Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

1/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

Organization (S):

EDF/IMA/MN

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

V2.03.100 document

SDLS100 - Study of mesh on a plate

square thin

Summary:

This three-dimensional problem consists in seeking the frequencies of vibration of a mechanical structure

composed of a thin square plate embedded on a side. One studies the influence of the distortion of the mesh

on the results. This test of Mechanics of the Structures corresponds to a dynamic analysis of a model

surface having a linear behavior. It comprises three modelings.

This problem makes it possible to test the element of plate

DKT

in transverse bending and the calculation of the frequencies

clean, either by the method of Lanczos, or by the method of Bathe and Wilson. The first modeling

consist in netting finely and regularly the plate by triangles. For the second modeling, it

mesh is coarser while for the third, it coarse and is distorted.

The first modeling is used as results of reference.

The results obtained are in concord between them and with those of a card NAFEMS. The effect of distortion of

mesh does not appear on the first frequencies of vibration.

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

2/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

1

Problem of reference

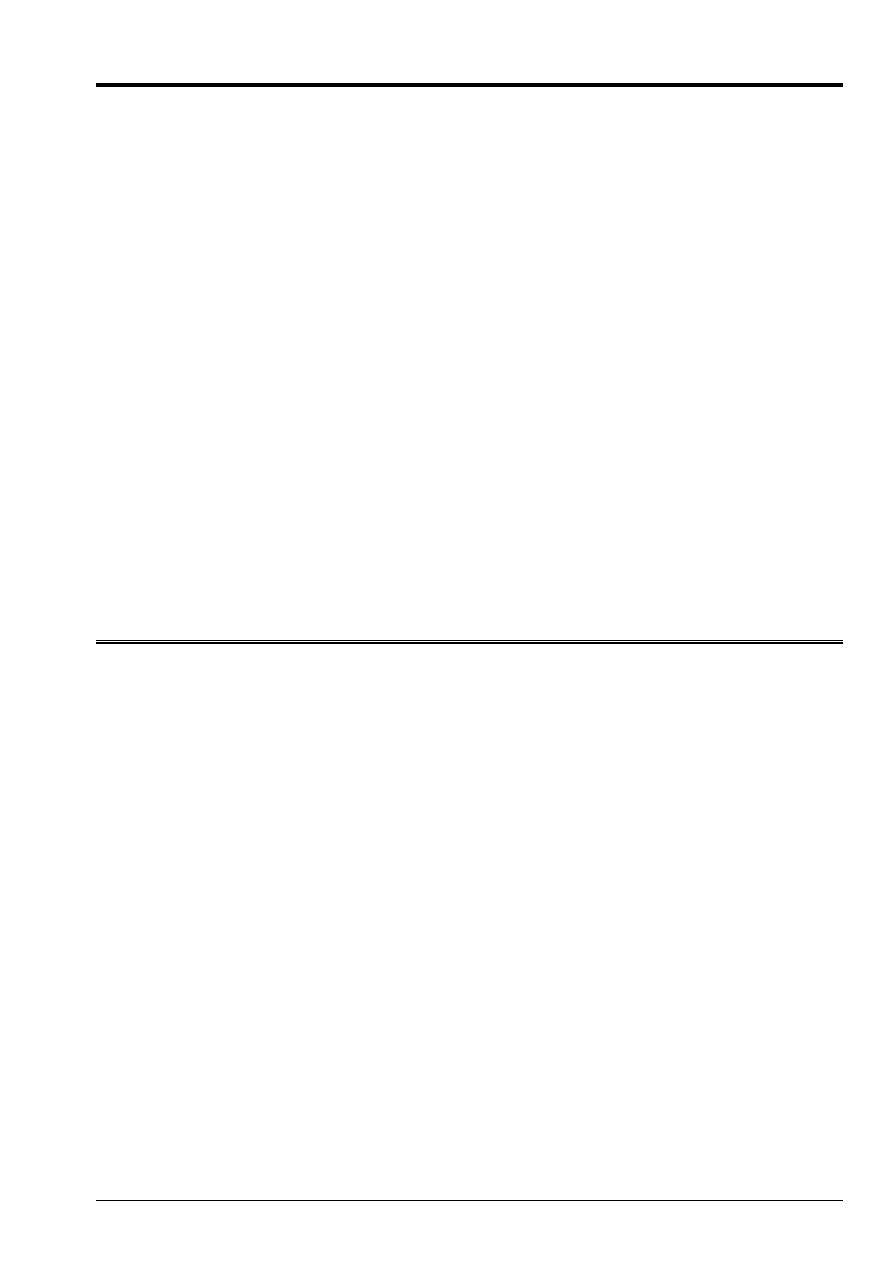

