Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

1/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

Organization (S):

EDF-R & D/AMA

Instruction manual

U4.4- booklet: Modeling

Document: U4.42.02

Macro-control

MACR_CARA_POUTRE

1 Goal

To calculate the characteristics of a cross section of beam starting from a mesh 2D of

section.

It makes it possible to build a table of values, usable by the control

AFFE_CARA_ELEM

[U4.42.01] to assign characteristics of cross-sections to all the finite elements of beam

(modelings

POU_D_E

,

POU_D_T

,

POU_C_T

,

POU_D_TG

,

POU_D_EM

,

POU_D_TGM

) or of bar

(modeling

BAR

) of unspecified section.

The characteristics necessary are defined in the note of reference [R3.08.03]. It is:

·

the geometrical characteristics (which can be calculated on the complete mesh, half

mesh with symmetry compared to

X

or with

Y

, quarter of mesh with two symmetries by

report/ratio with

X

and with

Y

),

·

characteristics of torsion: radius of torsion, constant of rigidity in torsion, position and

eccentricity of the center of torsion for the coupling bending-torsion,

·

characteristics of shearing for the models with deformations of shearing action,

·

characteristics of roll for the models of “open” torsion of the sections

nonsymmetrical.

Product a table containing the characteristics of the section. Values contained in this

table can be introduced directly (via python) into control AFFE_CARA_ELEM

for a calculation of the beam type.

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

2/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

2 Syntax

tabl_cara_geom = MACR_CARA_POUTRE (

UNITE_MAILLAGE =/20,

[DEFECT]

/

iuni,

[I]

INFORMATION

=

/

1

[DEFECT]

/2

ORIG_INER

=

/

(xp, YP),

[l_R]

/

(0.0,

0.0) [DEFECT]

# If one only wants the characteristics geometrical:

/

|

SYME_X

=

“YES”,

|

SYME_Y

=

“YES”,

GROUP_MA

=

lgm, [l_gr_maille]

# If one wants the characteristics geometrical and mechanical of one

section:

/

GROUP_MA_BORD

=

lgb, [l_gr_maille]

NODE

=

ln,

GROUP_MA_INTE

=

lgi,

# If one wants the characteristics of a network of beams between two

floors:

/

GROUP_MA_BORD

=

lgb, [l_gr_maille]

GROUP_MA

=

lgm, [l_gr_maille]

LENGTH

=

H,

MATERIAL

=

to subdue,

[to subdue]

CONNECTION =

/

“BALL JOINT”,

/“EMBEDDING”,

NODE

=

ln,

)

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

3/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

3 Operands

3.1 Operand

UNITE_MAILLAGE

UNITE_MAILLAGE

Logical number of unit for the reading of the mesh 2D of the section of beam which one will calculate

characteristics with the format Aster: i.e. a mesh which can be read by

LIRE_MAILLAGE

.

Note:

If one must call several upon

MACR_CARA_POUTRE

in the same command file on

the same mesh or of the different mesh it is then necessary to change

UNITE_MAILLAGE

.

3.2 Operands

SYME_X

/

SYME_Y

| SYME_X

Specify that the mesh provided by the user corresponds to a half mesh. The calculation of

characteristics of the cross-section takes account of a symmetry compared to

X

=

0

.

|

SYME_Y

Specify that the mesh provided by the user corresponds to a half mesh. The calculation of

characteristics of the cross-section takes account of a symmetry compared to

Y

=

0

.

The simultaneous use of the two options makes it possible to provide only one quarter of the mesh.

The properties of symmetry are used to accelerate the calculation of the characteristics

geometrical.

Note:

Key words

SYME_X

and

SYME_Y

are used only for the calculation of the characteristics

geometrical. Mechanical characteristics (constant of torsion, constant of

roll, coefficients of shearing) do not hold account of it. To calculate them, it is necessary

thus to net the section in entirety. This is why SYME_X and SYME_Y cannot be

informed simultaneously with GROUP_MA_BORD.

3.3

Calculation of the mechanical characteristics

GROUP_MA_BORD = lgb

lgb

indicate one (or several) group of meshs (SEG2 or SEG3) describing the contour (closed) of

the section with a grid. It is the presence of this key word which involves the calculation of the characteristics

mechanics of the section (cf [U4.42.01]

AFFE_CARA_ELEM

, key word

BEAM

).

GROUP_MA_INTE = lgi

lgi

indicate one or more groups of meshs describing contours of possible holes. This

data is used for calculation of the constant of torsion.

GROUP_MA = lgm

lgm

corresponds to a list of groups of meshs for which the calculation of the characteristics must

to be carried out independently. This functionality makes it possible in particular to seek them

characteristics of beam equivalent to several disjoined sections. If one wishes the calculation of

mechanical characteristics for each group of mesh, it is then necessary to give a group of

meshs of edge by section (using the key word

GROUP_MA_BORD

). Lists

lgb

and

lgm

must

then to correspond.

