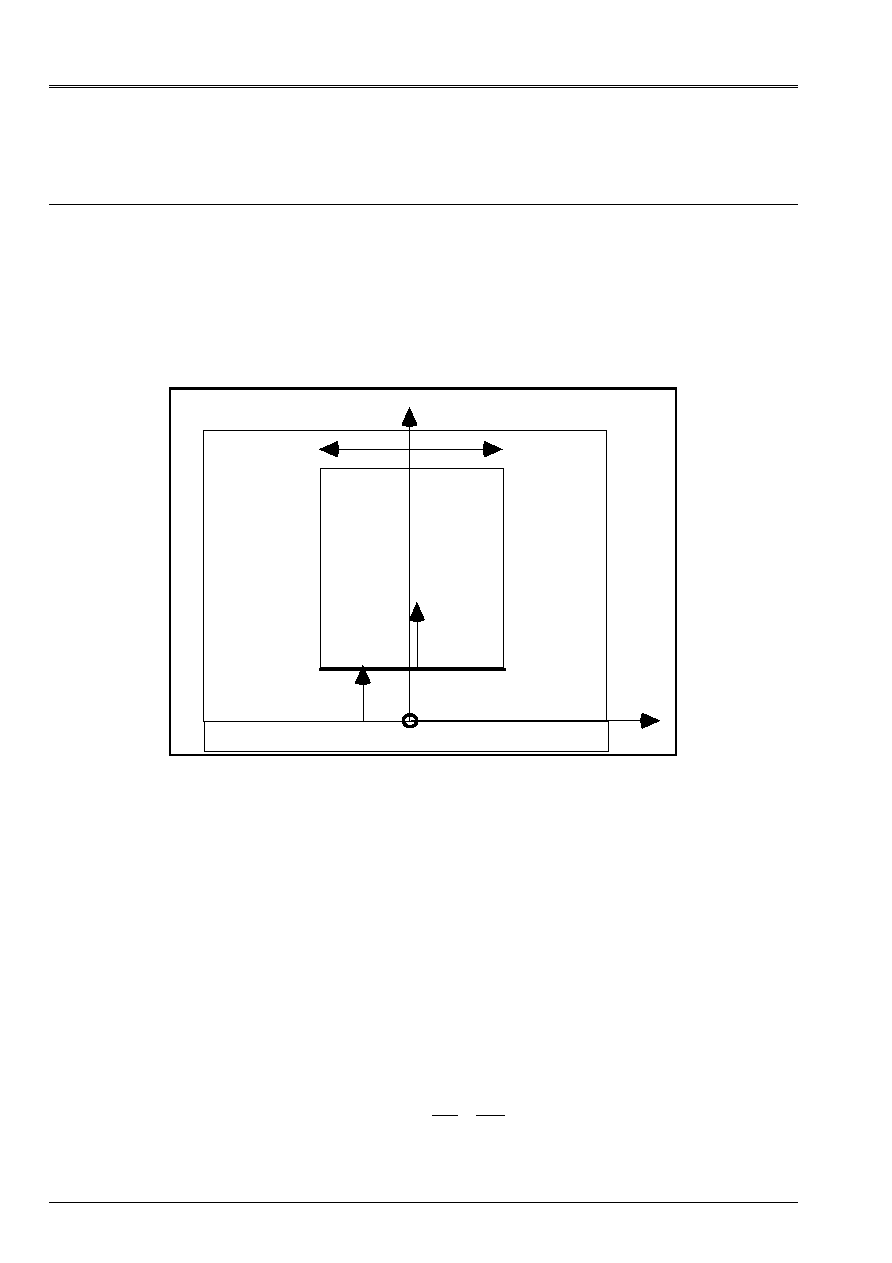

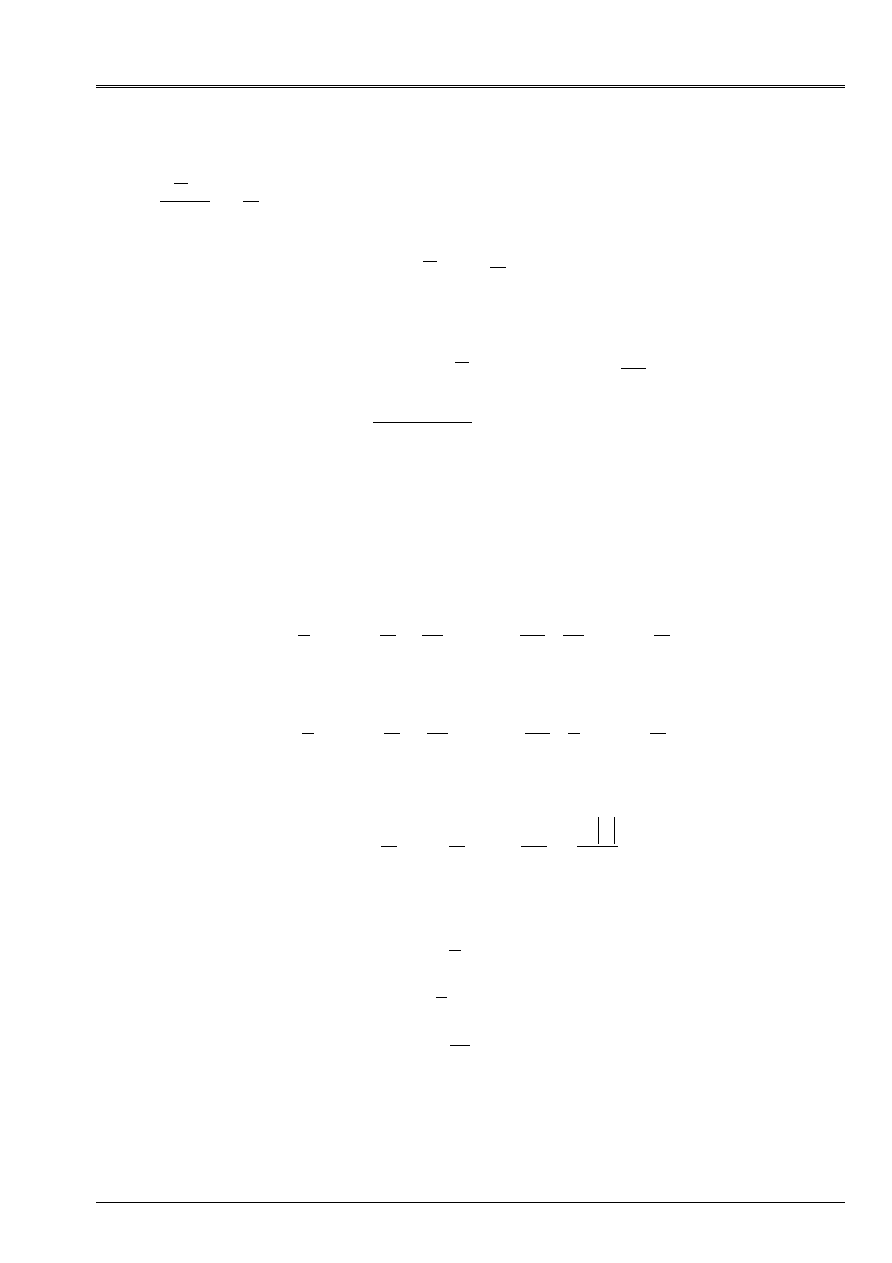

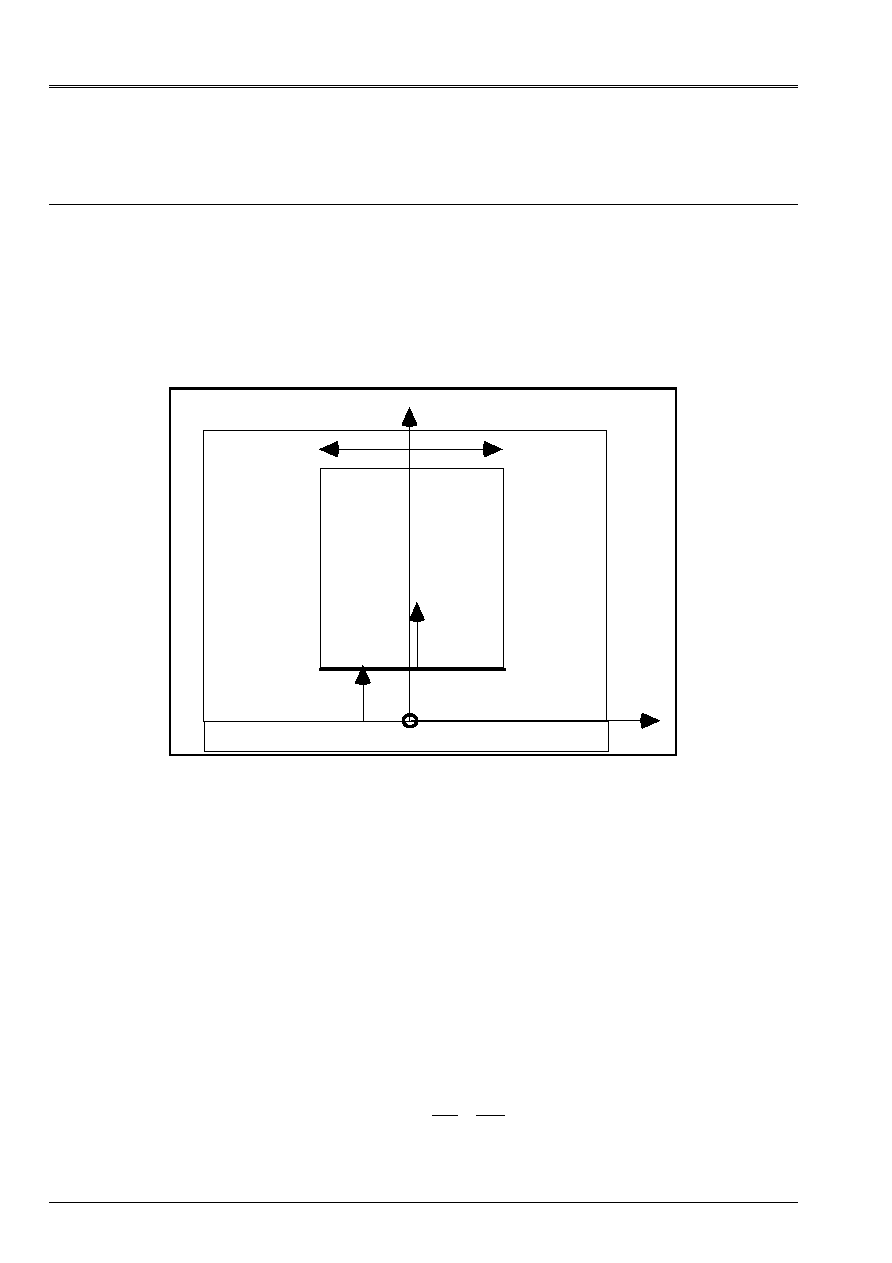

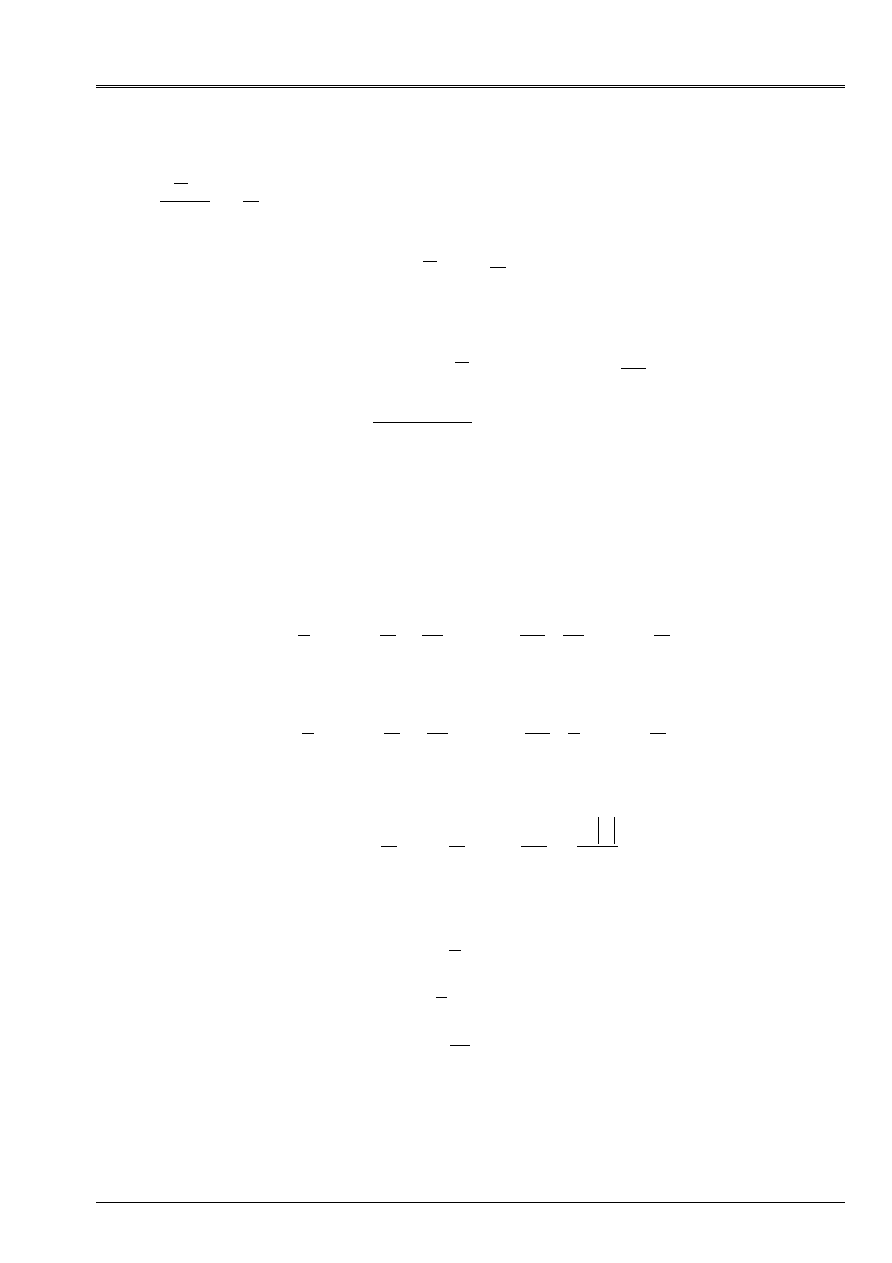

2.1 Configuration

geometrical

A problem of plane flow in the case of is placed (invariant in the direction there of [2.1-a]).

A solid body

is plunged in a fluid

F

. The solid has a plane face

of width 2 L

parallel in the yOz plan and vibrates in the vicinity of a wall fixes parallel with this plan.

Z

X

X

X

·

F

O

2L

y

Appear 2.1-Error! Argument of unknown switch. : Geometrical configuration of the fluid blade

2.2

Equations governing the behavior of the fluid

The problem is supposed invariant by translation according to the axis y, one is thus brought back to a problem

two-dimensional.

Speeds in the fluid will be noted:

() (

)

(

)

v

X

Z

T

X Z T

X Z T

=

+

U.

W.

One will note

X Z

,

, space co-ordinates eulériennes of the fluid, and

X X X

,

!!!

variables

Lagrangian defining the position, speed and acceleration of the solid.

The incompressible fluid being supposed, the components speeds must check:

div

X

Z

()

U

W

v

=

+

=

0

0

that is to say

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

5/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

The fluid also checks the Navier-Stokes equations:

()

()

µ

v

v

v

v

T

grad

grad

+

+

- =

p

.

2

0

In the fluid blade one will suppose that the profile according to

X

component

W

field speed is

of invariant form compared to

Z

. That amounts supposing that it can be written in the form of one

function with separate variables:

(

)

()

W,

W. (,)

X Z T

Z T

X T

=

One in general considers two rather simple assumptions of profile:

·

a uniform profile speed,

·

a profile speed parabolic or flow of One tenth of a poise, valid for speeds

W

weak,

2.3

Resolution of the fluid flow of blade with uniform profile

The flow according to

Z

does not depend on

X

:

(

)

()

W,

W,

X Z T

Z T

=

One neglects in that the effects of viscosity of the fluid in the blade.

Let us write the relation of incompressibility of the fluid, integrated on the thickness of the fluid blade:

[]

()

(U

W).

,

U

W

X

Z

dx

Z

Z

dx

X

X

X

+

=

+

=

0

0

0

0

0

that is to say

.