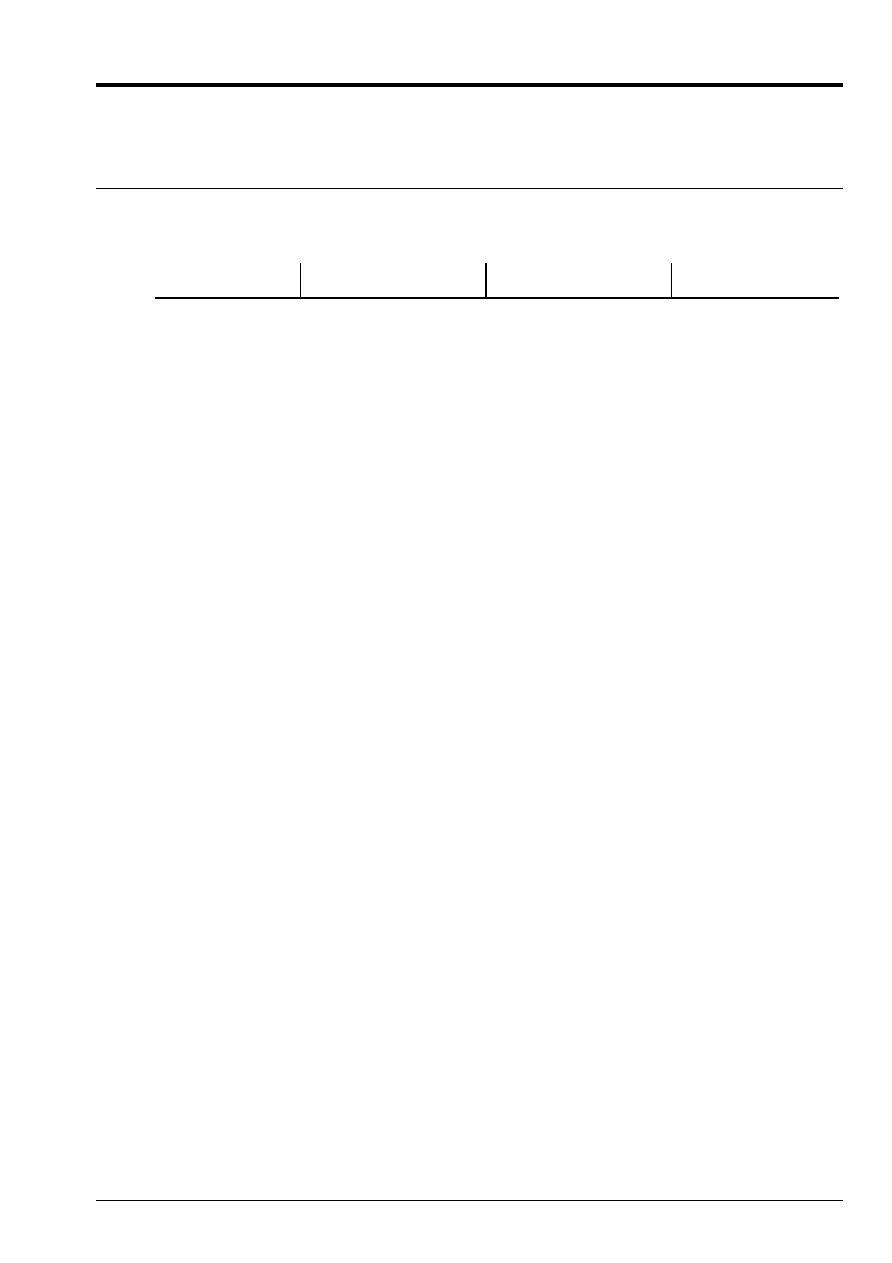

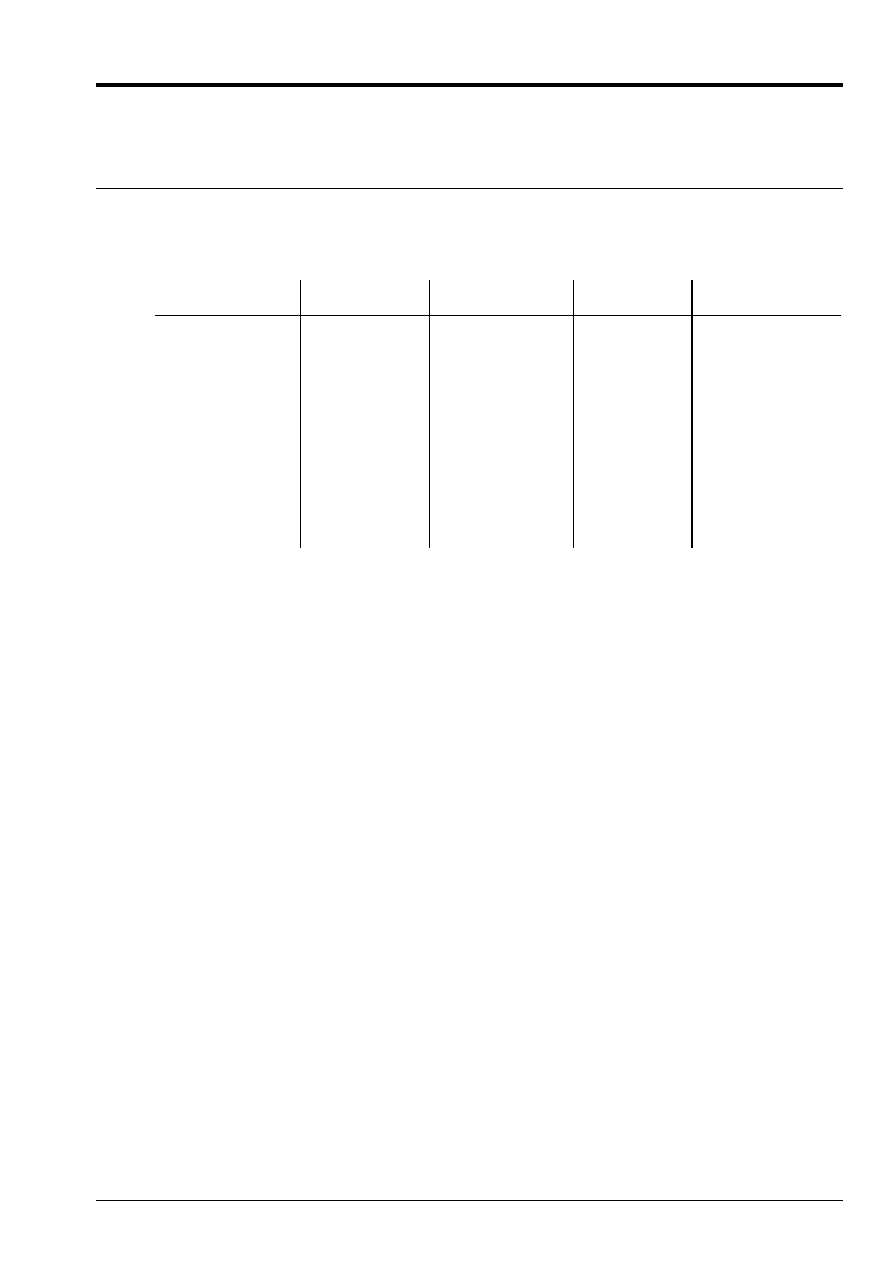

1.1 Geometry

has

y

has

8

7

6

9 1

5

2

3

4

1

Test 1

Test 2

Test 3

Test 4

Square plate:

side has = 10. m

thickness T = 0.05 m

Co-ordinates of the points (in m):

Test 2

Test 4

Node

X

y

Node

X

y

1

4.0

4.0

1

4.0

4.0

2

2.25

2.25

3

4.75

2.5

4

7.25

2.75

5

7.5

4.75

6

7.75

7.25

7

5.25

7.25

8

2.25

7.25

9

2.5

4.75

1.2

Properties of materials

E = 2.10

11

AP

= 0.3

= 8.000. kg/m

3

1.3

Boundary conditions and loadings

Any point P such as X

p

= 0: (U = v = W = 0,

y = 0).

1.4 Conditions

initial

Without object for the modal analysis.

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

3/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

2

Reference solution

2.1

Method of calculation used for the reference solution

The reference solution is that given in the card “Test 16” of the tests of reference published by

NAFEMS.

Card NAFEMS gives the results of reference as well as computation results carried out in

using elements of the mean hull type of Kirchoff based on a formulation of displacement

isoparametric quadratic (ddl of rotation and normal translation to the plate).

2.2

Results of reference

the first 6 clean modes.

2.3 References

bibliographical

[1]

F.

ABASSIAN, D.J.

DAWSWELL, N.C.

KNOWLES. Selected Benchmarks for Natural

Frequency Analysis. NAFEMS (1987).