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

4/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

ORIG_INER = (xp, YP)

This key word defines the point where the inertial characteristics of the section are calculated.

values of the moments of inertia are then provided in this point and to the center of gravity of the section

(for all the mesh or for each group of mesh if

GROUP_MA

is specified).

NODE = ln,

For the calculation of the coefficients of shearing (if the key word

GROUP_MA_BORD

is present), one is

brought to solve a thermal problem on the section (or each group of the list

lgm

), with

for only boundary condition a source term. This can produce messages of alarm due

with the presence of null pivots, without the quality of the result being affected. To avoid these

messages of alarm, it is possible to give a node (or a list of nodes if

lgm

is

data) for which the temperature is imposed.

3.4

Case of network of beams

LENGTH = H,

MATERIAL

=

to subdue,

CONNECTION =

/“BALL JOINT”,

/“EMBEDDING”,

These three key words allow the calculation of the coefficients of shearing equivalent to one

together of parallel beams (posts) located between two floors, distant the length h.

The sections of these beams are defined by the key word

GROUP_MA

.

They all are made up of same linear elastic material (key word

MATERIAL

). The connection

with the lower floor of type “embedding is”. That with the higher floor is

indicated by the key word

CONNECTION

.

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

5/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

4

Definition of the produced sizes

4.1

Reference marks used for the geometrical characteristics

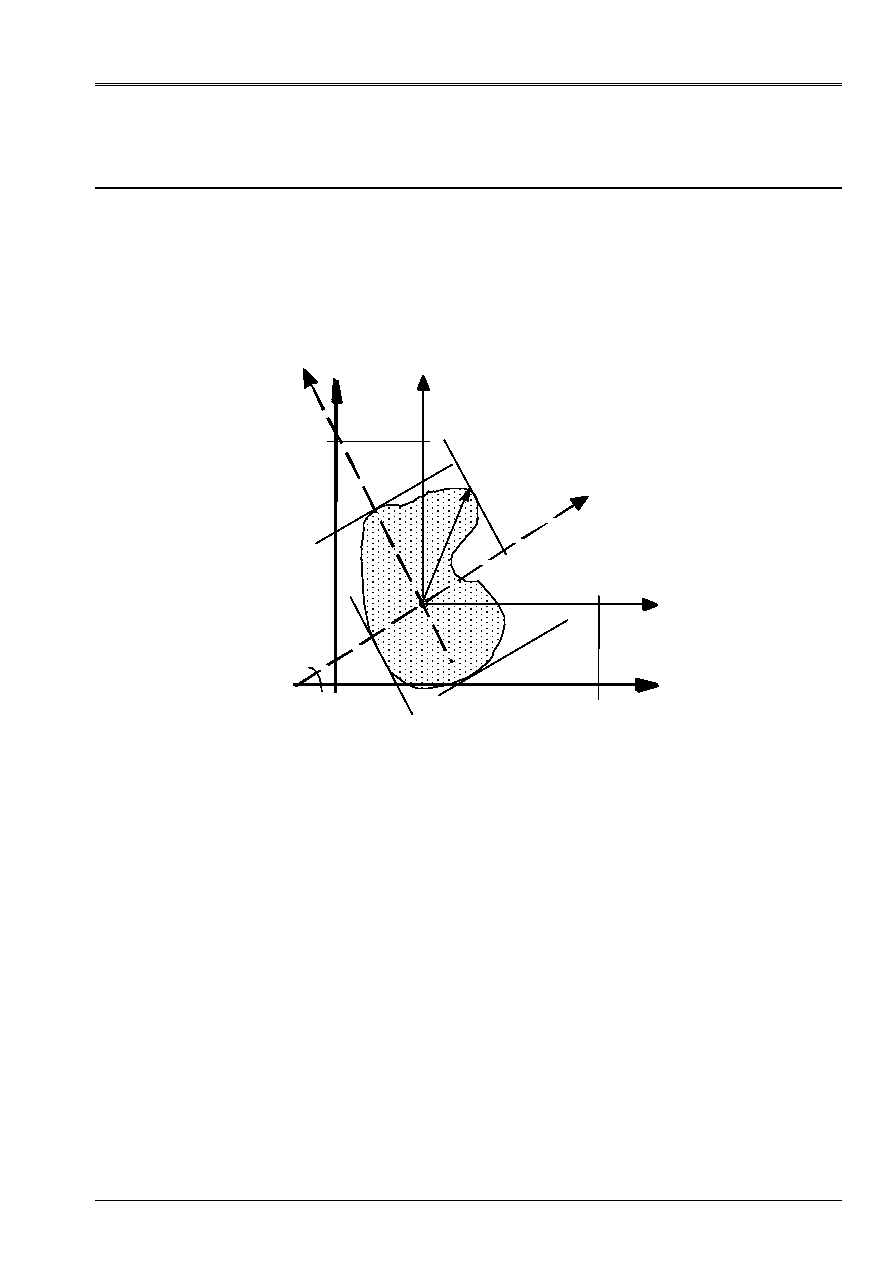

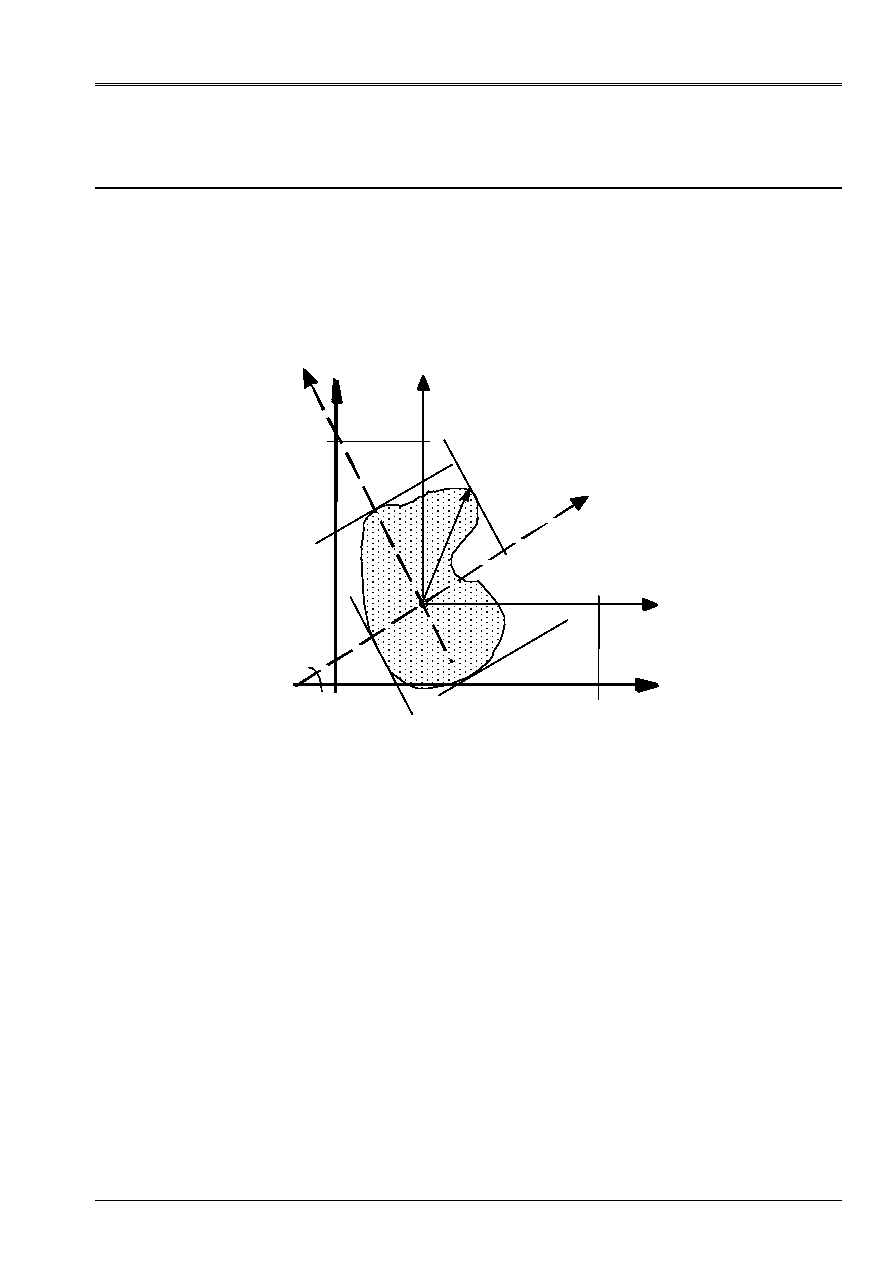

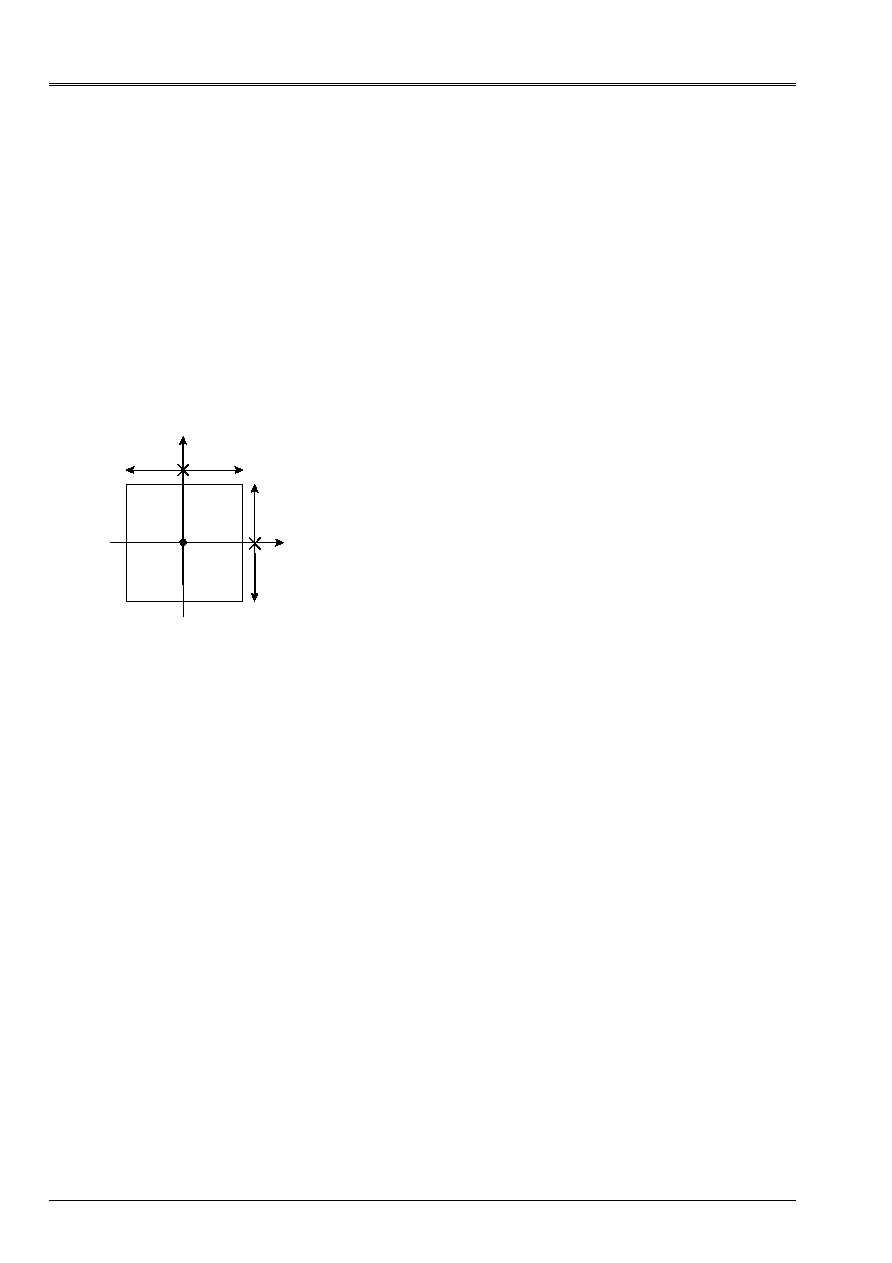

Two reference marks are used:

· the reference mark

OXY

of description of the mesh 2D;

· the main reference mark of inertia

Gyz

. cross-section, whose denomination corresponds to that

used with the description of the elements of neutral fiber beam

Gx

[U4.42.01].

G

X

Y

y (pri

ncipal

)

Z_MI

NR

Y_MAX

R_

MA

X

Z_MA

X

Y_MIN

ALPHA

X

CD

G

_

Y

CDG_X

Y

O

(the main thing)

Z

Definition of the geometrical magnitudes relating to a section of beam

4.2

Sizes available in the produced table

4.2.1 Characteristics

geometrical

These characteristics are given in the table for all the mesh and each group of

list

lgm

(which can correspond to a half or a quarter of the section if the key words

SYME_X