The boundary conditions are:

()

()

U

!

U

X

X

=

=

and

0

0

,

one thus obtains

()

W

!

Z

Z

X

X

= -

who gives by integration and by noticing that

()

W 0

0

=

:

()

W Z

X

X Z

= -

!

One then deduces immediately the fields from them speed:

()

()

()

()

W X, Z

W Z

X

X Z

U X, Z

U X

X

X X

=

= -

=

=

!

!

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

6/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

By using the Navier-Stokes equation to describe the behavior of the fluid and by projecting it on

the axis

Z

, then by replacing the expressions of

U

and of

W

established higher, and while placing itself in

the assumption of a thin blade of fluid like by considering assumptions of losses of loads

[bib2], one can show [bib5] that the fluid force has two expressions different according to the sign from

!X

:

if

!X

<

0

:

F

L Y X

X

L Y X

X

= -

+

2

3

4

3

3

3

2

…!!

…!

if

!X

>

0

:

F

L Y X

X

L Y X

X

= -

-

2

3

2

3

3

3

2

…!!

…!

One can give a general expression of the fluid force for the uniform profile in the form:

F

X

X

X

X

X X

X

= + +

. !!

. !

!. !

2

2

For the uniform profile, one a:

= -

=

= -

2

3

1

3

3

3

3

.

.

.

L Y

L Y

L Y

2.4

Resolution of the fluid flow of blade with parabolic profile

One gives at the horizontal speed

W

a parabolic profile which has as an expression:

(

)

(

)

()

W X, Z, T

a. X. X X .W Z, T

=

-

,

()

W Z

being mean velocity in the blade and

has

X

=

6

2

Let us write the relation of incompressibility of the fluid, integrated on the thickness of the fluid blade:

[]

()

[

]

U

X

W

Z dx

U

W Z

Z

a. X.(X

X) dx

X

X

X

+

=

+

-

=

.

0

0

0

0

0

,

that is to say

.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

7/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

The boundary conditions give:

()

()

U

!

U

X

X

=

=

and

0

0

, the expression is thus obtained:

()

W

!

Z

Z

X

X

= -

who gives by integration and by considering that

()

W 0

0

=

:

()

W

!

Z

X

X Z

= -

One then deduces immediately the fields from them speed:

(

)

()

(

)

(

)

W,

.(

). W,

.(

). !

U,

.

.

!

X Z T

X X X has

Z T

X X X

X

X Z

X Z T

X

X

X

X

X

=

-

= -

-

= -

-

6

3

2

3

2

3

By using the Navier-Stokes equation to describe the behavior of the fluid and by projecting it on

the axis

Z

, then by replacing the expressions of

U

and of

W

established higher, and while placing itself in

the assumption of a thin blade of fluid as well as assumptions of losses of loads [bib2], one can

to show [bib6] that the fluid force in the case of a parabolic profile has two different expressions

according to the sign of

!X

:

if

!X

<

0

:

F

L Y X

X

L Y

X

X

L Y X

X

= -

-

+

2

3

24

3

24

15

3

3

3

3

2

…!!

…. !

…!

if

!X

>

0

:

F

L Y X

X

L Y

X

X

L Y X

X

= -

-

-

2

3

24

3

2

5

3

3

3

3

2

…!!

…. !

…!

One can give a general expression of the fluid force in the form:

F

X

X

X

X

X

X

X X

X

= + +

+

. !!

. !

. !

!. !

2

3

2

with the formulated assumptions (parabolic profile), the coefficients are worth:

= -

=

= -

= -

2

3

3

5

24

3

3

3

3

3

.

.

….

.

L Y

L Y

L Y

L Y

The expression of the fluid force above thus represents the most complete form and is that

