Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

1/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Organization (S):

EDF-R & D/AMA

Instruction manual

U4.4- booklet: Modeling

Document: U4.43.01

Operator

DEFI_MATERIAU

1 Goal

To define the behavior of a material or the parameters associated with fatigue, the damage, or with

simplified methods.

The allowed laws of behavior currently by this operator relate to the following fields:

Linear mechanics and Thermics or not, Metallurgical for the modeling of steels,

Hydration and Drying for the concretes, Fluid for accoustics, Thermo Hydro-mechanical for

the modeling of the porous environments saturated with thermomechanical coupled and Soil mechanics.

If necessary, the same material can be defined at the time of a call to DEFI_MATERIAU with several

behaviors, such as rubber band, thermics,…

Product a Structure of data of the type MATER.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

2/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Count

matters

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

3/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.9

Key words factors

ECOU_VISC1

,

ECOU_VISC2

,

ECOU_VISC3

,

ECRO_CIN1

,

ECRO_CIN2

,

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

4/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

6.4.2

Operands COND_LMM/COND_LMP/COND_LPP/COND_LSI/COND_TMM/

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

5/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

6/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

7/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

8/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

9/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

10/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

11/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

12/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

13/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

14/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

2 Syntax

general

my [to subdue] = DEFI_MATERIAU

(

# Behavior General Rubber bands [§ 3]

|

/

ELAS,

#

to see [§

3.1]

/

ELAS_FO,

/

ELAS_FLUI, #

to see [§

3.2]

|

APPUI_ELAS,

#

to see [§

3.3]

|

CABLE,

#

to see [§

3.4]

|

/

ELAS_ORTH, #

to see [§

3.5]

/

ELAS_ORTH_FO,

|

/

ELAS_ISTR, #

to see [§

3.6]

/

ELAS_ISTR_FO,

|

/

ELAS_COQUE,

#

to see [§

3.7]

/

ELAS_COQUE_FO,

# General Nonlinear Mechanical Behaviors [§ 4]

|

TRACTION,

#

to see [§

4.1]

|

/

ECRO_LINE, #

to see [§

4.2]

/

ECRO_LINE_FO,

|

/

PRAGER, #

to see [§

4.3]

/

PRAGER_FO,

|

CHABOCHE,

#

to see [§

4.4]

|

/

CIN1_CHAB, #

to see [§

4.5]

/

CIN1_CHAB_FO,

|

/

CIN2_CHAB, #

to see [§

4.6]

/

CIN2_CHAB_FO,

|

/

TAHERI, #

to see [§

4.7]

/

TAHERI_FO,

|

/

POLY_CFC,

#

to see [§

4.8]

/

POLY_CFC_FO,

| ECOU_VISC1,

# to see [§

4.9]

| ECOU_VISC2,

| ECOU_VISC3,

| ECRO_CIN1,

| ECRO_CIN2,

| ECRO_ISOT1,

| ECRO_ISOT2,

|

/

LEMAITRE,

#

to see [§

4.10]

/

LEMAITRE_FO,

|

VISC_SINH,

# to see [§

4.11]

|

/

LEMA_SEUIL,

#

to see [§

4.12]

/

LEMA_SEUIL_FO,

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

15/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

|

ZIRC_CYRA2,

#

to see [§

4.13]

|

ZIRC_EPRI, #

to see [§

4.14]

|

VISC_IRRA_LOG,

#

to see [§

4.15]

|

/

LMARC,

#

to see [§

4.16]

/

LMARC_FO,

# Behaviors related to the damage and the rupture [§ 5]

|

/

ROUSSELIER,

#

to see [§

5.1]

/

ROUSSELIER_FO,

|

/

VENDO_CHAB,

#

to see [§

5.2]

/

VENDO_CHAB_FO,

|

ENDO_ORTH_BETON,

#

to see [§

5.3]

|

NON_LOCAL, #

to see [§

5.4]

|

/

RUPT_FRAG, #

to see [§

5.5]

/

RUPT_FRAG_FO,

|

CORR_ACIER,

#

to see [§

5.6]

#

Behaviors

Thermics

[§

6]

|

/

THER,

#

to see [§

6.1]

/

THER_FO,

/

THER_ORTH, #

to see [§

6.2]

/

THER_NL,

#

to see [§

6.3]

/

THER_COQU, #

to see [§

6.4]

/

THER_COQU_FO,

# Behaviors specific to the concretes [§ 7]

|

THER_HYDR, #

to see [§

7.1]

|

SECH_GRANGER,

#

to see [§

7.2]

|

SECH_MENSI,

#

to see [§

7.3]

|

SECH_BAZANT,

#

to see [§

7.4]

|

SECH_NAPPE,

#

to see [§

7.5]

|

PINTO_MENEGOTTO,

#

to see [§

7.6]

|

BPEL_BETON

and

BPEL_ACIER,

#

to see [§

7.7]

|

BETON_DOUBLE_BP,

#

to see [§

7.8]

|

GRANGER_FP, GRANGER_FP_INDT and V_GRANGER_FP,

#

to see [§

7.9]

|

NADAI_B,

#

to see [§

7.10]

|

BAZANT_FD, #

to see [§

7.11]

|

LABORD_1D, #

to see [§

7.12]

|

/

MAZARS, #

to see [§

7.13]

/

MAZARS_FO,

|

BETON_UMLV_FP,

#

to see [§

7.14]

|

BETON_ECRO_LINE,

#

to see [§

7.15]

|

GLRC,

#

to see [§

7.16]

|

JOINT_BA,

#

to see [§

7.17]

#

Behaviors

Metal-worker-mechanics

[§

8]

|

META_ACIER,

#

to see [§

8.1]

META_ZIRC, #

to see [§

8.2]

|

DURT_META, #

to see [§

8.3]

|

/

ELAS_META, #

to see [§

8.4]

/

ELAS_META_FO,

|

META_ECRO_LINE,

#

to see [§

8.5]

|

META_TRACTION,

#

to see [§

8.6]

|

META_VISC, #

to see [§

8.7]

|

META_PT,

#

to see [§

8.8]

|

META_RE,

#

to see [§

8.9]

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

16/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

# Thermo Behaviors Hydro-mechanical and of the grounds [§ 9]

COMP_THM =/`LIQU_SATU `, # to see [§ 9.1]

/`LIQU_GAZ `,

/`GAS `,

/`LIQU_GAZ_ATM `,

/`LIQU_VAPE_GAZ `,

/`LIQU_VAPE `,

/`LIQU_SATU_GAT `,

/`LIQU_NSAT_GAT `,

/`LIQU_AD_GAZ_VAPE `,

|

THM_INIT,

#

to see [§

9.2]

|

THM_LIQU,

#

to see [§

9.3]

|

THM_GAZ,

#

to see [§

9.4]

|

THM_VAPE_GAZ,

#

to see [§

9.5]

|

THM_AIR_DISS,

#

to see [§

9.6]

|

THM_DIFFU, #

to see [§

9.7]

|

SURF_ETAT_SATU,

#

to see [§

9.8]

|

SURF_ETAT_NSAT,

#

to see [§

9.9]

|

CAM_CLAY_THM,

#

to see [§

9.10]

|

CAM_CLAY,

#

to see [§

9.11]

|

CJS, #

to see [§

9.12]

|

LAIGLE, #

to see [§

9.13]

|

DRUCKER_PRAGER,

#

to see [§

9.14]

|

BARCELONA, #

to see [§

9.15]

|

HOEK_BROWN,

#

to see [§

9.16]

# Behavior specific to the elements 1D [§ 10]

|

/

VMIS_POUTRE,

#

to see [§

10.1]

/

VMIS_POUTRE_FO,

|

ECRO_FLEJOU,

#

to see [§

10.2]

|

ECRO_ASYM_LINE,

#

to see [§

10.3]

#

Behaviors

private individuals

[§

11]

|

LEMAITRE_IRRA,

#

to see [§

11.1]

|

LMARC_IRRA,

#

to see [§

11.2]

|

DIS_GRICRA,

#

to see [§

11.3]

|

GATT_MONERIE,

#

to see [§

11.4]

|

DIS_CONTACT,

#

to see [§

11.5]

|

ASSE_CORN, #

to see [§

11.6]

|

ARM,

#

to see [§

11.7]

#

Behavior

fluid

[§

12]

|

FLUID, #

to see [§

12.1]

# Given Materials associated with postprocessings [§ 13]

|

TIRE,

#

to see [§

13.1]

|

DOMMA_LEMAITRE,

#

to see [§

13.2]

|

CISA_PLAN_CRIT,

#

to see [§

13.3]

|

/

WEIBULL,

#

to see [§

13.4]

/

WEIBULL_FO,

|

/

RCCM,

#

to see [§

13.5]

/RCCM_FO,

)

Notice

:

For the majority of the behaviors, it is possible to define constant characteristics or

many characteristics depending on one or two variables. We chose to gather them

two key words factors, single-ended spanner words being identical in both cases, only them

arguments are characterized by the type of associated concept.

In the syntax of each behavior, one will adopt following convention to indicate it or

the variables of which can depend the concepts of the type

function

.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

17/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

[function *]

“TEMP” “X”, “Y”, “Z”

(two variables among four),

[function **]

“TEMP”

[function ***]

“EPSI” “TEMP”

[function ****] “ABSC”

[function +]

“INST”

[function ++]

'

NORM

'

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

18/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3

General elastic behaviors

3.1

Key words factor

ELAS/ELAS_FO

Definition of the constant linear elastic characteristics or functions of the parameter

“TEMP”

.

3.1.1 Syntax

|

/

ELAS

=

_F

(

E

=

yg

,

[R]

NAKED =

naked, [R]

RHO =

rho, [R]

ALPHA

= dil

, [R]

/AMOR_ALPHA

=

, [R]

AMOR_BETA

=

,

[R]

/

AMOR_HYST

=

,

[R]

)

/

ELAS_FO

=

_F

(

E

=

yg

,

[function **]

NAKED

= naked

,

[function **]

RHO

=

rho

, [R]

ALPHA

= dil

, [function **]

/AMOR_ALPHA

=

,

[function **]

AMOR_BETA

=

,

[function **]

/

AMOR_HYST

=

,

[function **]

TEMP_DEF_ALPHA=

Tdef,

[R]

PRECISION

=/

, [R]

/

1

,

[DEFECT]

K_DESSIC =/

K

, [R]

/

O

,

[DEFECT]

B_ENDOGE =/

E

, [R]

/

O

,

[DEFECT]

FONC_DESORP

=

/

F

, [function]

)

3.1.2 Operands

E/NAKED

E = yg

Young modulus. It is checked that E 0.

NAKED = naked

Poisson's ratio. It is checked that

- 1.

naked

0.5

.

3.1.3 Operand

RHO

RHO = rho

Real constant density (one does not accept a concept of the type

function

). Not

checking of about size.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

19/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.1.4 Operands

ALPHA/TEMP_DEF_ALPHA/PRECISION

ALPHA =

[function **]

Isotropic thermal expansion factor.

The thermal expansion factor is an average expansion factor which can depend on

the temperature

T

.

The values of the expansion factors are determined by tests of dilatometry which have

place at the ambient temperature (0°C or more generally 20°C).

So one in general has the values of the expansion factor defined compared to 20°C

(temperature to which one supposes the null thermal deformation).

Certain studies require to take a temperature of reference different from

ambient temperature (null thermal deformation for another temperature that

ambient temperature). It is then necessary to carry out a change of reference mark in the calculation of

thermal deformation [R4.08.01].

TEMP_DEF_ALPHA = Tdef

[R]

It is the value of the temperature to which the values of the thermal expansion factor have

summer determined, and were well informed under the key word

ALPHA

.

This key word becomes obligatory as soon as ALPHA was informed.

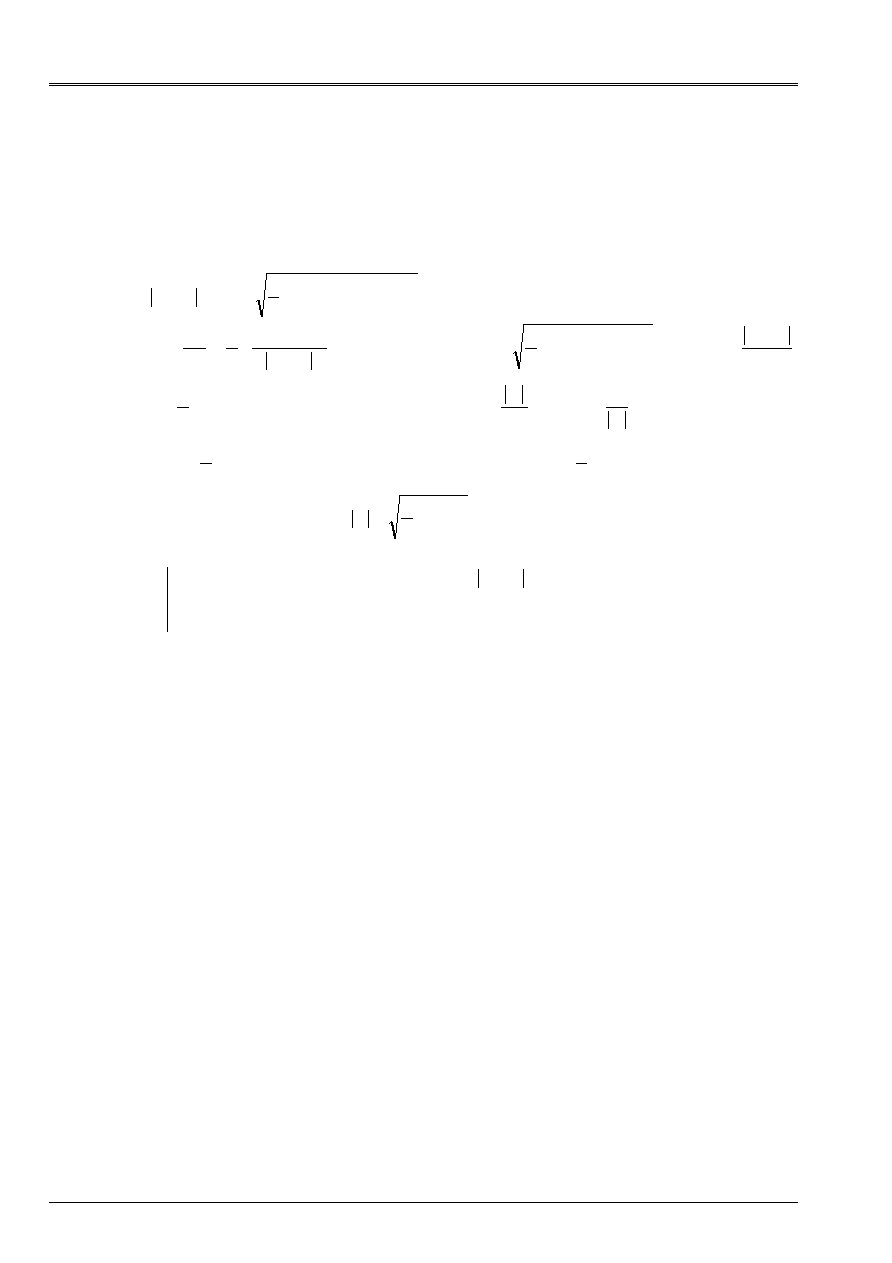

The calculation of the thermal deformation is done by the formula [R4.08.01]:

()

()

(

)

()

()

(

) () (

)

()

HT

ref.

def

ref.

ref.

def

ref.

HT

ref.

T

T T T

T

T T T

T

T

T

T T

T

=

-

=

-

-

-

-

=

$

$

with

and

0

PRECISION: /prec

/

1.

[DEFECT]

This key word is used when the key word

TEMP_DEF_ALPHA

is specified.

It is a reality which indicates with which precision a temperature

T

I

(of the list of the temperatures

being used for the definition of

()

T

I

I

NR

,

,

=1

) is close to the temperature of reference

T

ref.

.

This reality is used for calculation of the function

()

$

T

I

. The mathematical formula allowing the calculation of

()

$

T

I

is different according to whether

T

T

T

T

I

ref.

I

ref.

=

or

.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

20/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.1.5 Operands

AMOR_ALPHA

/

AMOR_BETHA

/

AMOR_HYST

/AMOR_ALPHA

=

AMOR_BETA

=

Coefficients

and allowing to build a matrix of viscous damping

proportional to rigidity and/or the mass [C] =

[K] + [M]. One will refer to the documents

of modeling of the mechanical cushioning [U2.06.03] and [R5.05.04].

/AMOR_HYST =

Coefficient

of damping hysteretic allowing to define the complex Young modulus

(viscoelastic material) from which the matrix of complex rigidity will be created

allowing the calculation of the harmonic answer [U2.06.03] and [R5.05.04].

