Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

1/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

Organization (S)

: EDF-R & D/AMA

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

Document: V3.01.106

SSLL106 - Right pipe

Summary:

This test allows a simple checking of the right pipe sections in static mechanics of the structures

linear.

The model is linear.

For each modeling, 6 types of loading are applied at the end: a traction, 2 efforts

edges, 2 moments bending and a torsion. One applies moreover one internal pressure, a linear force

distributed and a thermal expansion.

The values tested are displacements, the efforts with the nodes, and the stresses and deformations at the points

of Gauss. The reference solution is analytical (RDM).

Two modelings (A and B) make it possible to test the element PIPE with 3 modes of Fourier (modeling

TUYAU_3M)

: modeling A uses

MECA_STATIQUE

, modeling B uses

STAT_NON_LINE

(elastic behavior).

Two modelings (C and D) make it possible to test the element PIPE with 6 modes of Fourier (modeling

TUYAU_6M).

Two modelings (E and F) make it possible to test the element PIPE with 3 modes of Fourier and 4 nodes

(modeling TUYAU_3M).

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

2/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

1

Problem of reference

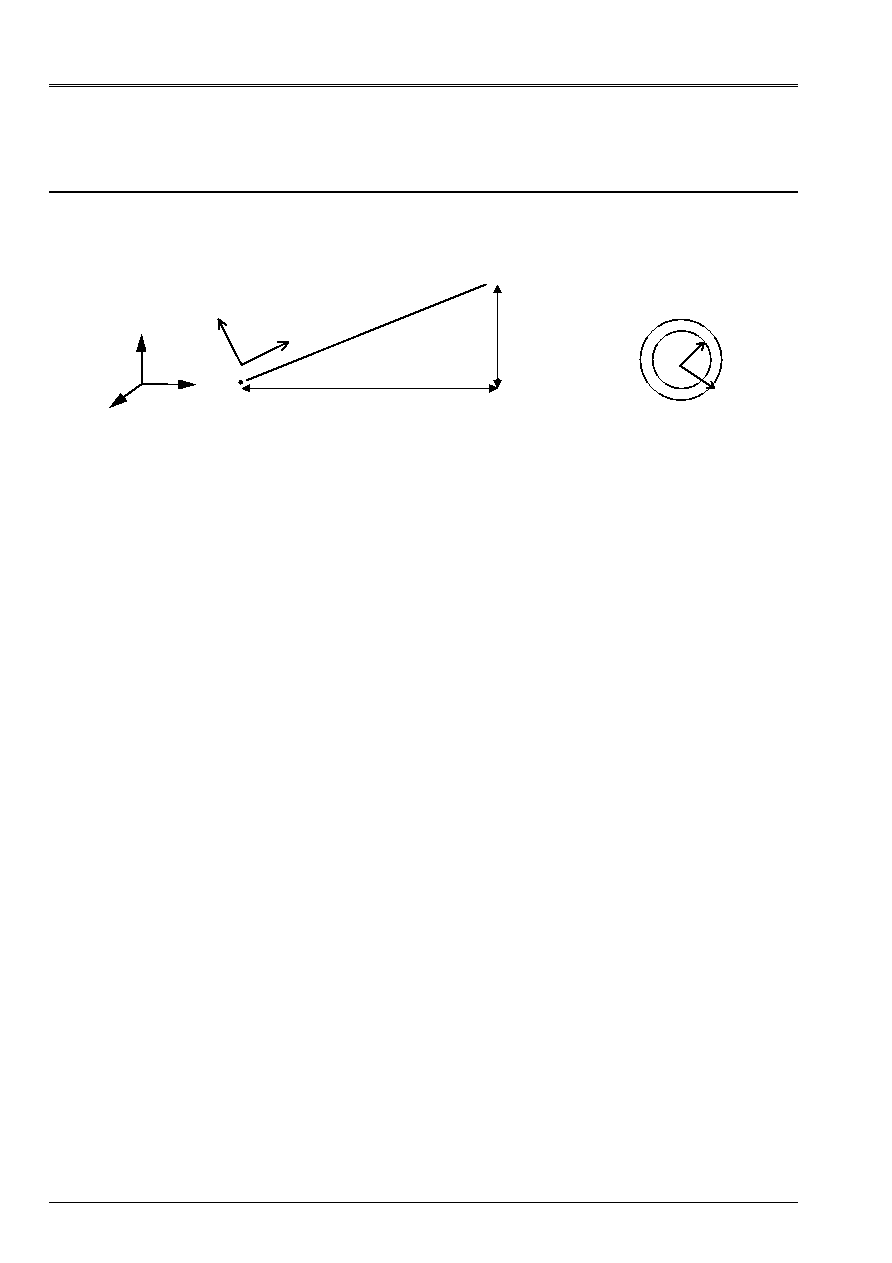

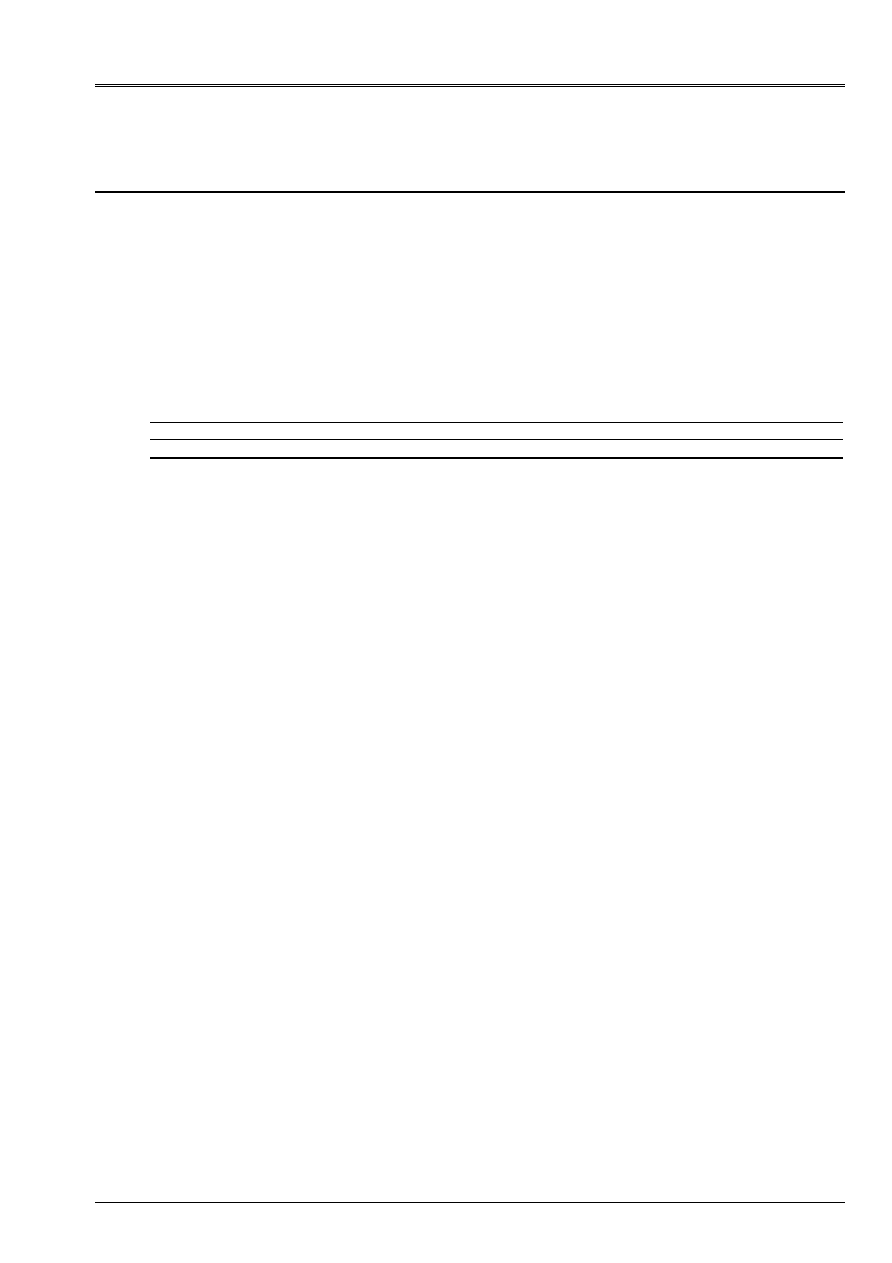

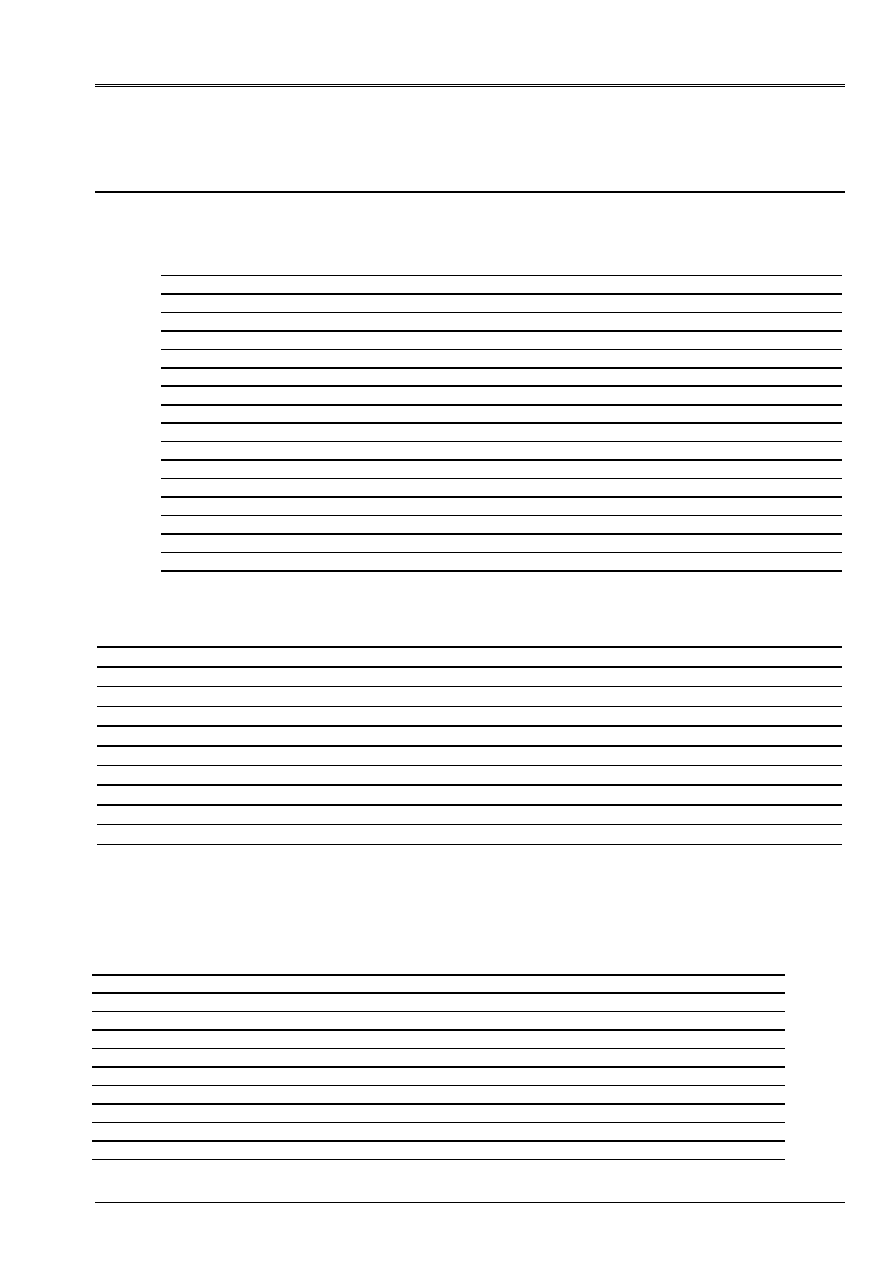

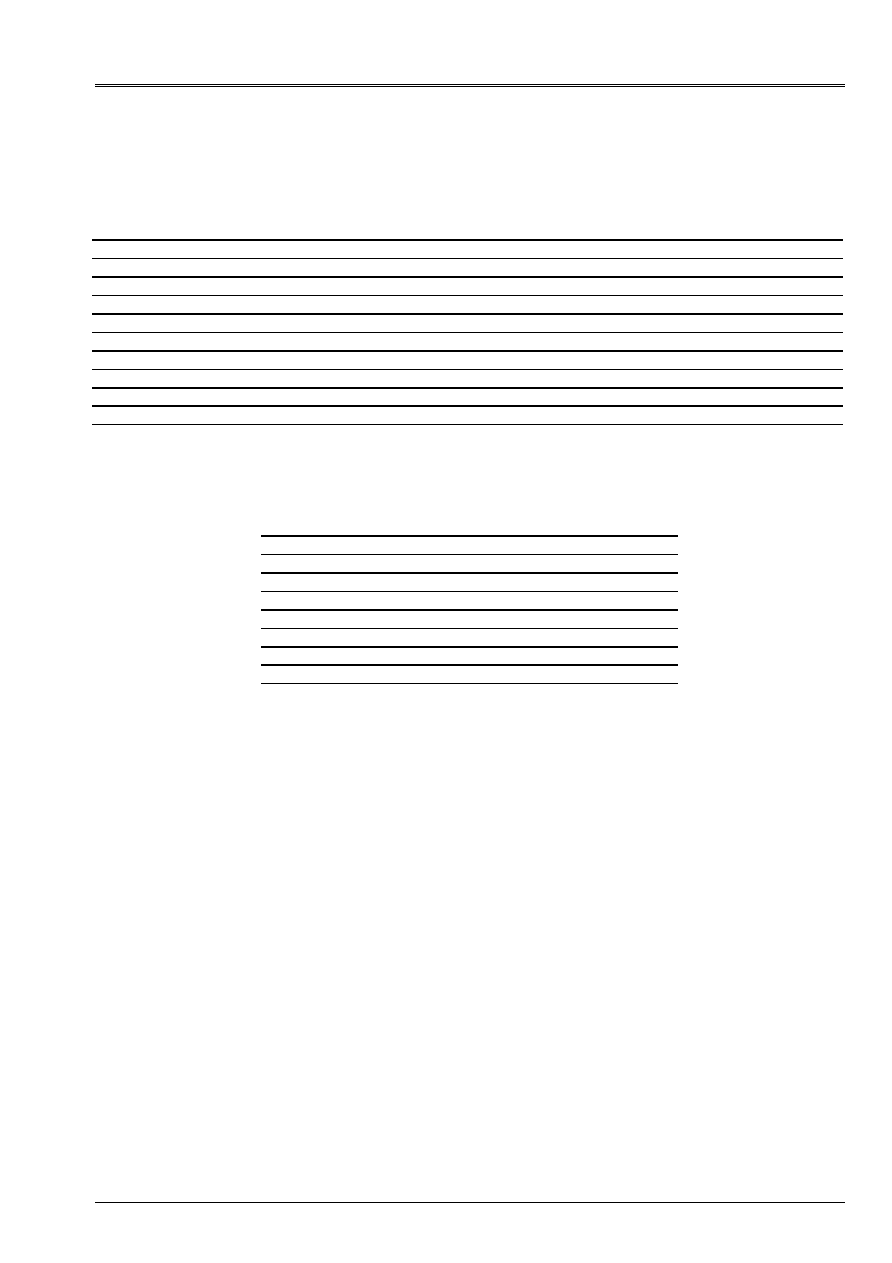

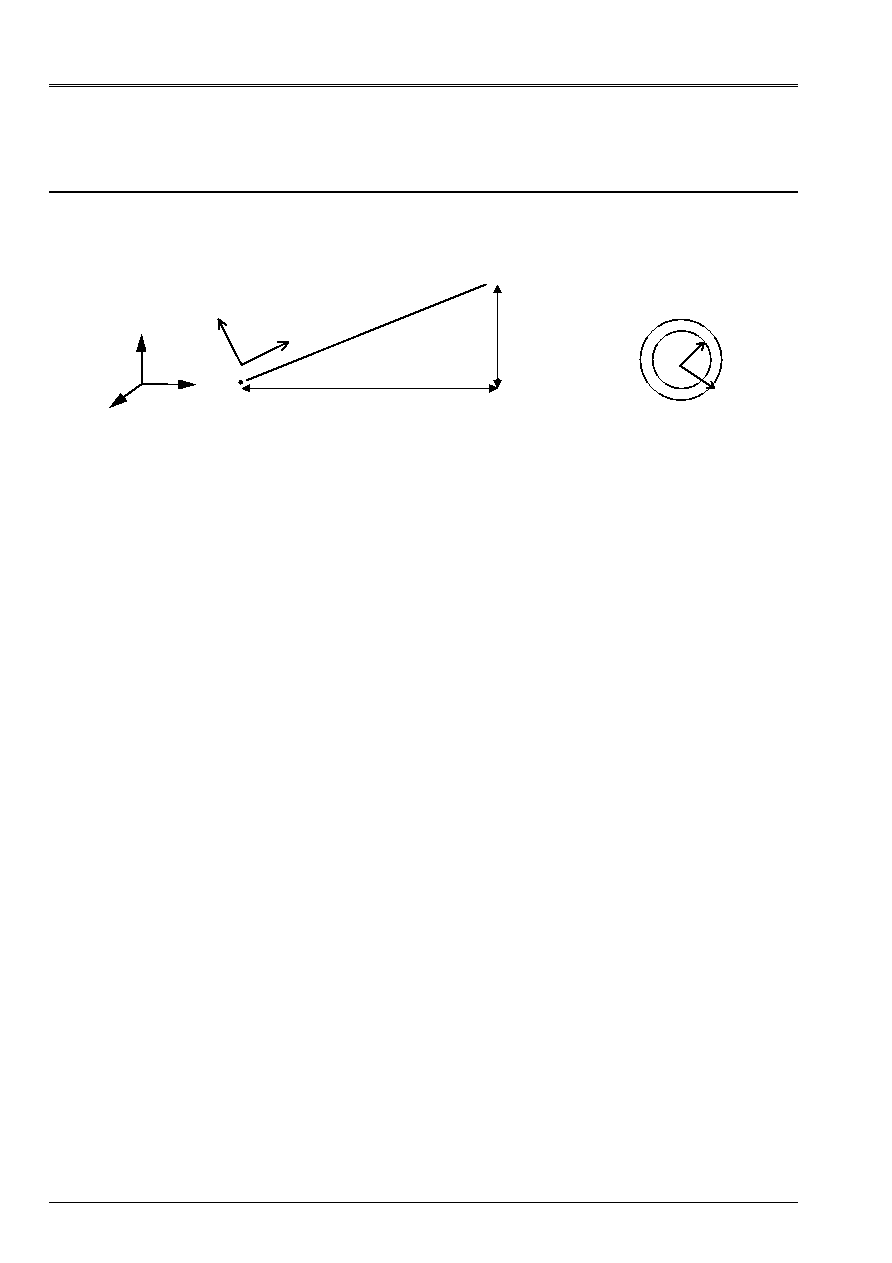

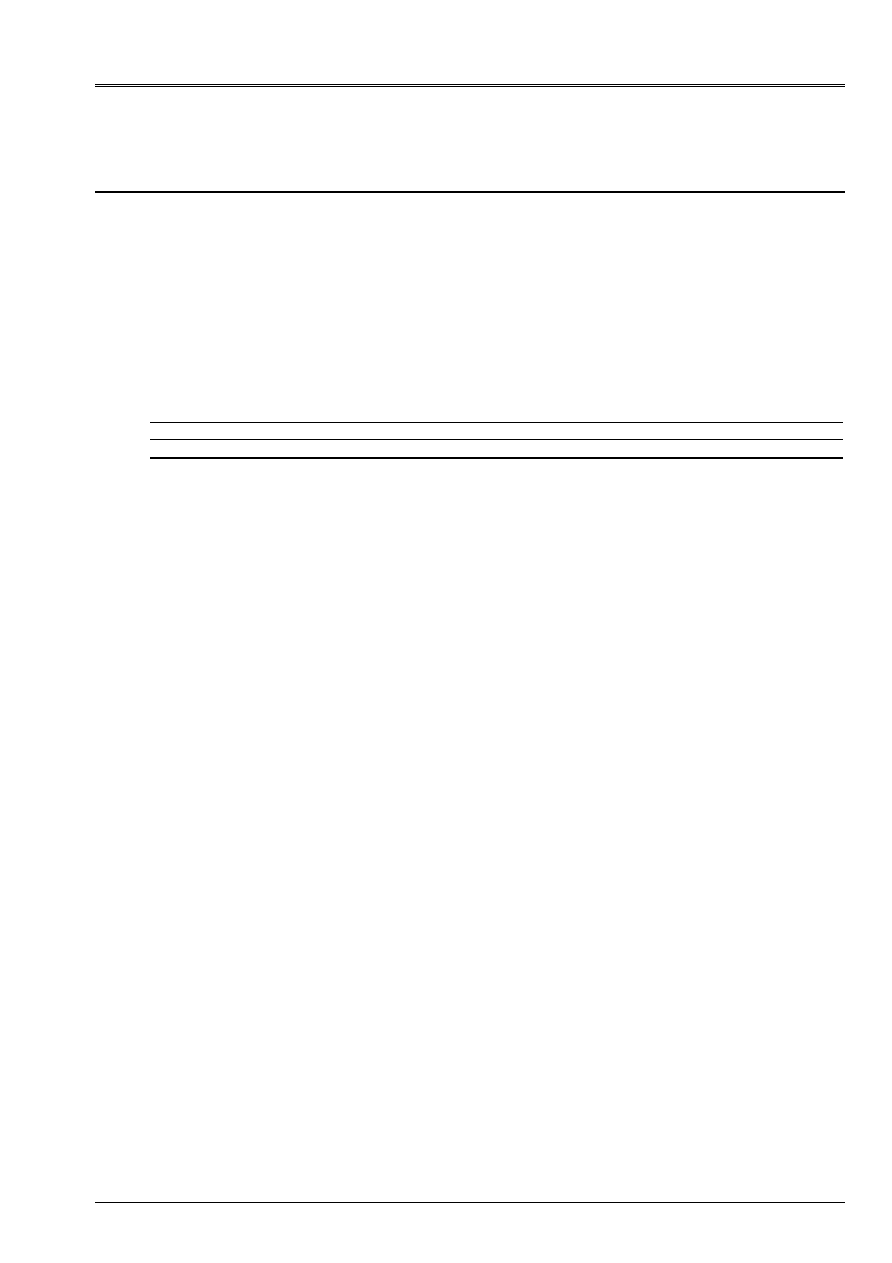

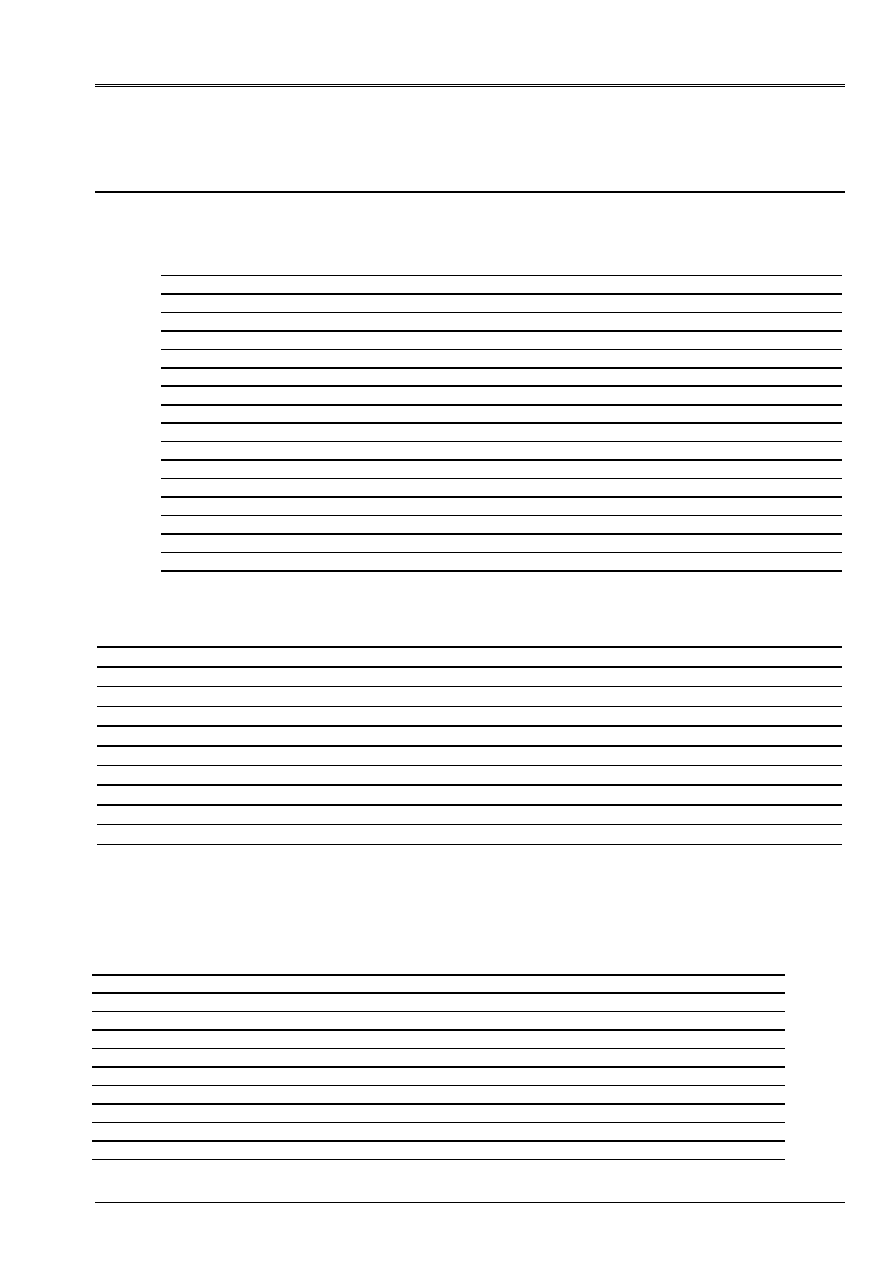

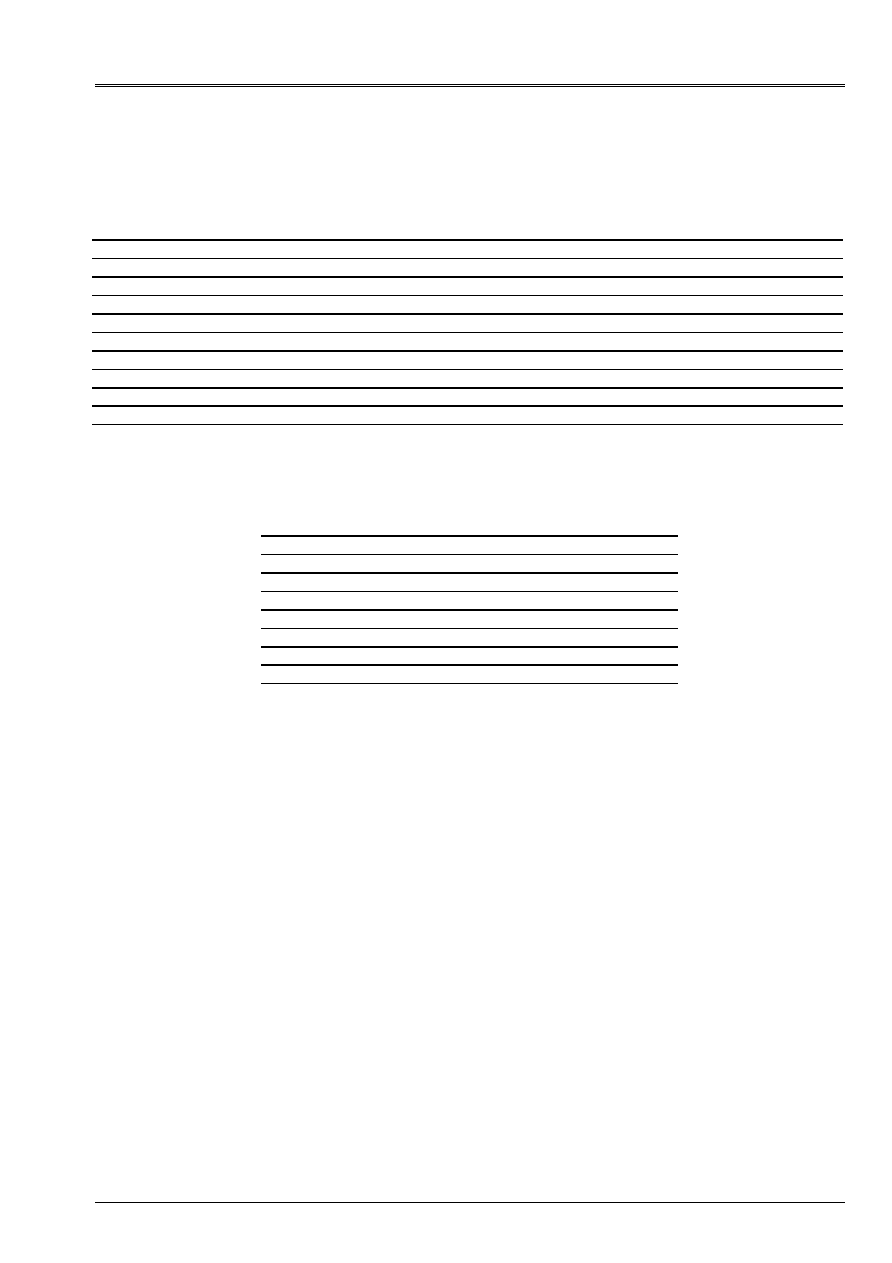

1.1 Geometry

Right beam length

L

, of directing vector (4, 3, 0).

O

B

L

L =5

Y

X

Z O

4

3

X

y

Z

0.032

0.04

Section of the pipe

Tubular section of external radius has = 0.04m, of radius interns B = 0.032m, thickness E = 0.008 m

1.2

Material properties

E = 2. 10

11

AP

= 0.3

density

=7800 kg/m3, thermal expansion factor

5

10

-

=

1.3

Boundary conditions and loadings

·

Embedding out of O

·

6 elementary Loadings at the end B