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

4/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

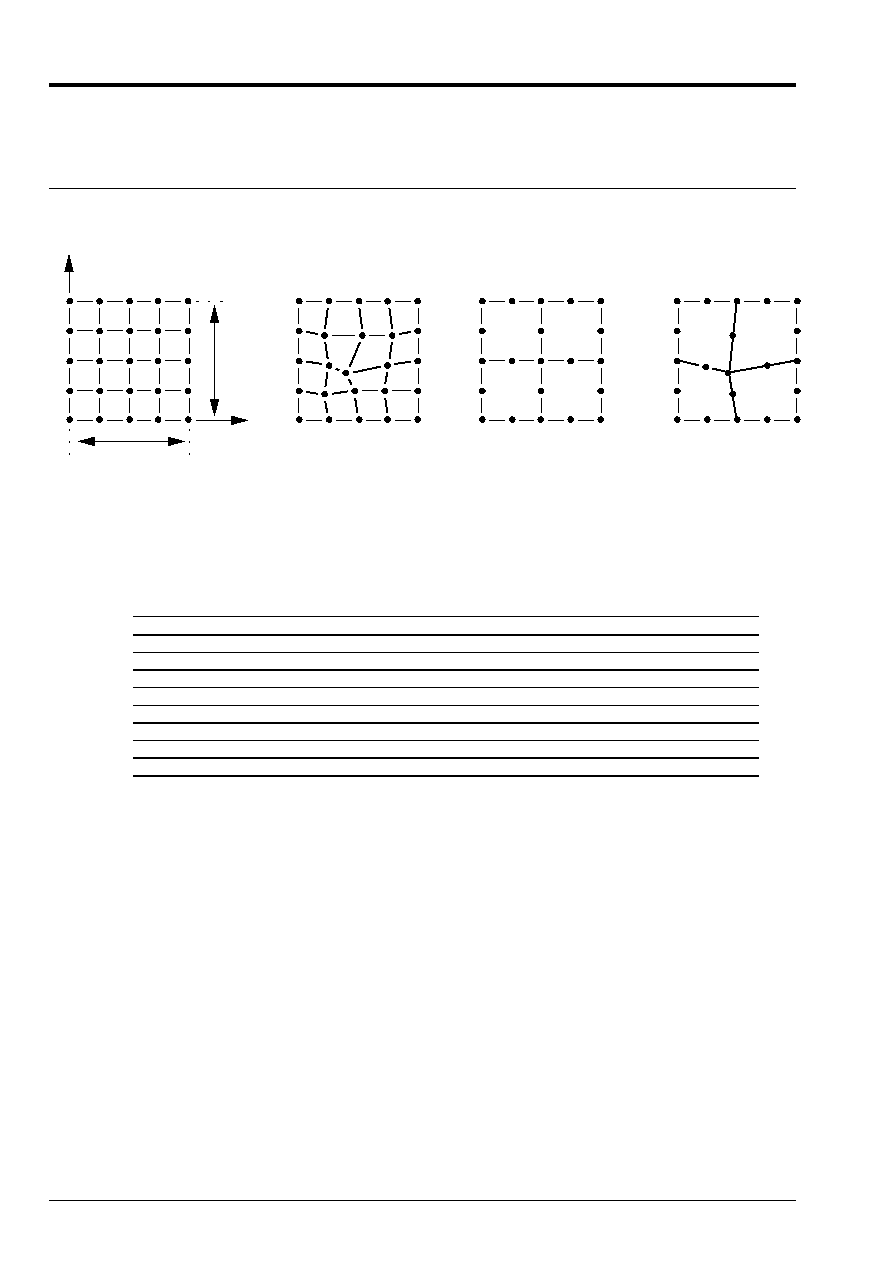

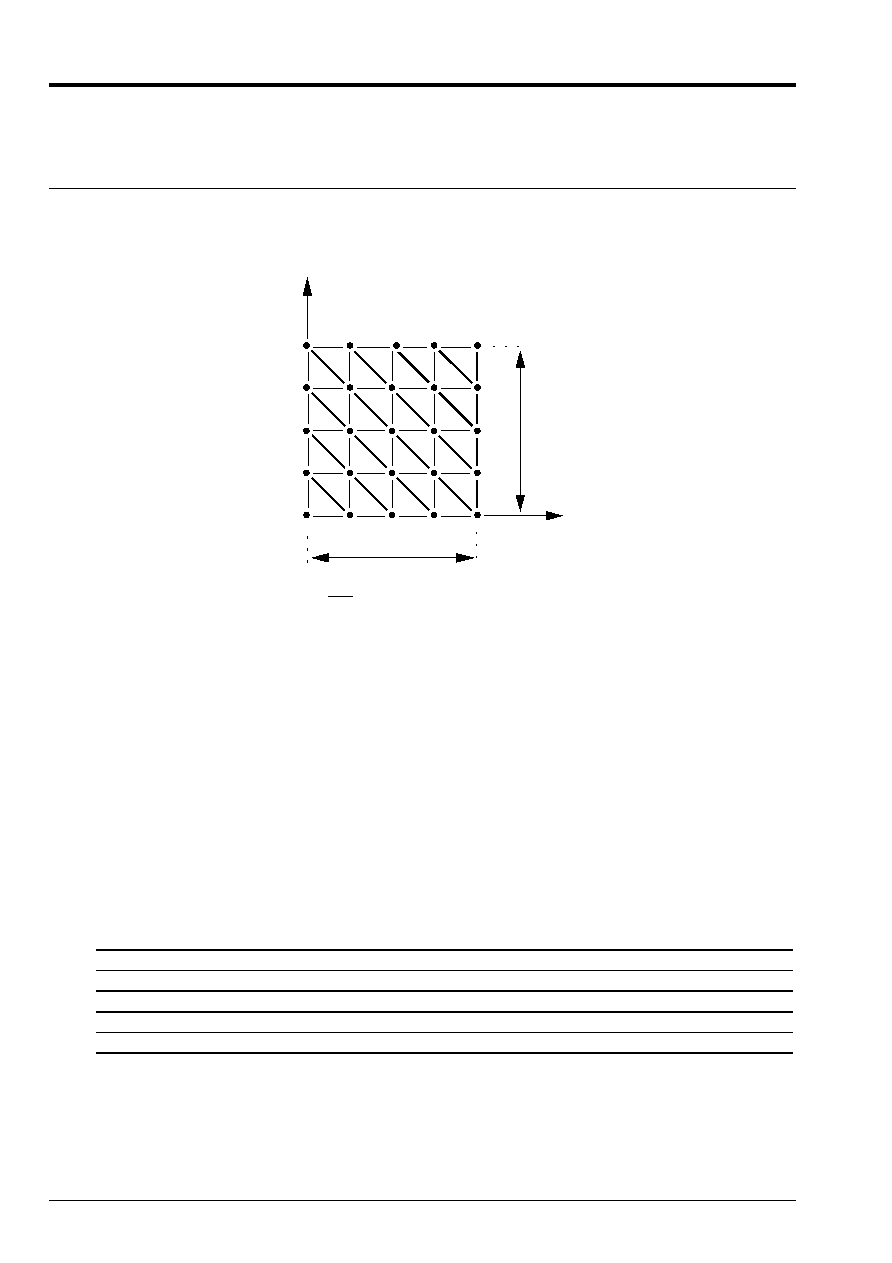

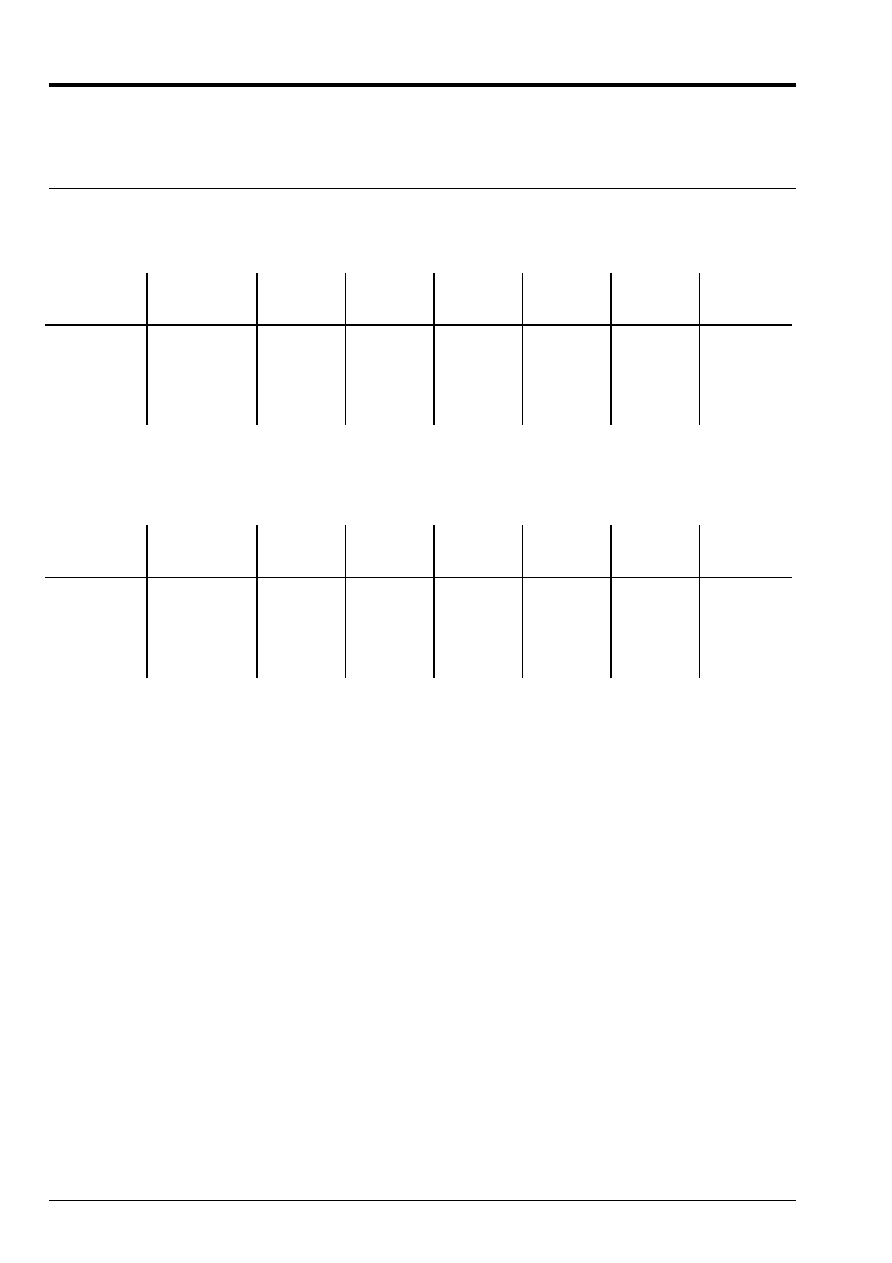

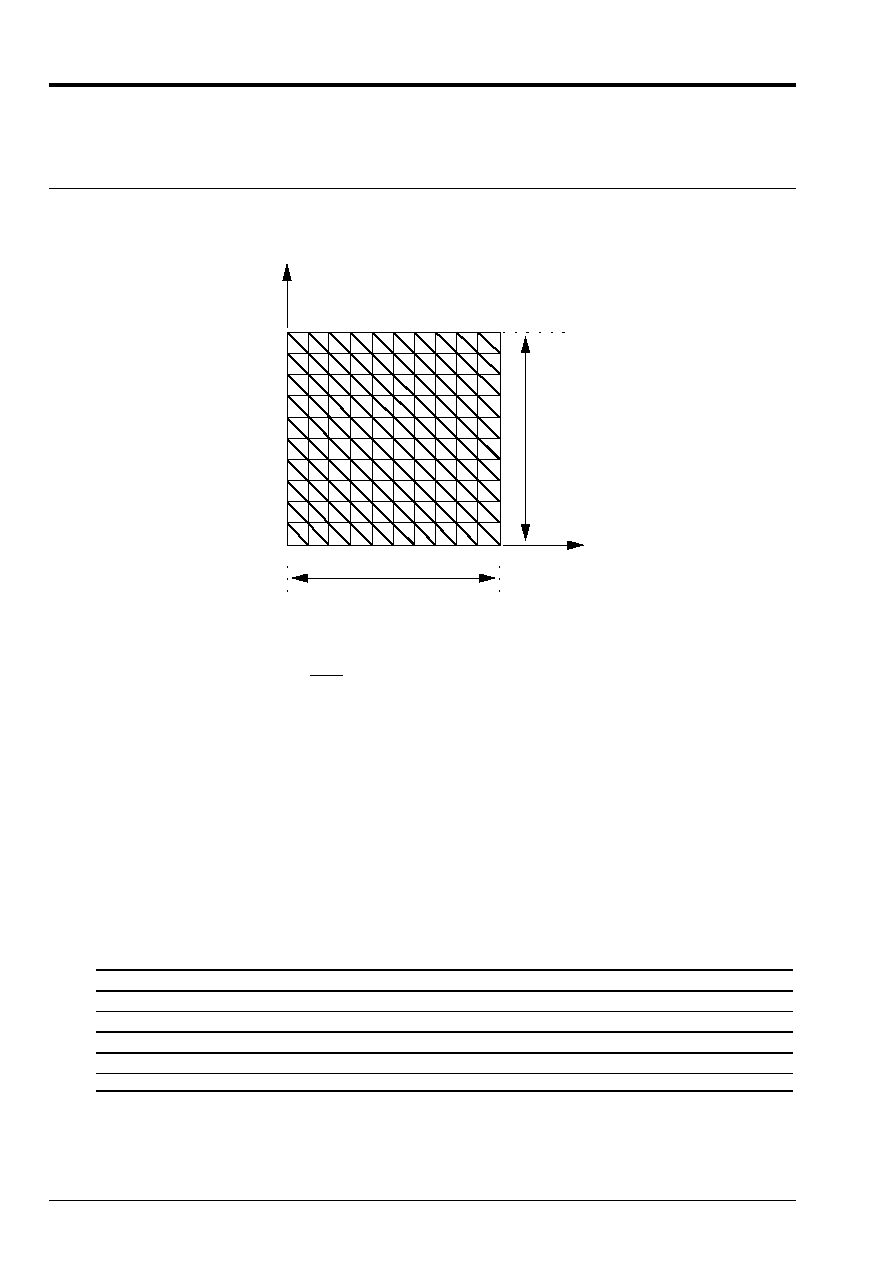

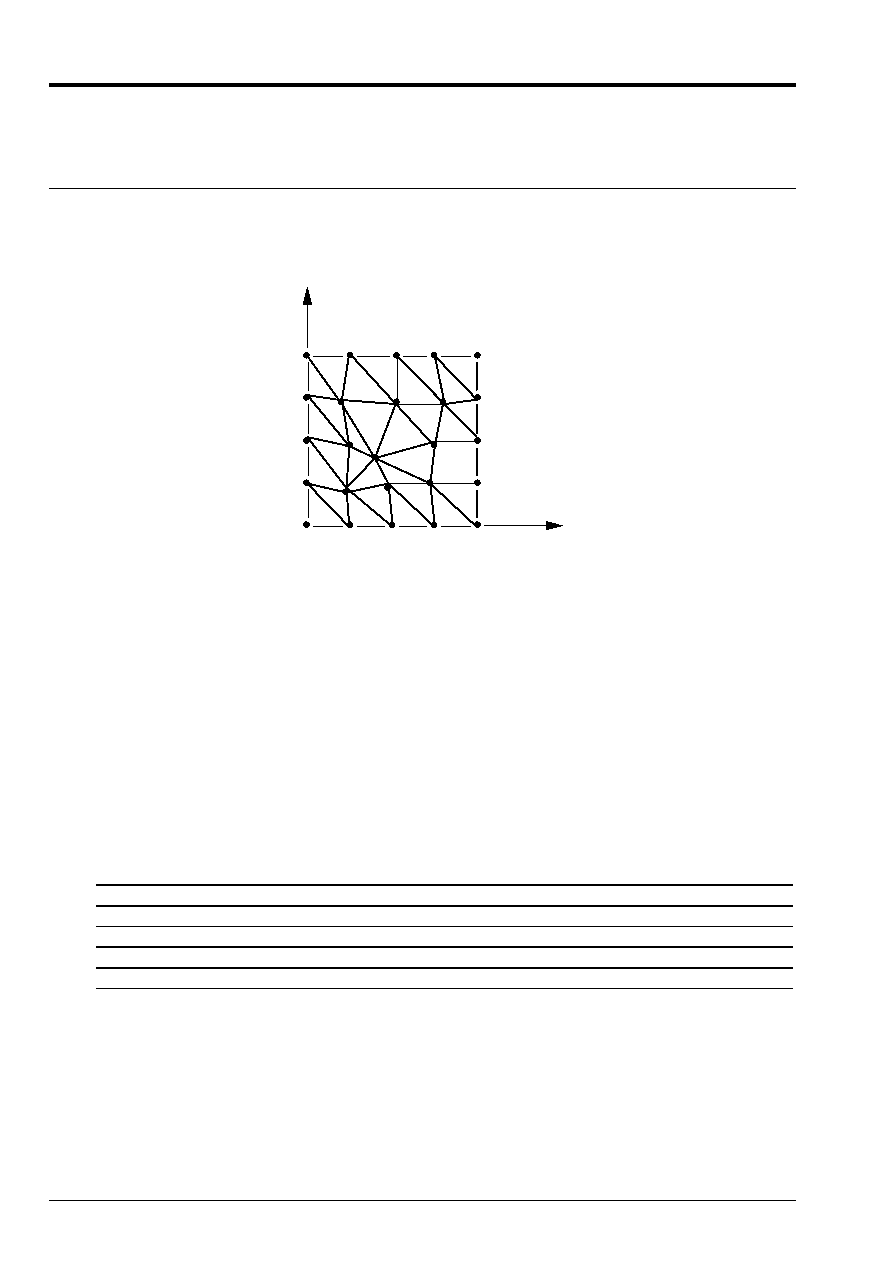

3 Modeling

With

3.1

Characteristics of modeling

Fine mesh for validation of the reference solution

121

has

y

111

89

67

45

23

1

3

5

7

9

11

has

Test 0

X

Cutting:

10 on each side of the rhombus

200 meshs TRIA3.

Twinge of the element

has

10 T

=

20

.

Limiting conditions:

in all the nodes P on the Xp side = 0. :

DDL_IMPO: (GROUP_NO: DIMENSION DX:0., DY:0., DZ: 0., DRY: 0. )

Name of the nodes:

Point 1 = N1

Point 121 = N121

3.2

Characteristics of the mesh

A number of nodes:

121

A number of meshs and types:

200 TRIA3

3.3 Functionalities

tested

Controls

Keys

AFFE_CARA_ELEM

HULL

ALL

[U4.24.01]

AFFE_CHAR_MECA

DDL_IMPO

GROUP_NO

[U4.25.01]

AFFE_MATERIAU

ALL

[U4.23.02]

AFFE_MODELE

“MECHANICAL”

“DKT”

ALL

[U4.22.01]

DEFI_MATERIAU

ELAS

[U4.23.01]

MODE_ITER_SIMULT

METHOD

“TRI_DIAG”

[U4.52.02]

CALC_FREQ

OPTION

“PLUS_PETITE”

NMAX_FREQ

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