3.1.6 Operands

K_DESSIC

/

B_ENDOGE

/K_DESSIC = K

Coefficient of withdrawal of dessication.

/K_ENDOGE = E

Coefficient of withdrawal of endogenous.

These characteristics are used with the behavior defined by key words BETON_DOUBLE_BP,

GRANGER_FP and BAZANT_FD.

3.1.7 Operand

FONC_DESORP

FONC_DESORP: curve of sorption-desorption [R7.01.12] giving the hygroscopy H according to

water content C. Operand obligatory with law BAZANT_FD [R7.01.01].

3.2

Key word factor

ELAS_FLUI

The key word

ELAS_FLUI

allows to define the equivalent density of a tubular structure

with internal and external fluid, by taking of account the effect of containment.

This operation lies within the scope of the study of the dynamic behavior of a configuration of

type “beam of tubes under transverse flow”. The study of the behavior of the beam is

brought back to the study of a single tube representative of the whole of the beam.

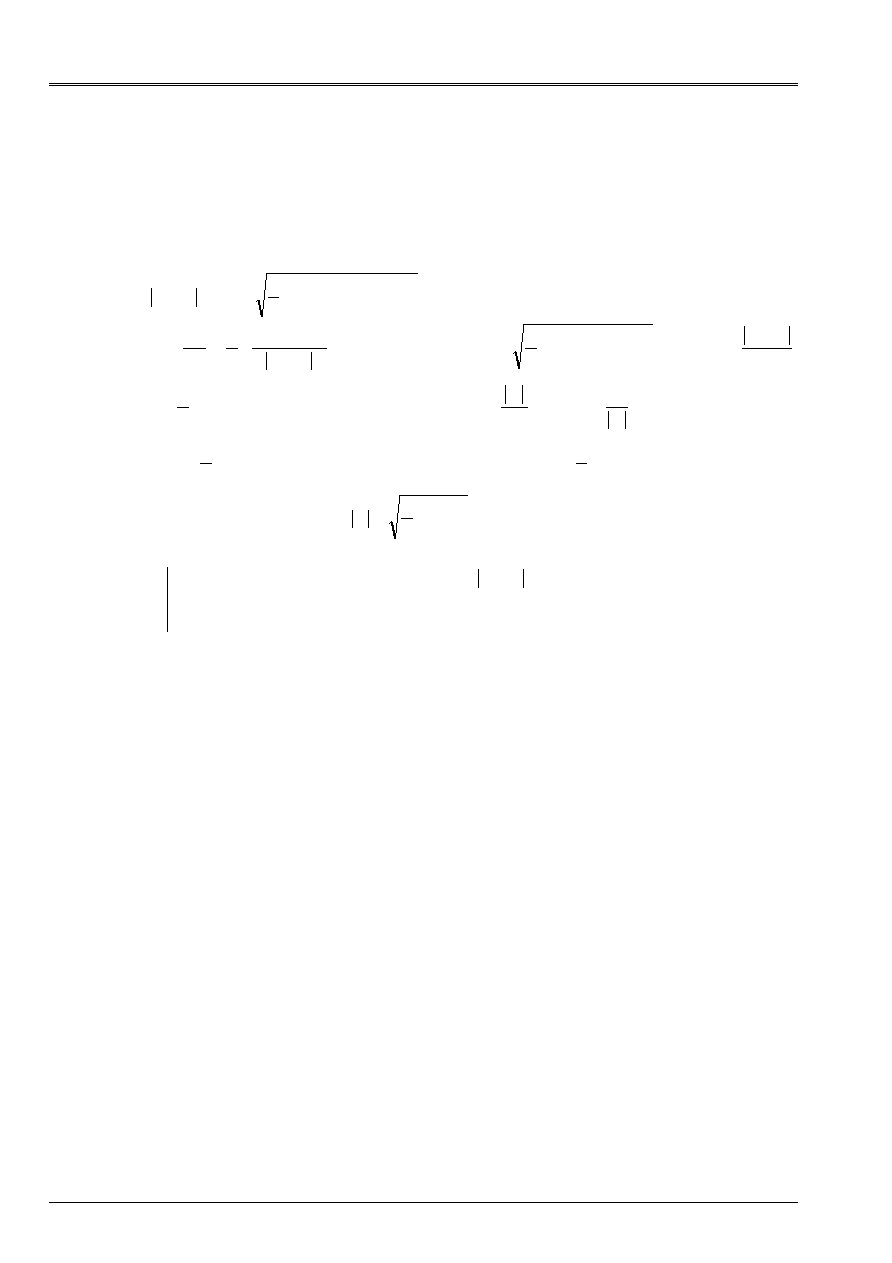

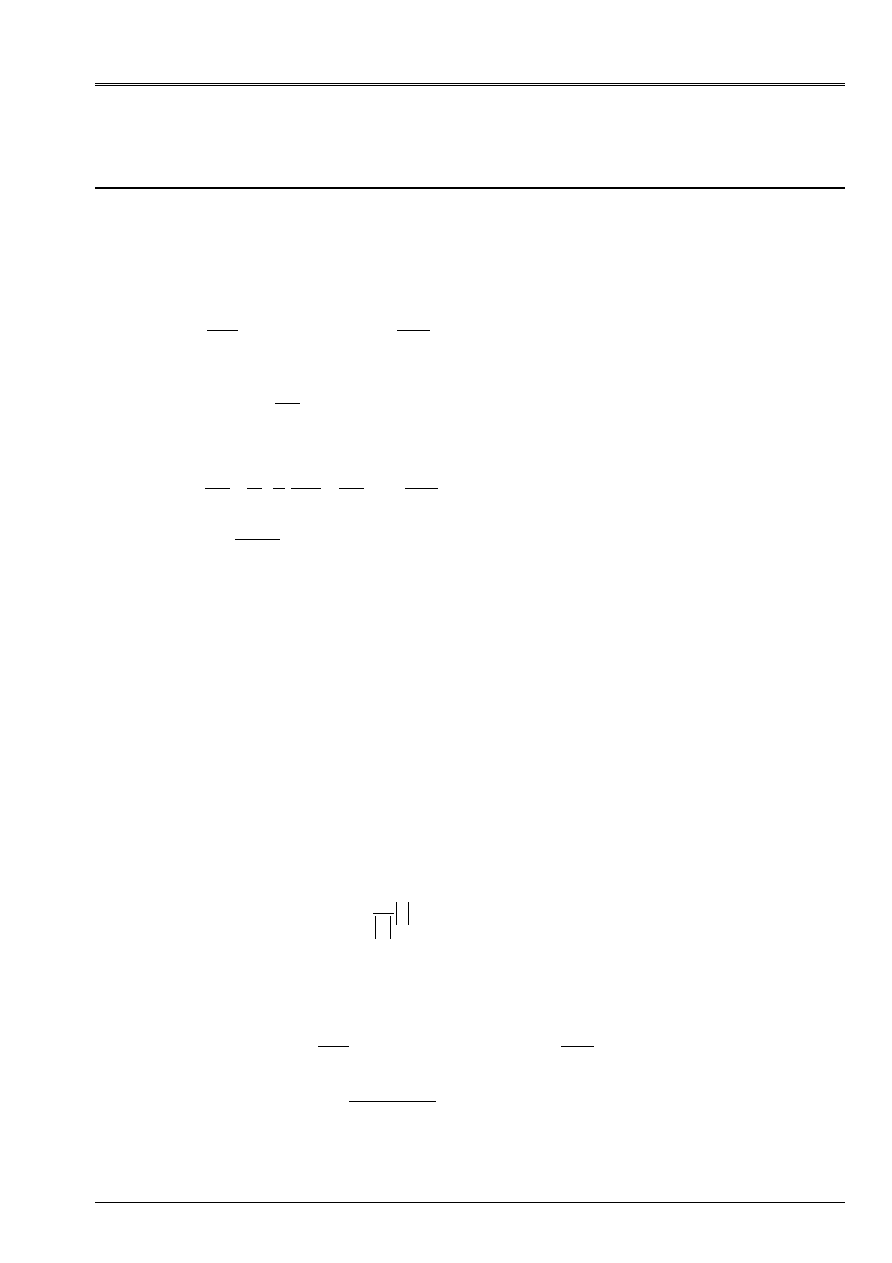

Equivalent density of the structure

eq

is defined by:

(

)

(

)

[

]

eq

E

I

I

I

T

E

I

E

eq

eq

E

I

E

T

E

I

D

D

D

D

D

D

D

Cm D

D D

Cm

=

-

+

-

+

=

1

2

2

2

2

2

2

2

2

2

.

.

.

.

.

,

,

,

are respectively the density of the fluid

intern, of the external fluid and the structure.

are respectively the external diameter and intern of the tube.

is a coefficient of added mass (containment defines).

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

21/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.2.1 Syntax

/ELAS_FLUI = _F

(

RHO

=

rho

[R]

E

=

yg

[R]

NAKED

=

naked

[R]

PROF_RHO_F_INT

=

rhoi [function ****]

PROF_RHO_F_EXT

=

rhoe [function ****]

COEF_MASS_AJOU

=

fonc_cm [function ****]

)

3.2.2 Operand

ELAS_FLUI

/

ELAS_FLUI = _F

(

Key word factor allowing to calculate the equivalent density of a structure beam

with internal and fluid fluid external (this relation of behavior cannot be used

that with elements of beam).

RHO = rho

Density of material.

E = yg

Young modulus.

NAKED = naked

Poisson's ratio.

PROF_RHO_F_INT = rhoi

Concept of the type [

function

] defining the profile of density of the fluid it interns

length of the tube. This function is parameterized by the curvilinear X-coordinate.

PROF_RHO_F_EXT = rhoe

Concept of the type [

function

] defining the profile of density of the external fluid

along the tube. This function is parameterized by the curvilinear X-coordinate,

“ABSC”

.

COEF_MASS_AJOU = fonc_cm

Concept of the type [

function

] produced by the operator

FONC_FLUI_STRU

[U4.35.02].

This constant function, parameterized by the curvilinear X-coordinate, provides the value of

coefficient of added mass

Cm

.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

22/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.3

Key word factor

APPUI_ELAS

/APPUI_ELAS = _F (

E_N =

rign,

[R]

E_TAN

=

/

0. ,

[DEFECT]

/

rigt

,

[R]

)

This key word factor makes it possible to define the characteristics of material associated with modeling

“APPUI_REP”

[U4.41.01]. This modeling relates to only the elements of the face type of

modeling

“3D”

associated the phenomenon

“MECHANICAL”

.

One modelizes the action of a medium characterized by the normal and tangential surface stiffness on

faces of three-dimensional elements.

In the case of the elements of hull, it is necessary to duplicate the meshs thanks to the control

CREA_MAILLAGE

[U4.23.02] and to affect modeling

“3D”

with these new meshs.

E_N

=

rign,

[R]

Value of the normal surface stiffness.

E_TAN = rigt,

[R]

Value of the tangential surface stiffness.

3.4

Key word factor

CABLE

Definition of the elastic characteristic nonlinear, constant, for the cables: two behaviors

different rubber bands in traction and compression, defined by the Young moduli

E

and

EC.

(module

in compression).

The standard characteristics of elastic material are to be informed under the key word factor ELAS.

3.4.1 Syntax

/

CABLE

=

_F (

EC_SUR_E =/ecse,

[R]

/

1.D-4,

[DEFECT]

)

3.4.2 Operands

of elasticity

EC_SUR_E = ecse

Report/ratio of the modules to compression and traction. If the module of compression is null, it

total linear system with displacements can become singular. It is the case when a node

is connected only to cables and that those all enter in compression.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

23/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.4.3 Operand of mass

RHO = rho

Density.

3.4.4 Operand of dilation

ALPHA = dil

Thermal expansion factor average compared to the temperature of reference defined under

AFFE_MATERIAU.

3.4.5 Operands

of damping

AMOR_ALPHA =

AMOR_BETA =

Coefficients

and allowing to build a matrix of viscous damping proportional to

rigidity and/or with the mass [C] =

[K] + [M]. One will refer to the document modeling of

mechanical cushioning [U2.06.03].

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

24/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.5

Key words factor

ELAS_ORTH

/

ELAS_ORTH_FO

Definition of the constant orthotropic elastic characteristics or functions of the temperature for

elements of hull and solid elements isoparametric or layers constitutive of one

composite (cf DEFI_COQU_MULT).

3.5.1 Syntax

/

ELAS_ORTH

=

_F

(

E_L =

ygl, [R]

E_T =

ygt, [R]

E_N =

ygn, [R]

G_LT =

glt, [R]

G_TN =

gtn, [R]

G_LN =

gln, [R]

NU_LT =

nult,

[R]

NU_TN =

nutn,

[R]

NU_LN =

nuln,

[R]

ALPHA_L =

/dil,

[R]

/

0.0,

[DEFECT]

ALPHA_T =

/known as,

[R]

/

0.0,

[DEFECT]

ALPHA_N =

/DIN,

[R]

/

0.0,

[DEFECT]

RHO =

/rho,

[R]

/

0.0,

[DEFECT]

XT =

/trl,

[R]

/

1.0,

[DEFECT]

TESTSTEMXÇ =

/neck,

[R]

/

1.0,

[DEFECT]

YT =

/trt,

[R]

/

1.0,

[DEFECT]

TESTSTEMYÇ =

/cot,

[R]

/

1.0,

[DEFECT]

S_LT =

/cis,

[R]

/

1.0,

[DEFECT]

)

/

ELAS_ORTH_FO

=_F

(

E_L =

ygl, [function **]

E_T =

ygt, [function **]

E_N =

ygn, [function **]

G_LT =

glt, [function **]

G_TN =

gtn, [function **]

G_LN =

gln, [function **]

NU_LT =

nult,

[function **]

NU_TN =

nutn,

[function **]

NU_LN =

nuln,

[function **]

ALPHA_L

=

dil

, [function **]

ALPHA_T

=

known as

, [function **]

ALPHA_N

=

DIN

, [function **]

RHO =

/rho,

[R]

/

0.0,

[DEFECT]

TEMP_DEF_ALPHA = Tdef, [R]

PRECISION

=/

,

[R]

/

1.,

[DEFECT]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

25/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

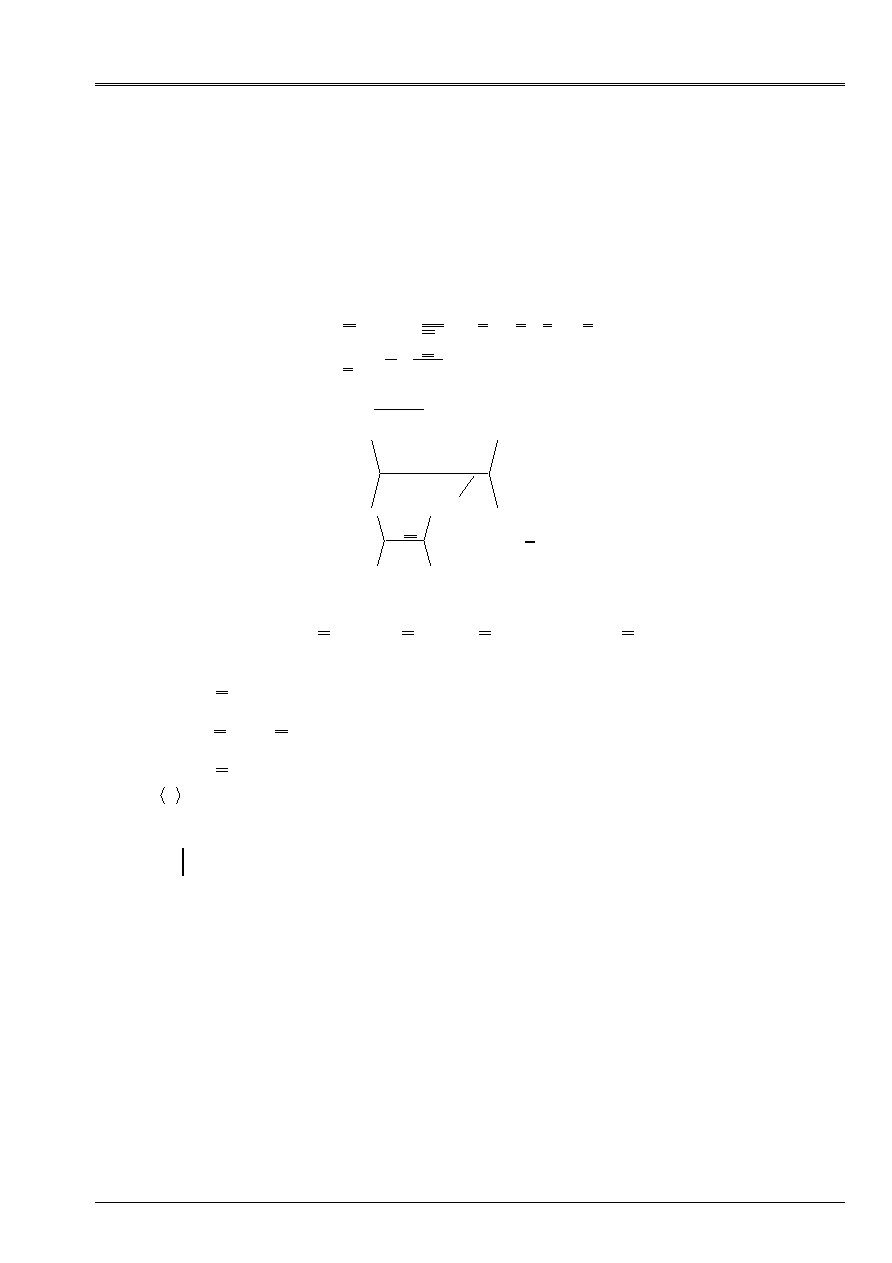

3.5.2 Operands

of elasticity

The reader will be able to refer to following documentations:

[U4.42.03]

DEFI_COQU_MULT

[U4.42.01]

AFFE_CARA_ELEM

to define the reference mark of orthotropism (L, T, NR) related to the elements.