-

in reference mark (X, y, Z) related to the beam:

F

X

= 5.10

2

NR M

X

= 5.10

2

Nm

F

y

= 5.10

2

NR M

y

= 5.10

2

Nm

F

Z

= 5.10

2

NR M

Z

= 5.10

2

Nm

-

maybe, in the total reference mark (X, Y, Z):

-

1 loading of traction: F

X

= 4.10

2

NR and

F

Y

= 3.10

2

NR

-

2 sharp efforts:in the plan (oxy) F

X

= 3.10

2

NR and

F

Y

= 4.10

2

NR and in the plan

(oyz) F

Z

= 5.10

2

NR

-

1 torque: M

X

= 4.10

2

Nm and

M

Y

= 3.10

2

Nm

-

2 sharp efforts:in the plan (oxy) M

X

= 3.10

2

Nm and

M

Y

= 4.10

2

Nm and in the plan

(oyz) M

Z

= 5.10

2

Nm

·

Internal pressure: P=10

7

AP

·

Gravity, with g=10m/s ², in the direction - Z

·

Linear loading, Fz=-141.146 NR/m (what corresponds to the load due to gravity:

Fz=mg)

·

Thermal dilation: Temp = 100°C

1.4

Notation of the characteristics of cross sections

The geometrical characteristics of the cross sections are noted:

S:

surface of the section

I I

y

Z

,

:

geometrical moments of inertia compared to the main axes of inertia of

section

Jx:

constant of torsion

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

3/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

2

Reference solution

2.1

Method of calculation used for the reference solution

·

Analytical solution [bib1]: displacements out of B in the reference mark (Oxyz) related to the beam.

()

(

) (

)

Simple traction

Pure bending

Pure bending

Torsion

Pure bending

Pure bending

Pressure

U

F

L

E S

U

F L

E I

L F

E I

L F

E I

MR. L

G J

U

MR. L

E I

MR. L

E I

X

X

y

y

Z

Z

y

Z

y

Z

y

X

X

X

Z

y

y

y

y

y

uz

Fz L

E I y

U y

M Z L

E I Z

Z

M Z L

E I Z

ur

P

E

has

B

has

R

B

R

=

=

=

= -

=

= -

=

=

=

= +

=

-

-

+ +

3

2

2

2

3

2

2

2

3

3

2

2

2

2

2

1

1

2

2

calculated in

in fact

vary between

in

and

in

R

B has

U

R B

R

has

R

= +

=

=

-

-

2

7 12 10

7 78 10

6

6

,

,

Here, the values are obtained with:

S

m

Iy

Iz

m

J

m

L

m

X

=

=

=

=

=

-

-

-

1809557 10

118707 10

2 37414 10

5

3

2

6

4

6

4

.