or

SYME_Y

are present).

4.2.1.1 Characteristics of the mesh read

·

surface:

AIRE_M

·

position of the center of gravity:

CDG_X_M,

CDG_Y_M

·

moments and product of inertia of surface, in the center of gravity G in reference mark GXY:

IX_G_M

IY_G_M

IXY_G_M

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

6/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

4.2.1.2 Characteristics of the section of beam

·

surface:

SURFACE

·

position of the center of gravity:

CDG_X,

CDG_Y

·

moments and product of inertia of surface, in the center of gravity

G

in the reference mark

GXY

:

IX_G IY_G IXY_G

· main moments of inertia of surface in the reference mark

Gyz

, usable for the calculation of the rigidity of

bending of the beam:

IY_PRIN_G

and

IZ_PRIN_G

· angle of flow of the reference mark

GXY

with the main reference mark of inertia

Gyz

:

ALPHA

· characteristic distances, compared to the center of gravity

G

section for calculations of

maximum stresses:

Y_MAX

,

Y_MIN

,

Z_MAX

,

Z_MIN

and

R_MAX

.

·

X_P, Y_P

: not calculation of the geometrical moments of inertia

·

IX_P, IY_P, IXY_P

: geometrical moments of inertia in the reference mark

PXY

·

IY_PRIN_P, IZ_PRIN_P

: moments of inertia in the reference mark

Pyz

.