E_L = ygl

Longitudinal Young modulus.

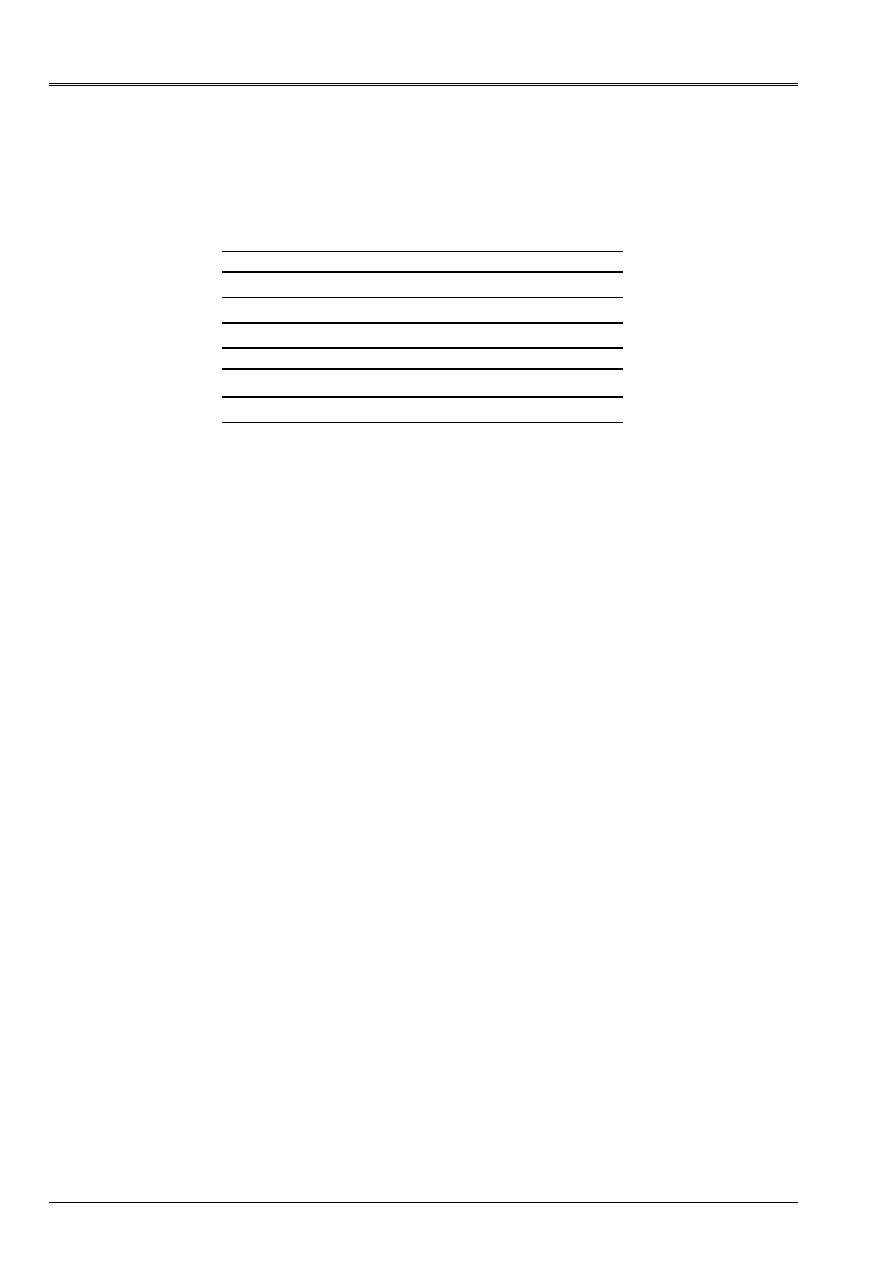

NR

T

L

L, T and NR: directions of orthotropism

longitudinal, transverse and normal

E_T = ygt

Transverse Young modulus.

E_N = ygn

Normal Young modulus.

GL_T = glt

Modulus of rigidity in plan LT.

G_TN = gtn

Modulus of rigidity in plan TN.

G_LN = gln

Modulus of rigidity in plan LN.

Note:

For the hulls, the transverse moduli of rigidity are not obligatory; in it

case, one calculates in thin hull by assigning an infinite rigidity to transverse shearing

(DST elements, DSQ and Q4G).

NU_LT = nult

Poisson's ratio in plan LT.

Important remarks:

nult

is not equal to

nutl

. In fact, one with the relation:

nult

ygl

ygt

nutl

*

=

nult

must be interpreted in the following way:

if one exerts a traction according to the axis

L

giving place to a deformation according to this axis equalizes with

ygl

L

L

=

, there is a deformation according to the axis

T

equalize with:

ygl

*

- nult

L

T

=

.

Various moduli of elasticity

E_L

,

G_LN

and

NU_LN

cannot be selected of

unspecified way: physically, it is necessary always that a nonnull deformation causes one

strictly positive deformation energy. That results in the fact that the matrix of

Hooke must be definite positive. The operator

DEFI_MATERIAU

calculate the eigenvalues of

this matrix and emits an alarm if this property is not checked.

For the models 2D, like the user its MODELING (D_PLAN did not choose yet,

C_PLAN,…), one checks the positivity of the matrix in the various cases of figure.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

26/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

NU_TN = nutn

Poisson's ratio in plan TN.

NU_LN = nuln

Poisson's ratio in plan LN.

The remark made for

NU_LT

is to be applied to these the last two coefficients. One has them thus

relations:

nunt

ygt

ygn

nutn

nunl

ygl

ygn

nuln

=

=

*

*

3.5.3 Operand

RHO

RHO = rho

Density.

3.5.4 Operands

ALPHA_L

/

ALPHA_T

/

ALPHA_N

ALPHA_L = dil

Thermal expansion factor average longitudinal.

ALPHA_T = known as

Thermal expansion factor average transverse.

ALPHA_N = DIN

Thermal expansion factor average normal.

3.5.5 Operands

TEMP_DEF_ALPHA/PRECISION

One will refer to the paragraph [§3.1.4]. This key word becomes obligatory as soon as one informed

ALPHA_L, or ALPHA_T or ALPHA_N.

3.5.6 Criteria of rupture

These various criteria can be used by control CALC_ELEM under the key word

“CRIT_ELNO_RUPT” [U4.81.01], [R4.01.01].

XT = trl

Criterion of rupture in traction in the longitudinal direction (first direction of orthotropism).

TESTSTEMXÇ = neck

Criterion of rupture in compression in the longitudinal direction.

YT = trt

Criterion of rupture in traction in the transverse direction (second direction of orthotropism).

TESTSTEMYÇ = cot

Criterion of rupture in compression in the transverse direction.

S_LT = cis

Criterion of rupture in shearing in plan LT.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

27/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.6

Key words factor

ELAS_ISTR

/

ELAS_ISTR_FO

Definition of the constant elastic characteristics or functions of the temperature in the case of

transverse isotropy for the elements of hull and the solid elements isoparametric.

By taking again the same notations as for the orthotropism [§3.4], the transverse isotropy means here,

isotropy in the plan (L, T).

3.6.1 Syntax

/

ELAS_ISTR

=

_F

(

E_L =

ygl, [R]

E_N =

ygn, [R]

G_LN =

gln, [R]

NU_LT =

nult,

[R]

NU_LN =

nuln,

[R]

ALPHA_L =

/dil,

[R]

/

0.0,

[DEFECT]

ALPHA_N =

/DIN,

[R]

/

0.0,

[DEFECT]

RHO =

/rho,

[R]

/

0.0,

[DEFECT]

)

/

ELAS_ISTR_FO

=_F

(

E_L =

ygl, [function **]

E_N =

ygn, [function **]

G_LN =

gln, [function **]

NU_LT =

nult,

[function **]

NU_LN =

nuln,

[function **]

ALPHA_L

=

dil

, [function **]

ALPHA_N

=

DIN

, [function **]

RHO =

/rho,

[R]

/

0.0,

[DEFECT]

TEMP_DEF_ALPHA = Tdef, [R]

PRECISION

=/

,

[R]

/

1.,

[DEFECT]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

28/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.6.2 Operands

of elasticity

The reader will be able to refer to following documentations:

[U4.42.03]

DEFI_COQU_MULT

[U4.42.01]

AFFE_CARA_ELEM

to define a reference mark (L, T, NR) related to the elements and defining the transverse isotropy of material, it

the last being isotropic in plan LT.

Note:

The directions L and T are arbitrary in plan LT.

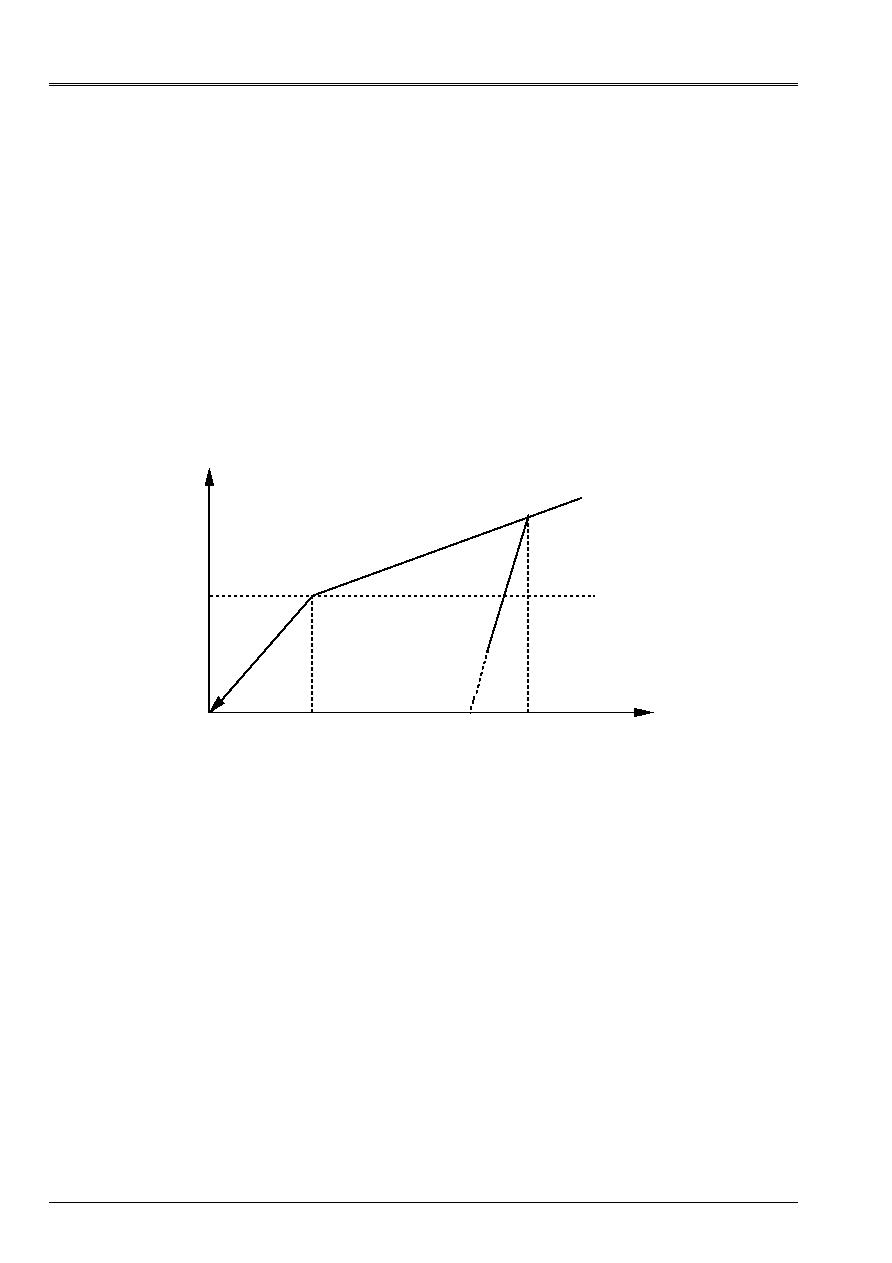

NR

T

L

L and T define the plan in which

the material is isotropic

E_L = ygl

Young modulus in plan LT.

E_N = ygn

Normal Young modulus.

GL_N = gln

Modulus of rigidity in plan LN.

Note:

The modulus of rigidity in plan LT is defined by the usual formula for materials

isotropic:

(

)

+

= 1

2

E

G

that is to say here

(

)

glt

ygl

nult

=

+

2 1

.

NU_LT = nult

Poisson's ratio in plan LT.

NU_LN = nuln

Poisson's ratio in plan LN.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

29/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

Important remarks:

nult

=

nutl

since the material is isotropic in plan LT, but

nuln

is not

not equal to

nunl

.

One with the relation:

nunl

ygl

ygn

nuln

=

*

nult

must be interpreted in the following way:

if one exerts a traction according to the axis NR giving place to a deformation of traction according to this

axis equalizes with

NR

NR

=

ygn

, there is a compression according to the axis L equalizes with:

nuln

ygn

*

NR

.

Various moduli of elasticity

E_L

,

G_LN

and

NU_LN

cannot be selected of

unspecified way: physically, it is necessary always that a nonnull deformation causes one

strictly positive deformation energy. That results in the fact that the matrix of

Hooke must be definite positive. The operator

DEFI_MATERIAU

calculate the eigenvalues of

this matrix and emits an alarm if this property is not checked.

For the models 2D, like the user its MODELING (D_PLAN did not choose yet,

C_PLAN,…), one checks the positivity of the matrix in the various cases of figure.

3.6.3 Operand

RHO

RHO = rho

Density.

3.6.4 Operands

ALPHA_L

/

ALPHA_N

ALPHA_L = dil

Thermal expansion factor average in plan LT.

ALPHA_N = DIN

Thermal expansion factor average normal.

3.6.5 Operands

TEMP_DEF_ALPHA/PRECISION

One will refer to the paragraph [§3.1.4]. This key word becomes obligatory as soon as the word was informed

key ALPHA_L or ALPHA_N.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

30/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

3.7

Key word factor

ELAS_COQUE

/

ELAS_COQUE_FO

ELAS_COQUE

allows the user to directly provide the coefficients of the matrix of elasticity

(broken up into membrane and bending) of the orthotropic thin hulls in linear elasticity [R3.07.03].