.

.

For the generalized deformations of beam, one obtains, by the law of behavior:

(

)

(

)

Z

I

E

Z

M

Z

S

G

Z

F

xz

y

y

y

X

X

X

y

Z

y

Z

y

Z

y

xy

X

X

I

E

M

J

G

M

I

E

X

L

F

I

E

X

L

F

S

G

F

S

E

F

E

+

=

=

=

=

-

=

-

=

=

=

pure

Bending

pure

Bending

Torsion

simple

Bending

simple

Bending

simple

Traction

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

4/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

Loading of gravity and linear loading:

If

p

indicate the distributed load, the moment in the beginning is worth:

2

)

(

2

pL

O

M

=

and of following displacement

Z at the end B is worth:

I.E.(internal excitation)

pL

B

U

Z

8

)

(

4

=

The thermal loading of dilation led to an axial displacement (in the local direction X):

()

T

L

B

U

X

=

)

(

The deformations of free dilation of the surface of the pipe are simply, in local reference mark:

()

T

yy

xx

=

=

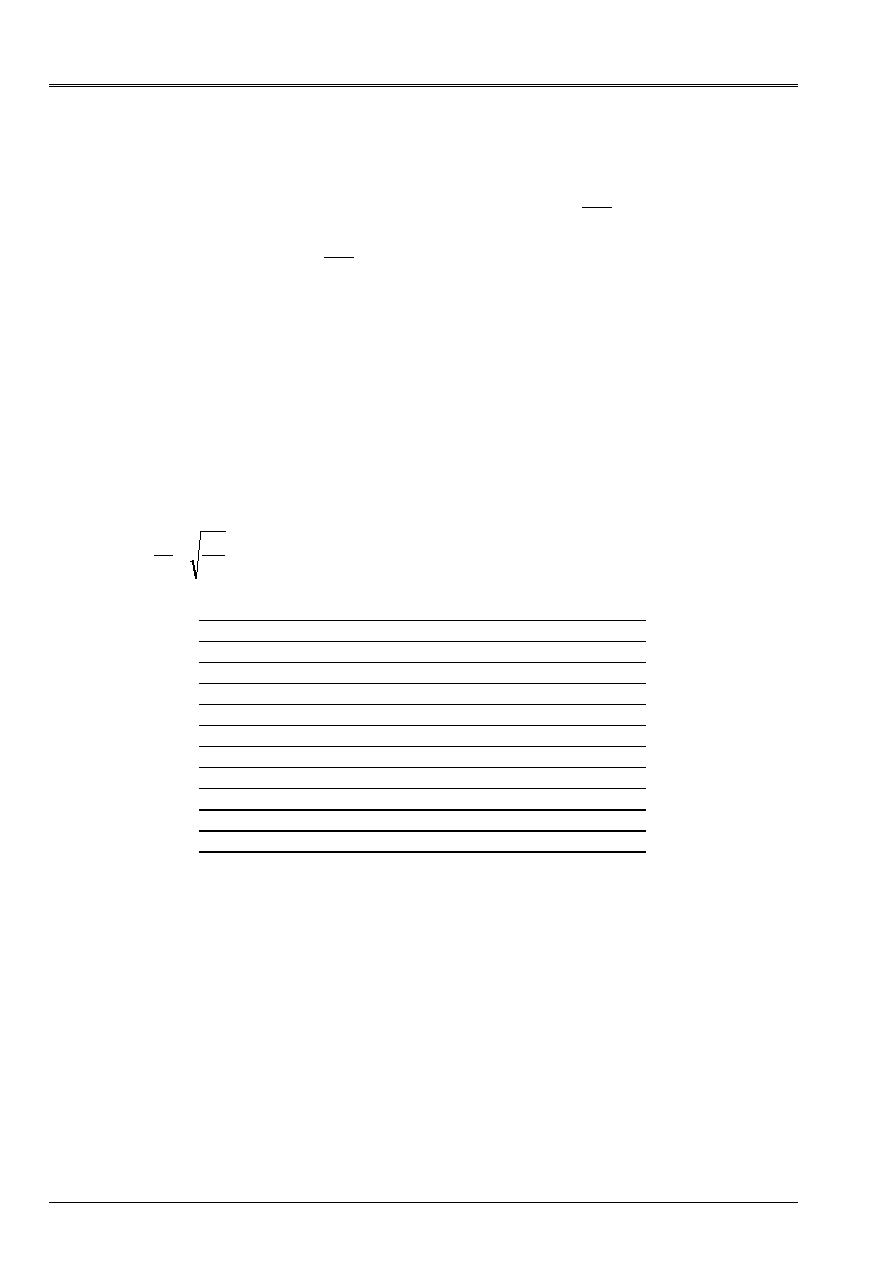

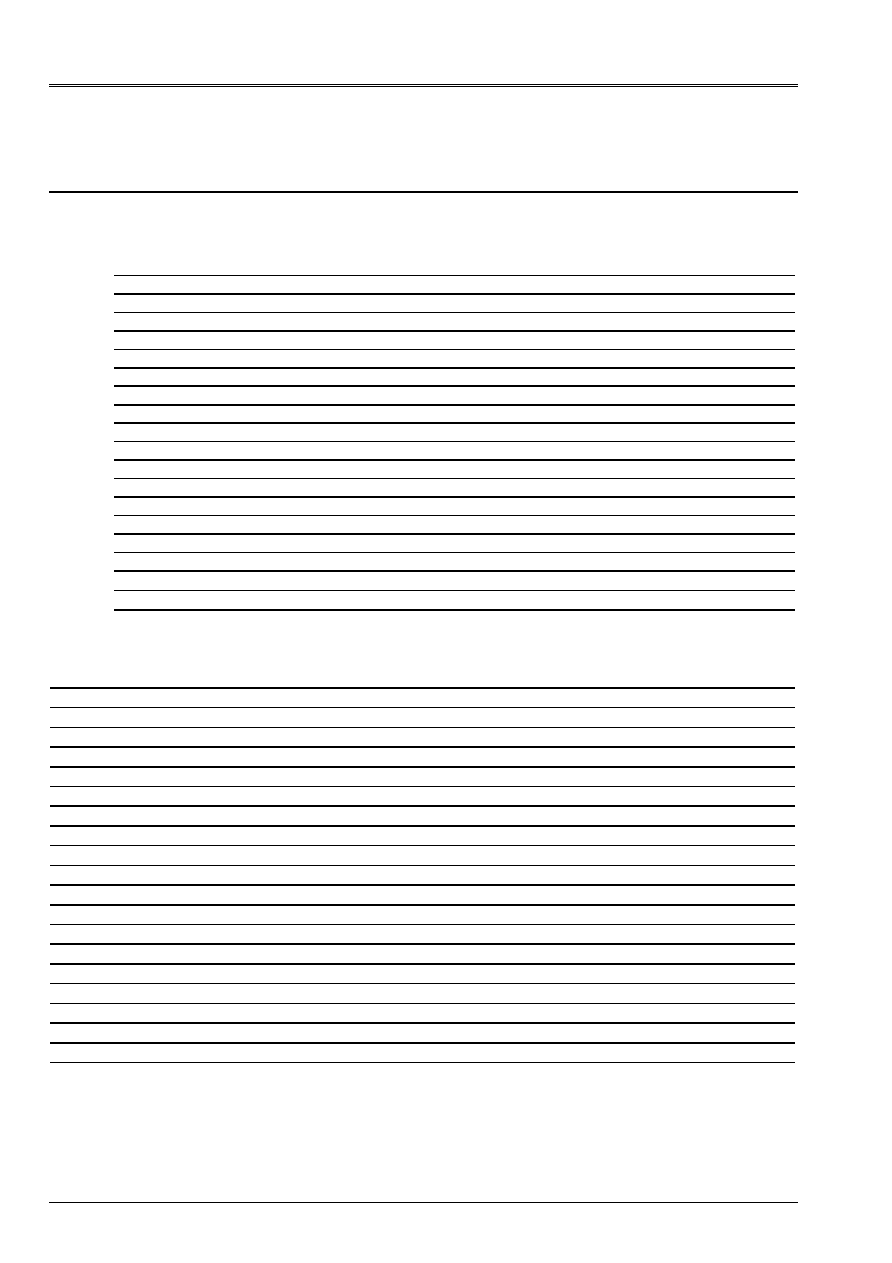