· IXR2, IYR2, IYR2_PRIN_G, IZR2_PRIN_G, IXR2_P, IYR2_P: useful characteristics for

the geometrical matrix of rigidity of elements POU_D_TG and POU_D_T_GM.

4.2.2 Characteristics

“mechanical”

These characteristics are provided in the table for all the mesh and each group of mesh

list

lgm

.

4.2.2.1 Characteristics of torsion

· constant of torsion:

CT

The resolution of a stationary thermal problem of unknown factor phi makes it possible to determine

constant of torsion and stresses shear.

· radius of torsion:

RT

The radius of torsion “RT” can vary along external contour; indeed, for a section

unspecified, shearings due to torsion vary on the edge. One chooses to take the value of

Rt leading to shearings maximum on the external edge, i.e. the maximum value of Rt

(in absolute value) on external contour. Moreover, if the section is alveolate, there are several

“several radii of torsion”: Rt = 2 * A (K)/L (K) (or A (K) represents the surface of the cell K and L (K) sound

perimeter).

If one is satisfied to seek the maximum value of shearing, it is necessary to take the maximum of

Rt values obtained on the external edge and the cells.

· Position of the center of torsion (point C) in the reference mark

GXY

:

PCTX

and

PCTY

. One deduces some

the eccentricity of the center of torsion (component of CG in the main reference mark of inertia

Gyz

):

EY

and

EZ.

· Constant of roll (usable for modelings

POU_D_TG

and

POU_D_TGM

with

7 degrees of freedom):

JG

4.2.2.2 Characteristics of shearing

The coefficients of shearing are given, in the main reference mark of inertia

Gyz

, in the form of

report/ratio (> 1) of the total surface to the actually sheared surface:

AY

and

AZ

4.3

Assignment of the sizes in AFFE_CARA_ELEM

The values contained in this table can be in control AFFE_CARA_ELEM for one

calculation of the beam type.

In AFFE_CARA_ELEM, the characteristics are to be provided in the main reference mark of inertia (G, y, Z).

Quantities required (IY, IZ.) correspond to those calculated in the main reference mark of inertia

defined starting from G, X, Y (

IY_PRIN_G

,

IZ_PRIN…).

It is thus necessary to take guard with directing well the local reference mark of the elements of beam (key word

ORIENTATION of AFFE_CARA_ELEM) in order to affect the quantities correctly.

It is possible to directly provide (via variables python) the characteristics of the sections

(general) resulting from a calculation with MACR_CARA_POUTRE. This is implemented in the test

SSLL107F.