3.7.1 Syntax

/

ELAS_COQUE =

_F (

/ELAS_COQUE_FO

= _F

MEMB_L

=

C1111

,

[R]

or

[function **]

MEMB_LT = C1122, [R]

or

[function **]

MEMB_T

=

C2222

,

[R]

or

[function **]

MEMB_G_LT

= C1212, [R]

or

[function **]

FLEX_L

=

D1111

,

[R]

or

[function **]

FLEX_LT = D1122, [R]

or

[function **]

FLEX_T

=

D2222

,

[R]

or

[function **]

FLEX_G_LT

= D1212, [R]

or

[function **]

CISA_L

=

G11

, [R] or [function **]

CISA_T

=

G22

, [R] or [function **]

RHO

=

rho

, [R] or [function **]

ALPHA

=

alpha

,

[R]

or

[function **]

M_LLLL

=

H1111

,

[R]

or

[function **]

M_LLTT

=

H1111

,

[R]

or

[function **]

M_LLLT

=

H1112

,

[R]

or

[function **]

M_TTTT

=

H2222

,

[R]

or

[function **]

M_TTLT

=

H2212

,

[R]

or

[function **]

M_LTLT

=

H1212

,

[R]

or

[function **]

F_LLLL

=

A1111

,

[R]

or

[function **]

F_LLLL

=

A1111

,

[R]

or

[function **]

F_LLLT

=

A1112

,

[R]

or

[function **]

F_TTTT

=

A2222

,

[R]

or

[function **]

F_TTLT

=

A2212

,

[R]

or

[function **]

F_LTLT

=

A1212

,

[R]

or

[function **]

MF_LLLL = B1111, [R]

or

[function **]

MF_LLTT = B1111, [R]

or

[function **]

MF_LLLT = B1112, [R]

or

[function **]

MF_TTTT = B2222, [R]

or

[function **]

MF_TTLT = B2212, [R]

or

[function **]

MF_LTLT = B1212, [R]

or

[function **]

MC_LLLZ = E1111, [R]

or

[function **]

MC_LLTZ = E1111, [R]

or

[function **]

MC_TTLZ = E1112, [R]

or

[function **]

MC_TTTZ = E2222, [R]

or

[function **]

MC_LTLZ = E2212, [R]

or

[function **]

MC_LTTZ = E1212, [R]

or

[function **]

FC_LLLZ = F1111, [R]

or

[function **]

FC_LLTZ = F1111, [R]

or

[function **]

FC_TTLZ = F1112, [R]

or

[function **]

FC_TTTZ = F2222, [R]

or

[function **]

FC_LTLZ = F2212, [R]

or

[function **]

FC_LTTZ = F1212, [R]

or

[function **]

C_LZLZ

=

G1313

,

[R]

or

[function **]

C_TZTZ

=

G2323

,

[R]

or

[function **]

C_TZTZ

=

G1323

,

[R]

or

[function **]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

31/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

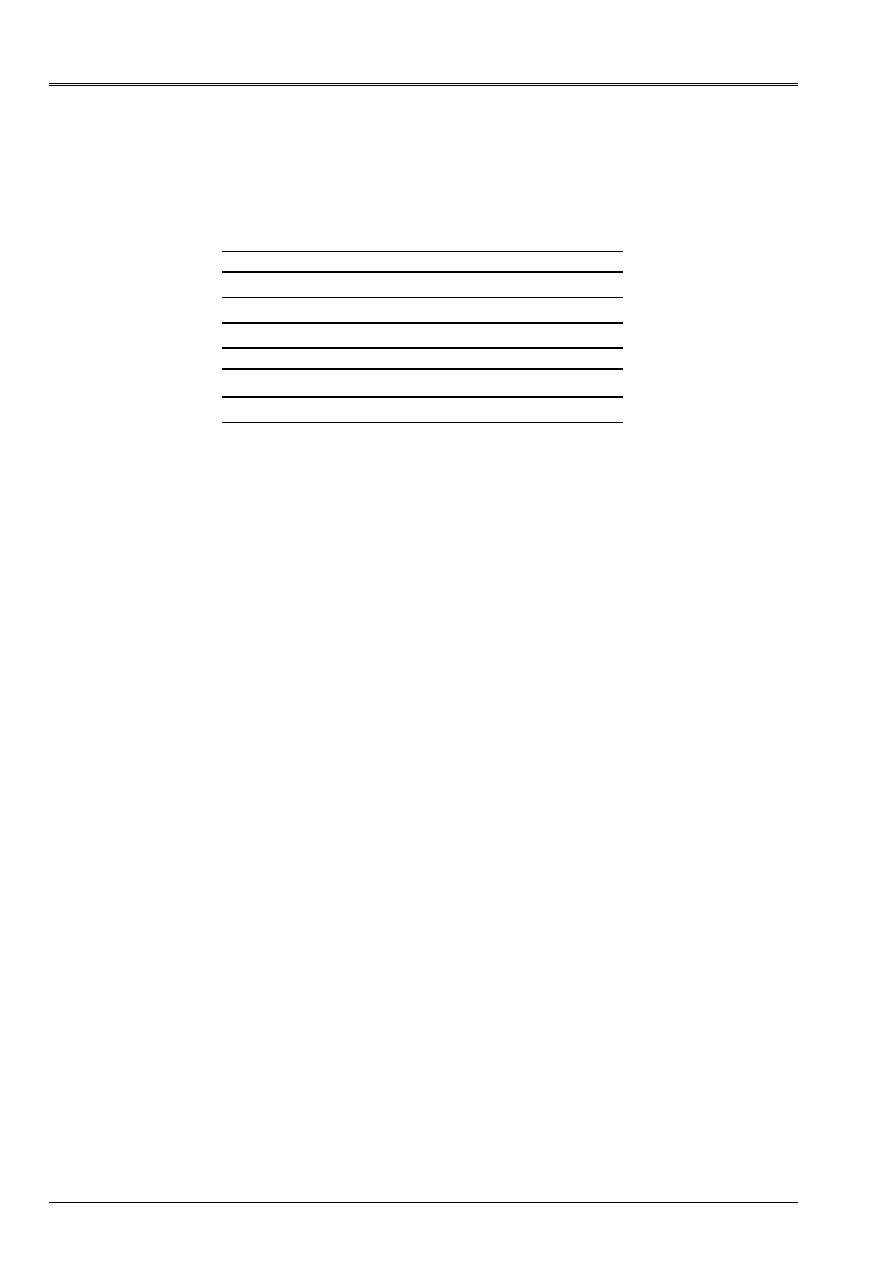

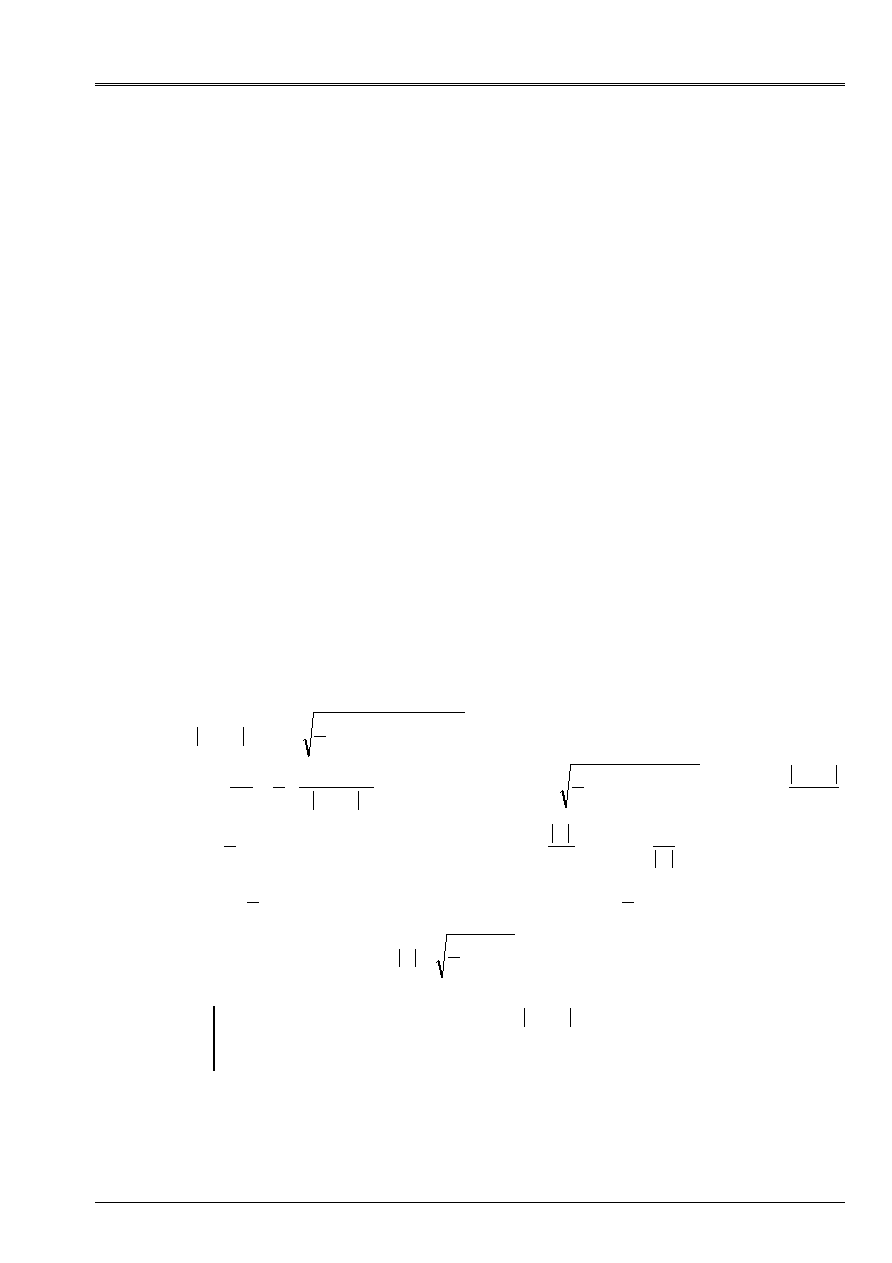

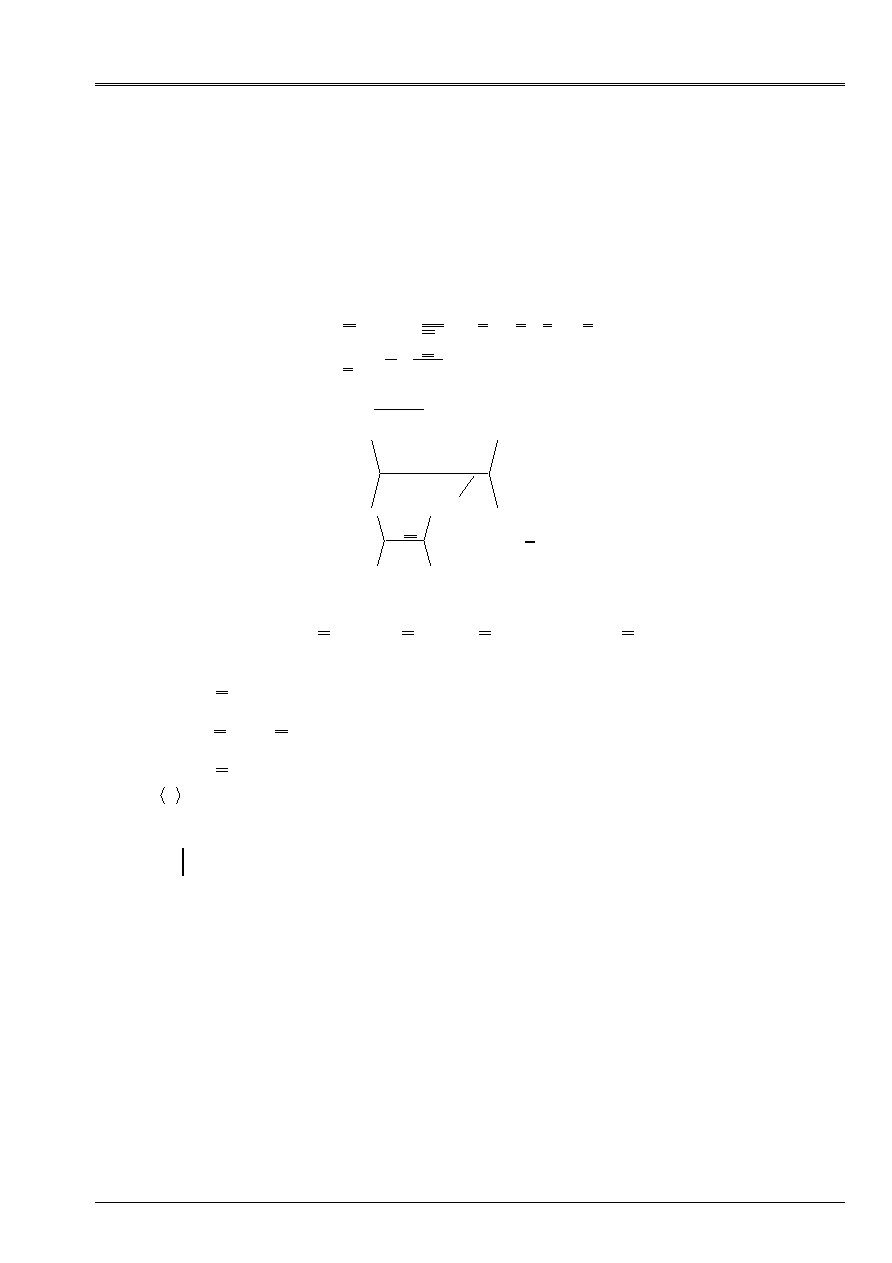

The matrix of behavior intervening in the matrix of rigidity in isotropic homogeneous elasticity

is form:

(

)

(

)

Membrane:

Bending:

Shearing:

1

0

1

1 0

0 0

1

2

1

0

1

1 0

0 0

1

2

1 0

1

0 1

2

2

C

Eh

D

Eh

12

G

5Eh

12

3

= -

-

=

-

-

=

+

For the orthotropic hulls whose moduli of elasticity are obtained by a method

of homogenization, it is not possible in the general case to find a Young modulus equivalent

Eeq, and an equivalent thickness heq to find the preceding expressions.

The matrices of rigidity are thus given directly in the form:

Membrane:

Bending:

Shearing:

C

C

C

C

C

D

D

D

D

D

G

G

1111

1122 0

1122

2222 0

0

0

1212

1111

1122 0

1122

2222 0

0

0

1212

11 0

0

22

C

D

G

=

=

=

On the other hand, one limits oneself to the cases where the thermal expansion factor is homogeneous isotropic.

These coefficients are to be provided in the local reference mark of the element. It is defined by the key word

ANGL_REP

of

AFFE_CARA_ELEM

[U4.42.01].

Notice concerning the taking into account of transverse shearing following the models of

hulls:

If one wishes to use

ELAS_COQUE

for transverse shearing it is necessarily necessary

to employ DST modeling. If one uses modeling DKT, transverse shearing

will not be taken into account, some are the values of G11 and G22. Correspondence for one

isotropic material is as follows:

·

The material

ELAS_COQUE

, DST modeling with CISA_ * = 5/12 * (Eh/(1+nu)) is equivalent

with material

ELAS

, DST modeling.

·

The material

ELAS_COQUE

, DST modeling with CISA_ * = 5/12 * (Eh/(1+nu))* NR, where NR is one

great number (for example 10

5

), is equivalent to the material ELAS, modeling DKT.

·

The material

ELAS_COQUE

, modeling DKT is equivalent to material

ELAS

, modeling

DKT.

Matrices of behavior connecting the efforts generalized to the deformations for the elements of

plate and fascinating account the terms of coupling are in the following way defined:

Membrane:

Bending:

Membrane

bending:

Membrane shearing:

Bending - shearing:

Shearing:

-

=

=

=

=

=

=

H

H

H

H

H

H

With

With

With

With

With

With

B

B

B

B

B

B

E

E

E

E

E

E

F

F

F

F

F

F

G

G

G

G

1111

1122

1112

0

2222

2212

0

0

1212

1111

1122

1112

0

2222

2212

0

0

1212

1111

1122

1112

0

2222

2212

0

0

1212

1113

1123

2213

2223

1213

1223

1113

1123

2213

2223

1213

1223

1313

1323

1323

2323

HM

HF

HMF

HMC

HFC

HC

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

32/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4

General nonlinear mechanical behaviors

In general, the definition of a nonlinear mechanical behavior requires on the one hand the definition

elastic properties and in addition those relating to the nonlinear aspect itself.

In Code_Aster, these 2 types of data are separately defined, except some exceptions.

4.1

Key word factor

TRACTION

Definition of a traction diagram (elastoplasticity of von Mises with nonlinear isotropic work hardening

or nonlinear elasticity).

4.1.1 Syntax

|

TRACTION = _F

(

SIGM

=

sigm_f

,

[function ***]

)

4.1.2 Operand

SIGM

SIGM = sigm_f

Curve

according to (one checks that the concept function depends many only parameters

EPSI

and possibly

TEMP

).

The ordinate of the first point defines the yield stress of material, it is thus imperative of not

to define of point of null X-coordinate.

Note:

For multiphase materials, the characteristics of work hardening are defined by

META_ECRO_LINE or META_TRACTION.

4.2

Key words factor

ECRO_LINE

/

ECRO_LINE_FO

Definition of a linear curve of work hardening or a whole of curves depending on

temperature.