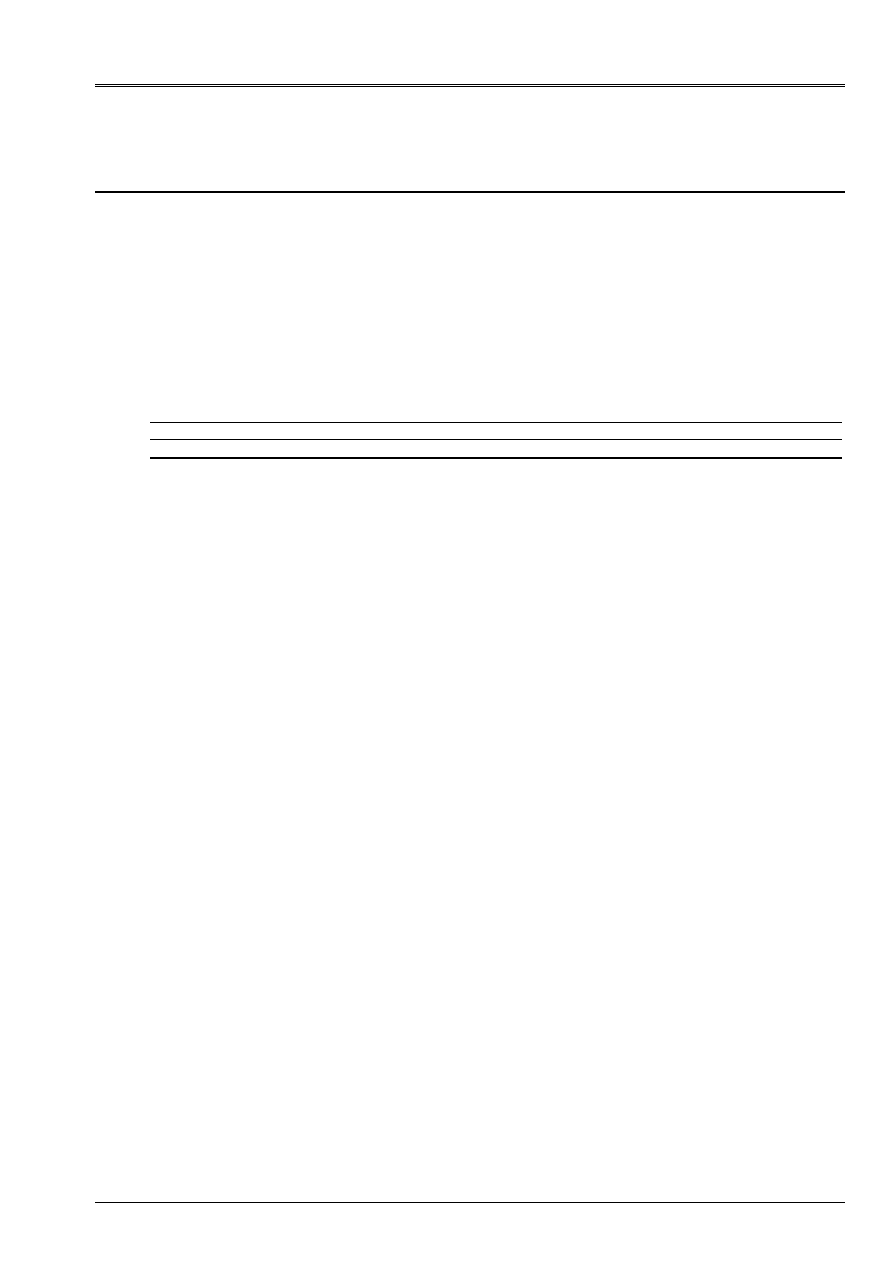

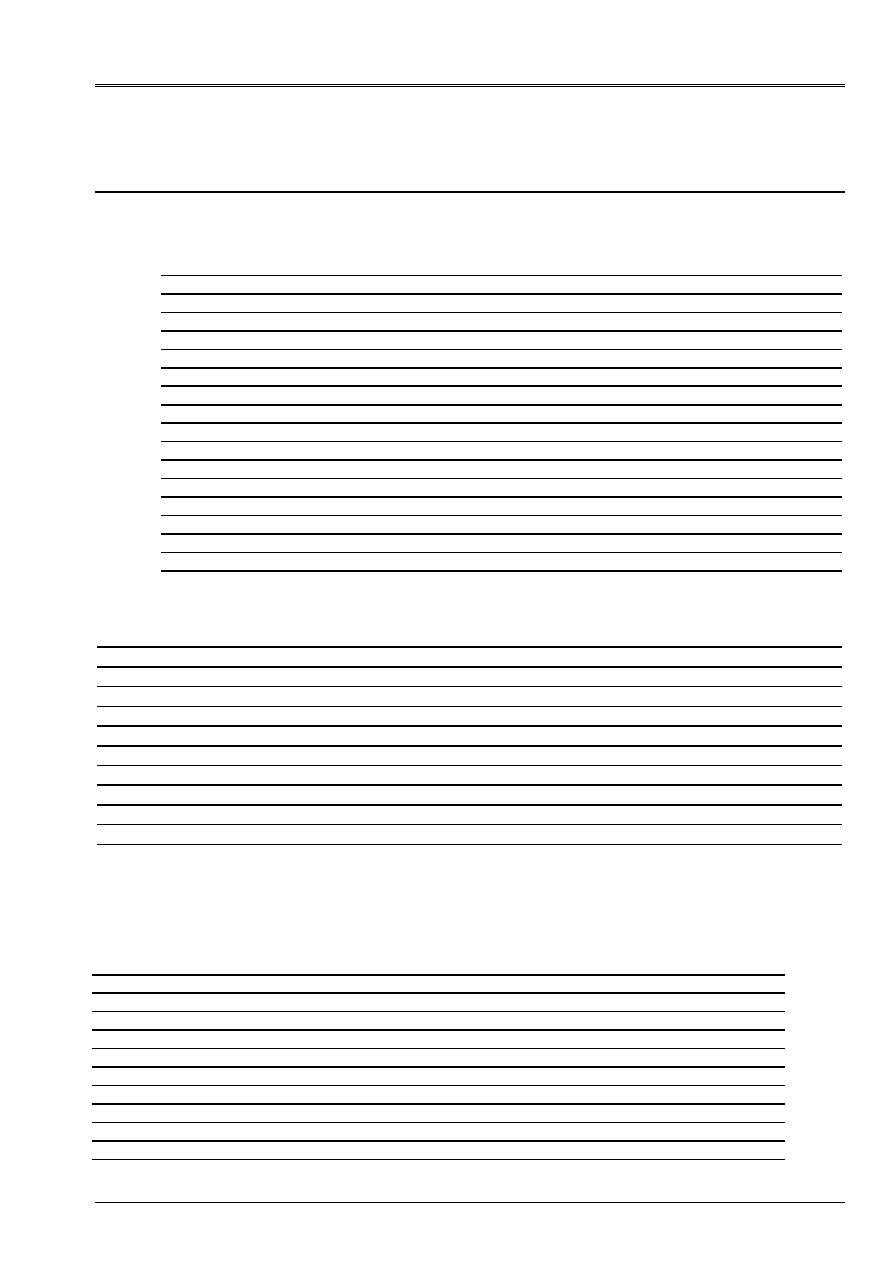

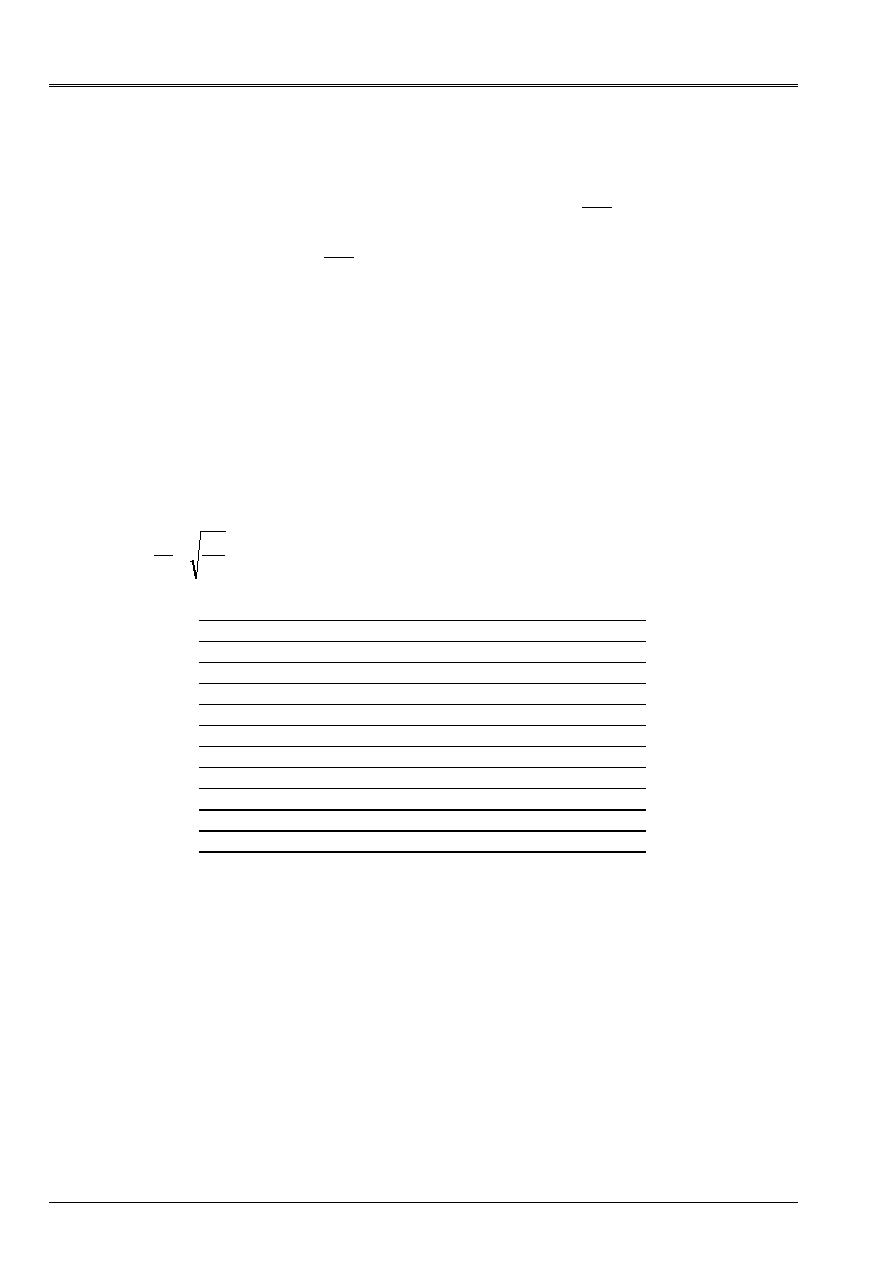

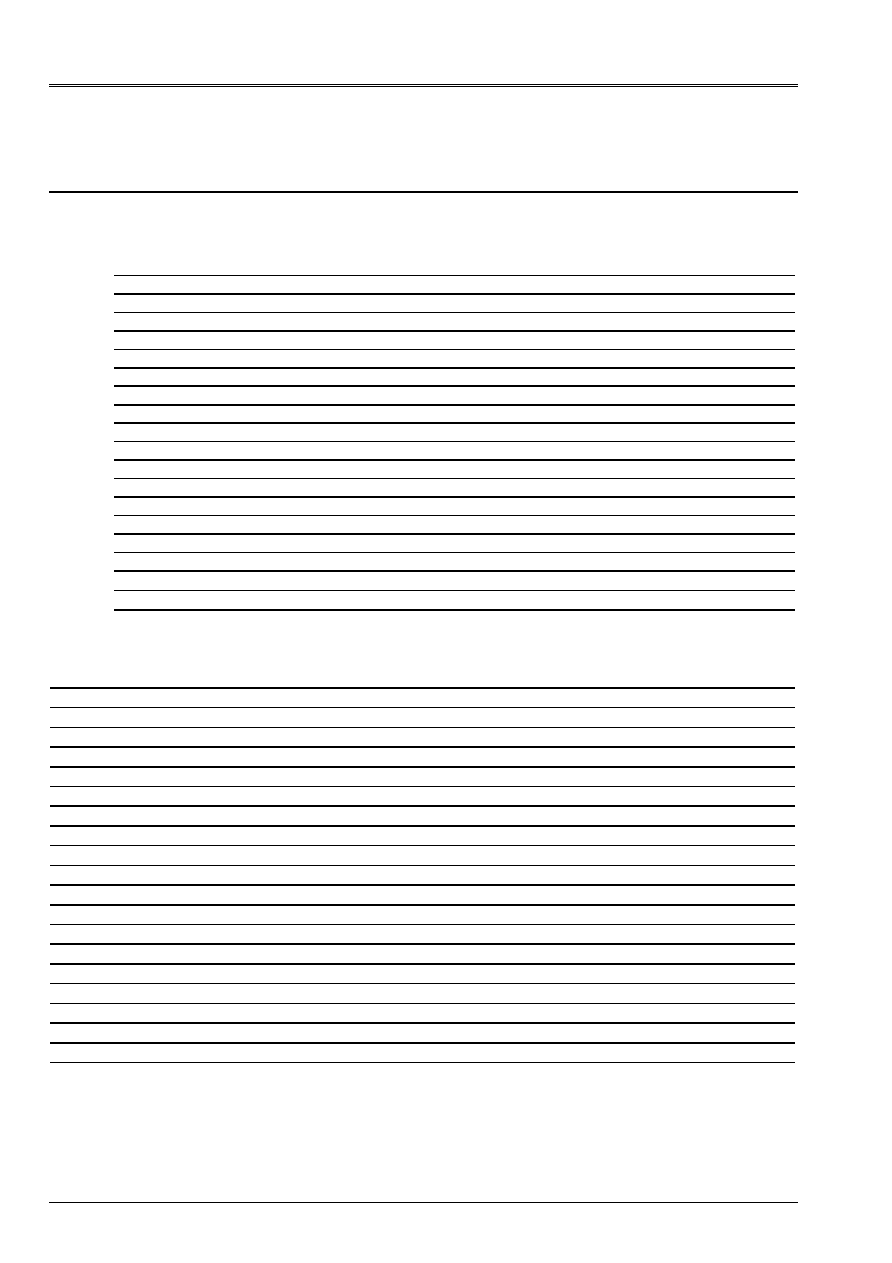

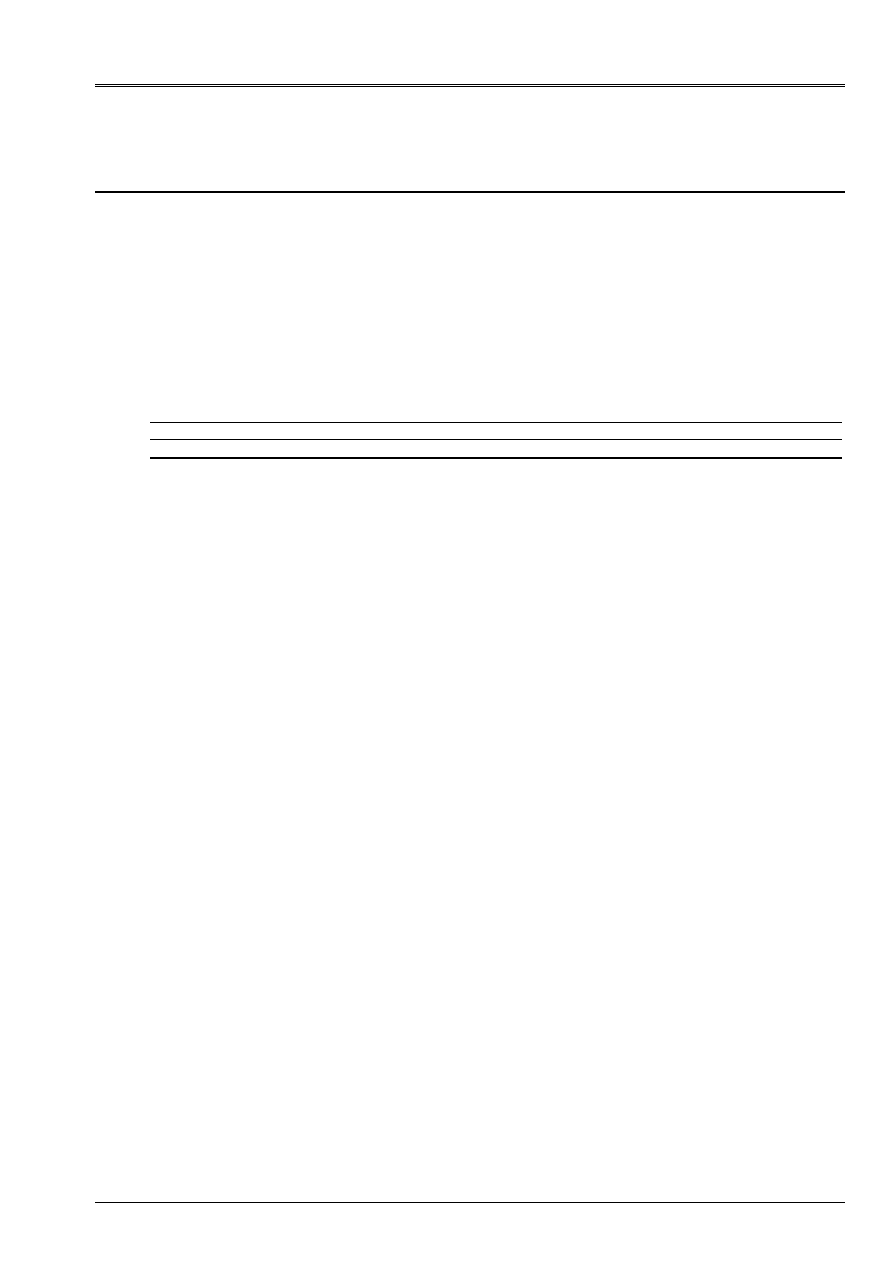

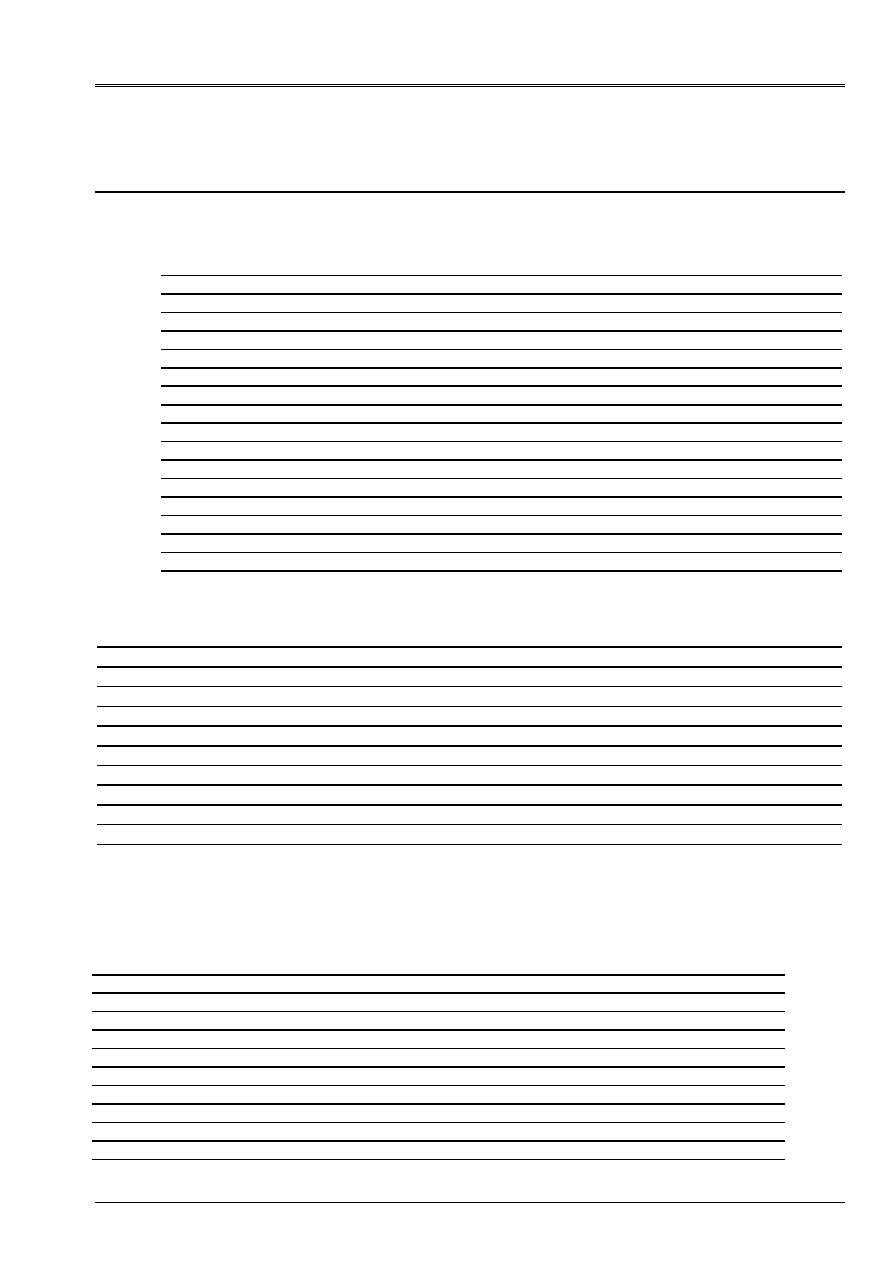

Finally to validate the calculation of the matrix of mass, a modal analysis of the first 12 modes

clean (with embedding out of O) must give, for the modes of bending:

S

I.E.(internal excitation)

L

F

I

I

2

=

Lambdai mode

Frequency

1 1,87510407

2,9030234

2 4,69409113 18,192937

3 7,85475744 50,9407506

4 10,9955407

99,8235399

5 14,1371684

165,015464

6 17,2787596

246,504532

7 20,4203522

344,291453

8 23,5619449

458,376195

9 26,7035376

588,758758

10 29,8451302

735,43914

11 32,9867229

898,417343

12 36,1283155

1077,69337

2.2

Results of reference

·

Displacement at the point B, efforts, stresses and deformations in the vicinity of the point O.

·

Deformation generalized.

·

Eigen frequencies

2.3

Uncertainty on the solution

Analytical solution.