established in Code_Aster.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

8/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

3

Study of the dynamic behavior of a system to one

degree of freedom in the presence of a fluid blade

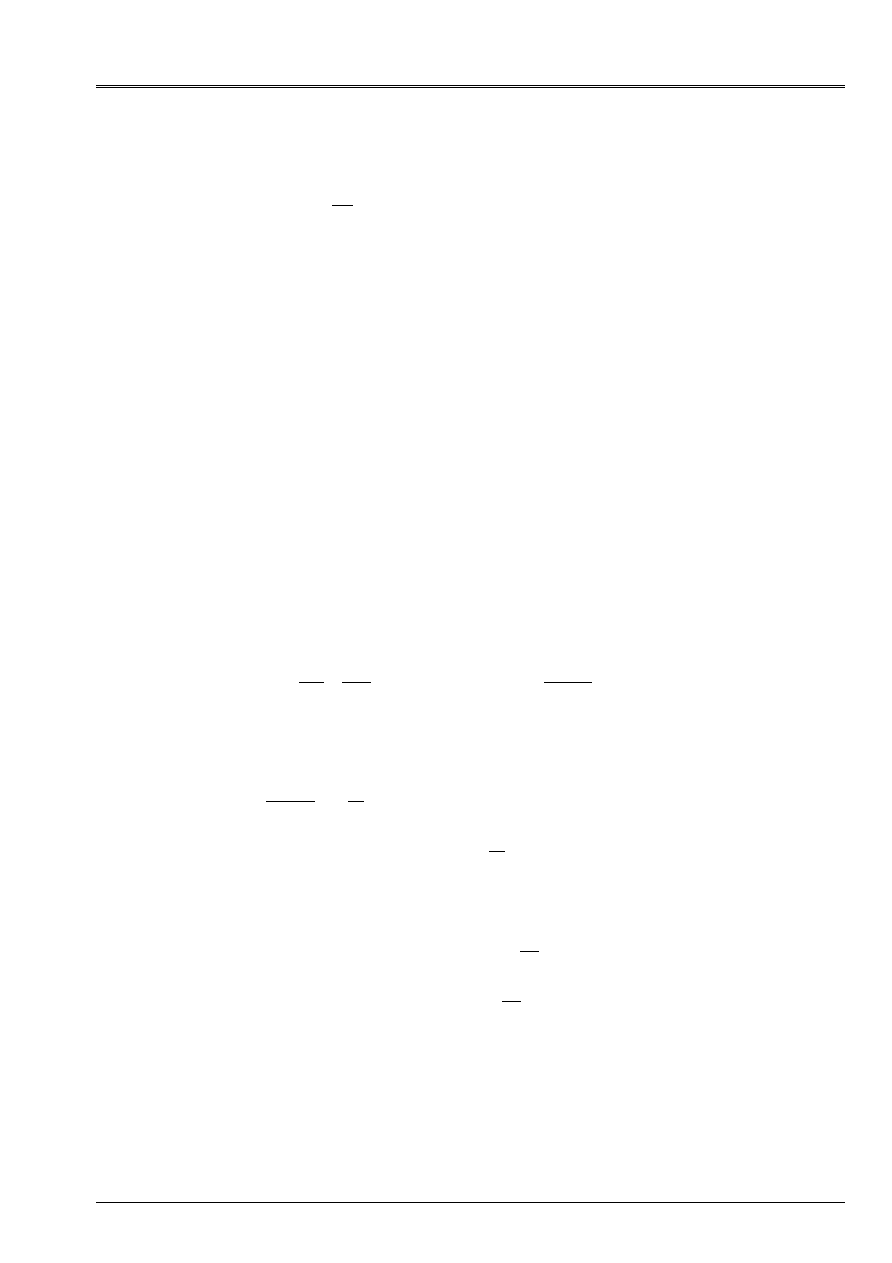

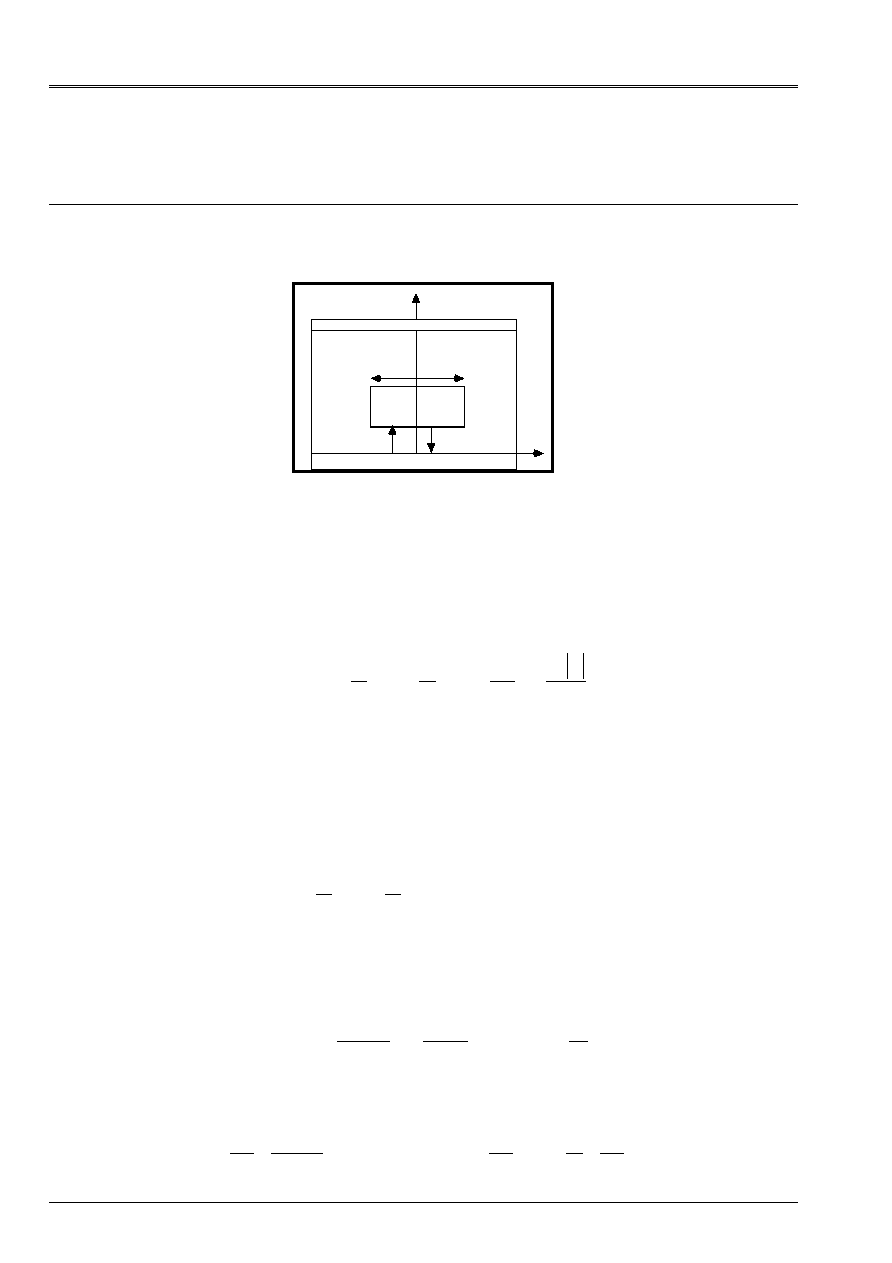

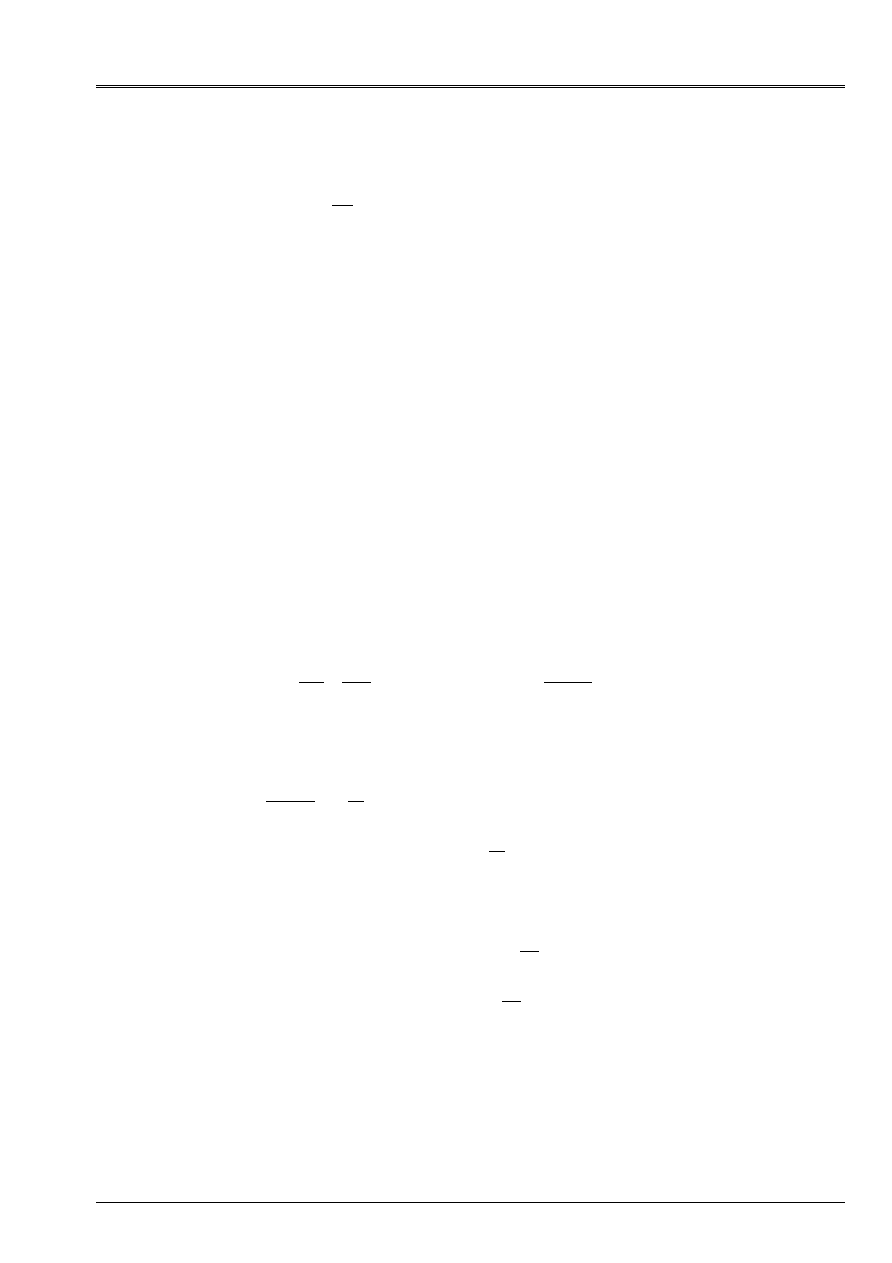

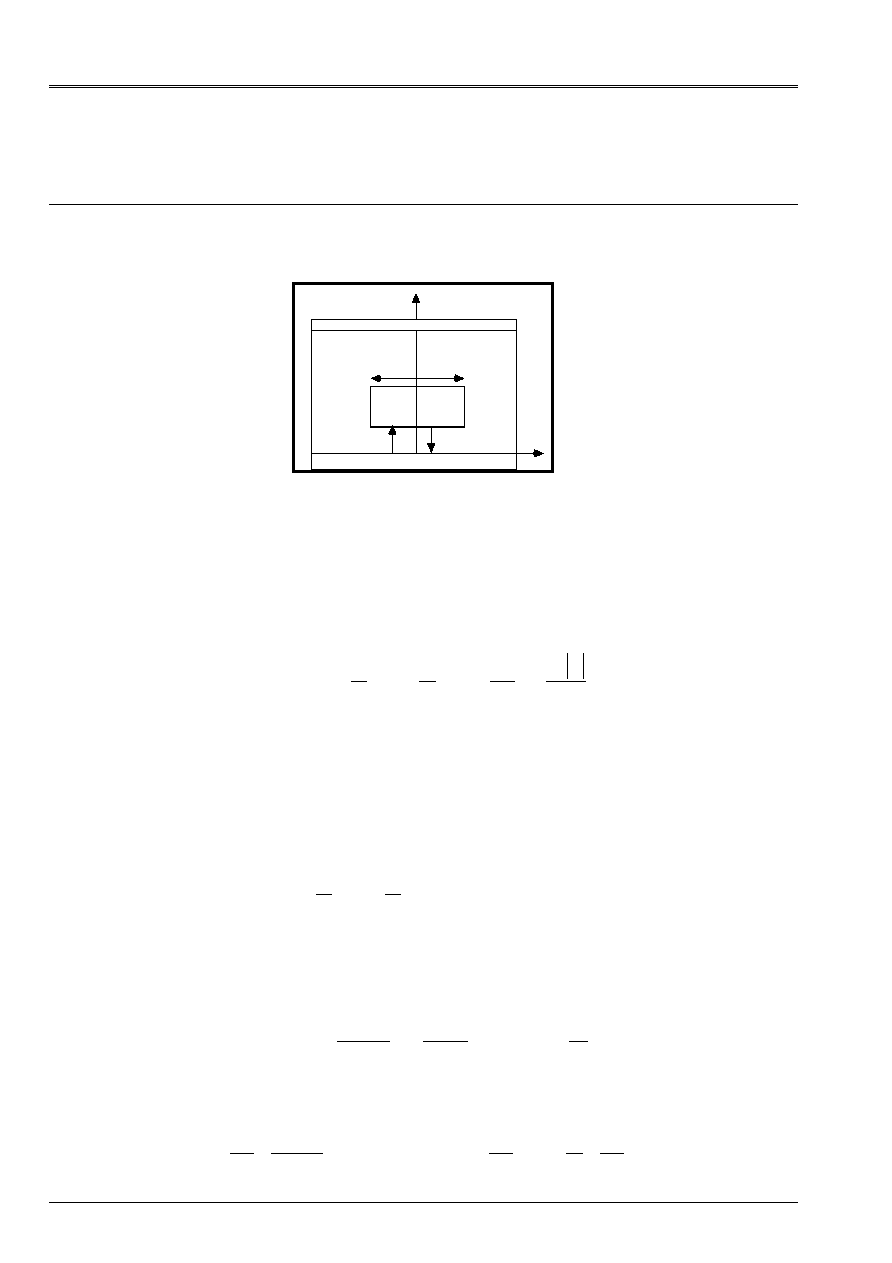

This chapter aims at integrating in an quasi-analytical way a system with fluid blade into a ddl, and serves as

references to tests SDND110A [V5.01.110] and SDND111A [V5.01.111].

Z

X

X

Xo

·

F

O

2L

M

Appear 3-Error! Argument of unknown switch. : Mass deadened by a fluid blade

One will consider the system without rigidity above nor external force applied.

The mass has an initial speed -

!X

0

, and a position

X

0

. One seeks to determine the position

of stop of the mass, evolution of the force of reaction. The equation of the system with the 2 assumptions of

profile: uniform and parabolic is as follows:

(

)

(

)

MR. X

X

X

X

X

X

X

X X

X

X T

X

X T

X

.

!!

. !!

. !

. !

!. !

!

!

= + +

+

=

=

=

= -

2

3

2

0

0

0

0

3.1

To launch of a mass slowed down by fluid blade with uniform profile

For the uniform mode, the differential equation governing the movement of stop of the mass is written

the following way:

MR. X

X

X

X

X

.

!!

. !!

. !

= +

2

.