5/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

4

Results of modeling A

4.1 Values

tested

Command of the mode

clean

Reference

Frequency (Hz)

Aster

Frequency (Hz)

% difference

1

0.421

0.4178

0.8

2

1.029

1.0255

0.3

3

2.582

2.5669

0.6

4

3.306

3.2733

1.

5

3.753

3.7347

0.5

6

6.555

6.5236

0.5

7

7.3756

8

7.7332

9

8.5567

10

11.1199

11

11.6474

12

14.3551

4.2 Remarks

Calculations carried out by:

MODE_ITER_SIMULT

METHOD: “TRI_DIAG”

OPTION:“PLUS_PETITE”

NMAX_FREQ: 12

4.3

Contents of the file results

the first 12 Eigen frequencies, clean vectors and modal parameters.

4.4 Parameters

of execution

Version: 3.03.25

Machine: CRAY C90

System:

UNICOS 8.0

Overall dimension memory:

8 megawords

Time CPU To use:

7.2 seconds

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

6/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

5 Modeling

B

5.1

Characteristics of modeling

Element DKT coarser mesh

has

y

22

23

24

25

10

11

12

13

14

Test 1

X

2

3

4

9

1

5

8

7

6

21

20

19

18

17

16

15

Twinge of the elements:

has

4 T

=

50

.

Limiting conditions:

in all the nodes P on the Xp side = 0. :

DDL_IMPO: (GROUP_NO: DIMENSION DX:0., DY:0., DZ: 0., DRY: 0. )

Name of the nodes:

Point 1 = N1