2.4 References

bibliographical

[1]

Manual of validation, test SSLL102 fixed Beam subjected to unit efforts

[V3.01.102]

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

5/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

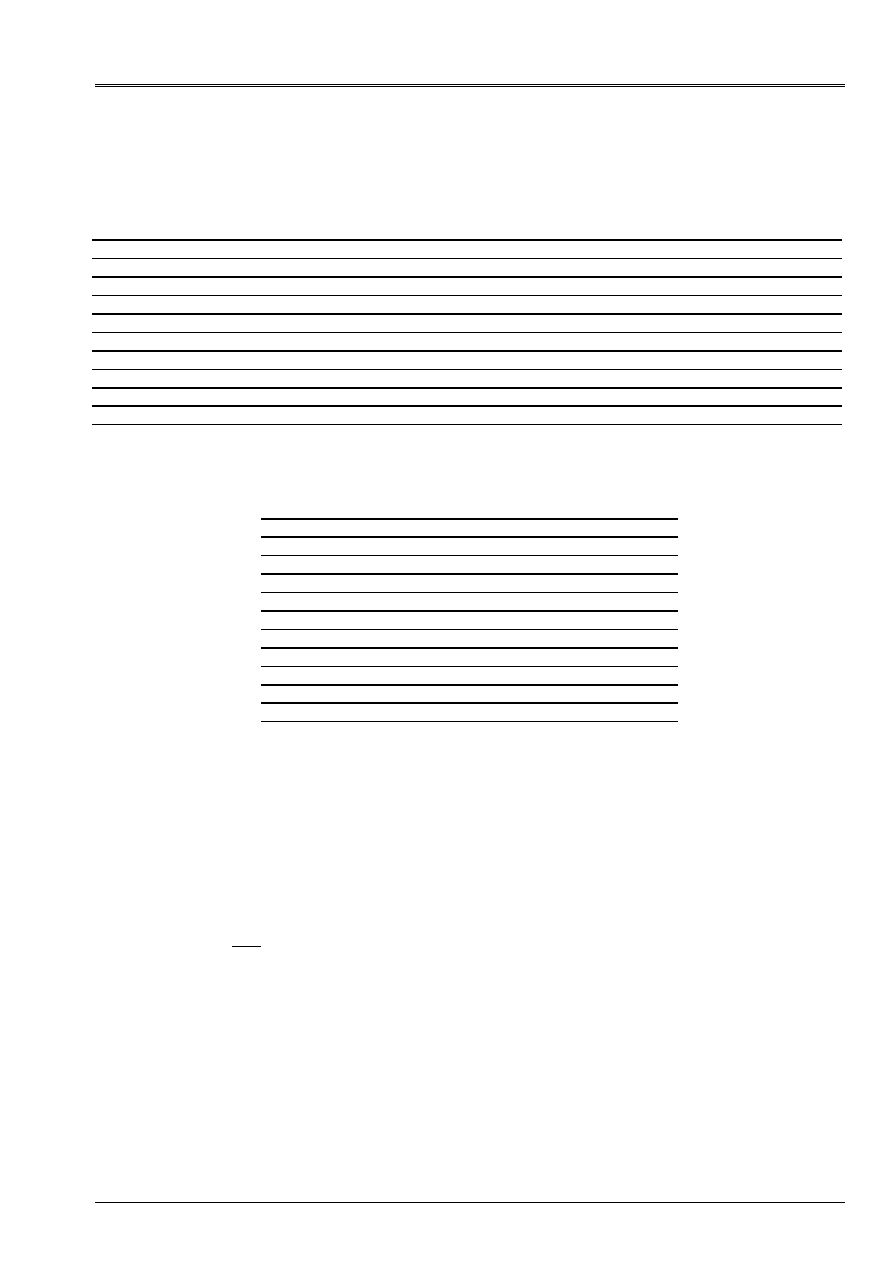

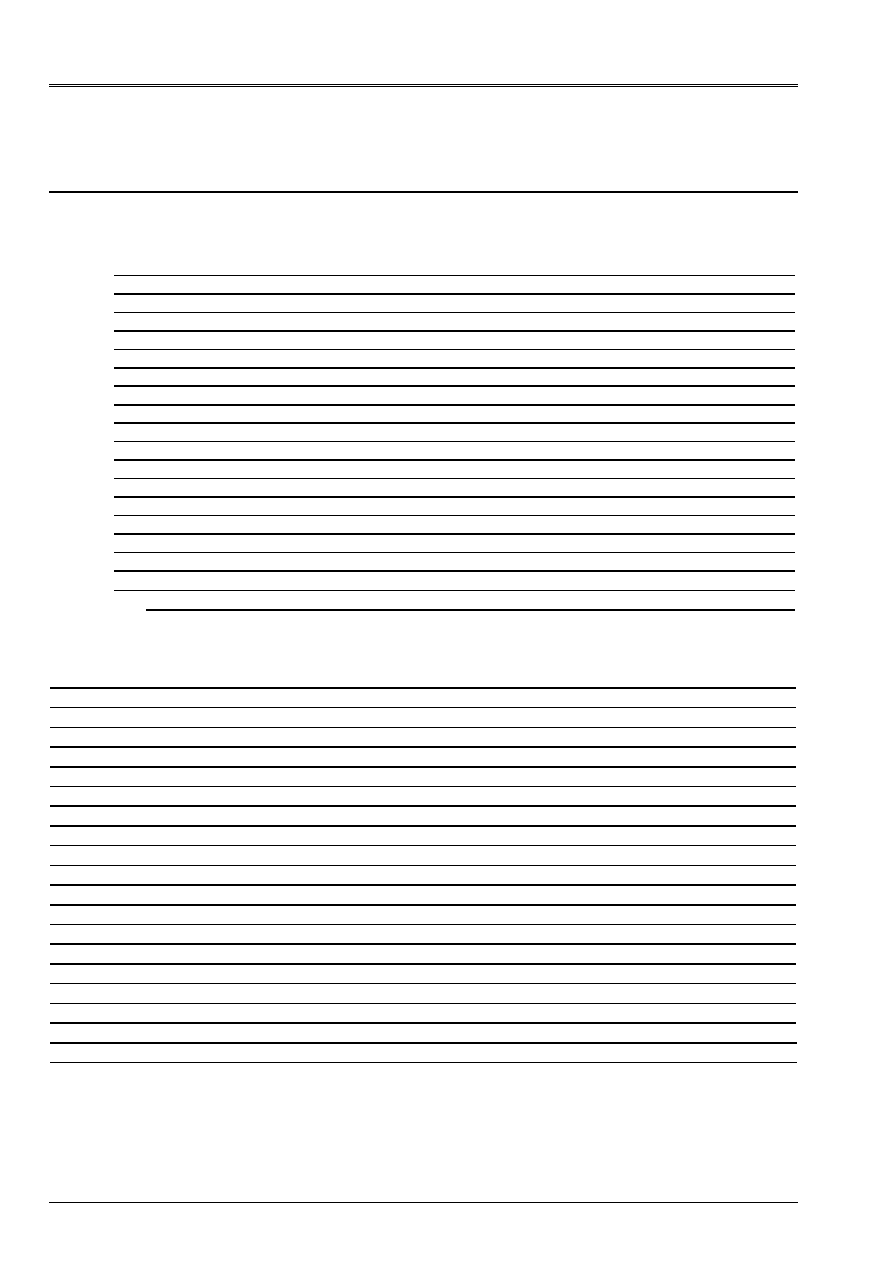

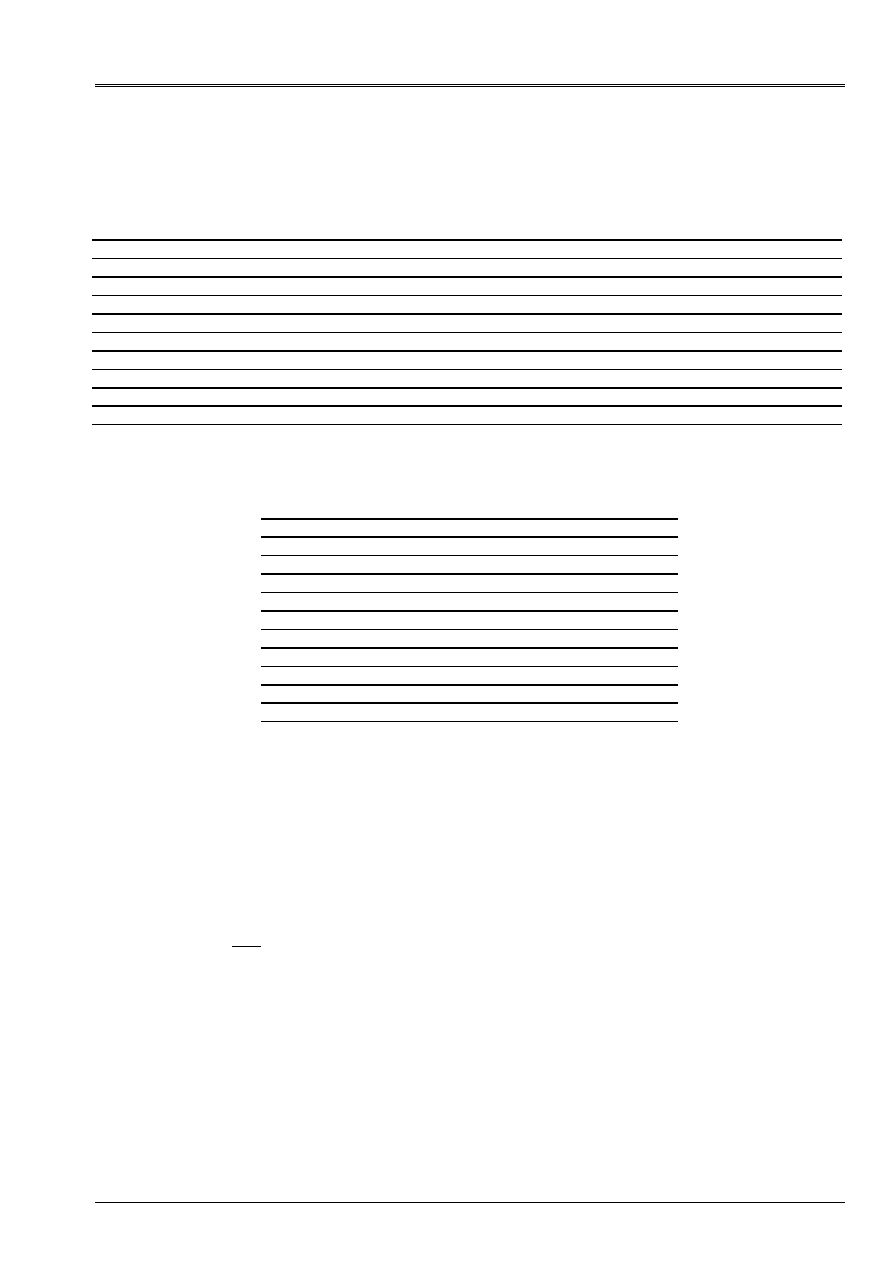

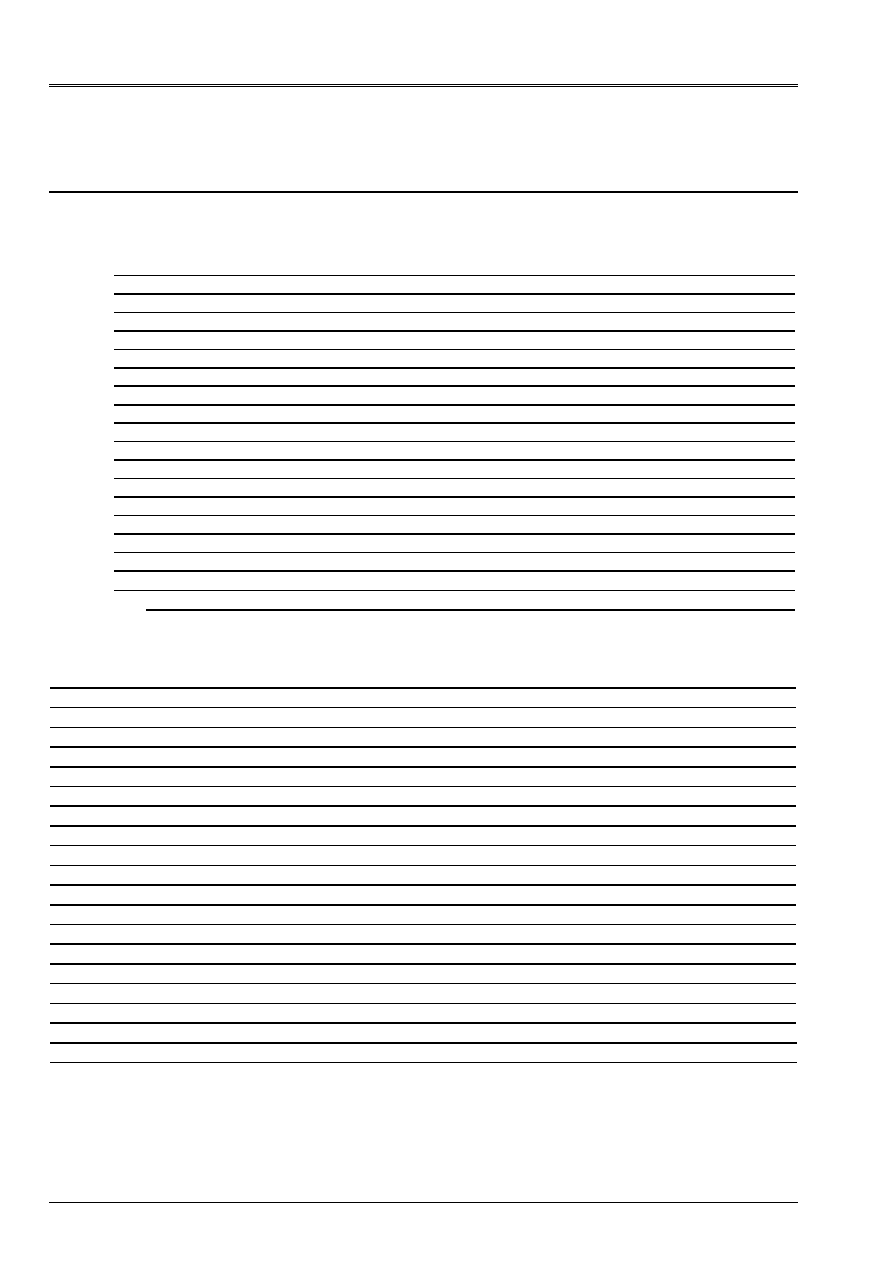

3 Modeling

With

3.1

Characteristics of modeling

10 elements

PIPE.

3.2

Characteristics of the mesh

10 meshs

SEG3

. The beam is directed according to the vector (4, 3, 0).

3.3 Functionalities

tested

Controls

AFFE_MODELE MODELING

PIPE

AFFE_CARA_ELEM BEAM

SECTION RINGS

MACRO_ELAS_MULT

OPTION

SIEF_ELGA_DEPL

OPTION

EPSI_ELGA_DEPL

OPTION

EFGE_ELNO_DEPL

Notice on the contents of the fields:

Fields at the points of Gauss for the element PIPE

,

EPSI_ELGA_DEPL

and

SIEF_ELGA_DEPL,

who provide the strains and the stresses to the points of integration

in the local reference mark of the element, are organized in the following way:

The values are stored:

·

for each point of Gauss in the length, (n=1, 3)

·

for each point of integration in the thickness, (n=1, 2N

NECK

+1=7)

·

for each point of integration on the circumference, (n=1, 2N

SECT

+1=33)

·

6 components of strain or stresses:

EPXX EPYY EPZZ EPXY EPXZ EPYZ

or

SIXX SIYY SIZZ SIXY

SIXZ SIYZ

where X indicates the direction given by the two nodes nodes of

the element, Y represents the angle

describing the circumference and Z

represent the radius.

EPZZ

and

EPYZ

agent with

rr

R

,

in

case of the deformations and

SIZZ

and

SIYZ

agent with

rr

R

,

in

the case of the stresses is taken equal to zero.

(for

MECA_STATIQUE

or

MACRO_ELAS_MULT

, the number of layers is fixed, and equal to 3, and

the number of sectors is equal to 16).