One can find in [bib1] an analytical resolution whose we will point out the main results here.

By integrating once the differential equation, one obtains an expression the speed of the projectile in

function of its position:

!

! .

.

X

X

X

X

X

X

M

= -

+

+

=

0

0

0

2

2

where

While integrating once again compared to time this differential equation it comes:

T

X

X

X

X

X

Log XX

X

X

=

+

- +

+

-

1

2

1

1

0

0

0

2

0

0

2

0

! .

.

.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

9/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

There is thus an implicit definition of the displacement of the mass in the course of time. One can release

following properties of this movement:

·

the solid can touch the obstacle only at the end of an infinite time,

·

the solid approaches at infinitely slow speed of the obstacle.

The total fluid force has as an expression:

()

(

)

F

X

. MR. X

X

X

X

X

fluid

=

+

+

2

0

2

0

0

4

3

5

.

.

! .

.

Its maximum value is obtained by cancelling the derivative of this function. It is reached in

X

F max

=

3

2

and is worth

F

MR. X

X

X

Max fluid

=

+

8 3

5

3

5

02

0

0

4

.

.

.

! .

.

The numerical values considered for calculations are:

M

= 1000 kg

2L

= 100 mm

X

0

= 6 mm,

!X

0

= - 0.1 m/s

F

= 1000 kg/m

3

= 10

6

Coefficients

,

are calculated according to the formula of paragraph 2.3 and are worth in this case:

= 0.0833,

= 0.1666

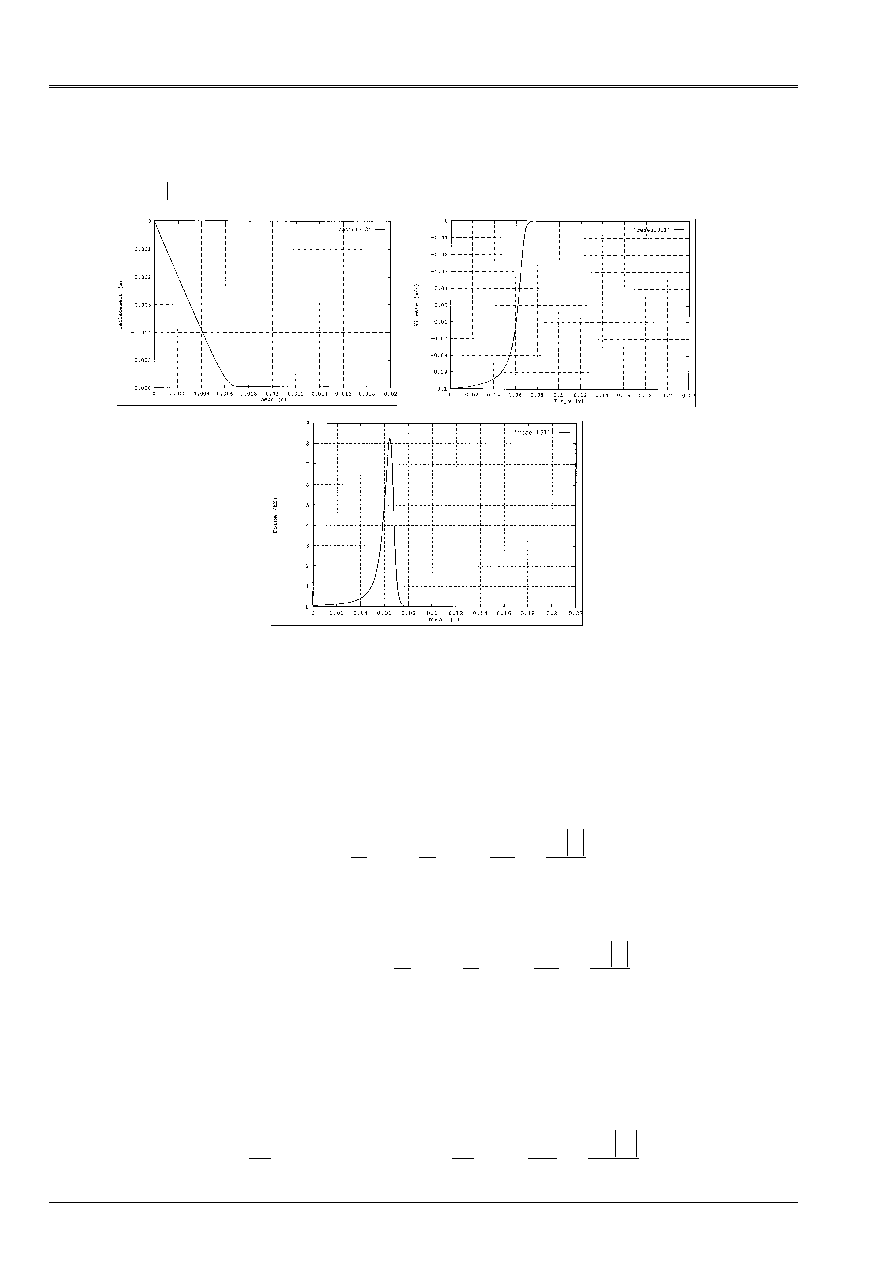

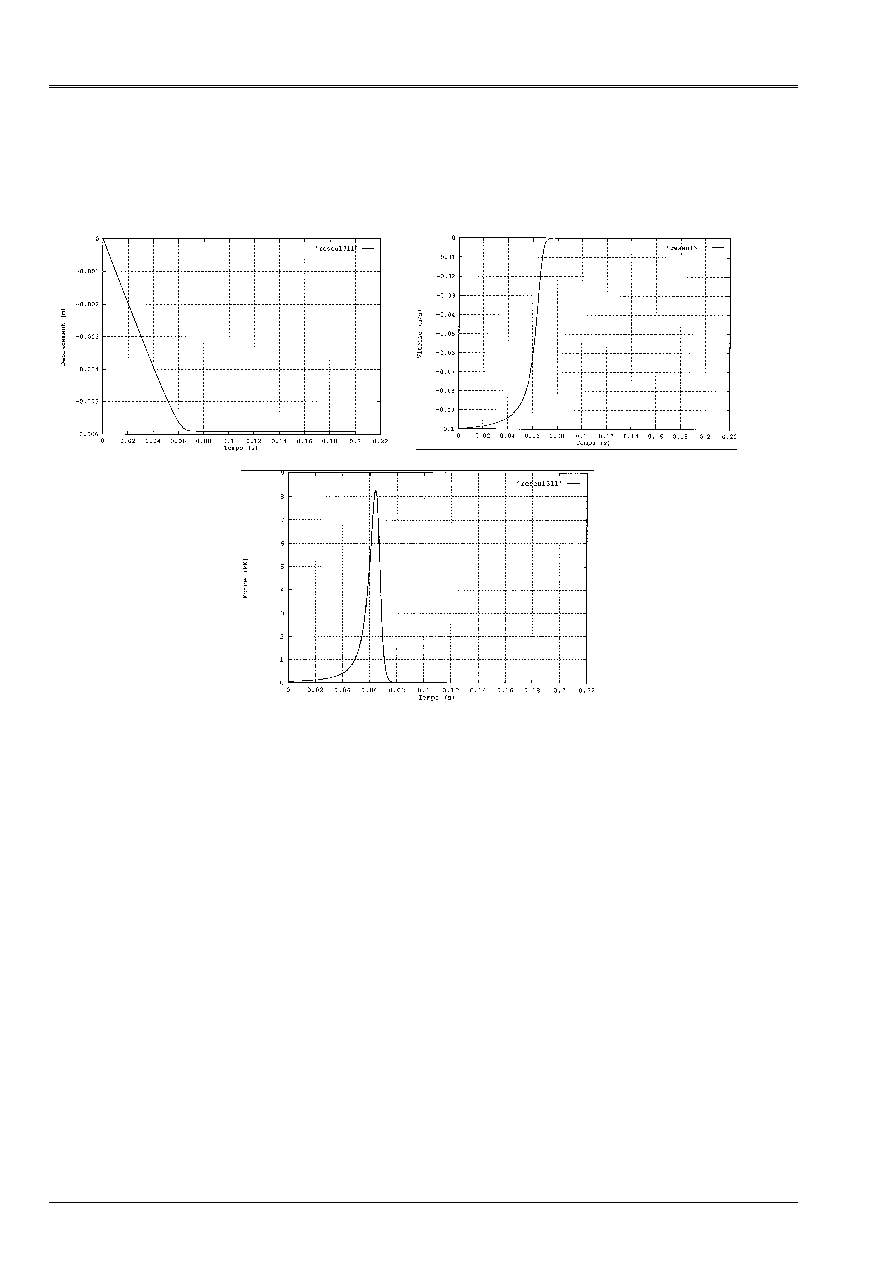

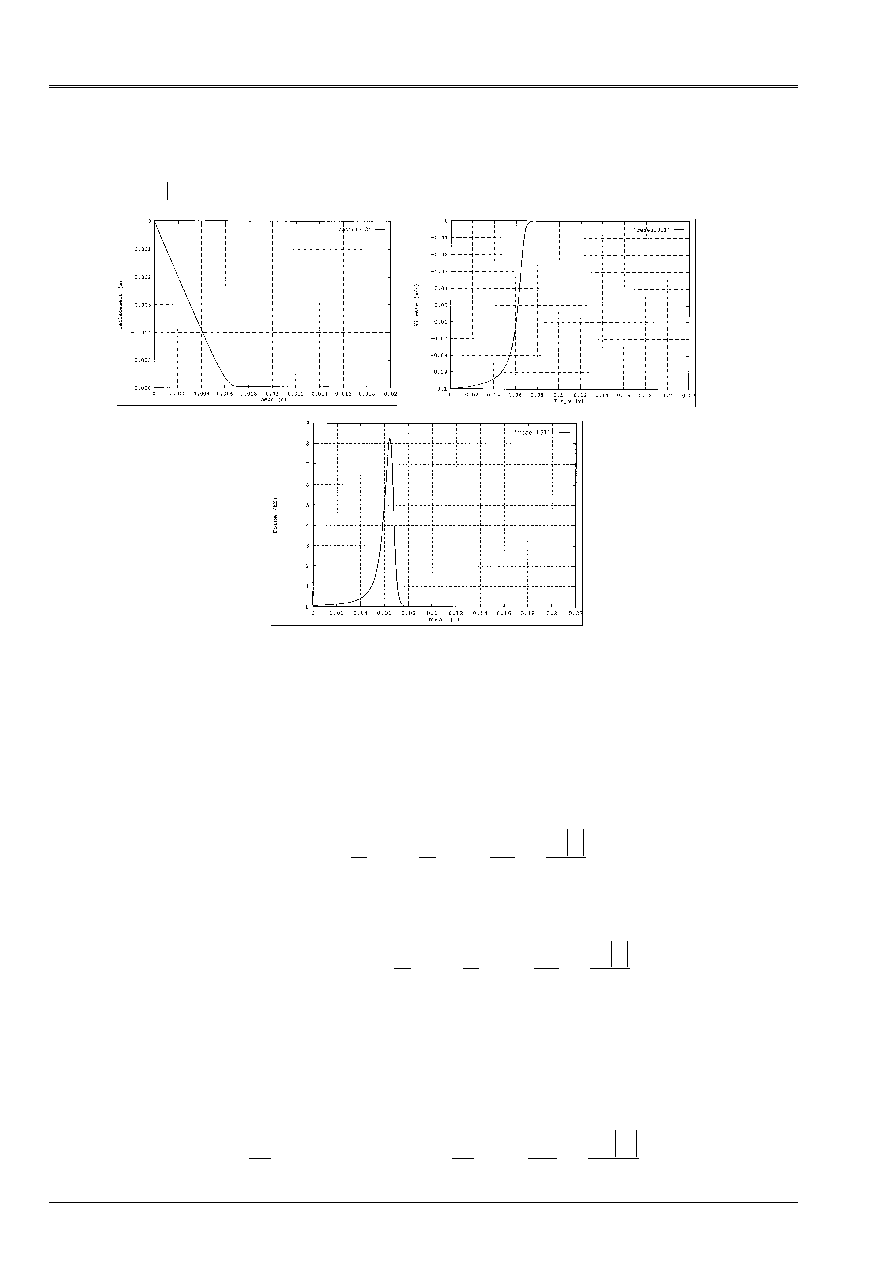

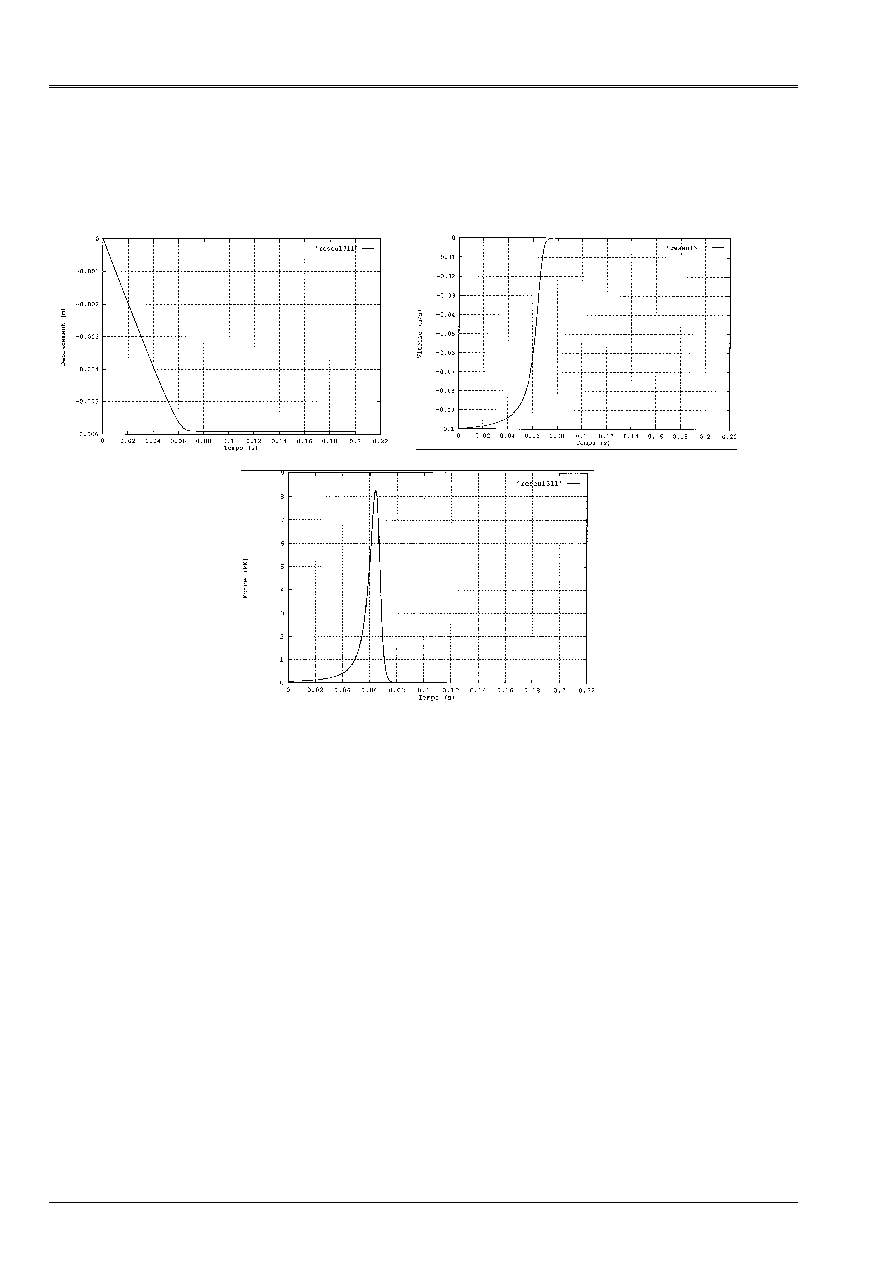

One can observe below displacement, the speed of the mass and the fluid force which it undergoes.

behavior of the mass is rather similar to that observed for the parabolic mode. The force

fluid maximum, given in an analytical way in the preceding paragraph, is worth in this case 8768 NR.

The mass in this case approaches in an asymptotic way of the wall and reaches it only at the end of one

infinite time.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

10/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

Note:

On the graph, at the end of the 0,2 S of calculation it remains a distance from 1.e-6 m to the wall.

3.2

To launch of a mass slowed down by fluid blade with parabolic profile

The analytical resolution of the differential equation governing the behavior of the mass is not any more

possible. One proposes to determine in an external way with any computer code, the dynamic response

this system with a ddl in the presence of a fluid blade. That gave place to the development of one

program dedicated FORTRAN, developed with this occasion.

As we established in the preceding paragraph, the force of reaction of the fluid blade takes

the following general form:

F

X

X

X

X

X

X

X X

X

fluid

= + +

+

. !!

. !

. !

!. !

2

3

2

The dynamic equation to which this system is subjected is as follows:

MR. X K X

F

X

X

X

X

X

X

X X

X

ext.

.

!!

.

. !!

. !

. !

!. !

+

=

+ + +

+

2

3

2

We propose a resolution by a temporal diagram of integration of the dynamic problem.

The expression of the second member is nonconventional because it utilizes acceleration. One proposes

to use an explicit diagram of integration, which requires the expression of

!!X

, according to

X X

,

!

. It

is thus necessary to rewrite the system in the form:

M

X

X

K X

F

X

X

X

X

X X

X

T

T

T

ext.

T

T

T

T

T

T

T

-

+

=

+ +

+

.

!!

.

. !

. !

! . !

2

3

2

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

11/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

We will use the diagram of Euler modified to integrate this equation in time:

X X

0

0

,

!

given to T

0

,

To repeat

!!

.

. !

. !

! . !

!

!

.

!!

.

!

X

F

K X

X

X

X

X

X X

X

M

X

T

T

dt

X

X

dt X

X

X

dt X

I

ext.

I

I

I

I

I

T

I

I

I

I

I

I

I

I

I

I

I

=

-

+ +

+

-

= +

=

+

=

+

+

+

+

+

2

3

2

1

1

1

1

as long as

T

T

I

end

+

<

1

For the type of non-linearities considered, one does not have criterion of stability a priori of the diagram

of integration. One thus made sure by a study of convergence by decreasing the pitch of time of

calculation which the results obtained were stable.

Coefficients

,

and

are calculated according to the formula of paragraph 2.4 and are worth in this case:

= 0.0833,

= 0.19992 and

= 0.9996. 10

6

and M masses it = 1000 kg

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

12/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

One can observe below displacement, the speed of the mass and the fluid force which it undergoes. One

note that it preserves a speed close to that initial before being sufficiently close to

wall. Then it undergoes an important fluid force which dissipates all the kinetic energy of the mass.