4.2.1 Syntax

|

ECRO_LINE = _F

(

D_SIGM_EPSI

=

dsde, [R]

SY

= sigm,

[R]

)

|

ECRO_LINE_FO

=_F

(

D_SIGM_EPSI

=

dsde, [function **]

SY

= sigm,

[function **]

)

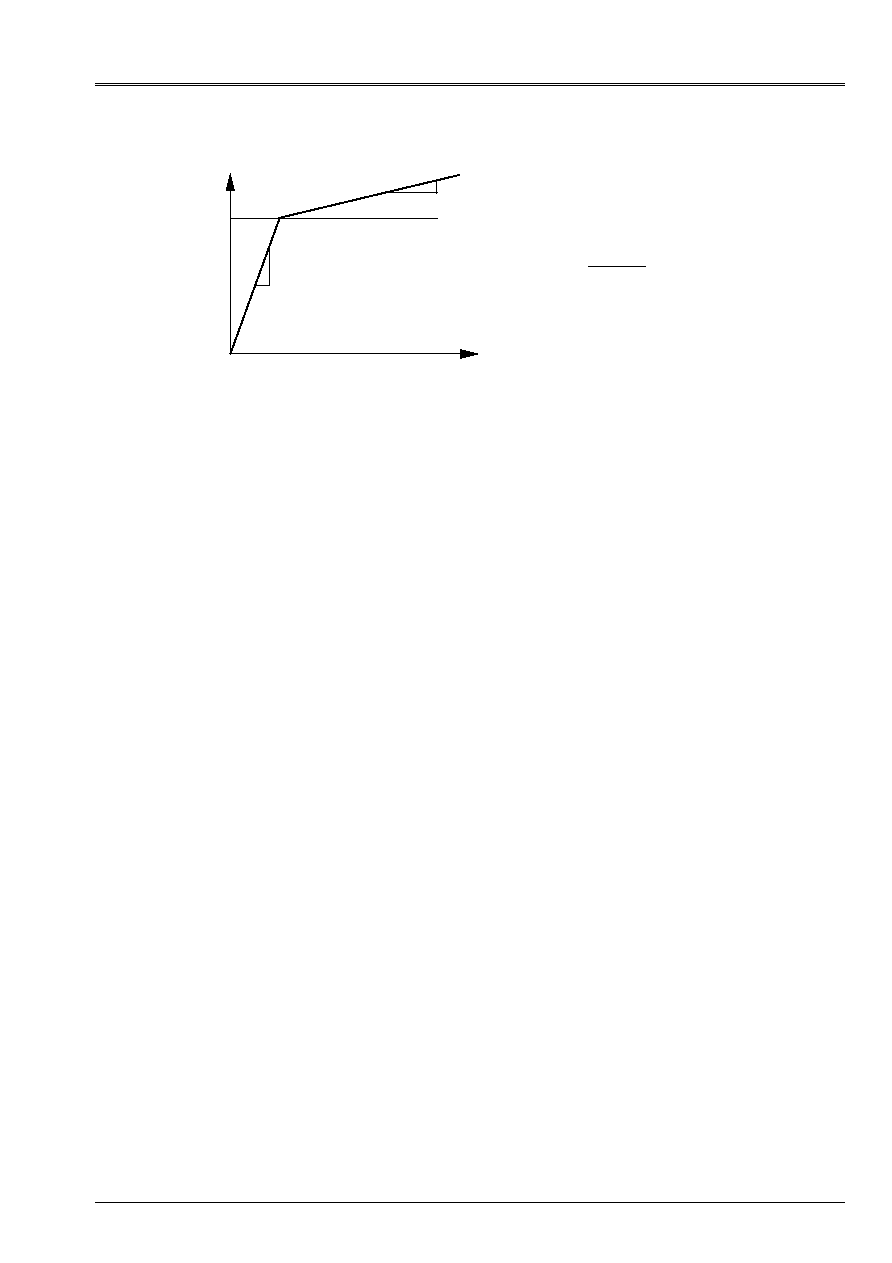

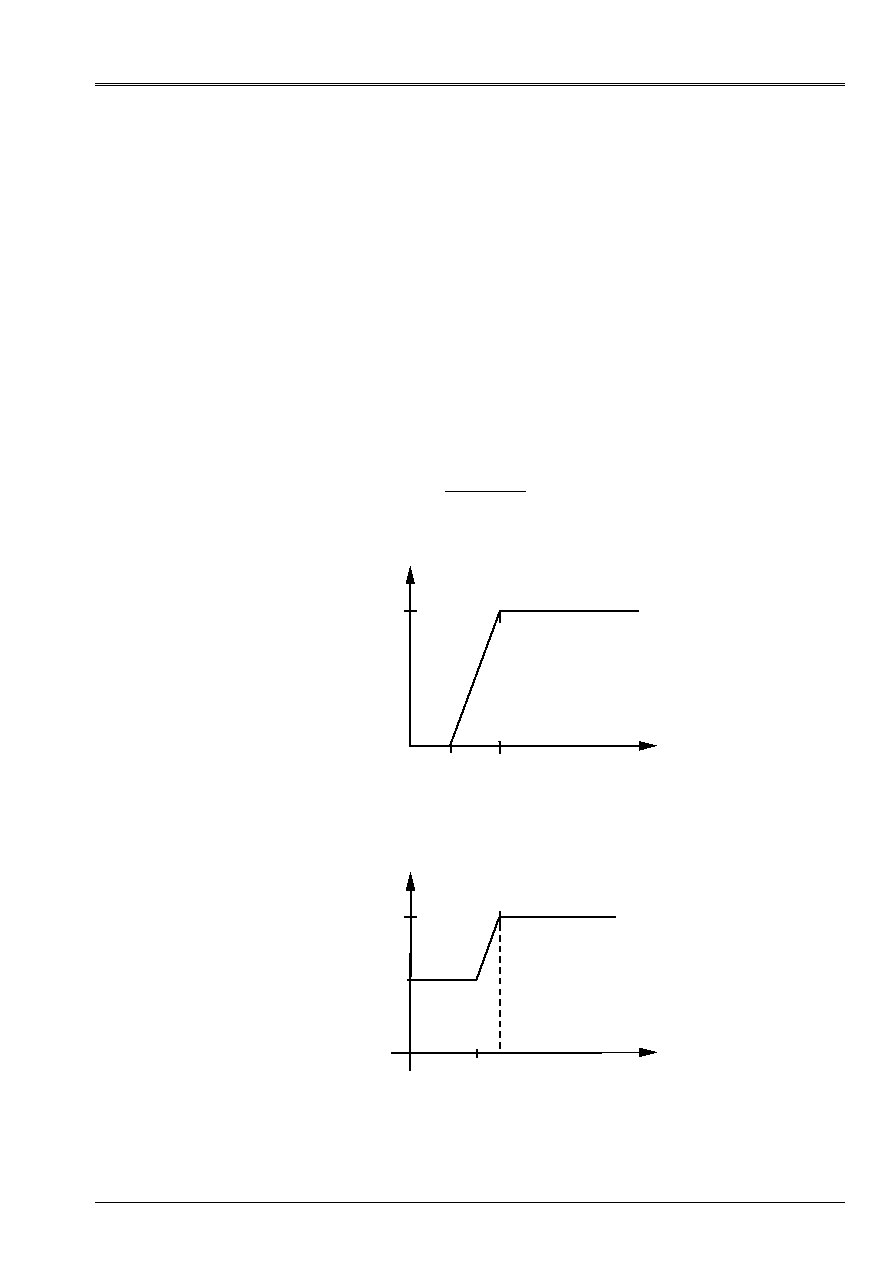

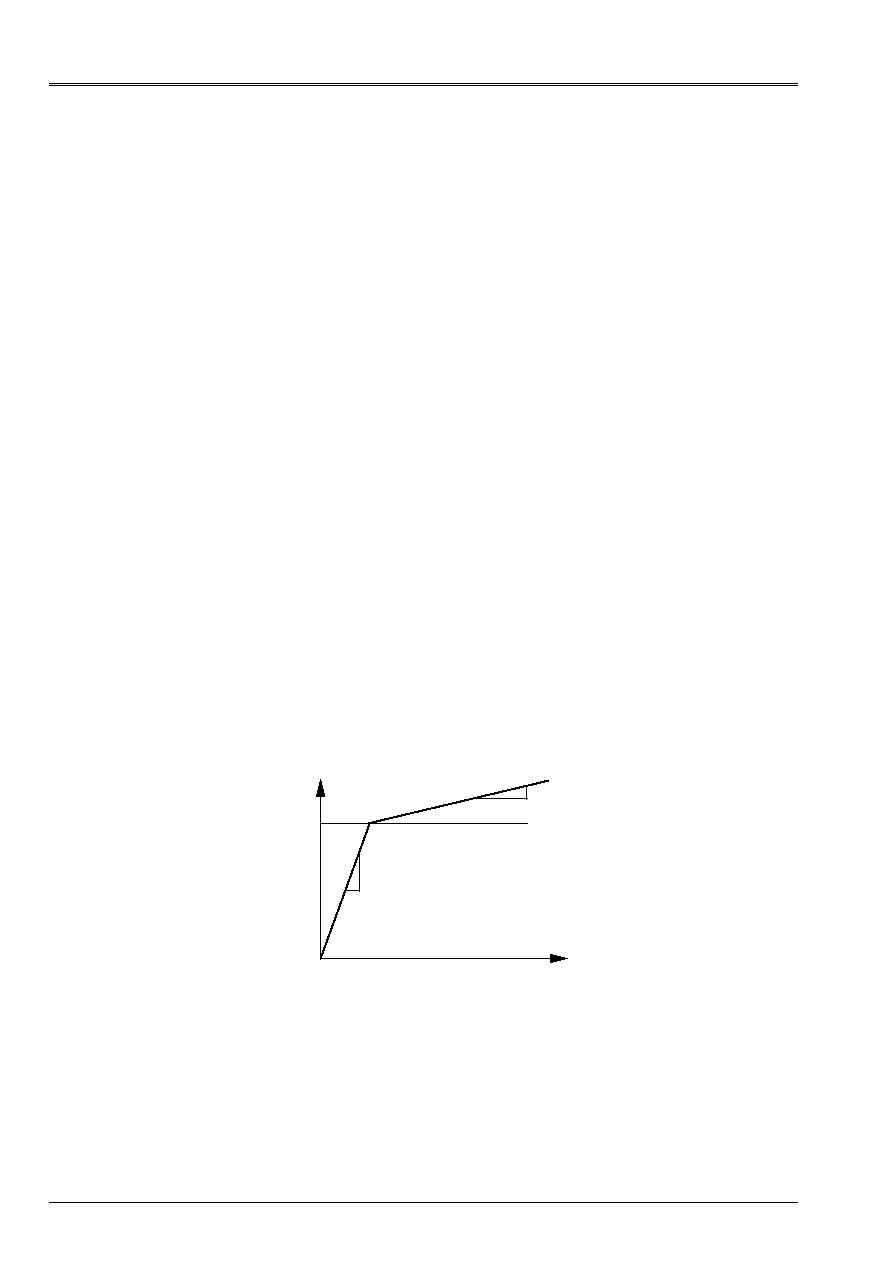

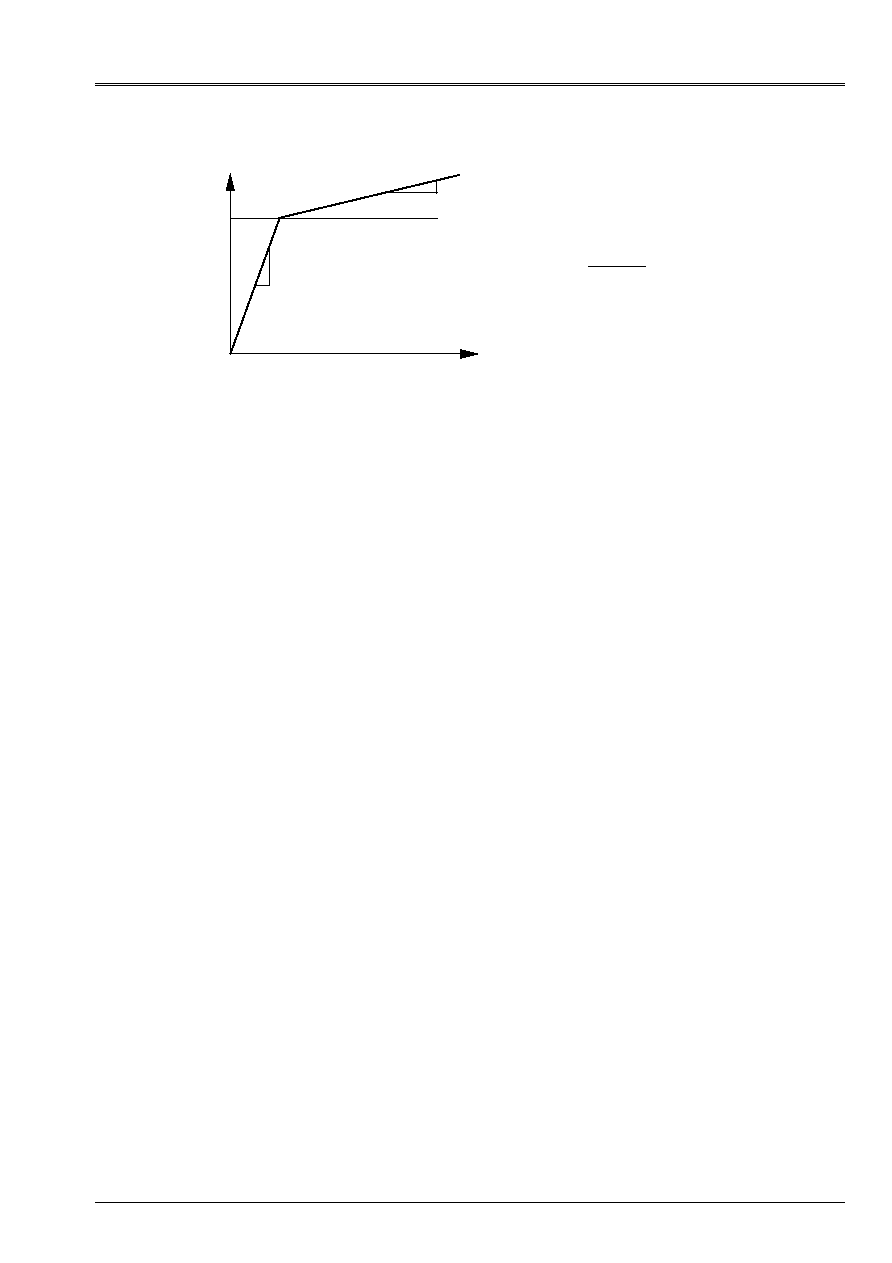

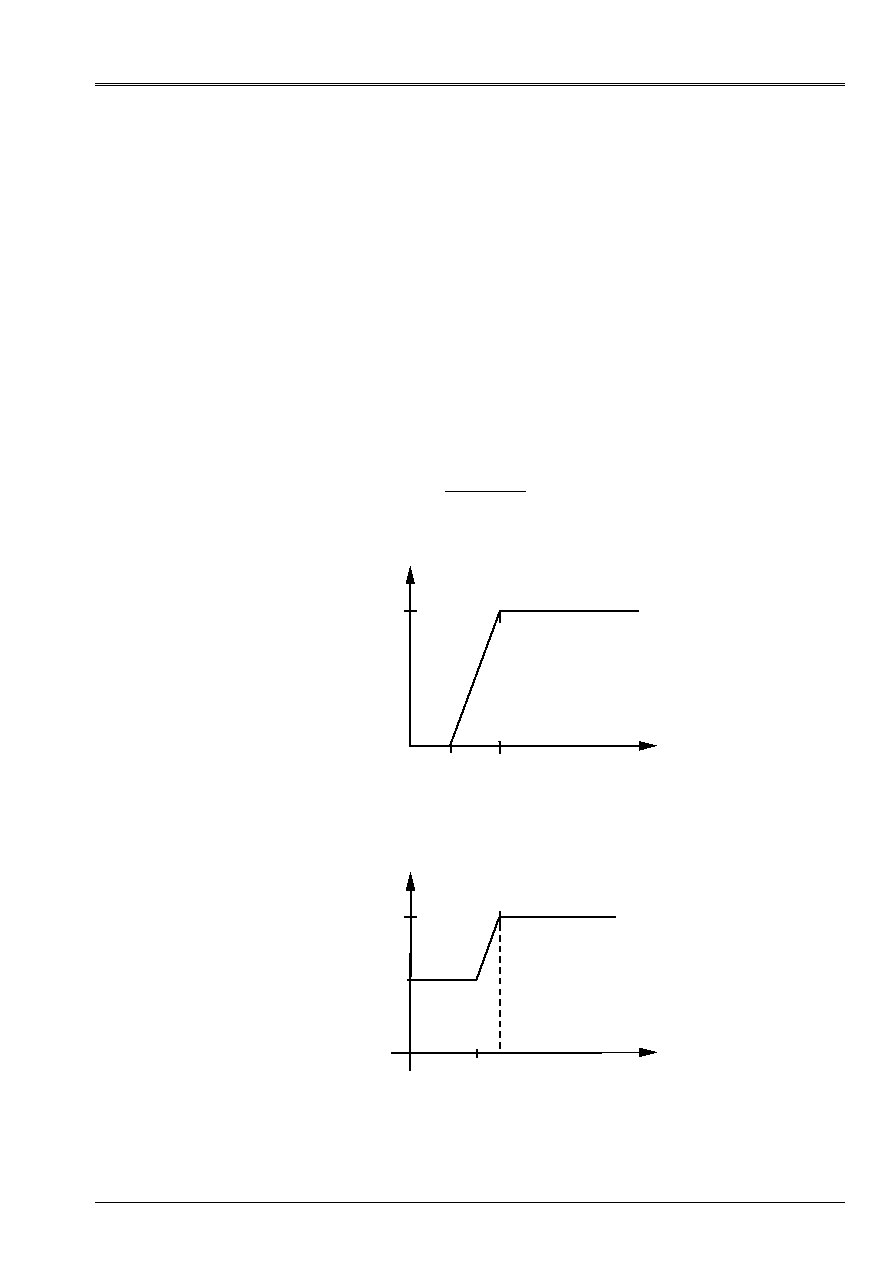

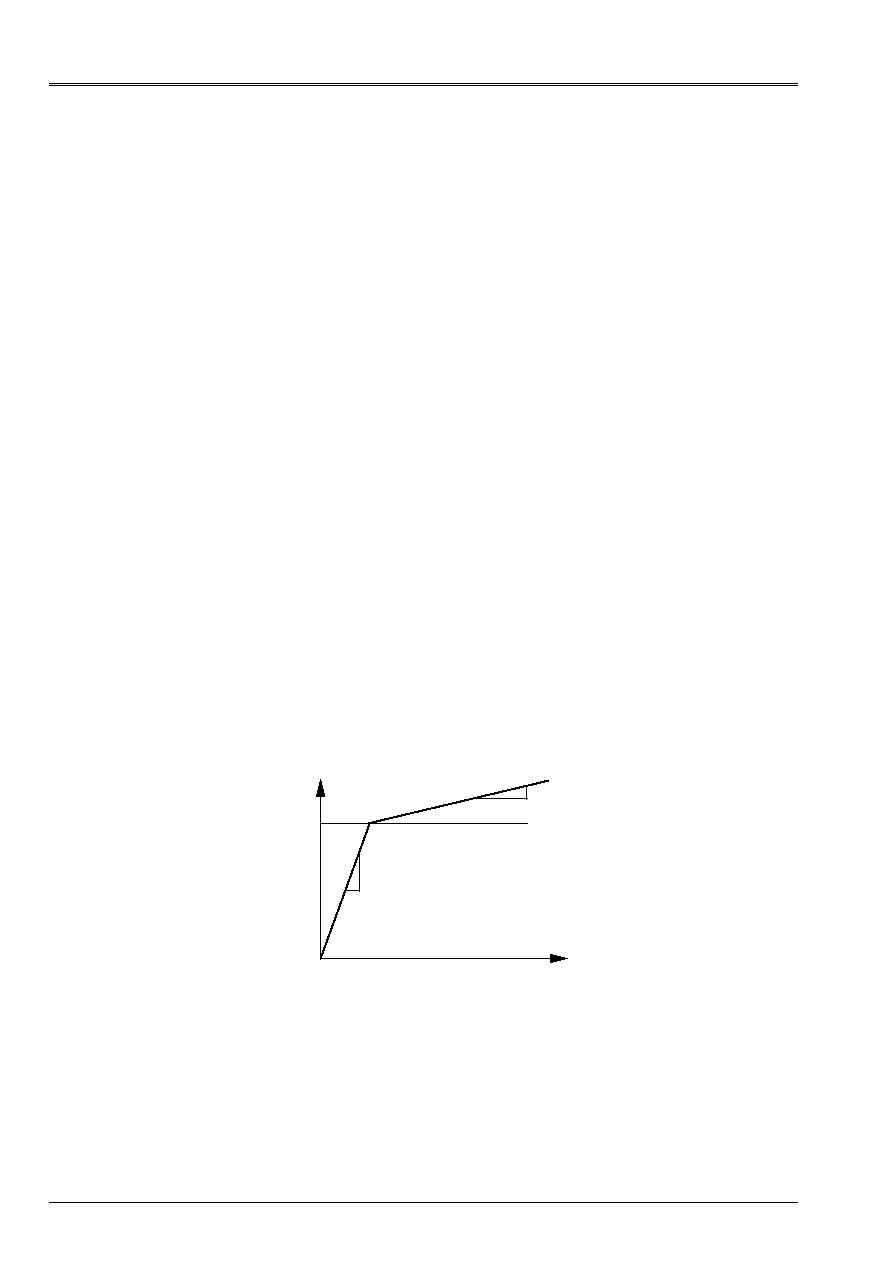

4.2.2 Operands

D

_

SIGM_EPSI = dsde (AND)

Slope of the traction diagram.