EFGE_ELNO_DEPL

represent the efforts generalized with the 3 nodes in the conventional way:

NR,

VY, VZ, MT, MFY, MFZ

.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

6/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

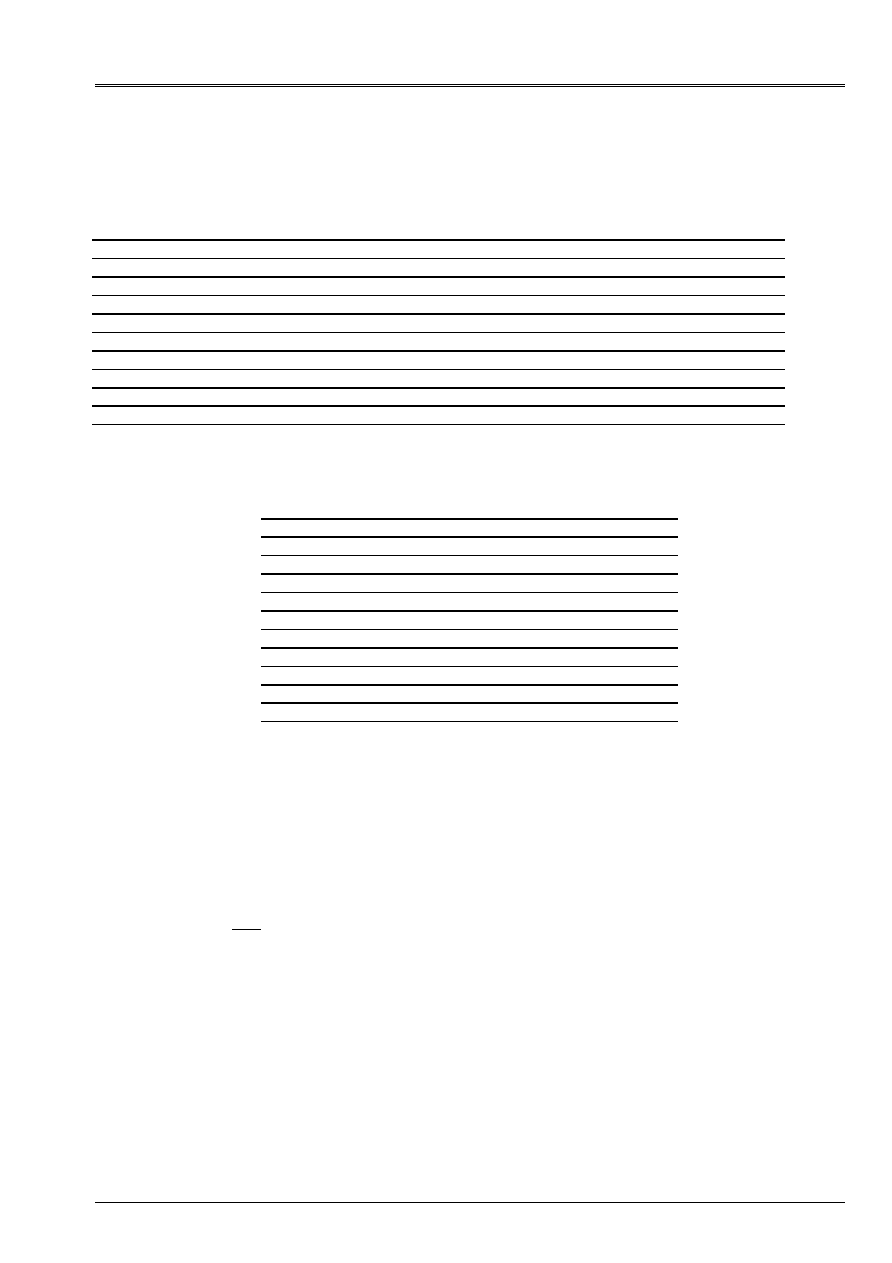

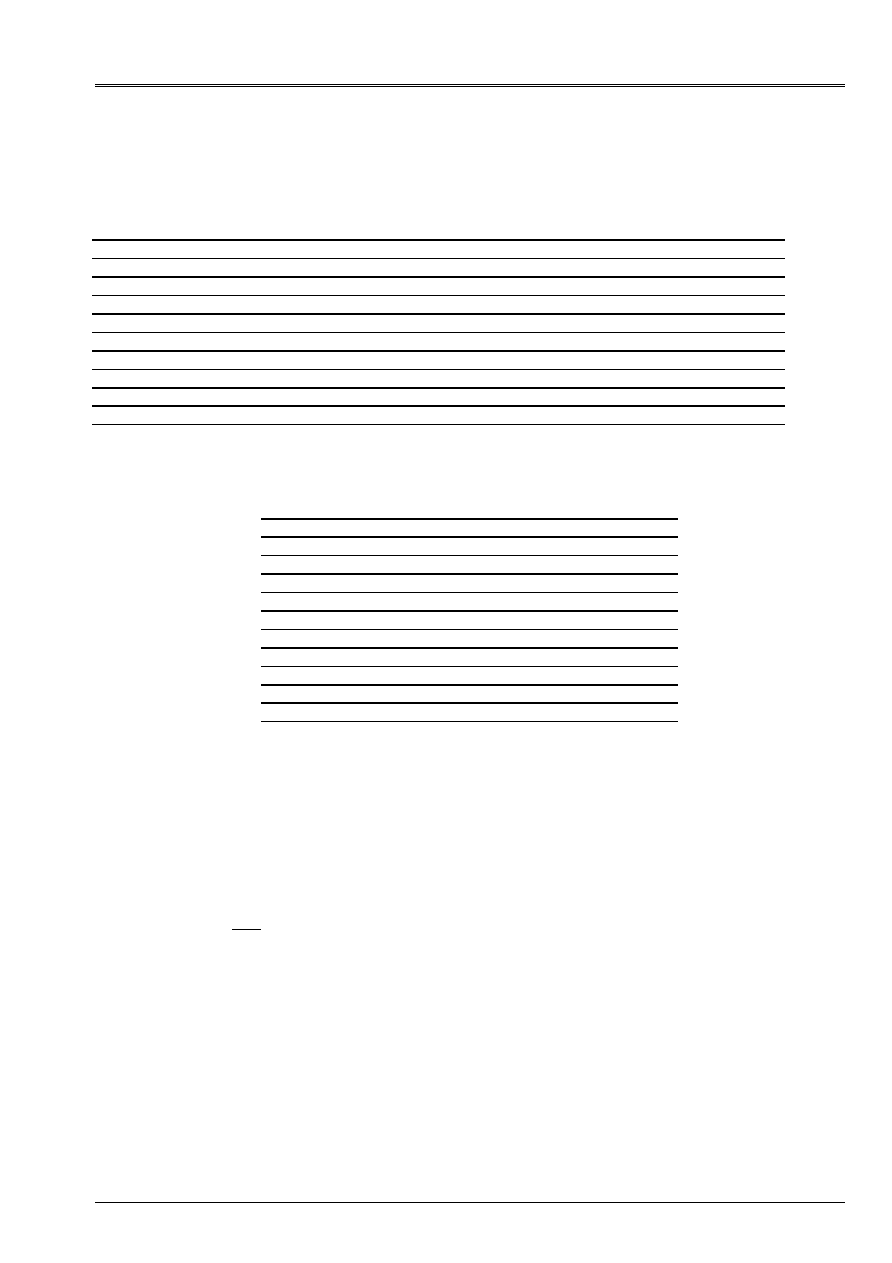

4

Results of modeling A

4.1 Values

tested

Loading case

Size

Reference

Aster %

difference

F

X

= 4.10

2

DX

5.53E06

5.52E06

0.04

F

Y

= 3.10

2

DY

4.14E06

4.14E06

0.04

F

X

= 3.10

2

DRZ

2.63E02

2.63E02

0.04

F

Y

= 4.10

2

DX

5.27E02

5.26E02

0.056

DY

7.02E02

7.02E02

0.056

F

Z

= 5.10

2

DRX

1.58E02

1.58E02

0.04

DRY

2.11E02

2.11E02

0.039

DZ

8.78E02

8.77E02

0.056

M

X

= 4.10

2

DRX

1.10E02

1.10E02

0

M

Y

= 3.10

2

DRY

8.21E03

8.21E03

0

M

X

= 3.10

2

DRX

6.32E03

6.32E03

0.04

M

Y

= 4.10

2

DRY

8.42E03

8.42E03

0.04

DZ

2.63E02

2.63E02

0.04

M

Z

= 5 10

2

DRZ

1.05E02

1.05E02

0.039

DX

1.58E02

1.58E02

0.04

DY

2.11E02

2.11E02

0.039

7: pressure

WO

7.38E06

7.16E06

2.946

8: gravity

DZ

4.646

E-02 4.642

E-02

0.09

9: charge distributed

DZ

4.646

E-02 4.642

E-02

0.09

Loading case

Field

Net Point Component Reference

Aster %

difference

1

EFGE_ELNO_DEPL

M18 1 NR

5.00E+02

5.01E+02 0.136

1

EPSI_ELGA_DEPL

M18 1 EPXX 1.38E06

1.38E06

0.031

1

SIEF_ELGA_DEPL

M18 1 SIXX 2.76E+05

2.73E+05

1.159

4

EFGE_ELNO_DEPL

M18 1 MT

5.00E+02

5.00E+02 0

4

EPSI_ELGA_DEPL

M18 1 EPXY 8.77E05 8.76E05

0.102

4

EPSI_ELGA_DEPL

M18 693 EPXY 1.09E04 1.10E04 0.049

4

SIEF_ELGA_DEPL

M18 1 SIXY 6.75E+06 6.74E+06

0.159

4

SIEF_ELGA_DEPL

M18 693 SIXY

8.42E+06 8.42E+06 0.049

5

EFGE_ELNO_DEPL

M18 1 MFY 5.00E+02

5.01E+02 0.123

5

EPSI_ELGA_DEPL

M18 479 EPXX

6.74E05

6.74E05 0.046

5

SIEF_ELGA_DEPL

M18 479 SIXX

1.35E+07

1.33E+07 1.288

6

EFGE_ELNO_DEPL

M18 1 MFZ 5.00E+02

5.01E+02 0.123

6

EPSI_ELGA_DEPL

M18 471 EPXX

6.74E05

6.74E05 0.046

6

SIEF_ELGA_DEPL

M18 471 SIXX

1.35E+07

1.33E+07 1.288

7

EPSI_ELGA_DEPL

M18 1 EPYY 2.28E04

2.24E04

1.716

7

EPSI_ELGA_DEPL

M18 693 EPYY

1.78E04

1.79E04 0.741

7

SIEF_ELGA_DEPL

M18 1 SIYY 4.56E+07

4.53E+07

0.641

7

SIEF_ELGA_DEPL

M18 693 SIYY

3.56E+07

3.54E+07 0.371

8

EFGE_ELNO_DEPL

M1 1 MFY

1764.3

1728

2

9

EFGE_ELNO_DEPL

M1 1 MFY

1764.3

1728

2

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

7/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

Generalized deformations

DEGE_ELNO_DEPL

:

Loading case

Loadings

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

EPXX

1.38155E-06

1.38155E-06

0.04

F

Y

= 3.10

2

2 F

X

= 3.10

2

GAXY 3.5920E-06 4.7415E06 32

F

Y

= 4.10

2

KZ

1.0530E02 1.04E02 1.2

3 F

Z

= 5.10

2

GAXZ 3.5920E-06 4.7415E06

32

KY

1.0530E02

1.04E02

1.2

4 M

X

= 4.10

2

GAT 2.73783E-03 2.73783E-03 0

M

Y

= 3.10

2

5 M

X

= 3.10

2

KY

2.1060E-03 2.1052E-03 0.04

M

Y

= 4.10

2

6 M

Z

= 5 10

2

KZ

2.1060E-03 2.1052E-03

0.04

Fréquenc

E clean

Reference

Aster %

difference

1 2.90229

2.90378

0.05

2 2.90229

2.

90378

0.05

3 18.18967

18.2047

0.08

4 18.18967

18.2047

0.08

5 50.99367

51.006 0.02

6 50.99367

51.006 0.02

7 99.81783

100.0478

0.2

8 99.81783

100.0478

0.2

9 157.0190

157.0185 0.001

10 164.9922

165.606 0.3

11 164.9922

165.606 0.3

12 253.185 247.82 2

4.2 Remarks

The values of shearings corresponding to the shearing action are not precise for this

modeling. This is due to the functions of interpolation of command 2 of this element, for displacements

of beam and rotations of beams. As transverse shearings of beam are obtained

by:

dx

y

Z

xy

-

=

, and that for the pure bending, rotations vary like polynomials of command 2,

but displacements, like polynomials of command 3, which is badly approached by the functions

of interpolation. The derivative of displacements is thus not precise.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

8/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

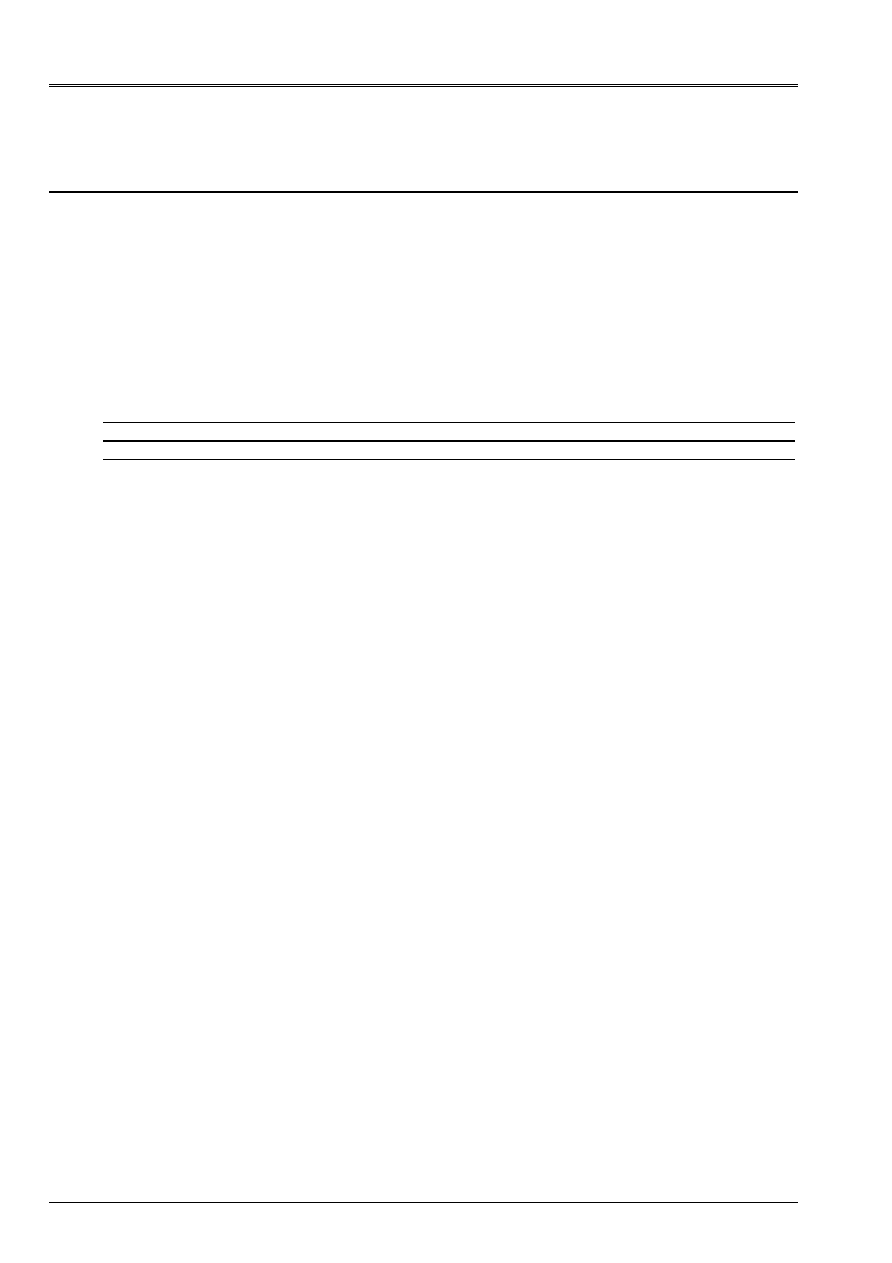

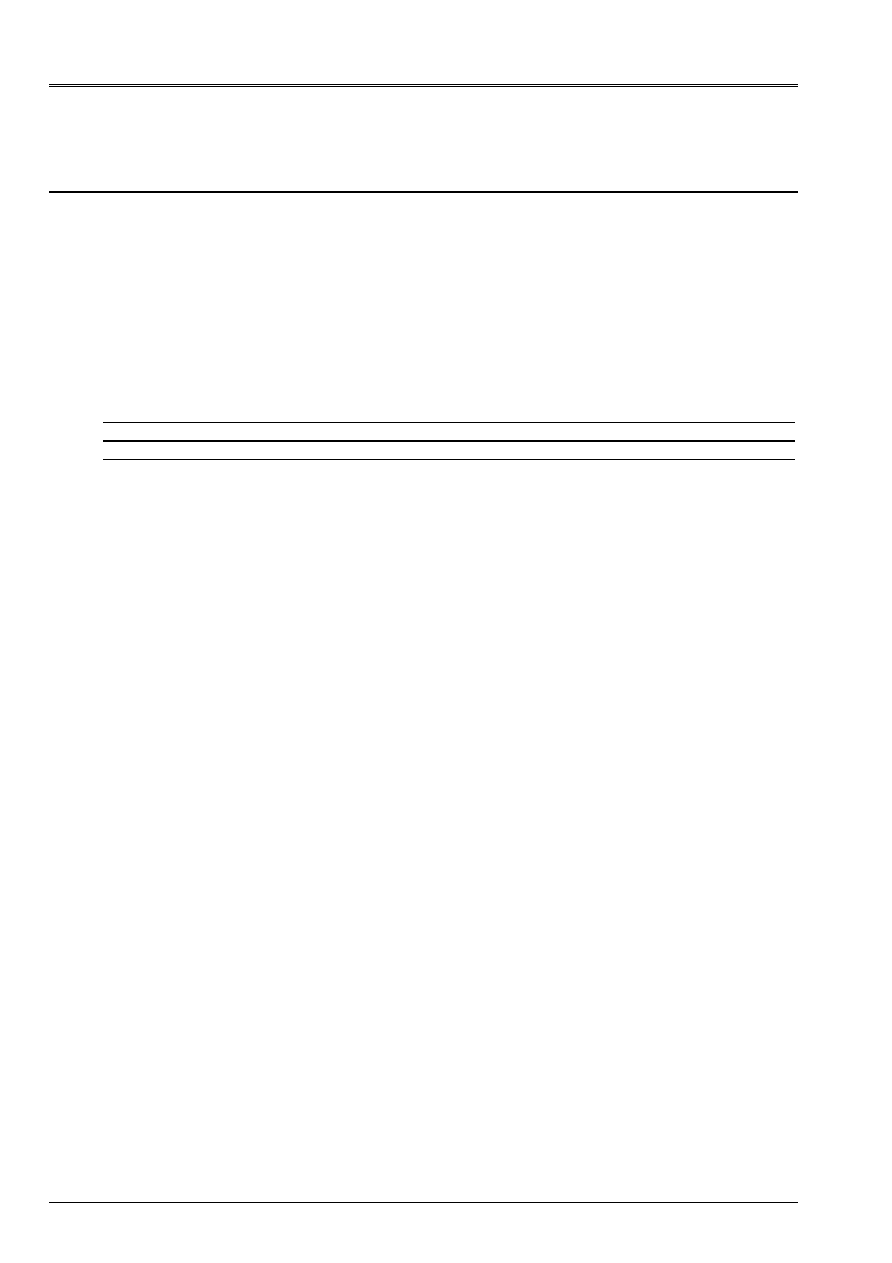

5 Modeling

B

5.1

Characteristics of modeling

10 elements

PIPE

, calculation with

STAT_NON_LINE

.