mass does not touch the wall, but preserves an asymptotic distance at the wall, which is worth 0.098 Misters.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

13/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

4 Calculation of a system multi degrees of freedom subjected

locally with forces of fluid blade

A means of simulating the forces of fluid blade is to introduce them like non-linear forces into

the algorithm of modal recombination

DYNA_TRAN_MODAL

[bib3] [U4.54.03], allowing to calculate

dynamics of a mechanical system by carrying out a projection on the basis of its free mode.

The temporal algorithms of Code_Aster treating the non-linear forces are the explicit diagrams

of Euler and Devogelaere. We saw in the preceding chapter that the intrinsic form of the forces

of fluid blade a problem for the resolution with an explicit diagram poses. An amendment of

the algorithm

DYNA_TRAN_MODAL

a suitable processing of the forces of fluid blade allows.

The direct dynamic problem discretized by finite elements is written:

MR. X

C X

K X

F

F

X X X

. !!

.

.

()

(

! !! )

T

T

T

ext.

fluid

T

T

T

T

+

+

=

+

Technique used in the operator

DYNA_TRAN_MODAL

consist in projecting on the basis of system

linear and to maintain the forces non-linear with the second member.

The projected dynamic system takes the form:

T

T

T

T

T

T

T

ext.

T

fluid

T

T

T

T

….

!!

….

!

….

.

()

.

(.

.

! . !! )

M

C

K

F

F

+

+

=

+

éq

4-1

The methods of explicit integration require to determine

!!

T

knowing

T

T

,

!

and

possibly their former values.

One thus sees in the expression of the system [éq 4-1] above that

!!

T

is not given in way

clarify according to

T

T

,

!

. From this moment, one proposes to use a method of point fixed

to obtain generalized accelerations.

This is obtained by applying the following operations:

!!

!! ,

,

!

0

1

T

T

T

T

=

-

given

to repeat until convergence:

[

]

(

)

!!

.

.

.

(.

.

! . !! )

.

()

….

!

….

I

T

T

T

fluid

T

T

it

T

ext.

T

T

T

T

T

+

-

=

+

-

-

1

1

M

F

F

C

K

convergence is tested by

!!

!!

.

!!

I

T

it

it

+

-

<

1

.

Unfortunately this technique of iteration of the fixed point is not necessarily convergent. For

that, it is necessary that the linear operator reiterated either contractor. However for thicknesses of fluid blade low,

the terms of inertias can be very important and thus prevent the convergence of

iterations of fixed point. It is thus not established such as it in the operator

DYNA_TRAN_MODAL

.

We will analyze more in detail the operator

T

fluid

T

T

T

.

(.

.

! . !! )

F

, to extract some

diagonal part and to make it pass to the first member.

In a node

N

comprising an effect of blade fluid, the fluid inertia will be expressed in the form,

linear in acceleration:

F

X

X

inertia

N

N

=

. !!

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

14/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

Sizes

!! ,

X X

N

N

are expressed in a local reference mark. They are thus obtained by one

operation of extraction

P

total assembled vector, followed by a series of rotations

R

N

to obtain

in the local reference mark, followed by an extraction

E

N

normal component.

One will note these operations in a matric way

!!

.

.

!!

X

E R P X

N

N

N

=

.