Point 25 = N25

5.2

Characteristics of the mesh

A number of nodes:

25

A number of meshs and types:

32 TRIA3

5.3 Functionalities

tested

Controls

Keys

AFFE_CARA_ELEM

HULL

ALL

[U4.24.01]

AFFE_CHAR_MECA

DDL_IMPO

GROUP_NO

[U4.25.01]

AFFE_MATERIAU

ALL

[U4.23.02]

AFFE_MODELE

“MECHANICAL”

“DKT”

ALL

[U4.22.01]

DEFI_MATERIAU

ELAS

[U4.23.01]

MODE_ITER_SIMULT

METHOD

“JACOBI”

[U4.52.02]

CALC_FREQ

OPTION

“PLUS_PETITE”

NMAX_FREQ

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

7/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

6

Results of modeling B

6.1 Values

tested

Frequency (Hz)

Command of the mode

clean

Reference

Test NAFEMS

Aster

% difference

NAFEMS

1

0.421

0.4174

0.4165

1.07

2

1.029

1.020

1.0301

0.11

3

2.582

2.564

2.5793

0.10

4

3.306

3.302

3.2572

1.47

5

3.753

3.769

3.7397

0.35

6

6.555

6.805

6.4544

1.54

Test 0

7

7.3756

7.2821

1.27

8

7.7332

7.6852

0.62

9

8.5567

8.3764

2.11

10

11.1199

10.7209

3.59

11

11.6474

11.2904

3.06

12

14.3531

13.7573

4.16

6.2 Remarks

Calculations carried out by:

MODE_ITER_SIMULT

METHOD: “JACOBI”

OPTION:“PLUS_PETITE”

NMAX_FREQ: 12

6.3

Contents of the file results

the first 12 Eigen frequencies, clean vectors and modal parameters.

