Code_Aster

®

Version

8.0

Titrate:

SDLL134 - Method of Connors for the analysis of the behavior

Date:

06/10/05

Author (S):

A. ADOBES, L. SALMONA

Key

:

V2.02.134-A

Page:

1/6

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

HT-66/05/005/A

Organization (S):

EDF-R & D/MFTT, CS IF

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

V2.02.134 document

SDLL134 - Method of Connors for the analysis of

vibratory behavior of the tubes of Steam Generator

Summary:

This case test aims at the validation of the establishment in Code_Aster of the method of Connors, in so much

that method of analysis of the vibratory behavior of the tubes of Steam Generator.

Code_Aster

®

Version

8.0

Titrate:

SDLL134 - Method of Connors for the analysis of the behavior

Date:

06/10/05

Author (S):

A. ADOBES, L. SALMONA

Key

:

V2.02.134-A

Page:

2/6

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

HT-66/05/005/A

1

Problem of reference

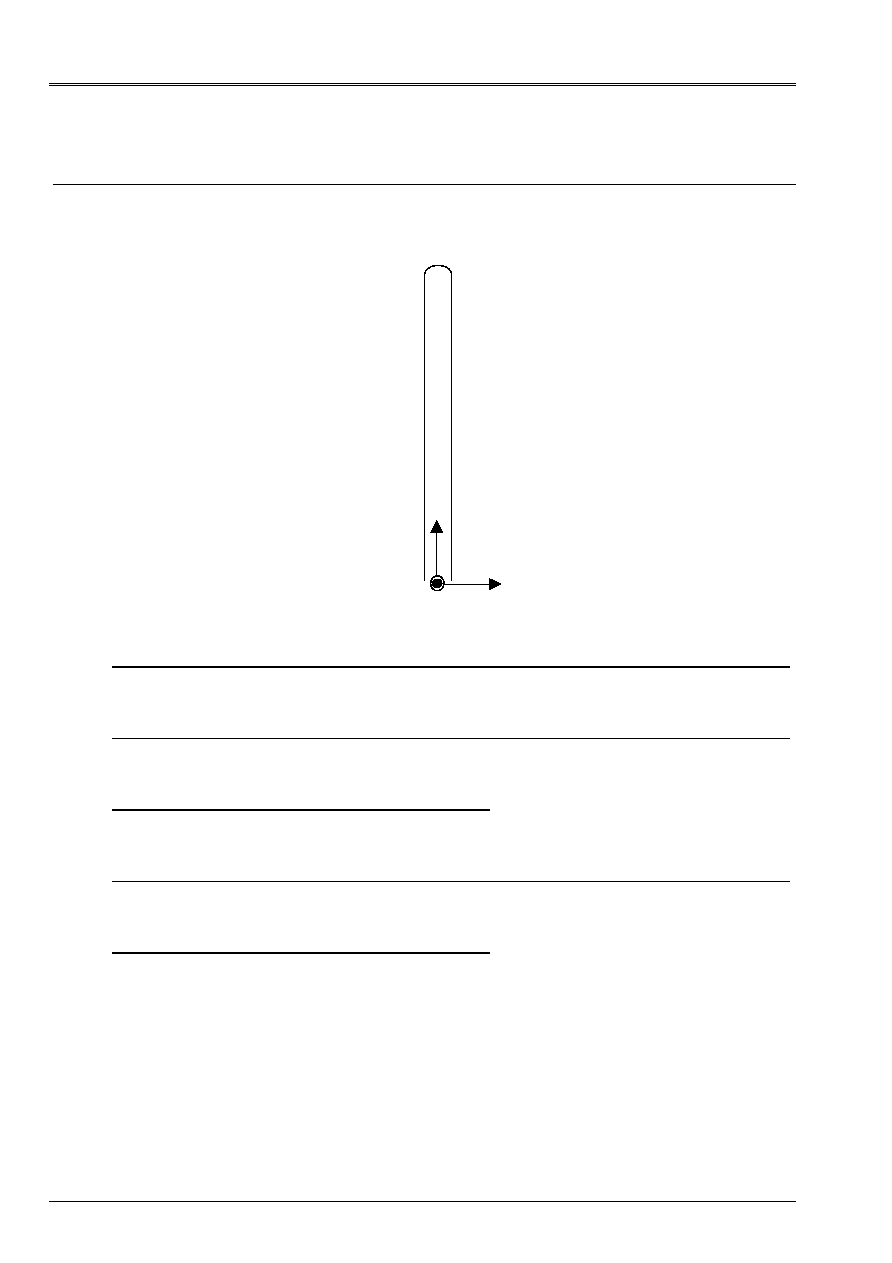

1.1 Geometry

Co-ordinates of the points:

WITH B C

D

E

X - 0.2944

- 0.2944

0. 0.2944

0.2944

y 0.