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

7/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

5 Examples

of use

5.1

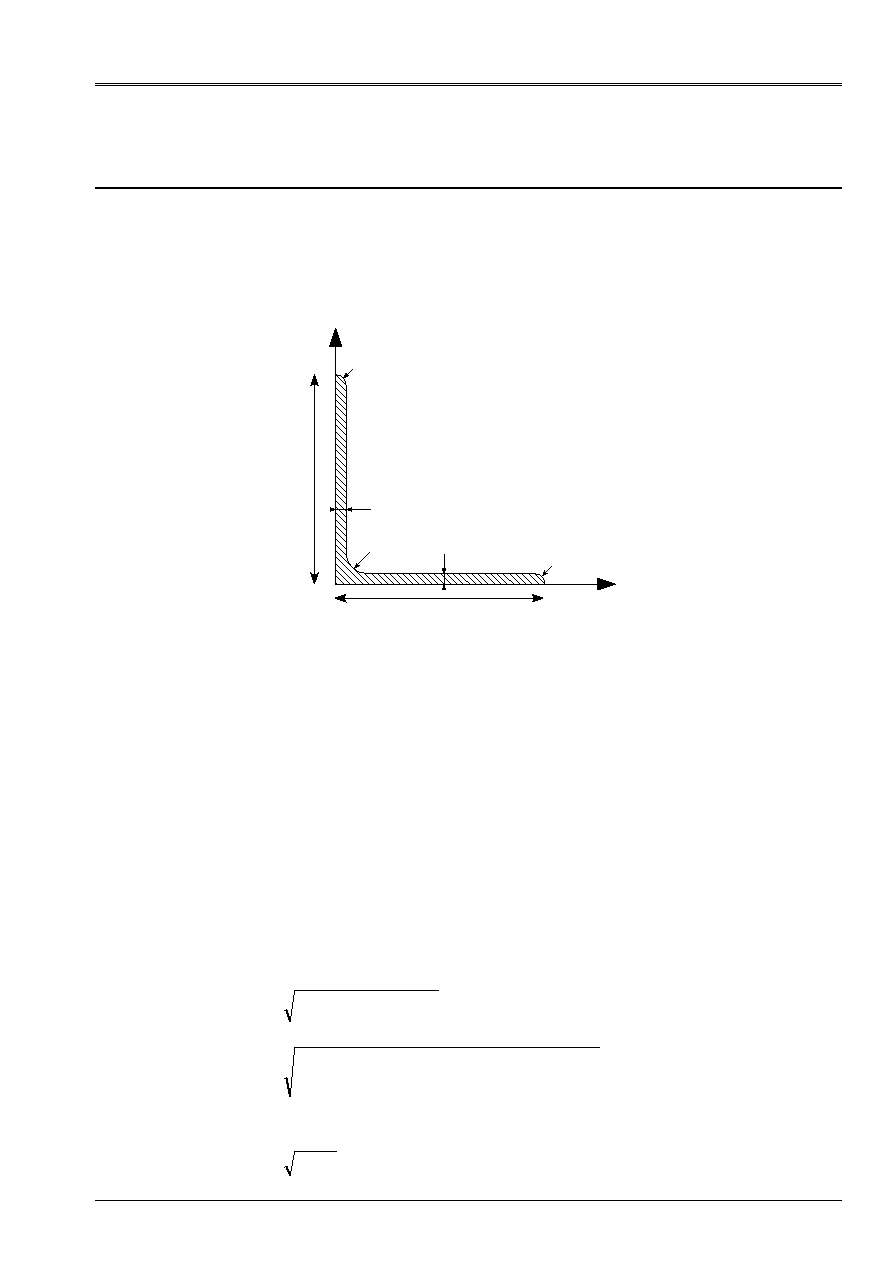

Characteristic of a section in angle with equal wings

(50 X 50 X 8) treated by test SSLL107A [V1.01.105].

5.1.1 Section

studied

With

With

R1

R1

R

To = 0.0500

E

= 0.0080

R = 0.0050

R1 = 0.0025

E

E

Y

X

5.1.2 Command file

TCARA = MACR_CARA_POUTRE (GROUP_MA_BORD = “LSURF”, NODE = “N1”, INFORMATION = 2)

or LSURF is the group of the linear meshs of the contour of the section.

5.1.3 Characteristics

geometrical obtained

The characteristics of the mesh are identical to those of the section. They are in conformity with those

found in the “Catalog of iron and steel products OTUA: Condition of uses in construction

metal - 1959 "

AIRE_M

=

SURFACE

=

7.39E-4

CDG_X_M

=

CDG_X

=

1.53148E-02

CDG_Y_M

=

CDG_Y

=

1.53148E-02

IX_G_M

=

IX_G

=

1.64141E-07

IY_G_M

=

IY_G

=

1.64141E-07

IXY_G_M

=

IXY_G

=

- 9.48843E-08

IY_PRIN_G

=

2.59025E-07

IZ_PRIN_G

=

6.92568E-08

(

)

(

) (

)

(

)

(

)

(

)

(

)

(

)

ALPHA

45

OG

CDG_ X

CDG_ Y

2.166E

02

Y_ MIN

OG

2.166E

02

Y_ MAX

WITH - R

E - R

R

OG

1.465E

02

Z_ MIN

With

3.536E

02

Z_ MAX

With

3.536E

02

R_ MAX

A/2

With

OG

3.792E

02

1

2

1

2

1

2

2

=

=

+

=

=

=

=

+

+

-

=

= -

=

=

=

=

+

=

°

-

-

-

-

-

-

-

-

-

-

2

2

4

4

4

4

cos

/

cos

/

cos

/

cos

/

Code_Aster

®

Version

7.4

Titrate:

Macro-control

MACR_CARA_POUTRE

Date:

11/02/05

Author (S):

J-L.FLÉJOU

Key

:

U4.42.02-E

Page

:

8/8

Instruction manual

U4.4- booklet: Modeling

HT-66/05/004/A

5.1.4 Characteristics

mechanics

CT =

1.596E8

RT =

1.164E2

PCT_X = 4.665E3

PCT_Y = 4.665E3

EY =

1.51E2

EZ =

0

AY =

2.174

AZ =

2.174

5.2

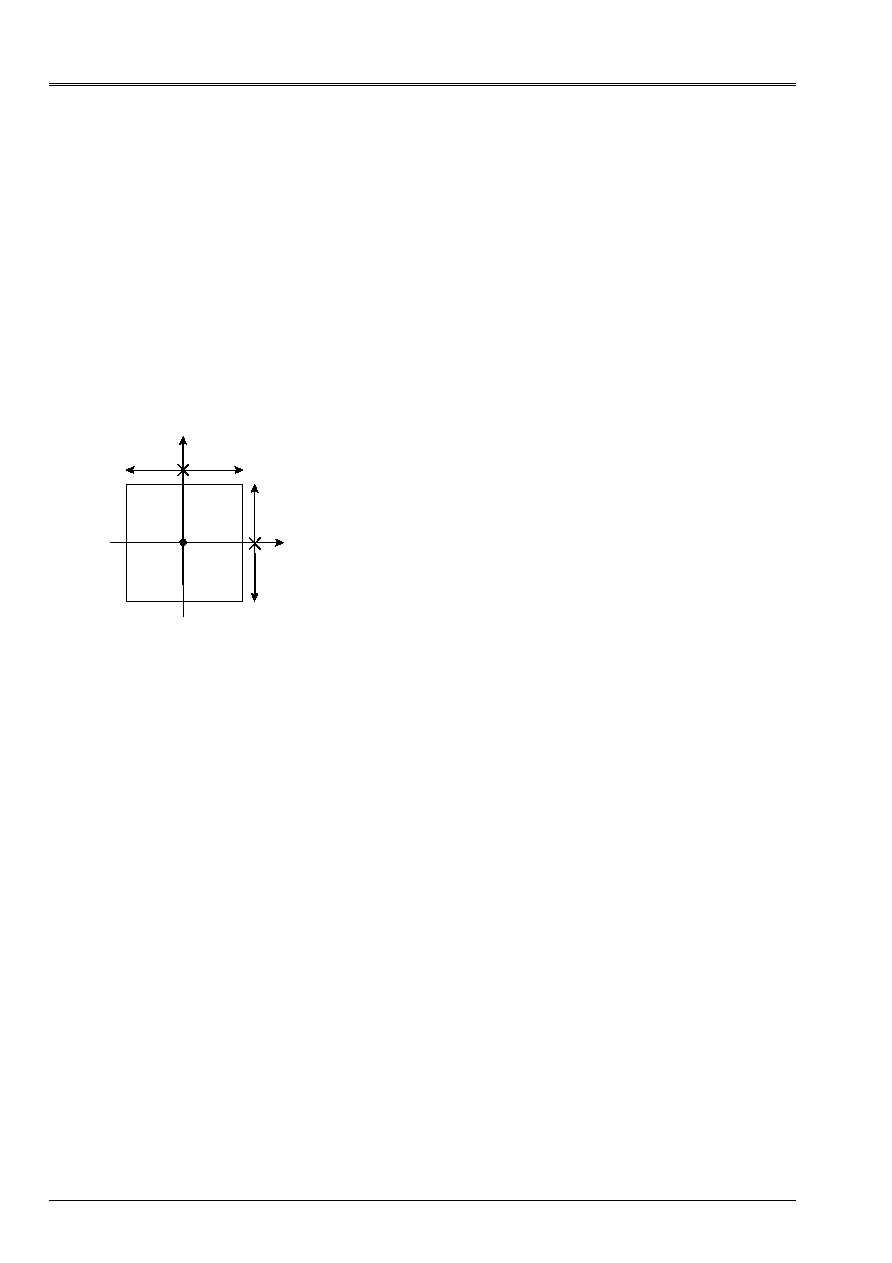

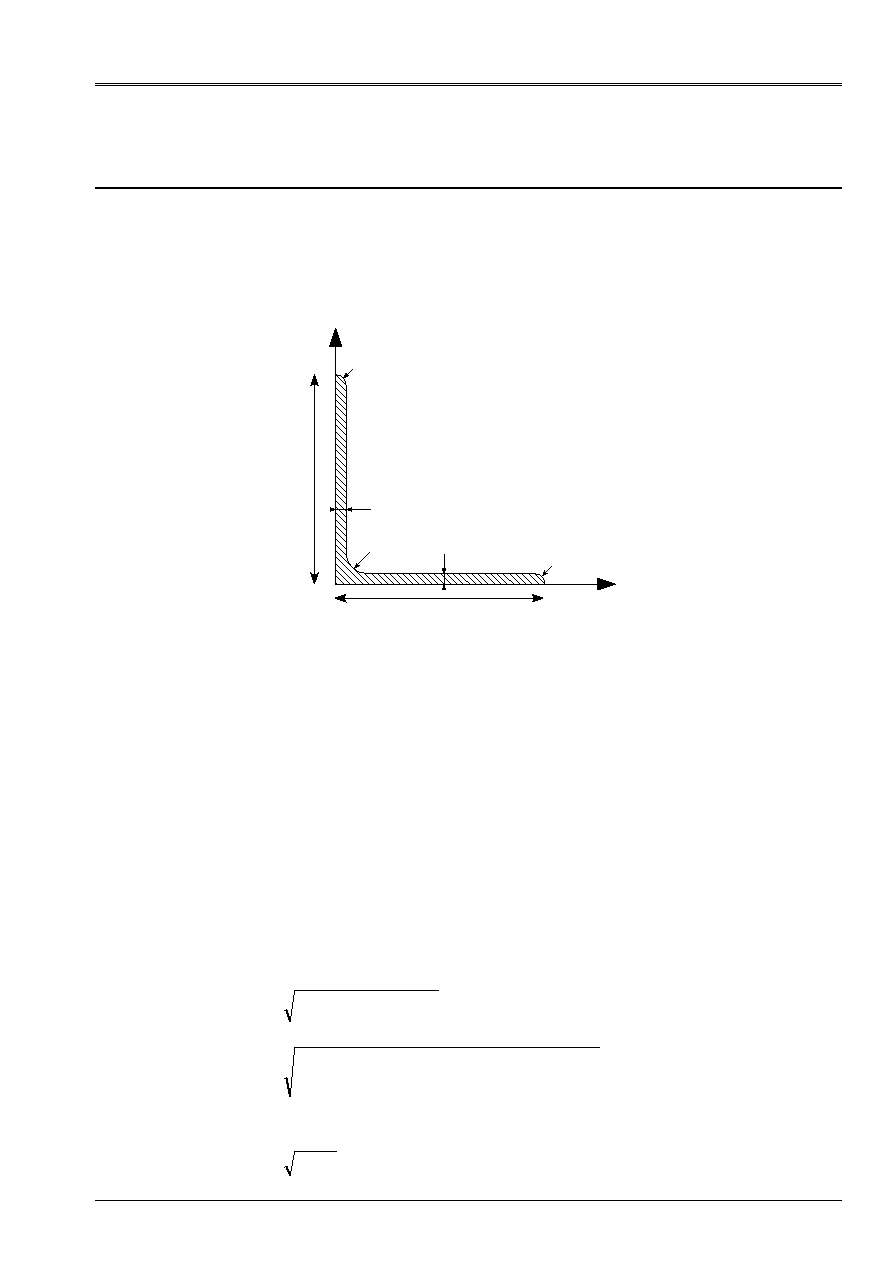

Full rectangle (treaty by test ZZZZ105G)

5.2.1 Section

studied

5.2.2 Order

TCARS = MACR_CARA_POUTRE (GROUP_MA_BORD = “LR1”, NODE = “N64”)

5.2.3 Characteristics

geometrical obtained

PLACE

AIRE_M

CDG_X_M

CDG_Y_M

IX_G_M

IY_G_M

IXY_G_M

0.000003

1.00E-03

4.24E-18 - 3.39E-18 2.08E-07

3.33E-08

2.65E-23

GR1

5.00E-04

2.20E-17 - 1.25E-02 2.60E-08

1.67E-08

3.97E-23

GR2

5.00E-04

- 8.47E-18

1.25E-02

2.60E-08

1.67E-08

5.62E-23

PLACE

SURFACE

CDG_X

CDG_Y IX_G IY_G IXY_G IY_PRIN_G IZ_PRIN_G ALPHA

0.000003

1.00E-03 4.24E-18 - 3.39E-18 2.08E-07 3.33E-08 2.65E-23 3.33E-08 2.08E-07 9.00E+01

GR1

5.00E-04 2.20E-17 - 1.25E-02 2.60E-08 1.67E-08 3.97E-23 1.67E-08 2.60E-08 9.00E+01

GR2