6.4 Parameters

of execution

Version: 3.03.25

Machine: CRAY C90

System:

UNICOS 8.0

Overall dimension memory:

8 megawords

Time CPU To use:

5.36 seconds

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

8/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

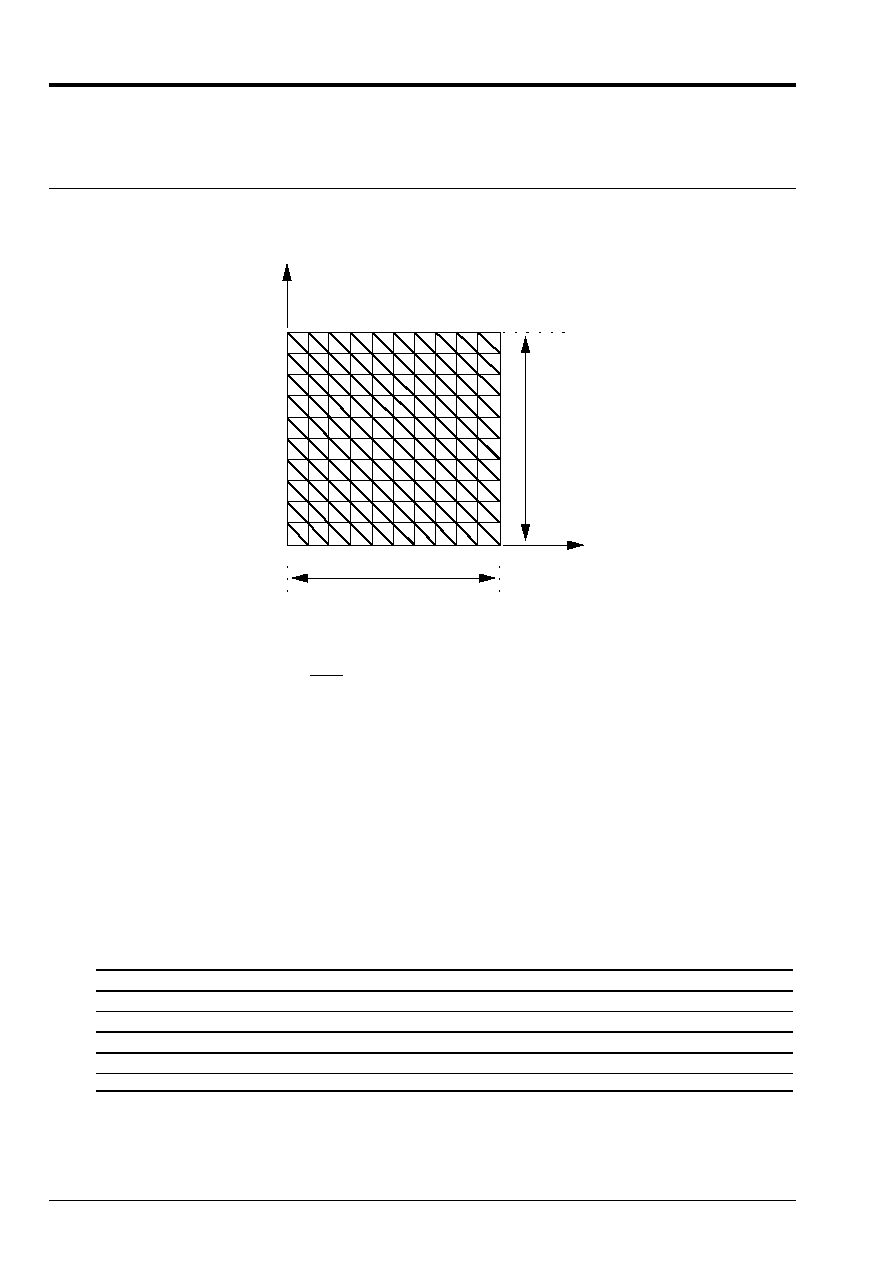