9.693

9.9874 9.693 0.

F1 G1 H1

I1

J1

X - 0.2944

- 0.2944

- 0.2944

- 0.2944

- 0.2944

y 1.068 2.136

3.204 4.272 5.34

K1 L1 M1

X - 0.2944

- 0.2944

- 0.2944

y 6.408 7.476

8.544

F2 G2 H2

I2

J2

X 0.2944

0.2944

0.2944

0.2944

0.2944

y 1.068 2.136

3.204 4.272 5.34

K2 L2 m2

X 0.2944

0.2944

0.2944

y 6.408 7.476

8.544

1.2

Properties of materials and characteristic of the tube

Elastic properties

E = 202000 MPa

= 0.3

= 8330 kg/m

3

The tube is hollow. Its external radius is worth 9.525 mm and its thickness 1.09 Misters.

With

B

C

D

E

F1

G1

H1

I1

J1

K1

L1

M1

F2

G2

H2

I2

J2

K2

L2

M2

X

y

Code_Aster

®

Version

8.0

Titrate:

SDLL134 - Method of Connors for the analysis of the behavior

Date:

06/10/05

Author (S):

A. ADOBES, L. SALMONA

Key

:

V2.02.134-A

Page:

3/6

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

HT-66/05/005/A

1.3

Boundary conditions

Boundary conditions:

· on points A, B, D and E: embedding (DX=DY=DZ=RX=RY=RZ=0).

· on the F1 points, G1, H1, I1, J1, K1, L1, M1, F2, G2, H2, I2, J2, K2, L2 and m2: support

(DX=DY=DZ=0).

Fluid loading:

The internal fluid and the external fluid are distinguished. Each one has a dependant density

curvilinear X-coordinate along the tube. Moreover, for the external fluid, the profile speed inter-tubes

transverse with the tube in the plan of the tube is provided.

1.4

Type of network and characteristic of the model of Connors

The network is a square pitch of pitch reduces 1.439895. The constant of Connors is supposed to be

ranging between 3.0 and 5.0 with 3 values équiréparties in this interval, that is to say 3.0, 4.0 and 5.0.

Damping necessary to the application of the method of Connors is damping in fluid

at rest. It is taken equal to 0.64%.

Code_Aster

®

Version

8.0

Titrate:

SDLL134 - Method of Connors for the analysis of the behavior

Date:

06/10/05

Author (S):

A. ADOBES, L. SALMONA

Key

:

V2.02.134-A

Page:

4/6

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

HT-66/05/005/A

2

Reference solution

2.1

Method of calculation used for the reference solution

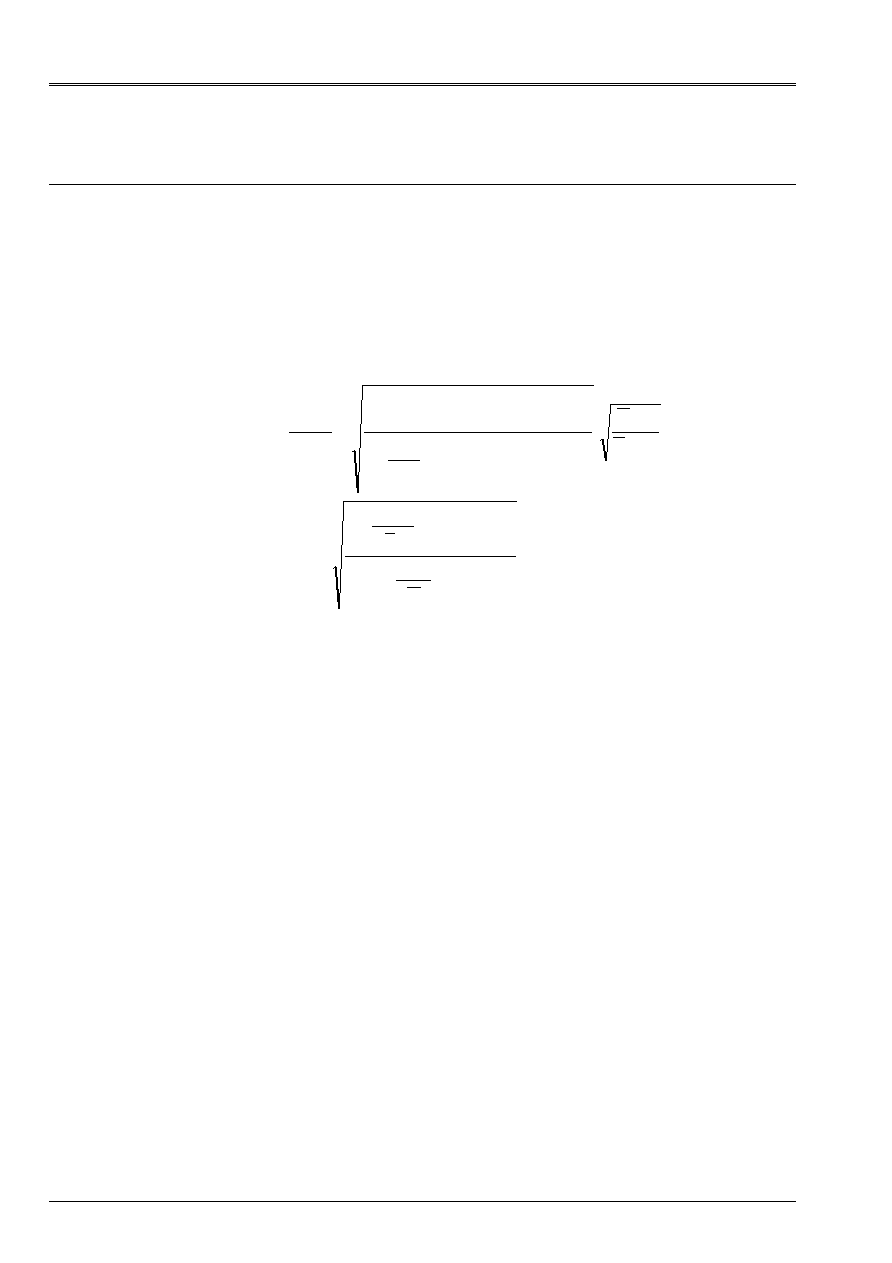

One is interested in the mode 21 which is more penalizing on the vibratory level. Its frequency

(estimated with aid MODE_ITER_SIMULT with 61.53761 Hz) is regarded as a data of

problem. The values of interest for the case-test are, on the one hand effective speed

in

V

, and

in addition critical engine failure speed

Cn

V

. Their values are given by the equations

(see nomenclature of the variables in [R4.07.04]):

() () ()

() () ()

() () ()

() ()

=

=

=

tube

N

tube

N

S

S

in

E

S

N

Nex

I

Lex

N

S

I

tube

N

S

E

N

Cn

ds

S

m

S

m

ds

S

S

V

S

V

D

m

ds

S

S

V

S

K

ds

S

S

V

S

D

F

V

I

2

2

2

2

1

2

2

2

2

2

1

By using the Excel spreadsheet, it is possible to calculate these values for the different ones

constants of Connors requested.

2.2

Results of reference

The value of reference is the sum of the various values for each constant of

Connors. One thus has for effective speed and the critical engine failure speed of the respective values of

3.0039 and 6.9156.

2.3

Uncertainty on the solution

It is about an semi-analytical solution. Only uncertainty relates to the frequency of mode 21.

2.4 References

bibliographical

[1]

T. KESTENS, Mr. LAINET: Coupling fluid-structure for the tubular structures and them

coaxial hulls, document [R7.07.04].

Code_Aster

®

Version

8.0

Titrate:

SDLL134 - Method of Connors for the analysis of the behavior

Date:

06/10/05

Author (S):

A. ADOBES, L. SALMONA

Key

:

V2.02.134-A

Page:

5/6

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

HT-66/05/005/A

3 Modeling

With

3.1

Characteristics of modeling

Elements 1D POU_D_T (SEG2)

3.2

Characteristics of the mesh

A number of nodes: 311

A number of meshs and types: 310 SEG2

3.3 Functionalities

tested

Controls

DEFI_FLUI_STRU CSTE_CONNORS

NB_CONNORS

CALC_FLUI_STRU AMOR_REDUIT_CONN

4

Results of modeling A

4.1 Values

tested

Size Reference

Aster %

difference

Summon

Cn

V

6.9156037078201 6.9156037078201 1.03E-13

Summon

in

V

3.0039489978201 3.0039544634875 1.82E-04

With

B

D

E

Code_Aster

®

Version

8.0

Titrate:

SDLL134 - Method of Connors for the analysis of the behavior

Date:

06/10/05

Author (S):

A. ADOBES, L. SALMONA

Key

:

V2.02.134-A

Page:

6/6

Manual of Validation

V2.02 booklet: Linear dynamics of the beams

HT-66/05/005/A

5

Summary of the results

The error made by Code_Aster on speeds (critical and effective) is with more than 1.82 10

- 4

% it

who is acceptable and valid the establishment of the method of Connors in the software.