SY = sigm

Elastic limit.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

33/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

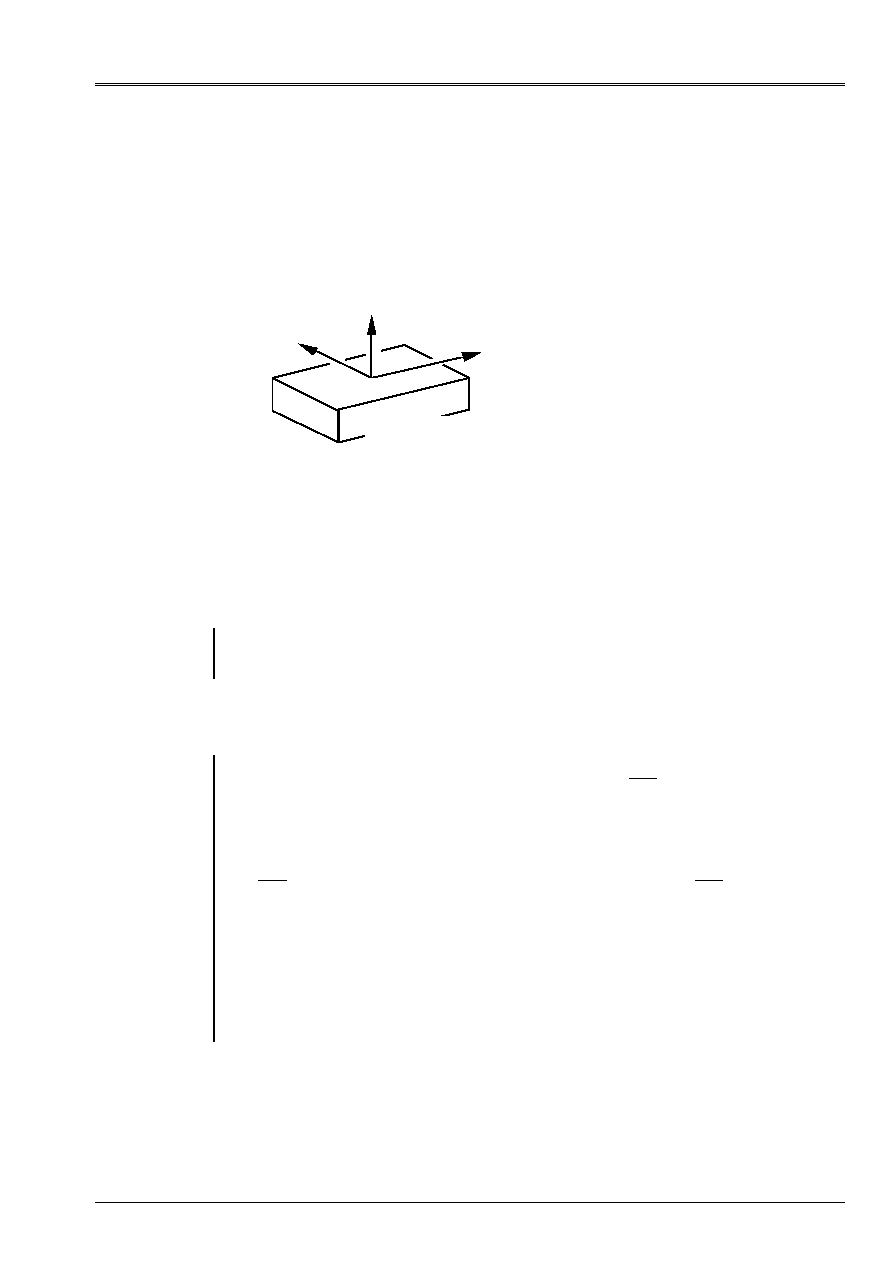

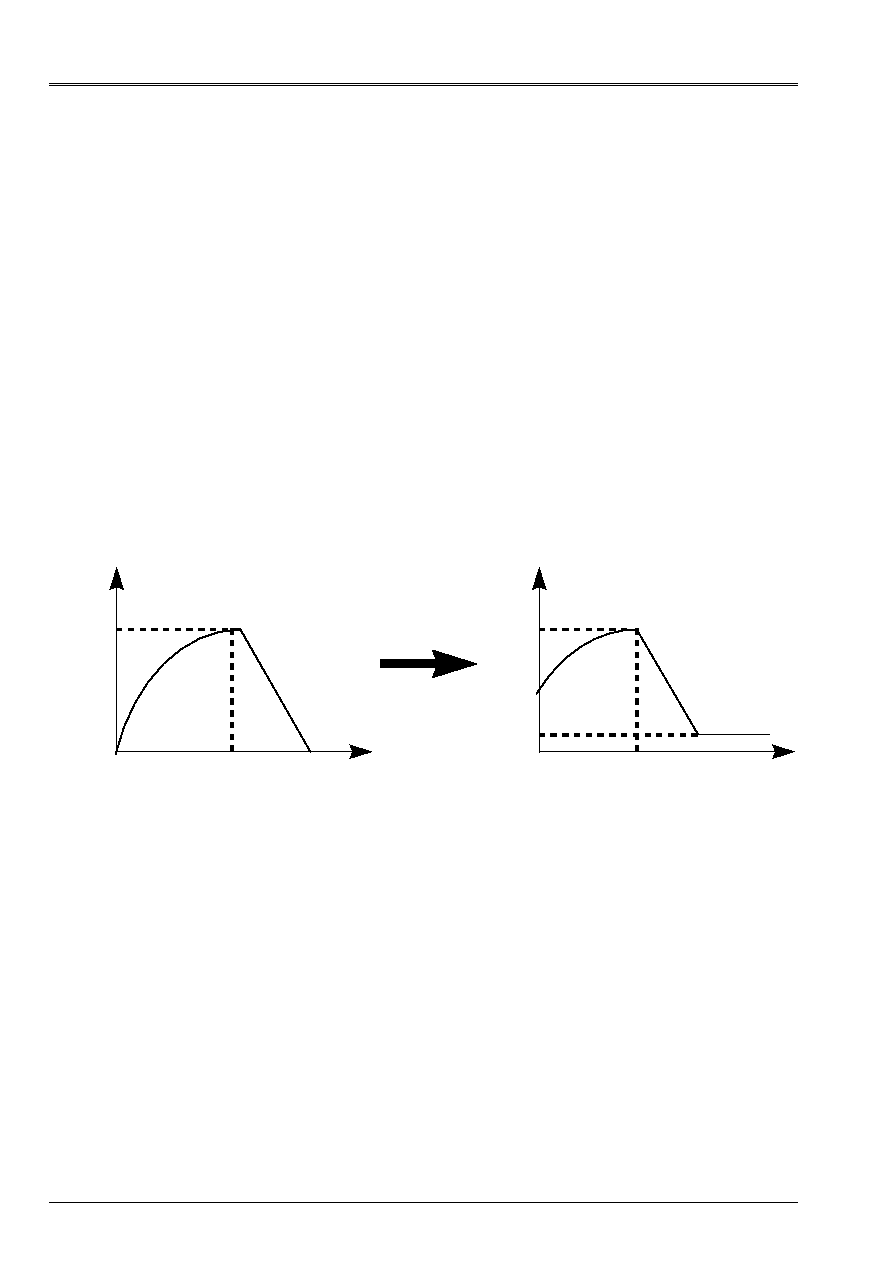

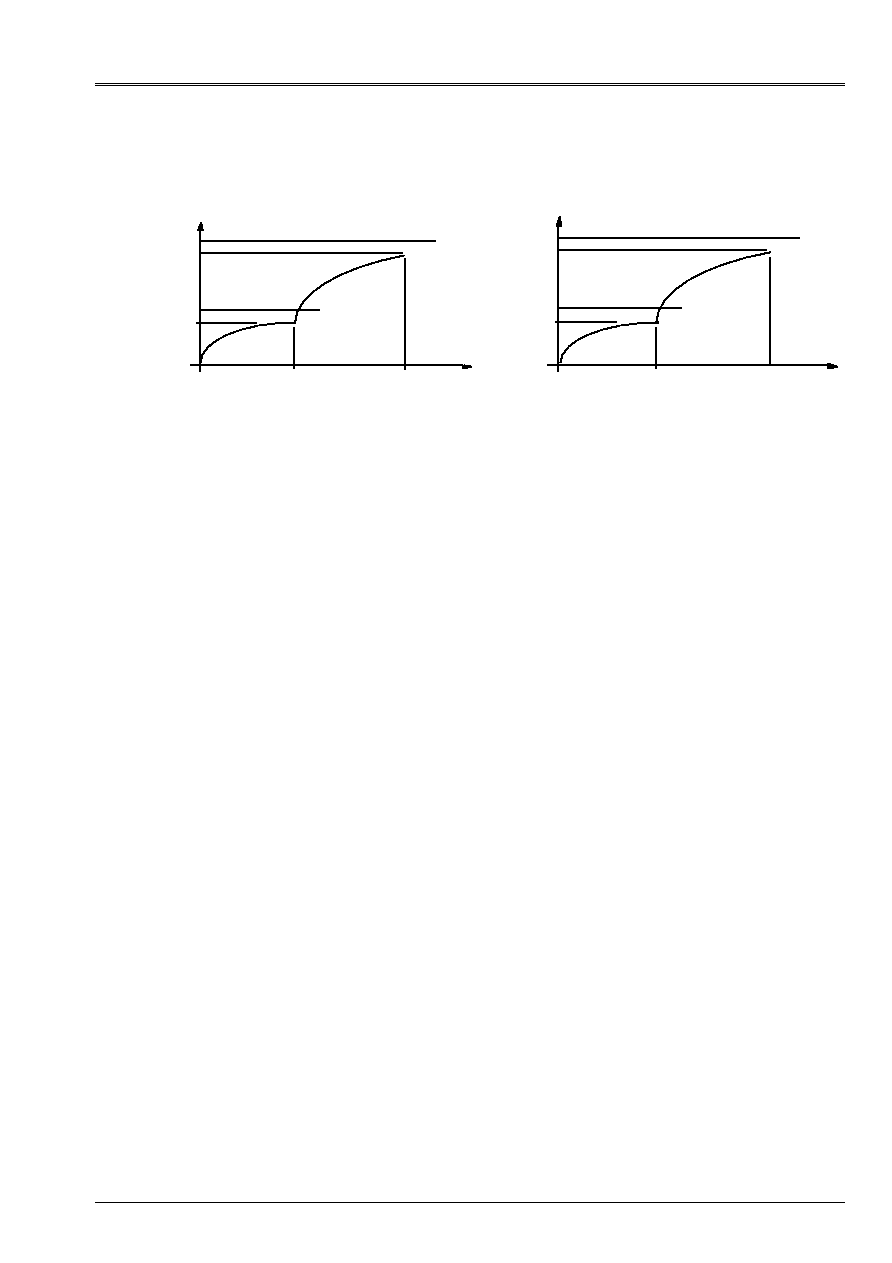

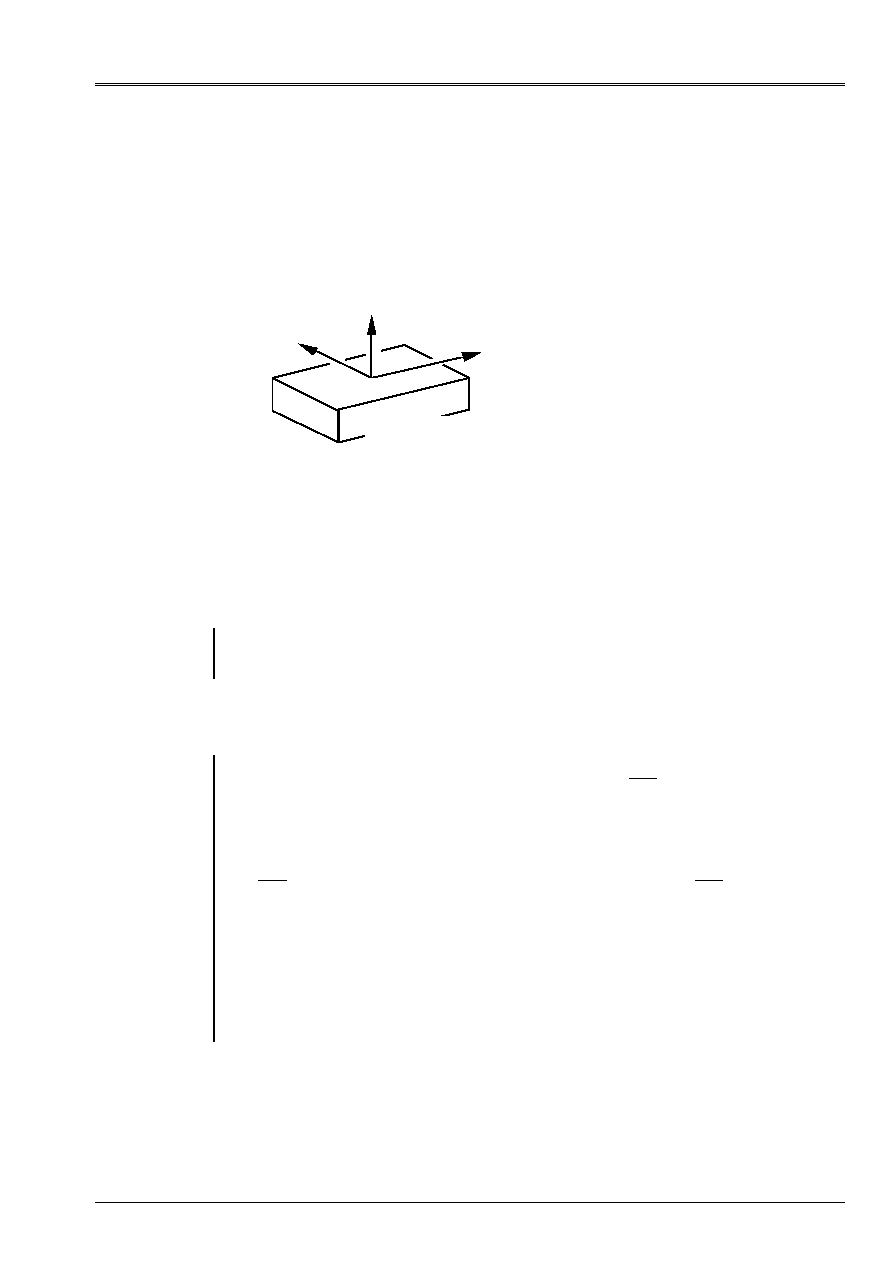

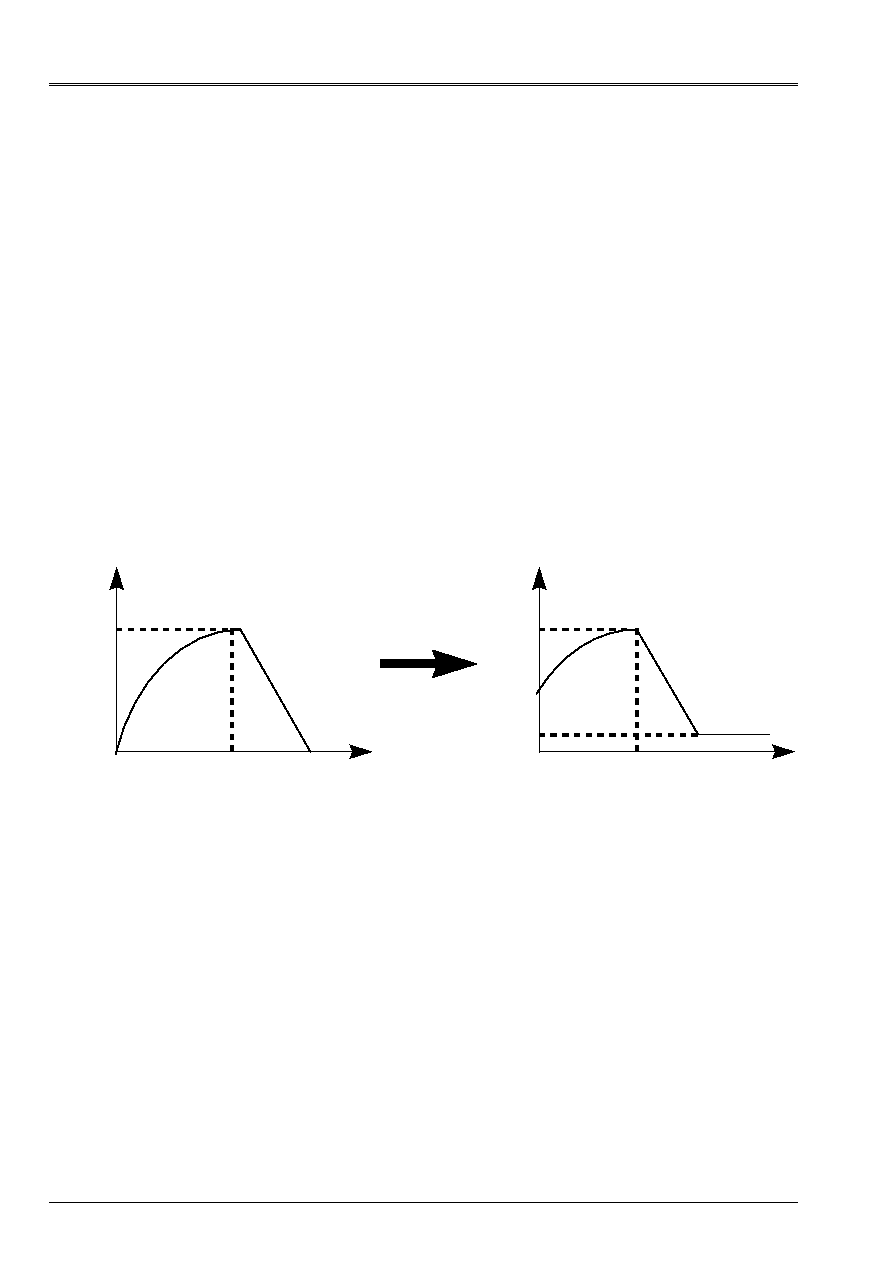

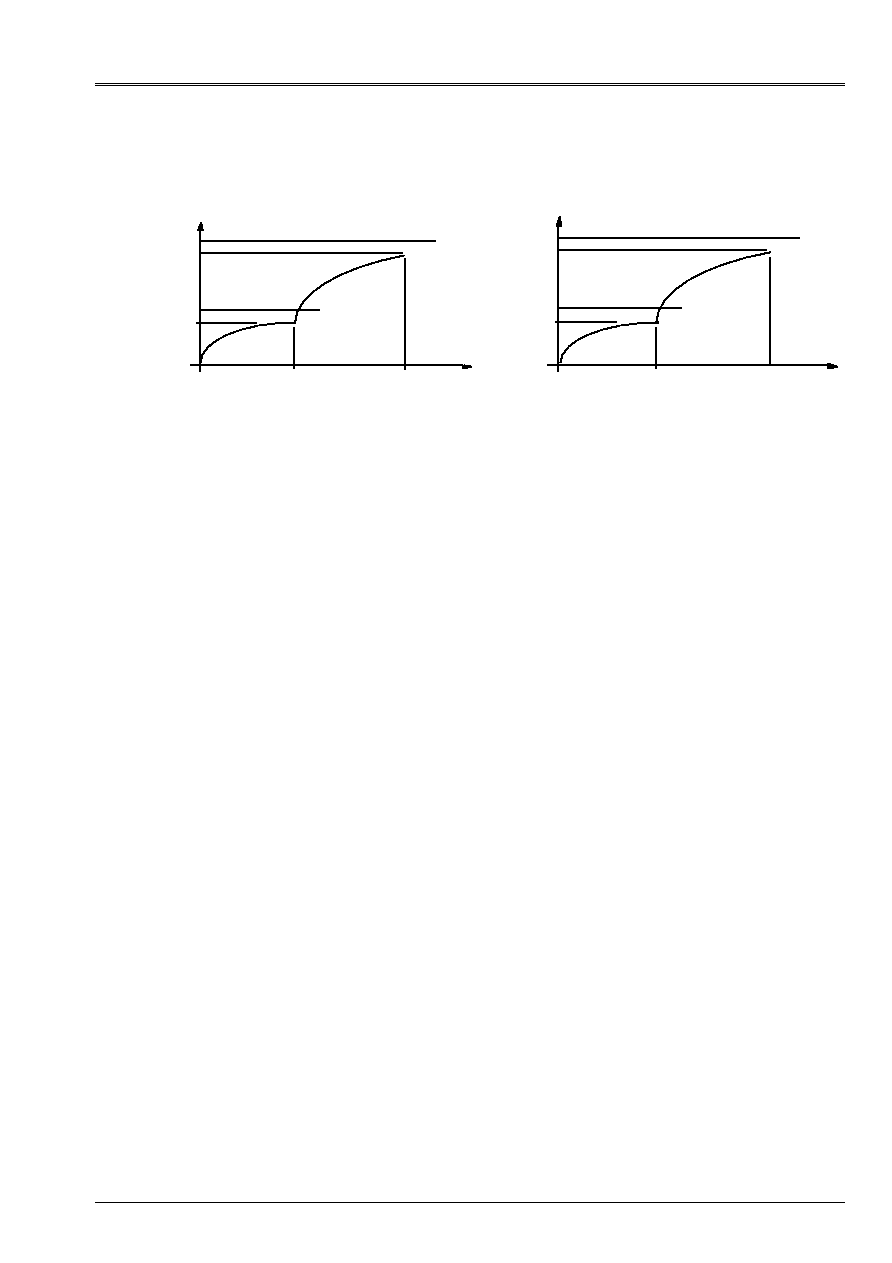

sigm

E

1

E

T

The curve of work hardening used in

models of behavior is then:

()

R p

H

y

p

=

+

with

H

E E

E E

T

T

=

-

.

It is thus necessary to respect:

E

E

T

<

The Young modulus E is to be specified by the key words

ELAS

or

ELAS_FO

.

4.3

Key words factor PRAGER/PRAGER_FO

When the way of loading is not monotonous any more, work hardenings isotropic and kinematic are not

more equivalent. In particular, one can expect to have simultaneously a kinematic share and one

isotropic share. If one seeks to precisely describe the effects of a cyclic loading, it is

desirable to adopt modelings sophisticated (but easy to use) such as the model of

Taheri, for example, cf [R5.03.05]. On the other hand, for less complex ways of loading,

one can wish to include only one linear kinematic work hardening, all nonthe linearities of

work hardening being carried by the isotropic term. That makes it possible to follow a curve precisely of

traction, while representing nevertheless phenomena such as the Bauschinger effect [R5.03.16].

The characteristics of work hardening are then given by a traction diagram and a constant,

said of Prager, for the term of kinematic work hardening linear. Key word PRAGER makes it possible to define

the constant of PRAGER, used in the models with mixed work hardening (kinematic linear compound

with isotropic) VMIS_ECMI_LINE or VMIS_ECMI_TRAC.

4.3.1 Syntax

|

PRAGER = _F

(

C = C, [R]

)

|

PRAGER_FO = _F

(

C = C, [function **]

)

The identification of C is described in [R5.03.16].

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

34/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.4 Word

key

CHABOCHE

Behavior of the model of Chaboche describes in the document [R5.03.04].

Briefly these relations are:

(

)

()

(

)

(

)

()

& &

~

~

&

&

&

-

-

-

=

-

-

-

-

=

-

X

X

R p

p

X

X

X

X

X

C

has

p

X p

eq

p

I

I

I

p

I

1

2

1

2

1

2

0

3

2

2

3

eq

éq

4.4-1

with:

()

(

)

()

(

)

R p

R

R

R E

p

K

E

LP

wp

=

+

-

=

+

-

-

-

0

1

1

and of the conventional relations of plasticity.

Note:

~

represent the diverter of the stresses and ()

eq

the equivalent within the meaning of von Mises.

This model does not make it possible to take into account the variation of the coefficients with

temperature.

With this intention, it is necessary to use VMIS_CIN1_CHAB_FO or VMIS_CIN2_CHAB_FO.

4.4.1 Syntax

|

/CHABOCHE = _F

(

R_I

=

Rinfi,

[R]

R_0

=

Rzero,

[R]

B =

B,

[R]

K =

K,

[R]

W =

W,

[R]

A1 =

a1, [R]

A2 =

a2, [R]

C1 =

C1, [R]

C2 =