5.2

Characteristics of the mesh

10 meshs

SEG3

. The beam is directed according to the vector (4, 3, 0).

5.3 Functionalities

tested

Controls

AFFE_MODELE

MODELING

PIPE

AFFE_CARA_ELEM BEAM

SECTION RINGS

STAT_NON_LINE COMP_INCR

RELATION ELAS

COMP_INCR

TUYAU_NCOU

3

COMP_INCR

TUYAU_NSEC

16

OPTION

SIEF_ELNO_ELGA

Notice on the contents of the fields:

Stress fields at the points of Gauss for the element PIPE,

SIEF_ELGA,

in

the local reference mark of the element, are organized in the following way:

The values are stored:

·

for each point of Gauss in the length, (n=1, 3)

·

for each point of integration in the thickness, (n=1, 2N

NECK

+1)

·

for each point of integration on the circumference, (n=1, 2N

SECT

+1)

·

6 components of strain or stresses:

EPXX EPYY EPZZ EPXY EPXZ EPYZ

or

SIXX SIYY SIZZ SIXY

SIXZ SIYZ

where X indicates the direction given by the two nodes nodes of

the element, Y represents the angle

describing the circumference and Z

represent the radius.

EPZZ

and

EPYZ

agent with

rr

R

,

in

case of the deformations and

SIZZ

and

SIYZ

agent with

rr

R

,

in

the case of the stresses is taken equal to zero.

(in

STAT_NON_LINE

, the number of layers is variable, as well as the number of sectors.

One uses here 3 layers and 16 sectors by analogy with modeling A).

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

9/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

6

Results of modeling B

6.1 Values

tested

Loading case

Size

Reference

Aster %

difference

1 DX

5.53E06

5.52E06

0.04

1 DY

4.14E06

4.14E06

0.04

2 DRZ

2.63E02

2.63E02

0.04

2 DX

5.27E02

5.26E02

0.056

2 DY

7.02E02

7.02E02

0.056

3 DRX

1.58E02

1.58E02

0.04

3 DRY

2.11E02

2.11E02

0.039

3 DZ

8.78E02

8.77E02

0.056

4 DRX

1.10E02

1.10E02

0

4 DRY

8.21E03

8.21E03

0

5 DRX

6.32E03

6.32E03

0.04

5 DRY

8.42E03

8.42E03

0.04

5 DZ

2.63E02

2.63E02

0.04

6 DRZ

1.05E02

1.05E02

0.039

6 DX

1.58E02

1.58E02

0.04

6 DY

2.11E02

2.11E02

0.039

7 WO

7.38E06

7.16E06

2.946

Loading case

Field

Net

Not Component Reference

Aster %

difference

1

SIEF_ELGA

M18 Z SIXX 2.76E+05

2.73E+05

1.159

1

SIEF_ELNO_ELGA

M18 1 NR 5.00E+02

5.01E+02 0.136

4

SIEF_ELGA

M18 1 SIXY 6.75E+06

6.74E+06

0.159

4

SIEF_ELGA

M18 693

SIXY 8.42E+06

8.42E+06 0.049

4

SIEF_ELNO_ELGA

M18 1 MT 5.00E+02

5.00E+02 0

5

SIEF_ELGA

M18 479

SIXX 1.35E+07

1.33E+07 1.288

5

SIEF_ELNO_ELGA

M18 1 MFY 5.00E+02

5.01E+02 0.123

6

SIEF_ELGA

M18 471

SIXX 1.35E+07

1.33E+07 1.288

6

SIEF_ELNO_ELGA

M18 1 MFZ 5.00E+02

5.01E+02 0.123

7

SIEF_ELGA

M18 1 SIYY 4.56E+07

4.53E+07

0.641

7

SIEF_ELGA

M18 693

SIYY 3.56E+07

3.54E+07 0.371

Generalized deformations

DEGE_ELNO_DEPL

:

Loading case

Loadings

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

EPXX

1.38155E-06 1.38155E-06

0.04

F

Y

= 3.10

2

2 F

X

= 3.10

2

GAXY 3.5920E-06

4.7415E06

32

F

Y

= 4.10

2

KZ 1.0530E02

1.04E02

1.2

3 F

Z

= 5.10

2

GAXZ

3.5920E-06

4.7415E06

32

KY

1.0530E02

1.04E02

1.2

4 M

X

= 4.10

2

GAT 2.73783E-03

2.73783E-03

0

M

Y

= 3.10

2

5 M

X

= 3.10

2

KY

2.1060E-03

2.1052E-03

0.04

M

Y

= 4.10

2

6 M

Z

= 5 10

2

KZ 2.1060E-03

2.1052E-03

0.04

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

10/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

6.2 Remarks

The values of shearings corresponding to the shearing action are not precise for this

modeling. This is due to the functions of interpolation of command 2 of this element, for displacements

of beam and rotations of beams. As transverse shearings of beam are obtained

by:

dx

y

Z

xy

-

=

, and that for the pure bending, rotations vary like polynomials of command 2,

but displacements, like polynomials of command 3, which is badly approached by the functions

of interpolation. The derivative of displacements is thus not precise.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

11/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

7 Modeling

C

7.1

Characteristics of modeling

10 elements

TUYAU_6M

.

7.2

Characteristics of the mesh

10 meshs

SEG3

. The beam is directed according to the vector (4, 3, 0).

7.3 Functionalities

tested

Controls

AFFE_MODELE MODELING

TUYAU_6M

AFFE_CARA_ELEM BEAM

SECTION RINGS

MACRO_ELAS_MULT

OPTION

SIEF_ELGA_DEPL

OPTION

EPSI_ELGA_DEPL

OPTION

EFGE_ELNO_DEPL

Notice on the contents of the fields:

Fields at the points of Gauss for the element PIPE

,

EPSI_ELGA_DEPL

and

SIEF_ELGA_DEPL,

who provide the strains and the stresses to the points of integration

in the local reference mark of the element, are organized in the following way:

The values are stored:

·

for each point of Gauss in the length, (n=1, 3)

·

for each point of integration in the thickness, (n=1, 2N

NECK

+1=7)

·

for each point of integration on the circumference, (n=1, 2N

SECT

+1=33)

·

6 components of strain or stresses:

EPXX EPYY EPZZ EPXY EPXZ EPYZ

or

SIXX SIYY SIZZ SIXY

SIXZ SIYZ

where X indicates the direction given by the two nodes nodes of

the element, Y represents the angle

describing the circumference and Z

represent the radius.

EPZZ

and

EPYZ

agent with

rr

R

,

in

case of the deformations and

SIZZ

and

SIYZ

agent with

rr

R

,

in

the case of the stresses is taken equal to zero.

(for

MECA_STATIQUE

or

MACRO_ELAS_MULT

, the number of layers is fixed, and equal to 3, and

the number of sectors is equal to 16).

EFGE_ELNO_DEPL

represent the efforts generalize with the 3 nodes in the conventional way:

NR,

VY, VZ, MT, MFY, MFZ

.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

12/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

8

Results of modeling C

8.1 Values

tested

Loading case

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

DX

5.53E06

5.52E06

0.04

1 F

Y

= 3.10

2

DY

4.14E06

4.14E06

0.04

2 F

X

= 3.10

2

DRZ

2.63E02

2.63E02

0.04

2 F

Y

= 4.10

2

DX

5.27E02

5.26E02

0.056

2

DY

7.02E02

7.02E02

0.056

3 F

Z

= 5.10

2

DRX

1.58E02

1.58E02

0.04

3

DRY

2.11E02

2.11E02

0.039

3

DZ

8.78E02

8.77E02

0.056

4 M

X

= 4.10

2

DRX

1.10E02

1.10E02

0

4 M

Y

= 3.10

2

DRY

8.21E03

8.21E03

0

5 M

X

= 3.10

2

DRX

6.32E03

6.32E03

0.04

5 M

Y

= 4.10

2

DRY

8.42E03

8.42E03

0.04

5

DZ

2.63E02

2.63E02

0.04

6 M

Z

= 5 10

2

DRZ

1.05E02

1.05E02

0.039

6

DX

1.58E02

1.58E02

0.04

6

DY

2.11E02

2.11E02

0.039

7: pressure

WO

7.38E06

7.16E06

2.946

8: gravity

DZ

4.646

E-02 4.642

E-02

0.09

9: charge distributed

DZ

4.646

E-02 4.642

E-02

0.09

Loading case

Field

Net Point Component Reference

Aster %

difference

1

EFGE_ELNO_DEPL

M18 1 NR

5.00E+02

5.01E+02 0.136

1

EPSI_ELGA_DEPL

M18 1 EPXX 1.38E06

1.38E06

0.031

1

SIEF_ELGA_DEPL

M18 1 SIXX 2.76E+05

2.73E+05

1.159

4

EFGE_ELNO_DEPL

M18 1 MT

5.00E+02

5.00E+02 0

4

EPSI_ELGA_DEPL

M18 1 EPXY 8.77E05 8.76E05

0.102

4

EPSI_ELGA_DEPL

M18 693

EPXY 1.09E04 1.10E04 0.049

4

SIEF_ELGA_DEPL

M18 1 SIXY 6.75E+06 6.74E+06

0.159

4

SIEF_ELGA_DEPL

M18 693

SIXY 8.42E+06 8.42E+06 0.049

5

EFGE_ELNO_DEPL

M18 1 MFY 5.00E+02

5.01E+02 0.123

5

EPSI_ELGA_DEPL

M18 479

EPXX

6.74E05

6.74E05 0.046

5

SIEF_ELGA_DEPL

M18 479

SIXX

1.35E+07

1.33E+07 1.288

6

EFGE_ELNO_DEPL

M18 1 MFZ 5.00E+02

5.01E+02 0.123

6

EPSI_ELGA_DEPL

M18 471

EPXX

6.74E05

6.74E05 0.046

6

SIEF_ELGA_DEPL

M18 471

SIXX

1.35E+07

1.33E+07 1.288

7

EPSI_ELGA_DEPL

M18 1 EPYY 2.28E04

2.24E04

1.716

7

EPSI_ELGA_DEPL

M18 693

EPYY

1.78E04

1.79E04 0.741

7

SIEF_ELGA_DEPL

M18 1 SIYY 4.56E+07

4.53E+07

0.641

7

SIEF_ELGA_DEPL

M18 693

SIYY

3.56E+07

3.54E+07 0.371

8

EFGE_ELNO_DEPL

M1 1 MFY

1764.3

1728

2

9

EFGE_ELNO_DEPL

M1 1 MFY

1764.3

1728

2

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

13/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

Generalized deformations

DEGE_ELNO_DEPL

:

Loading case

Loadings

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

EPXX

1.38155E-06 1.38155E-06

0.04

F

Y

= 3.10

2

2 F

X

= 3.10

2

GAXY 3.5920E-06

4.7415E06

32

F

Y

= 4.10

2

KZ 1.0530E02

1.04E02

1.2

3 F

Z

= 5.10

2

GAXZ

3.5920E-06

4.7415E06

32

KY

1.0530E02

1.04E02

1.2

4 M

X

= 4.10

2

GAT 2.73783E-03

2.73783E-03

0

M

Y

= 3.10

2

5 M

X

= 3.10

2

KY

2.1060E-03

2.1052E-03

0.04

M

Y

= 4.10

2

6 M

Z

= 5 10

2

KZ 2.1060E-03

2.1052E-03

0.04

Fréquenc

E clean

Reference

Aster %

difference

1 2.90229 2.90378

0.05

2 2.90229 2.

90378

0.05

3 18.18967 18.2047 0.08

4 18.18967 18.2047 0.08

5 50.99367 51.006 0.02

6 50.99367 51.006 0.02

7 99.81783 100.0478 0.2

8 99.81783 100.0478 0.2

9 157.0190 157.0185 0.001

10 164.9922

165.606

0.3

11 164.9922

165.606

0.3

12 253.185

247.82

2

8.2 Remarks

The values of shearings corresponding to the shearing action are not precise for this

modeling. This is due to the functions of interpolation of command 2 of this element, for displacements

of beam and rotations of beams. As transverse shearings of beam are obtained

by:

dx

y

Z

xy

-

=

, and that for the pure bending, rotations vary like polynomials of command 2,

but displacements, like polynomials of command 3, which is badly approached by the functions

of interpolation. The derivative of displacements is thus not precise.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

14/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

9 Modeling

D

9.1

Characteristics of modeling

10 elements

TUYAU_6M

, calculation with

STAT_NON_LINE

.

9.2

Characteristics of the mesh

10 meshs

SEG3

. The beam is directed according to the vector (4, 3, 0).

9.3 Functionalities

tested

Controls

AFFE_MODELE

MODELING

TUYAU_6M

AFFE_CARA_ELEM BEAM

SECTION

RING

STAT_NON_LINE COMP_INCR

RELATION ELAS

COMP_INCR

TUYAU_NCOU

3

COMP_INCR

TUYAU_NSEC

16

OPTION

SIEF_ELNO_ELGA

Notice on the contents of the fields:

Stress fields at the points of Gauss for the element PIPE,

SIEF_ELGA,

in

the local reference mark of the element, are organized in the following way:

The values are stored:

·

for each point of Gauss in the length, (n=1, 3)

·

for each point of integration in the thickness, (n=1, 2N

NECK

+1)

·

for each point of integration on the circumference, (n=1, 2N

SECT

+1)

·

6 components of strain or stresses:

EPXX EPYY EPZZ EPXY EPXZ EPYZ

or

SIXX SIYY SIZZ SIXY

SIXZ SIYZ

where X indicates the direction given by the two nodes nodes of

the element, Y represents the angle

describing the circumference and Z

represent the radius.

EPZZ

and

EPYZ

agent with

rr

R

,

in

case of the deformations and

SIZZ

and

SIYZ

agent with

rr

R

,

in

the case of the stresses is taken equal to zero.

(in

STAT_NON_LINE

, the number of layers is variable, as well as the number of sectors.

One uses here 3 layers and 16 sectors by analogy with modeling A).