5.00E-04 - 8.47E-18 1.25E-02 2.60E-08 1.67E-08 5.62E-23 1.67E-08 2.60E-08 9.00E+01

PLACE

X_P

Y_P

IX_P

IY_P

IXY_P

IY_PRIN_P

IZ_PRIN_P

0.000003

0.00E+00

0.00E+00

2.08E-07 3.33E-08 2.65E-23

3.33E-08

2.08E-07

GR1

0.00E+00

0.00E+00

1.04E-07 1.67E-08 - 9.79E-23

1.67E-08

1.04E-07

GR2

0.00E+00

0.00E+00

1.04E-07 1.67E-08 3.31E-24

1.67E-08

1.04E-07

PLACE

Y_MAX

Z_MAX

Y_MIN

Z_MIN

R_MAX

0.000003

2.50E-02

1.00E-02 - 2.50E-02 - 1.00E-02 2.69E-02

GR1

2.50E-02

2.25E-02 - 2.50E-02

2.50E-03 3.36E-02

GR2

2.50E-02

- 2.50E-03 - 2.50E-02 - 2.25E-02 3.36E-02

PLACE

CT

AY

AZ

EY

EZ

PCTX

PCTY

JG

0.000003

-

-

-

-

-

-

-

-

GR1

3.43E-08

1.20E+00

1.20E+00

9.00E-17

- 3.97E-18

2.60E-17 - 1.25E-02 -

GR2

3.43E-08

1.20E+00

1.20E+00

- 4.03E-17

1.19E-16

- 1.27E-16 1.25E-02 -

PLACE

RT

0.000003 1.93871E-2

GR1

1.56391E-2

GR2

1.56391E-2

B

B

y

GR2

GR1

H

H

X

0

B = 0.01

H = 0.025

3 groups of meshs are defined:

GR1 corresponds to the part y 0

GR2

corresponds to the part y 0

LR1 corresponds to the linear meshs of contour