C2, [R]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

35/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.5

Key words factor

CIN1_CHAB

/

CIN1_CHAB_FO

Behavior of the model of Chaboche (news version with only one kinematic variable) described

in the document [R5.03.04].

Briefly these relations are:

(

)

(

)

()

F,

~

R

R p

eq

X

X

=

-

-

(

)

&

& F

& ~

~

p

X

X

=

=

-

-

3

2

eq

&

&

&

&

p

= =

2

3

p

p

:

éq 4.5-1

if

or

if

and

F

&F

&

F

&F

&

<0

0

0

0

0

0

<

=

=

=

éq

4.5-2

()

()

X

p

,

& &

&

=

=

-

2

3 C p

p

p

éq

4.5-3

Functions

() ()

C p

p

and

()

R p

are defined by:

()

(

)

()

(

)

(

)

R p

R

R

R E

C p

C

K

E

LP

wp

=

+

-

=

+

-

-

-

0

1

1

()

(

)

(

)

1

0

1

p

has

E has

LP

=

+ -

-

Note:

~

represent the diverter of the stresses and ()

eq

the equivalent within the meaning of von Mises.

The definition of

X

in the form [éq 4.5-3] allows to keep a formulation which takes in

count the variations of the parameters with the temperature. These terms are necessary because them

not taken into account would lead to inaccurate results.

4.5.1 Syntax

CIN1_CHAB (CIN1_CHAB_FO)

= _F (

R_0 =

R_0

,

[R]

or

[function **]

R_I

= R_I, (useless if B=0) [R] or [function **]

B =

B

, (defect: 0.)

[R] or [function **]

C_I =

C_I,

[R]

or

[function **]

K =

K

, (defect: 1.)

[R] or [function **]

W =

W

, (defect: 0.)

[R] or [function **]

G_0

=

G_0,

[R]

or

[function **]

A_I

= A_I, (defect: 0.)

[R] or [function **]

)

Note:

A viscoplastic version of the model of Chaboche to a true kinematics is also

available (cf [R5.03.04]). It requires to define viscous characteristics using

key word factor LEMAITRE or LEMAITRE_FO, by putting parameter UN_SUR_M obligatorily

to zero.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

36/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.6

Key words factor

CIN2_CHAB

/

CIN2_CHAB_FO

Behavior of the model of Chaboche (news version with two variables kinematics) described in

the document [R5.03.04].

Briefly these relations are:

(

)

(

)

()

F,

~

R

R p

eq

X

X

X

=

-

-

-

1

2

(

)

&

& F

& ~

~

p

X

X

X

X

=

=

-

-

-

-

3

2

1

2

1

2 eq

&

&

&

&

p

= =

2

3

p

p

:

éq 4.6-1

if

or

if

and

F

&F

&

F

&F

&

<0

0

0

0

0

0

<

=

=

=

éq 4.6-2

()

()

()

()

X

X

p

p

1

1

2

2

1

2

2

3

2

3

,

,

&

&

&

&

&

&

=

=

=

-

=

-

C p

C p

p

p

p

p

1

2

1

1

2

2

éq 4.6-3

Functions

() () () ()

C PC p

p

p

1

2

1

2

and

()

R p

are defined by:

()

(

)

()

(

)

(

)

()

(

)

(

)

R p

R

R

R E

C p

C

K

E

C p

C

K

E

LP

wp

wp

=

+

-

=

+

-

=

+

-

-

-

-

0

1

1

2

2

1

1

1

1

()

(

)

(

)

()

(

)

(

)

1

1

0

2

2

0

1

1

p

has

E has

p

has

E has

LP

LP

=

+ -

=

+ -

-

-

Note:

~

represent the diverter of the stresses and ()

eq

the equivalent within the meaning of von Mises.