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

15/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

10 Results of modeling D

10.1 Values

tested

Loading case

Size

Reference

Aster %

difference

1 DX

5.53E06

5.52E06

0.04

1 DY

4.14E06

4.14E06

0.04

2 DRZ

2.63E02

2.63E02

0.04

2 DX

5.27E02

5.26E02

0.056

2 DY

7.02E02

7.02E02

0.056

3 DRX

1.58E02

1.58E02

0.04

3 DRY

2.11E02

2.11E02

0.039

3 DZ

8.78E02

8.77E02

0.056

4 DRX

1.10E02

1.10E02

0

4 DRY

8.21E03

8.21E03

0

5 DRX

6.32E03

6.32E03

0.04

5 DRY

8.42E03

8.42E03

0.04

5 DZ

2.63E02

2.63E02

0.04

6 DRZ

1.05E02

1.05E02

0.039

6 DX

1.58E02

1.58E02

0.04

6 DY

2.11E02

2.11E02

0.039

7 WO

7.38E06

7.16E06

2.946

Loading case

Field

Net

Not Component Reference

Aster %

difference

1

SIEF_ELGA

M18 Z SIXX 2.76E+05

2.73E+05

1.159

1

SIEF_ELNO_ELGA

M18 1 NR 5.00E+02

5.01E+02 0.136

4

SIEF_ELGA

M18 1 SIXY 6.75E+06

6.74E+06

0.159

4

SIEF_ELGA

M18 693

SIXY 8.42E+06

8.42E+06 0.049

4

SIEF_ELNO_ELGA

M18 1 MT 5.00E+02

5.00E+02 0

5

SIEF_ELGA

M18 479

SIXX 1.35E+07

1.33E+07 1.288

5

SIEF_ELNO_ELGA

M18 1 MFY 5.00E+02

5.01E+02 0.123

6

SIEF_ELGA

M18 471

SIXX 1.35E+07

1.33E+07 1.288

6

SIEF_ELNO_ELGA

M18 1 MFZ 5.00E+02

5.01E+02 0.123

7

SIEF_ELGA

M18 1 SIYY 4.56E+07

4.53E+07

0.641

7

SIEF_ELGA

M18 693

SIYY 3.56E+07

3.54E+07 0.371

Generalized deformations

DEGE_ELNO_DEPL

:

Loading case

Loadings

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

EPXX

1.38155E-06 1.38155E-06

0.04

F

Y

= 3.10

2

2 F

X

= 3.10

2

GAXY 3.5920E-06

4.7415E06

32

F

Y

= 4.10

2

KZ 1.0530E02

1.04E02

1.2

3 F

Z

= 5.10

2

GAXZ

3.5920E-06

4.7415E06

32

KY

- 1.0530E02

- 1.04E02

1.2

4 M

X

= 4.10

2

GAT 2.73783E-03

2.73783E-03

0

M

Y

= 3.10

2

5 M

X

= 3.10

2

KY

2.1060E-03

2.1052E-03

0.04

M

Y

= 4.10

2

6 M

Z

= 5 10

2

KZ 2.1060E-03

2.1052E-03

0.04

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

16/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

10.2 Remarks

The values of shearings corresponding to the shearing action are not precise for this

modeling. This is due to the functions of interpolation of command 2 of this element, for displacements

of beam and rotations of beams. As transverse shearings of beam are obtained

by:

dx

y

Z

xy

-

=

, and that for the pure bending, rotations vary like polynomials of command 2,

but displacements, like polynomials of command 3, which is badly approached by the functions

of interpolation. The derivative of displacements is thus not precise.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

17/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

11 Modeling

E

11.1 Characteristics of modeling

8 elements

PIPE

with 3 modes of Fourier and 4 nodes

11.2 Characteristics of the mesh

8 meshs

SEG4

. The beam is directed according to the vector (4, 3, 0).

11.3 Functionalities

tested

Controls

AFFE_MODELE MODELING

PIPE

AFFE_CARA_ELEM BEAM

SECTION

RING

MACRO_ELAS_MULT

OPTION

SIEF_ELGA_DEPL

OPTION

EPSI_ELGA_DEPL

OPTION

EFGE_ELNO_DEPL

CREA_MAILLAGE OPTION

SEG3_4

Notice on the contents of the fields:

Fields at the points of Gauss for the element PIPE

,

EPSI_ELGA_DEPL

and

SIEF_ELGA_DEPL,

who provide the strains and the stresses to the points of integration

in the local reference mark of the element, are organized in the following way:

The values are stored:

·

for each point of Gauss in the length, (n=1, 3)

·

for each point of integration in the thickness, (n=1, 2N

NECK

+1=7)

·

for each point of integration on the circumference, (n=1, 2N

SECT

+1=33)

·

6 components of strain or stresses:

EPXX EPYY EPZZ EPXY EPXZ EPYZ

or

SIXX SIYY SIZZ SIXY

SIXZ SIYZ

where X indicates the direction given by the two nodes nodes of

the element, Y represents the angle

describing the circumference and Z

represent the radius.

EPZZ

and

EPYZ

agent with

rr

R

,

in

case of the deformations and

SIZZ

and

SIYZ

agent with

rr

R

,

in the case of the stresses are taken equal to zero.

(for

MECA_STATIQUE

or

MACRO_ELAS_MULT

, the number of layers is fixed, and equal to 3, and

the number of sectors is equal to 16).

EFGE_ELNO_DEPL

represent the efforts generalize with the 3 nodes in the conventional way:

NR,

VY, VZ, MT, MFY, MFZ

.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

18/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

12 Results of modeling E

12.1 Values

tested

Loading case

Size

Reference

Aster %

difference

F

X

= 4.10

2

DX

5.53E06

5.52E06

0.04

F

Y

= 3.10

2

DY 4.14E06

4.14E06

0.04

F

X

= 3.10

2

DRZ 2.63E02 2.63E02

0.04

F

Y

= 4.10

2

DX

5.27E02

5.264E02

0.02

DY

7.02E02

7.019E02

0.02

F

Z

= 5.10

2

DRX

1.58E02

1.58E02

0.04

DRY

2.11E02

2.11E02

0.04

DZ

8.78E02

8.77E02

0.02

M

X

= 4.10

2

DRX

1.10E02

1.10E02

0

M

Y

= 3.10

2

DRY

8.21E03

8.21E03

0

M

X

= 3.10

2

DRX

6.32E03

6.32E03

0.04

M

Y

= 4.10

2

DRY

8.42E03

8.42E03

0.04

DZ

2.63E02

2.63E02

0.04

M

Z

= 5 10

2

DRZ

1.05E02

1.05E02

0.039

DX

1.58E02

1.58E02

0.04

DY

2.11E02

2.11E02

0.039

7: pressure

WO

7.38E06

7.16E06

2.946

8: gravity

DZ

4.646

E-02 4.644

E-02 0.04

9: charge distributed

DZ

4.646

E-02 4.644

E-02 0.04

Loading case

Field

Net

Not Component Reference

Aster %

difference

1

EFGE_ELNO_DEPL

M18 1 NR

5.00E+02

5.01E+02

0.136

1

EPSI_ELGA_DEPL

M18 1 EPXX 1.38E06

1.38E06

0.031

1

SIEF_ELGA_DEPL

M18 1 SIXX 2.76E+05

2.73E+05

1.159

4

EFGE_ELNO_DEPL

M18 1 MT 5.00E+02

5.00E+02

0

4

EPSI_ELGA_DEPL

M18 1 EPXY

8.77E05 8.76E05

0.102

4

EPSI_ELGA_DEPL

M18 693

EPXY 1.09E04 1.10E04 0.049

4

SIEF_ELGA_DEPL

M18 1 SIXY 6.75E+06 6.74E+06

0.159

4

SIEF_ELGA_DEPL

M18 693

SIXY 8.42E+06 8.42E+06 0.049

5

EFGE_ELNO_DEPL

M18 1 MFY 5.00E+02

5.01E+02

0.123

5

EPSI_ELGA_DEPL

M18 479

EPXX 6.74E05

6.74E05 0.046

5

SIEF_ELGA_DEPL

M18 479

SIXX

1.35E+07

1.33E+07 1.288

6

EFGE_ELNO_DEPL

M18 1 MFZ 5.00E+02

5.01E+02

0.123

6

EPSI_ELGA_DEPL

M18 471

EPXX 6.74E05

6.74E05 0.046

6

SIEF_ELGA_DEPL

M18 471

SIXX

1.35E+07

1.33E+07 1.288

7

EPSI_ELGA_DEPL

M18 1 EPYY 2.28E04

2.24E04

1.716

7

EPSI_ELGA_DEPL

M18 693

EPYY 1.78E04

1.79E04 0.741

7

SIEF_ELGA_DEPL

M18 1 SIYY 4.56E+07

4.53E+07

0.641

7

SIEF_ELGA_DEPL

M18 693

SIYY

3.56E+07

3.54E+07 0.371

8

EFGE_ELNO_DEPL

M1 1 MFY

1764.3

1760

0.2

9

EFGE_ELNO_DEPL

M1 1 MFY

1764.3

1760

0.2

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

19/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

Generalized deformations

DEGE_ELNO_DEPL

:

Loading case

Loadings

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

EPXX

1.38155E-06

1.38155E-06

0.04

F

Y

= 3.10

2

2 F

X

= 3.10

2

GAXY 3.5920E-06 4.7415E06 1.1

F

Y

= 4.10

2

KZ

1.0530E02

1.04E02 0.05

3 F

Z

= 5.10

2

GAXZ 3.5920E-06

4.7415E06 1.1

KY

1.0530E02

1.04E02

0.05

4 M

X

= 4.10

2

GAT 2.73783E-03

2.73783E-03

0

M

Y

= 3.10

2

5 M

X

= 3.10

2

KY

2.1060E-03 2.1052E-03 0.04

M

Y

= 4.10

2

6 M

Z

= 5 10

2

KZ

2.1060E-03 2.1052E-03

0.04

Fréquenc

E clean

Reference

Aster %

difference

1 2.90229

2.90303

0.02

2 2.90229

2.90303

0.02

3 18.18967

18.171 0.1

4 18.18967

18.171 0.1

5 50.99367

50.781 0.4

6 50.99367

50.781 0.4

7 99.81783

99.923 0.6

8 99.81783

99.923 0.6

9 157.0190

157.0185 0.001

12.2 Remarks

The values of shearings corresponding to the shearing action are precise for this modeling.

This is due to the functions of interpolation of command 3 of this element, for displacements of beam and

rotations of beams.

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

20/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

13 Modeling

F

13.1 Characteristics of modeling

1 elements

TUYAU_3M

with 4 nodes, calculation with

STAT_NON_LINE

.

13.2 Characteristics of the mesh

1 meshs

SEG4

. The beam is directed according to the vector (4, 3, 0).

13.3 Functionalities

tested

Controls

AFFE_MODELE

MODELING

PIPE

AFFE_CARA_ELEM BEAM

SECTION RINGS

STAT_NON_LINE COMP_INCR

RELATION ELAS

COMP_INCR

TUYAU_NCOU

3

COMP_INCR

TUYAU_NSEC

16

OPTION

SIEF_ELNO_ELGA

CREA_MAILLAGE OPTION

SEG3_4

Notice on the contents of the fields:

Stress fields at the points of Gauss for the element PIPE,

SIEF_ELGA,

in

the local reference mark of the element, are organized in the following way:

The values are stored:

·

for each point of Gauss in the length, (n=1, 3)

·

for each point of integration in the thickness, (n=1, 2N

NECK

+1)

·

for each point of integration on the circumference, (n=1, 2N

SECT

+1)

·

6 components of strain or stresses:

EPXX EPYY EPZZ EPXY EPXZ EPYZ

or

SIXX SIYY SIZZ SIXY

SIXZ SIYZ

where X indicates the direction given by the two nodes nodes of

the element, Y represents the angle

describing the circumference and Z

represent the radius.

EPZZ

and

EPYZ

agent with

rr

R

,

in

case of the deformations and

SIZZ

and

SIYZ

agent with

rr

R

,

in

the case of the stresses is taken equal to zero.

(in

STAT_NON_LINE

, the number of layers is variable, as well as the number of sectors.

One uses here 3 layers and 16 sectors by analogy with modeling A).

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

21/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

14 Results of modeling F

14.1 Values

tested

Loading case

Size

Reference

Aster %

difference

1 DX

5.53E06

5.52E06 0.04

1 DY

4.14E06

4.14E06 0.04

2 DRZ

2.63E02

2.63E02 0.04

2 DX

5.27E02

5.26E02 0.02

2 DY

7.02E02

7.02E02 0.02

3 DRX

1.58E02

1.58E02 0.04

3 DRY

2.11E02

2.11E02 0.02

3 DZ

8.78E02

8.77E02 0.04

4 DRX

1.10E02

1.10E02 0

4 DRY

8.21E03

8.21E03 0

5 DRX

6.32E03

6.32E03 0.04

5 DRY

8.42E03

8.42E03 0.04

5 DZ

2.63E02

2.63E02 0.04

6 DRZ

1.05E02

1.05E02 0.04

6 DX

1.58E02

1.58E02 0.04

6 DY

2.11E02

2.11E02 0.04

7 WO

7.38E06

7.167E06 3.3

Loading case

Field

Net

Not Component Reference

Aster %

difference

1

SIEF_ELGA

M18 Z SIXX 2.76E+05

2.73E+05

1.159

1

SIEF_ELNO_ELGA

M18 1 NR 5.00E+02

5.01E+02 0.136

4

SIEF_ELGA

M18 1 SIXY 6.75E+06

6.74E+06

0.159

4

SIEF_ELGA

M18 693

SIXY 8.42E+06

8.42E+06 0.049

4

SIEF_ELNO_ELGA

M18 1 MT 5.00E+02

5.00E+02 0

5

SIEF_ELGA

M18 479

SIXX 1.35E+07

1.33E+07 1.288

5

SIEF_ELNO_ELGA

M18 1 MFY 5.00E+02

5.01E+02 0.123

6

SIEF_ELGA

M18 471

SIXX 1.35E+07

1.33E+07 1.288

6

SIEF_ELNO_ELGA

M18 1 MFZ 5.00E+02

5.01E+02 0.123

7

SIEF_ELGA

M18 1 SIYY 4.56E+07

4.53E+07

0.641

7

SIEF_ELGA

M18 693

SIYY 3.56E+07

3.54E+07 0.371

Generalized deformations

DEGE_ELNO_DEPL

:

Loading case

Loadings

Size

Reference

Aster %

difference

1 F

X

= 4.10

2

EPXX

1.38155E-06 1.38155E-06

0.04

F

Y

= 3.10

2

2 F

X

= 3.10

2

GAXY 3.5920E-06

4.7415E06

21

F

Y

= 4.10

2

KZ 1.0530E02

1.04E02

0.04

3 F

Z

= 5.10

2

GAXZ

3.5920E-06

4.7415E06

21

KY

1.0530E02

1.04E02

0.04

4 M

X

= 4.10

2

GAT 2.73783E-03

2.73783E-03

0

M

Y

= 3.10

2

5 M

X

= 3.10

2

KY

2.1060E-03

2.1052E-03

0.04

M

Y

= 4.10

2

6 M

Z

= 5 10

2

KZ 2.1060E-03

2.1052E-03

0.04

Code_Aster

®

Version

7.2

Titrate:

SSLL106 - Right pipe

Date:

05/01/04

Author (S)

:

J. Mr. PROIX

Key:

V3.01.106-B

Page:

22/22

Manual of Validation

V3.01 booklet: Linear statics of the linear structures

HT-66/03/008/A

14.2 Remarks

The values of shearings corresponding to the shearing action are not precise for this

modeling. This is due to the weak discretization for this modeling (only one element).

15 Summary of the results

This test makes it possible to check the correct operation of the element

PIPE

(3 modes and 6 modes of Fourier)

in linear elasticity, with the operators

MECA_STATIQUE

and

STAT_NON_LINE

, for the whole of

loadings applicable to this element.

The variations compared to the analytical reference solution (solution in assumption of beam) are very

weak for displacements (0,04% to 0,06%), except for the loading of pressure where the variation of 3%

is due to the fact that Wo represents an average radial displacement. Actually this radial displacement varies

in the thickness. The variation on the strains and the stresses

(

)

~

-

1%

is more important than that

on displacements but remains acceptable taking into account the fact that these values are calculated in

points of integration located in the thickness of the pipe.