In a similar way, the local inertia must be turned over in the physical reference mark and to dimension

vector assembled, before being projected on the basis

. These operations can be noted of

matric way:

{}

T

T

T

N

NT

fluid

.

.

.

.

.

F

P R

E

F

=

-

1

The vector of the generalized forces representing the component of inertia of the fluid blade is:

T

N

T

T

N

N

T

N

N

X

.

.

.

.

.

.

….

!!

F

P R

E E R P

=

-

1

.

In the general case, one cannot determine once for all the value of this matric product because it

thus depends on the local reference mark of the position of the structure compared to the fluid blade. One proposes

to use an approximation of this matrix in the form:

m

P P

'

.

.

.

T

T N

T

T

X

=

To return the operator of point contractor it fixes is enough to modify the matrix of mass of the operator

of iteration by cutting off the matrix to him

me

. That amounts adding to him in fact of the mass bus

is

negative.

One will use in the algorithm of Euler modified for the taking into account of the effects of fluid blade,

the algorithm of point fixes opposite:

!!

!!

0

1

T

T

=

-

to repeat until convergence:

(

!!

.

. diag (')

.

.

(.

.

! . !! )

.diag (').

!!

.

()

….

!

….

I

T

T

N

nodes fluid

T

fluid

T

T

it

N

nodes fluid

it

T

ext.

T

T

T

T

T

+

-

=

-

-

+

-

-

1

1

M

m

F

m

F

C

K

convergence is tested by

!!

!!

.

!!

I

T

it

it

+

-

<

1

, where

is a precision given for the stop of

iterations.

The parameter

,

chosen higher than one, is used to guarantee the character contracting of the iterations of

not fixes. In practice, one chooses for value

= 10 what seems to guarantee convergence in all

the cases observed, one can possibly modify this parameter in the event of problems of convergence.

There is not theoretical result giving a best alternative for

. One will be possibly led to

to modify this value according to the importance of the non-linear forces in the response of the system, for

to improve convergence of the calculation of acceleration.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

15/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

5

Establishment of the non-linear forces of fluid blade

5.1

Specific integration for the forces of fluid blade

The forces of fluid blade compatible with the diagram of integration are named

“EULER”

and

“ADAPT”

in the operator

DYNA_TRAN_MODAL

. The processing of the forces of fluid blade is not activated

that when fluid blades are present in the model what guarantees a hold of

performances of the algorithms

EULER

and

DEVOGE

former, and allows to use a blade in the case of

fluid, a specific option but preserving nevertheless non-linearities and the functionalities

existing of the initial algorithm.

5.2

Use of the forces of fluid blade in

DYNA_TRAN_MODAL

The forces of fluid blade are designed to function like non-linearities of shock, i.e.,

that an effect of blade fluid can act between a point of a structure and a fixed obstacle, or between two

antagonistic points of two structures.

The parameters of fluid blade are thus provided in the key word factor

SHOCK

of the operator

DYNA_TRAN_MODAL

. Syntax under this key word will be as follows:

SHOCK:

(

….

RIGI_NOR: KN [r8]

….

LAME_FLUIDE: /

“NOT”

[DEFECT]

/

item

[KN]

ALPHA

:

/

0.

[DEFECT]

/

[R8]

BETA:

/

0.

[DEFECT]

/

[R8]

CHI

:

/

0.

[DEFECT]

/

[R8]

DELTA

:

/

0.

[DEFECT]

/

[R8]

)

The key word

LAME_FLUIDE

allows to specify if the interaction enters the node and the obstacle or between

two nodes takes place in the presence of a fluid blade. By defect the connection is supposed of contact type

dryness.

Key words

ALPHA

,

BETA

,

CHI

,

DELTA

allow to describe the form of the non-linear force of

fluid blade, their values correspond to the coefficients

,

,

and

are mentioned in the chapter

[§2]. They make it possible to define in the choice a uniform or parabolic profile.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

16/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

6

Model of fluid transition blade - shock

The studies justifying the development of the forces of fluid blade comprise situations where

structure vibrates in the presence of fluid blade and can even according to certain conditions of excitation outward journey

until the dry contact with the obstacle in the event of fluid film rupture.

This situation is particularly difficult to manage numerically from the nature of the expression of

forces of fluid blade used. In fact, one is obliged to consider a physical limit of validity with

the expression of these forces of fluid, limiting blade beyond which it is necessary to forward towards conditions

of mechanical contact (dry) between the structures.

One thus introduces consequently occasion the concept fluid thickness of blade limits beyond

which the fluid model of blade only is not valid any more, and the blade becomes in fact incompressible.

To preserve at the force of reaction (fluid blade and contact) a continuous character, we introduced

a weight function

()

F

ponder

D

N

who allows continuously to forward force of repulsion

of fluid blade to a force of repulsion of dry the contact type.

()

()

()

[]

F

F

F

,

ponder

ponder

ponder

D

D

D

D

D

C

D

N

N

N

N

N

N

=

=

0

0

1

0

0

if

if

of continuity

for

In the area of transition

[]

D

N

0,

, the force of reaction is written:

()

(

)

()

(

)

(

)

F

D

D D D

D

D

D

reaction

N

N

N

N

N

N

N

=

×

+ -

×

-

F

F

,

! !!

F

Fchoc

,

!

ponder

fluid

ponder

1

The boundary layer

is dynamically given with heuristics according to the formula:

(

)

=

F

! !!

fluid

D D D

K

N

N

N

NR

éq 6-1

If this boundary layer is reached or exceeded

D

N

by the wall of the structure one enters one

phase of transition towards the shock. The limiting value thickness is then filed and the model of

transition is used until

D

N

becomes again

.

One explains physically the choice of the formula [éq 6-1] to determine the fluid thickness of blade in

considering that in this situation the fluid force of blade is such as it can deform the structure

on its stiffness of shock and thus the fluid blade in it even becomes incompressible, from where need for

to forward towards the model of force of shock.

Note: Use of the forces of fluid blade with the model of transition

The fluid model of transition - shock was introduced in a systematic way. As soon as one introduces

a fluid force of blade, one can forward towards the shock. It is thus necessary systematically

to introduce a stiffness of shock

K

NR

(key word

RIGI_NOR

). If one never wishes not to forward

towards a dry contact (mainly for case-tests) it will be necessary to take a value of

K

NR

very large (10

15

).

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

17/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

7 Conclusion

This document describes the expression of the fluid forces which are exerted when a structure vibrates with

vicinity of a plane wall, in an incompressible fluid at rest (put in flow by

movement of the structure). These forces are called forces of fluid blade.

For two assumptions of profile of flow in the blade, an analytical form of the force is established.

The latter depends in a non-linear way of acceleration, the speed and the position of

structure compared to the obstacle.

For a system with a degree of freedom with initial speed deadened by a fluid blade, a calculation

analytical could be carried out with a uniform profile. For the other profile, like configurations

of system masses spring, a numerical integration was necessary. One could analyze on these

calculations the behavior of the fluid blade, which introduces in particular a strong damping.

The processing of these forces for systems with several degrees of freedom resulted in modifying

the explicit algorithm of integration on the basis of modal

DYNA_TRAN_MODAL

to integrate correctly

the ram effect of these forces in Code_Aster.

Code_Aster

®

Version

3

Titrate:

Forces of fluid blade in transitory calculation on modal basis

Date:

14/05/97

Author (S)

:

G. JACQUART

Key:

R5.06.05-A

Page:

18/18

Manual of Reference

R5.06 booklet: Dynamics in modal base

HP-51/96/079 - Ind A

8 Bibliography

[1]

J. CHRIGUI - “Contribution to the study of the shocks of structures in the presence of fluid”, Thesis

presented at the INSTN July 12, 1986

[2]

I.E. IDEL' CIK “Memorandum of the losses of loads”, Eyrolles Paris Editor, 1969, Collection of

And Test research center of CHATOU

[3]

G. JACQUART - “Operator

DYNA_TRAN_MODAL

“, Documentation of Aster Use

[U4.54.03], Version 2.7

[4]

D. BOSSELUT, G. JACQUART, D. BANC - “Vibrations with shocks. Experimental validation

biaxial on the MASSIVE test rig ", Report/ratio EDF DER HP-61/92.158

[5]

G. JACQUART - “Modeling of the forces of fluid blade”, Report/ratio EDF DER HP-61/94.159/A