The definition of

X

1

and

X

2

in the form [éq 4.5-3] allows to keep a formulation which takes in

count the variations of the parameters with the temperature. These terms are necessary because them

not taken into account would lead to inaccurate results.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

37/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.6.1 Syntax

CIN2_CHAB (CIN2_CHAB_FO)

= _F (

R_0 =

R_0,

[R]

or

[function **]

R_I

= R_I, (useless if B=0) [R] or [function **]

B =

B

, (defect: 0.)

[R] or [function **]

C1_I =

C1_I,

[R]

or

[function **]

C2_I =

C2_I,

[R]

or

[function **]

K = K,

(defect

:

1.)

[R] or [function **]

W = W,

(defect

:

0.)

[R] or [function **]

G1_0 =

G1_0,

[R]

or

[function **]

G2_0 =

G2_0,

[R]

or

[function **]

A_I

=

A_I, (defect:

0.)

[R] or [function **]

)

Note:

A viscoplastic version of the model of Chaboche with two variables kinematics is

also available (cf [R5.03.04]). It requires to define characteristics

viscous using the key word factor LEMAITRE or LEMAITRE_FO, while putting

obligatorily parameter UN_SUR_M to zero.

4.7

Key words factor

TAHERI

/

TAHERI_FO

Definition of the coefficients of the model of cyclic behavior of elastoplasticity of Said Taheri

[R5.03.05].

Briefly we have to solve, for an elastoplastic increment:

(

)

()

(

)

(

)

(

)

(

)

(

)

()

}

& & ~

~

& &

/

.

p

eq

eq

T

p

p

p pn

eq

p

T

eq

p

eq

p

X

X

with X

X X

R

D WITH

R

X

C S

X

R

X

R

R

X

D

=

-

-

=

=

+

=

-

=

-

-

-

=

=

+

-

-

=

=

3

2

3

2

0

0

1

1 2

0

Max

&

-

=

=

+

-

-

-

-

me

C

C

C E

LP

S

p

N

LP

S

p

p

1

1

1

0

where the various parameters of material are

S C

C B m A

and R

,

,

,

,

.

,

1

0

The various parameters can depend on the temperature, in this case one will employ the key word

TAHERI_FO

.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

38/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.7.1 Syntax

|

/

TAHERI

=

_F

(

R_0

= R, [R]

ALPHA =

, [R]

M = m, [R]

WITH = A, [R]

B = B, [R]

C1

=

C1

,

[R]

C_INF = Cinfi,

[R]

S = S, [R]

)

/

TAHERI_FO

=

_F

(

R_0

= R, [function **]

ALPHA =

, [function **]

M = m, [function **]

With = A, [function **]

B = B, [function **]

C1

=

C1

,

[function **]

C_INF = Cinfi,

[function **]

S = S, [function **]

)

Note:

A viscoplastic version of the model of TAHERI is also available (cf [R5.03.05]).

It requires to define viscous characteristics using the key word factor

LEMAITRE or LEMAITRE_FO.

4.7.2 Syntax

|

/OHNO:

/

OHNO_FO: _F (

R_0:

R0

[R]

or [function **]

R_I:

R

inf

[R]

or [function **]

PHI:

phi_inf

[R]

or [function **]

B: B [R]

or [function **]

A1

:

C1

[R]

or [function **]

A2

:

C2

[R]

or [function **]

A3

:

C3

[R]

or [function **]

A4

:

C4

[R]

or [function **]

A5

:

C5

[R]

or [function **]

GAMMA1

:

G

1

[R]

or [function **]

GAMMA2

:

g2

[R]

or [function **]

GAMMA3

:

g3

[R]

or [function **]

GAMMA4

:

g4

[R]

or [function **]

GAMMA5

:

g5

[R]

or [function **]

M1

:

m1

[R]

or [function **]

M2

:

m2

[R]

or [function **]

M3

:

m3

[R]

or [function **]

M4

:

m4

[R]

or [function **]

M5

:

m5

[R]

or [function **]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

39/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.8

Key word factor

POLY_CFC

/

POLY_CFC_FO

Definition of the coefficients of the model of polycrystalline behavior of the School of the Mines of Paris

[R5.03.13]. In addition to these characteristics, constant the rubber bands must be defined under the word

key ELAS by the real coefficients or ELAS_FO by the coefficients depending on the temperature.

Total behavior: definition of the deformations on a point scale of Gauss

“

“

N

orientatio

of

granulates

of

proportion

G

F

F

G

G

vp

ij

G

vp

ij

vp

ij

HT

ij

E

ij

ij

G

:

+

+

=

=

Intragranular behavior:

(

)

&

&

ij

vp

S

S G

ijs

I

J

J

I

G

m

N

L

L

N

=

=

+

m

ijs

1

2

&

|

& |

p

F

K

S

S

S N

=

=

with <x>=0 if x<0 and <x>=x if x>0

Criterion:

()

2

0

2

1

S

S

S

S

S

X

D

C

R

X

F

+

-

-

-

=

S

G

m

=

ij

ijs

:

X

C

X

S

S

S

=

+

=

+

S

S

has

has

&

&

&

S

S

p

=

-

S

S

D

R

H Q

Q

S

rs

R S

S

S

= Q

Q

1

2

(

)

+

1

2

(

)

(

)

S

R

S

R

H

H

I

p

Q

B

Q

rs

rs

rs

rs

rs

S

is

I

is

=

=

=

+

-

=

=

-

if

and

if

with

)

=

0

1

1

2

,

1

1

(

&

&

Relations of scaling

(

)

G

G

G

vp

ij

vp

ij

G

ij

vp

ij

G

ij

G

G

ij

G

ij

G

ij

ij

G

ij

D

F

B

E

B

ij

µ

µ

&

&

&

-

-

=

=

+

=

-

+

=

1

2

1

where the various parameters of material are:

D

N K

Q

H Q

C D has

,

,

,

,

0

1

2

, B,

, B,

1

2

.

various parameters can depend on the temperature, in this case one will employ the key word

POLY_CFC_FO

.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

40/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.8.1 Syntax

The model is accessible in Code_Aster in 3D, plane deformations (

D_PLAN

), forced

plane (

C_PLAN

) and axisymmetric (

AXIS

) starting from the key word

COMP_INCR

control

STAT_NON_LINE

. The whole of the parameters of the model is provided under the key word factor

POLY_CFC

or

POLY_CFC_FO

:

/

POLY_CFC

=

_F

(

DLL

=

D,

[R]

DA

=

delta,

[R]

NR

=

N,

[R]

K

=

K,

[R]

TAU_0 =

tau

0,

[R]

Q1

= Q1,

[R]

B1

= b1,

[R]

HL

=

H,

[R]

Q2

= Q2,

[R]

B2

= b2,

[R]

C1

=

C,

[R]

D1

=

D,

[R]

C2

=

has,

[R]

)

/

POLY_CFC_FO

=_F

(

DLL

=

D,

[function **]

DA

=

delta,

[function **]

NR

=

N,

[function **]

K

=

K,

[function **]

TAU_0 =

tau

0,

[function **]

Q1

= Q1,

[function **]

B1

= b1,

[function **]

HL

=

H,

[function **]

Q2

= Q2,

[function **]

B2

= b2,

[function **]

C1

=

C,

[function **]

D1

=

D,

[function **]

C2

=

has,

[function **]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

41/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.9 Key words factors

ECOU_VISC1

,

ECOU_VISC2

,

ECOU_VISC3

,

ECRO_CIN1

,

ECRO_CIN2

,

ECRO_ISOT1

,

ECRO_ISOT2

Definition of the coefficients of the models of single-crystal or polycrystalline behavior [R5.03.11]. In

more these characteristics, constant the rubber bands must be defined under key word ELAS or

ELAS_ORTH

for the real coefficients or ELAS_FO for the coefficients depending on the temperature.

The behavior related to each system of slip of a monocrystal or a phase of a polycrystal

is (in the whole of the behaviors considered) of élasto-visco-plastic type. Owing to the fact that one

be interested each time in only one direction of slip, the behavior is mono

dimensional. It can break up into 3 types of equations:

· relation of flow:

(

)

S

S

S

S

S

p

G

,

,

,

=

· evolutions of kinematic work hardening:

(

)

S

S

S

S

S

p

H

,

,

,

=

· evolution of isotropic work hardening:

()

S

S

p

R

, with

S

S

p

=

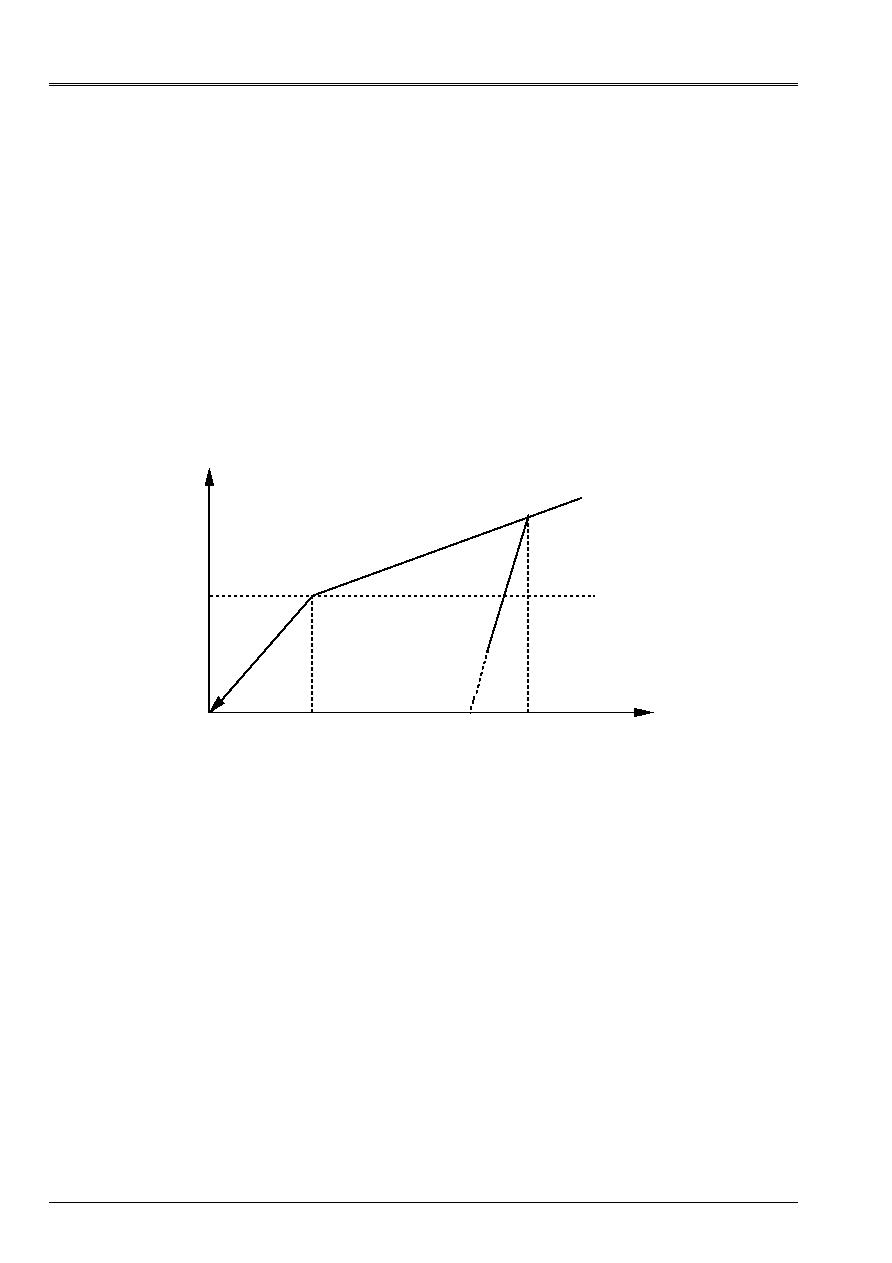

The relation of flow ECOU_VISC1 is:

(

)

S

S

S

S

S

p

G

,

,

,

=

=

()

S

S

S

S

N

S

S

S

S

C

C

K

p

R

C

-

-

-

-

.

, the parameters are: C, K, N

The relation of flow ECOU_VISC2 is:

(

)

S

S

S

S

S

p

G

,

,

,

=

=

()

()

S

S

S

S

S

S

N

S

S

S

S

S

S

has

C

has

C

K

C

D

C

p

R

has

C

-

-

-

-

+

-

-

-

.

2

2

,

the parameters are then: C, K, N, has, D

The relation of flow ECOU_VISC3 is:

(

)

S

S

S

S

S

p

G

,

,

,

=

=

S

S

S

kT

V

kT

G

µ

.

exp

exp

*

0

*

0

-

-

&

,

the parameters are: K, Boltzmann constant, in eV/K,

,

µ

Threshold of flow (homogeneous to one

stress),

*

0

&

Initial rate of flow,

*

V

Volume of activation,

0

G

Gain of bound energy on

crossing of obstacle.

Kinematic work hardening can be form ECRO_CIN1:

(

)

S

S

S

S

S

S

S

S

p

D

p

H

-

=

=

.

.

,

,

,

, with for parameter:

D

or ECRO_CIN2:

(

)

S

S

m

S

S

S

S

S

S

S

S

S

M

C

p

D

p

H

-

-

=

=

.

.

,

,

,

, parameters being then:

D

,

M

and

m

Isotropic work hardening can for example be form ECRO_ISOT1

()

(

)

(

)

Sr

Sr

Sr

NR

R

LP

Sr

S

S

H

H

E

H

Q

R

p

R

R

+

-

=

-

+

=

=

-

1

with

1

1

0

, the parameters are H, Q, R

0

, B

Or ECRO_ISOT2:

()

(

)

dp

Q

B

dq

Q

Q

Q

H

Q

R

p

R

is

I

is

S

sg

S

rs

S

.

1

with

,

2

2

1

1

0

-

=

+

+

=

the parameters are H, Q

1

, Q

2

, B

1

, B

2

,

R

0

.

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

42/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.9.1 Syntax

These relations are accessible in Code_Aster in 3D, plane deformations (

D_PLAN

), forced

plane (

C_PLAN

) and axisymmetric (

AXIS

) starting from the key word

COMP_INCR

control

STAT_NON_LINE

. The choice of the relations allowing to build the model of behavior of

monocrystal is carried out via the operator

DEFI_COMPOR

[U4.43.05].

ECOU_VISC1

=

_F

(

C = C [R]

K =

K,

[R]

NR

=

N,

[R]

)

ECOU_VISC1

=

_F

(

C = C [R]

K =

K,

[R]

NR

=

N,

[R]

With =

K,

[R]

D

=

N,

[R]

)

ECOU_VISC3

=

_F

(

K

=

K

[R]

TAUMU =

µ

[R]

GAMMA0

=

*

0

&

[R]

DELTAV

=

*

V

[R]

DELTAG0=

0

G

[R]

)

ECRO_ISOT1

=_F (

R_0

=

R [R]

Q

=

Q,

[R]

B

=

B

[R]

H

=

H

[R]

),

ECRO_ISOT2 =_F (

R_0

=

R0

[R]

Q1

=

Q1

[R]

B1

=

b1

[R]

H

=

H

[R]

Q2

=

Q2 [R]

B2

=

b2 [R]

),

ECRO_CINE1

=_F (

D

=

D

[R]),

),

ECRO_CINE2

=_F (

D

=

D

[R]

GM

=

M

[R]

PM

=

m

[R]

C

=

C

[R]

)

Code_Aster

®

Version

8.2

Titrate:

Operator

DEFI_MATERIAU

Date:

22/02/06

Author (S):

J.P. LEFEBVRE

Key

:

U4.43.01-I1

Page

:

43/148

Instruction manual

U4.4- booklet: Modeling

HT-62/06/004/A

4.10 Key words factor

LEMAITRE

/

LEMAITRE_FO

Definition of the coefficients of the non-linear relation of viscoplasticity of Lemaitre [R5.03.08].

The equations are as follows:

(

)

-

=

=

=

v

N

m

eq

eq

ij

v

ij

p

K

p

p

/

1

1

~

2

3

&

&

&

The coefficients to be introduced are:

N

K

m

>

0 1

1

0

,

.

and

4.10.1 Syntax

/

LEMAITRE

=

_F

(

NR

=

N,

[R]

UN_SUR_K

= 1/K

, [R]

UN_SUR_M =

/1/m, [R]

/

0.0,

[DEFECT]

)

/

LEMAITRE_FO

=

_F

(

NR

=

N,

[function]

UN_SUR_K

= 1/K

, [function]

UN_SUR_M =

1/m, [function]

)

NR:

N

UN_SUR_K:

1/K

UN_SUR_M:

1/m

If it is wished that the behavior depend on the fluence (description of