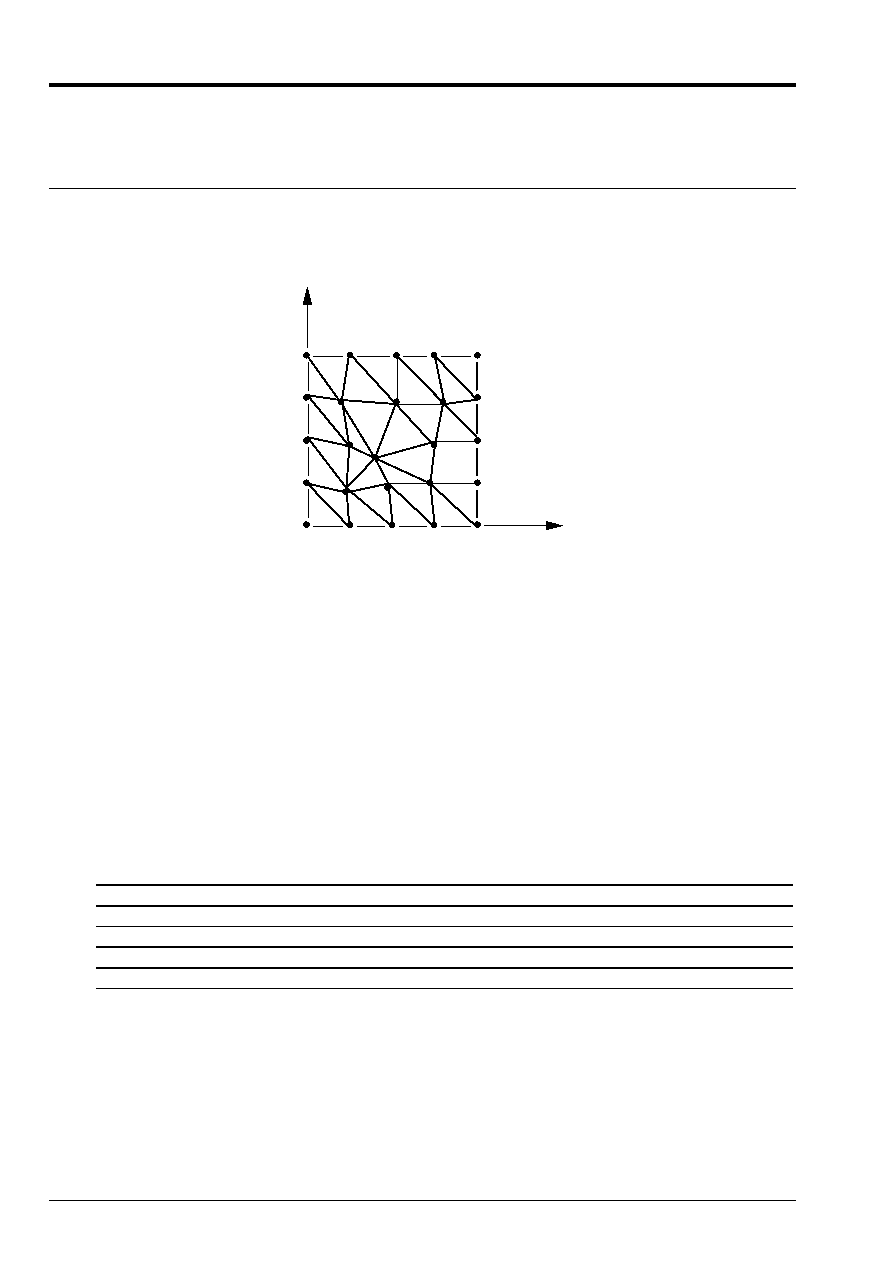

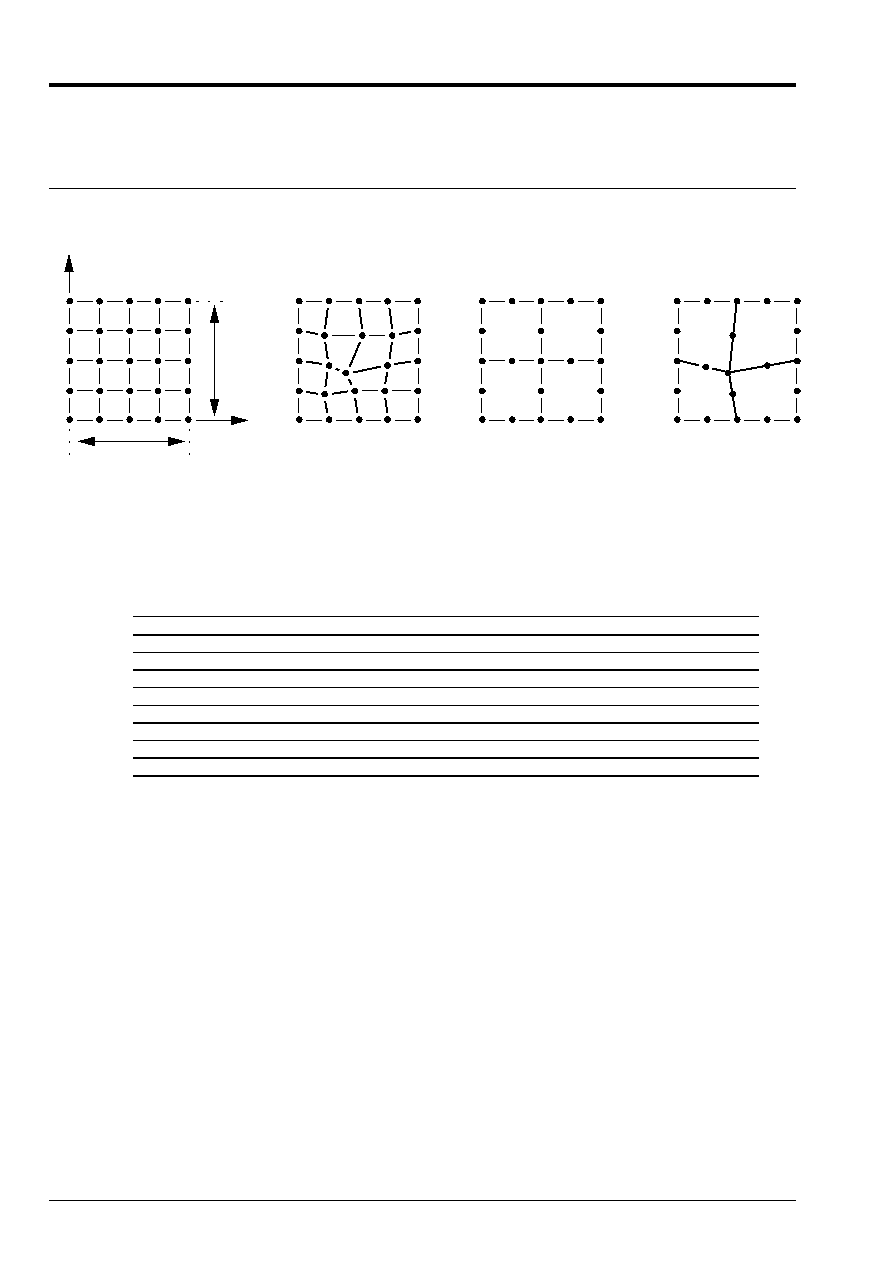

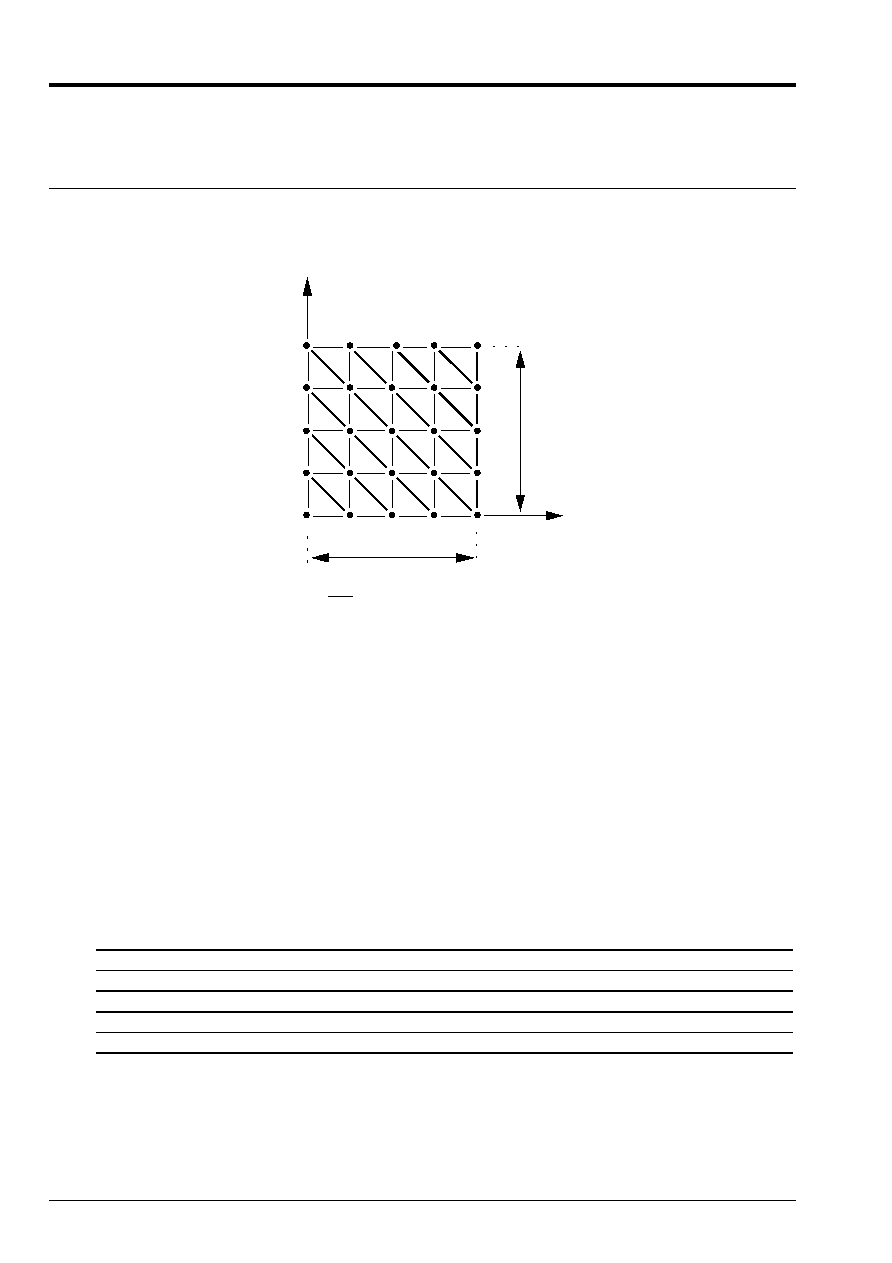

7 Modeling

C

7.1

Characteristics of modeling

Element DKT with distorted mesh

y

22

23

24

25

10

11

12

13

14

Test 2

X

2

4

9

1

5

8

7

6

21

20

19

18

17

16

15

3

Twinge of the element: between 50 and 75.

Limiting conditions:

in all the nodes P on the Xp side = 0. :

DDL_IMPO: (GROUP_NO: DIMENSION DX:0., DY:0., DZ: 0., DRY: 0. )

Name of the nodes:

Point 1 = N1

Point 25 = N25

7.2

Characteristics of the mesh

A number of nodes:

25

A number of meshs and types:

32 TRIA3

7.3 Functionalities

tested

Controls

Keys

AFFE_CARA_ELEM

HULL

ALL

[U4.24.01]

AFFE_CHAR_MECA

DDL_IMPO

GROUP_NO

[U4.25.01]

AFFE_MATERIAU

ALL

[U4.23.02]

AFFE_MODELE

“MECHANICAL”

“DKT”

ALL

[U4.22.01]

DEFI_MATERIAU

ELAS

[U4.23.01]

MODE_ITER_SIMULT

METHOD

“TRI_DIAG”

[U4.52.02]

CALC_FREQ

OPTION

“PLUS_PETITE”

NMAX_FREQ

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

9/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

8

Results of modeling C

8.1 Values

tested

Frequency (Hz)

Command of the mode

clean

Reference

Test NAFEMS

Aster

% difference

NAFEMS

1

0.421

0.4174

0.4163

1.12

2

1.029

1.020

1.0340

0.49

3

2.582

2.571

2.5644

0.68

4

3.306

3.317

3.2539

1.58

5

3.753

3.780

3.7433

0.26

6

6.555

6.883

6.4898

0.99

Test 0

7

7.3756

7.2119

2.22

8

7.7332

7.6026

1.69

9

8.5567

8.3232

2.73

10

11.1199

10.7735

3.12

11

11.6474

11.2607

3.32

12

14.3531

13.3008

7.34

8.2 Remarks

Calculations carried out by:

MODE_ITER_SIMULT

METHOD: “TRI_DIAG”

OPTION:“PLUS_PETITE”

NMAX_FREQ: 12

8.3

Contents of the file results

the first 12 Eigen frequencies, clean vectors and modal parameters.

8.4 Parameters

of execution

Version: 3.03.25

Machine: CRAY C90

System:

UNICOS 8.0

Overall dimension memory:

8 megawords

Time CPU To use:

5.2 seconds

Code_Aster

®

Version

4.0

Titrate:

SDLS100 Study of mesh on a thin square plate

Date:

08/01/98

Author (S):

B. QUINNEZ

Key:

V2.03.100-C

Page:

10/10

Manual of Validation

V2.03 booklet: Linear dynamics of the hulls and the plates

HI-75/96/013 - Ind A

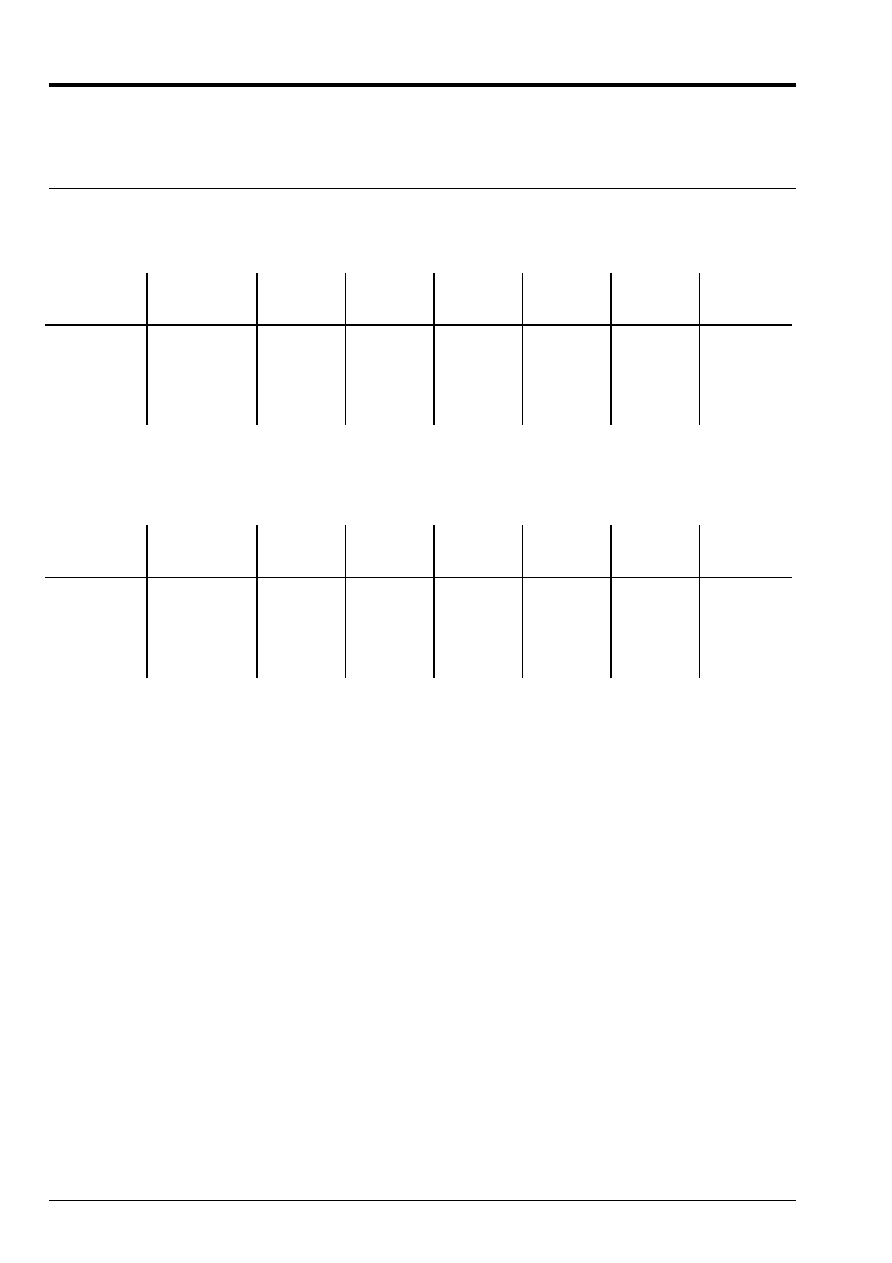

9

Summary of the results

% differences/reference

Command of

mode

clean

Reference

NAFEMS

Aster

Test 0

Aster

Test 1

Aster

Test 2

% diff.

Test 0

% diff.

Test 1

% diff.

Test 2

1

0.421

0.4178

0.4165

0.4163

0.76

1.07

1.12

2

1.029

1.0255

1.0301

1.0340

0.34

0.11

0.49

3

2.582

2.5669

2.5793

2.5644

0.58

0.10

0.68

4

3.306

3.2733

3.2572

3.2539

0.99

1.47

1.58

5

3.753

3.7347

3.7397

3.7433

0.49

0.35

0.26

6

6.555

6.5236

6.4544

6.4898

0.48

1.54

0.99

% differences/reference

Command of

mode

clean

Reference

NAFEMS

Aster

Test 0

Aster

Test 1

Aster

Test 2

% diff.

Test 0

% diff.

Test 1

% diff.

Test 2

7

7.3756

7.2821

7.2119

1.27

2.22

8

7.7332

7.6852

7.6026

0.62

1.69

9

8.5567

8.3764

8.3232

2.11

2.73

10

11.1199

10.7209

10.7735

3.59

3.12

11

11.6474

11.2904

11.2607

3.07

3.32

12

14.3551

13.7573

13.3008

4.16

7.34

·

For tests 1 and 2, the quadrangles of card NAFEMS were cut out in triangles.

·

Tests 3 and 4 can be carried out by

Aster

(not of quadratic element of hull).

·

Until the 9th mode, the error on the frequency is ² 2.5%.

·

The effect of distortion of the mesh appears really only on modes 7 and 12.