Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

1/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

Organization (S):

EDF/AMA, INSA-Lyon

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

V3.03.109 document

SSLS109 - Plate in traction made up of three

tablecloths of reinforcements (Model ROASTS)

Summary

This test quasi-static 2D forced plane enters within the framework of the validation of the finite elements in elasticity

linear. A plate made up of three tablecloths of reinforcements offset compared to the average layer is

subjected to a uniaxial traction. The orientations of the reinforcements and the mechanical characteristics are

different for the three tablecloths.

The main interest of this test is to validate in linear elasticity the model “ROASTS” which is in fact an element

of thin section (DKT) with a offsetting compared to the average layer.

The results provided by the model “ROASTS” (modeling B) are identical to those obtained by

modeling “DEFI_COQU_MULT” of Code_Aster (modeling A).

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

2/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

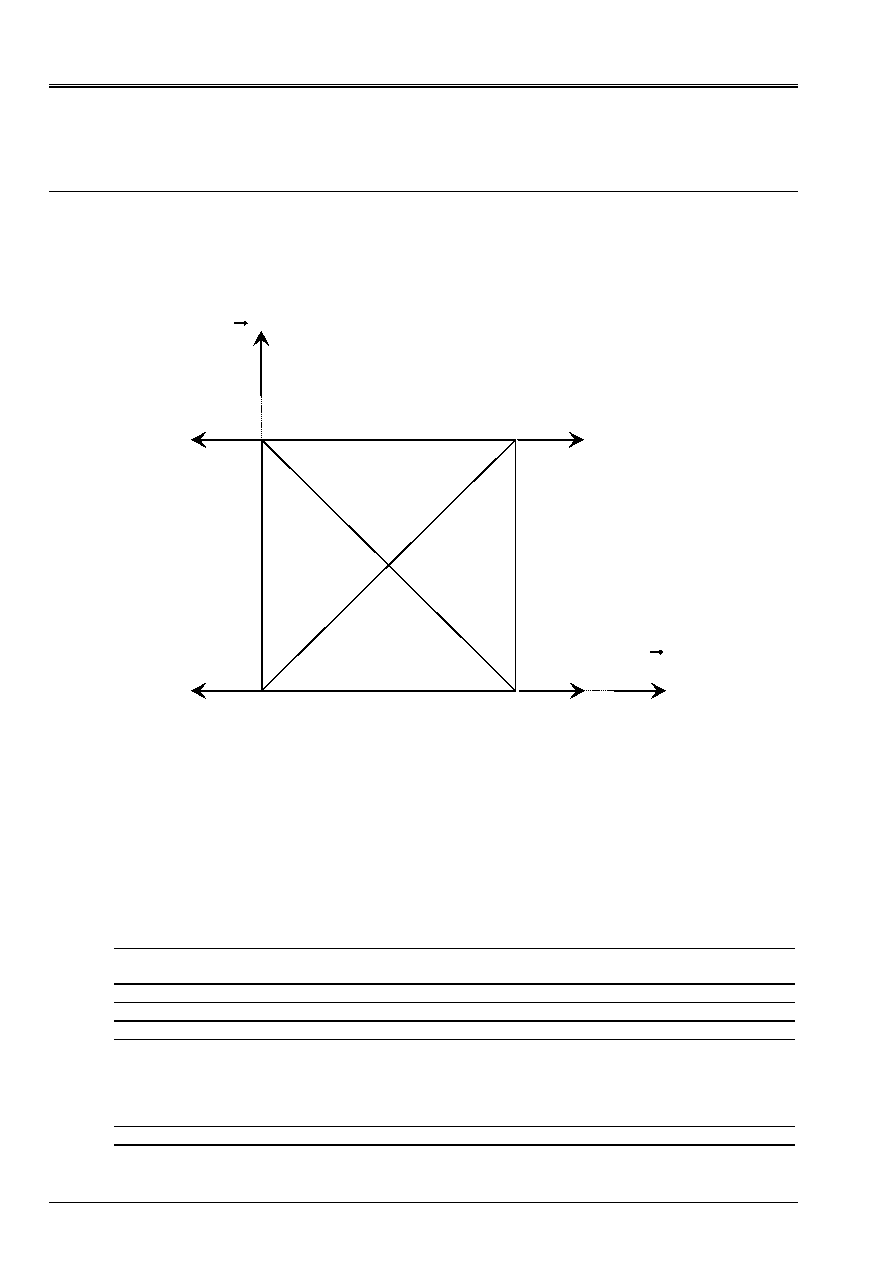

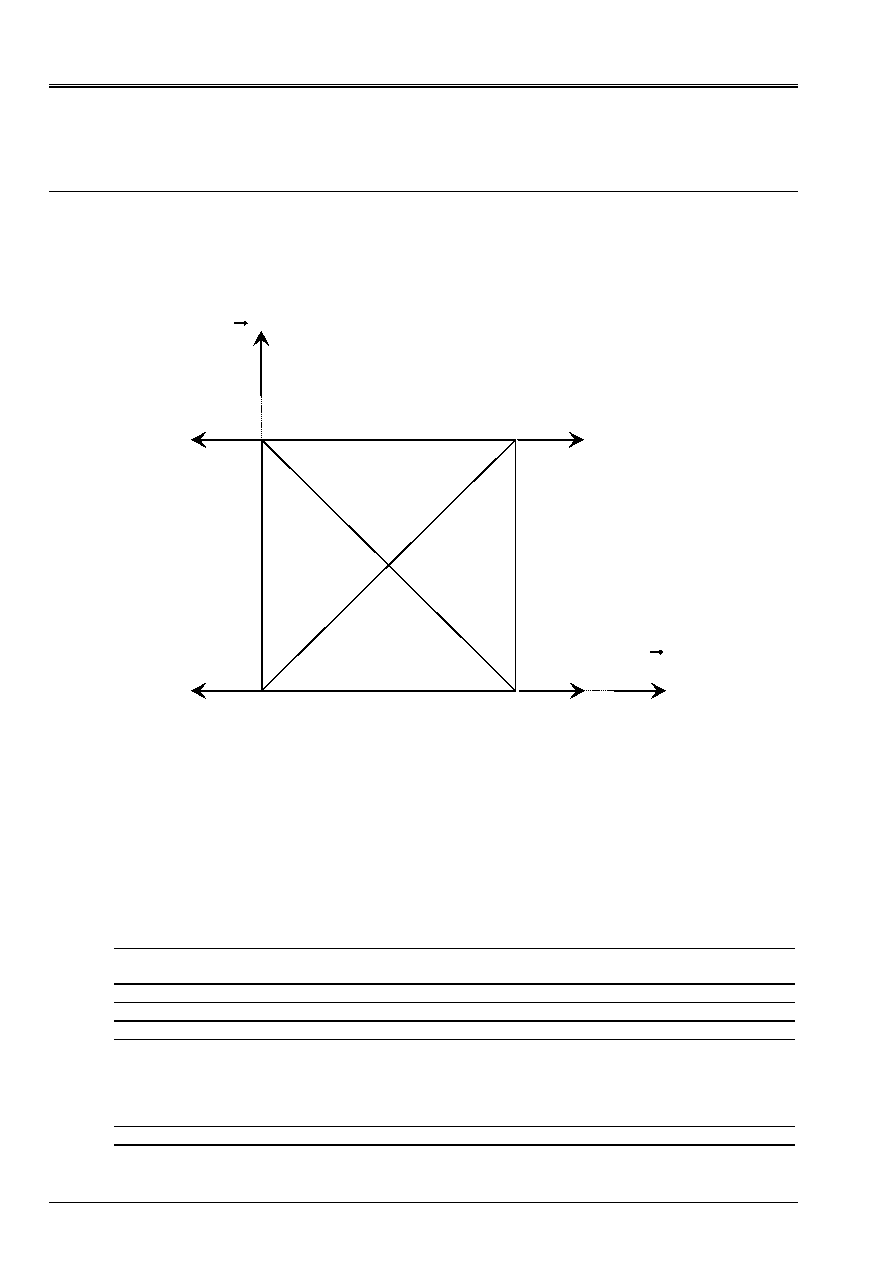

1

Problem of reference

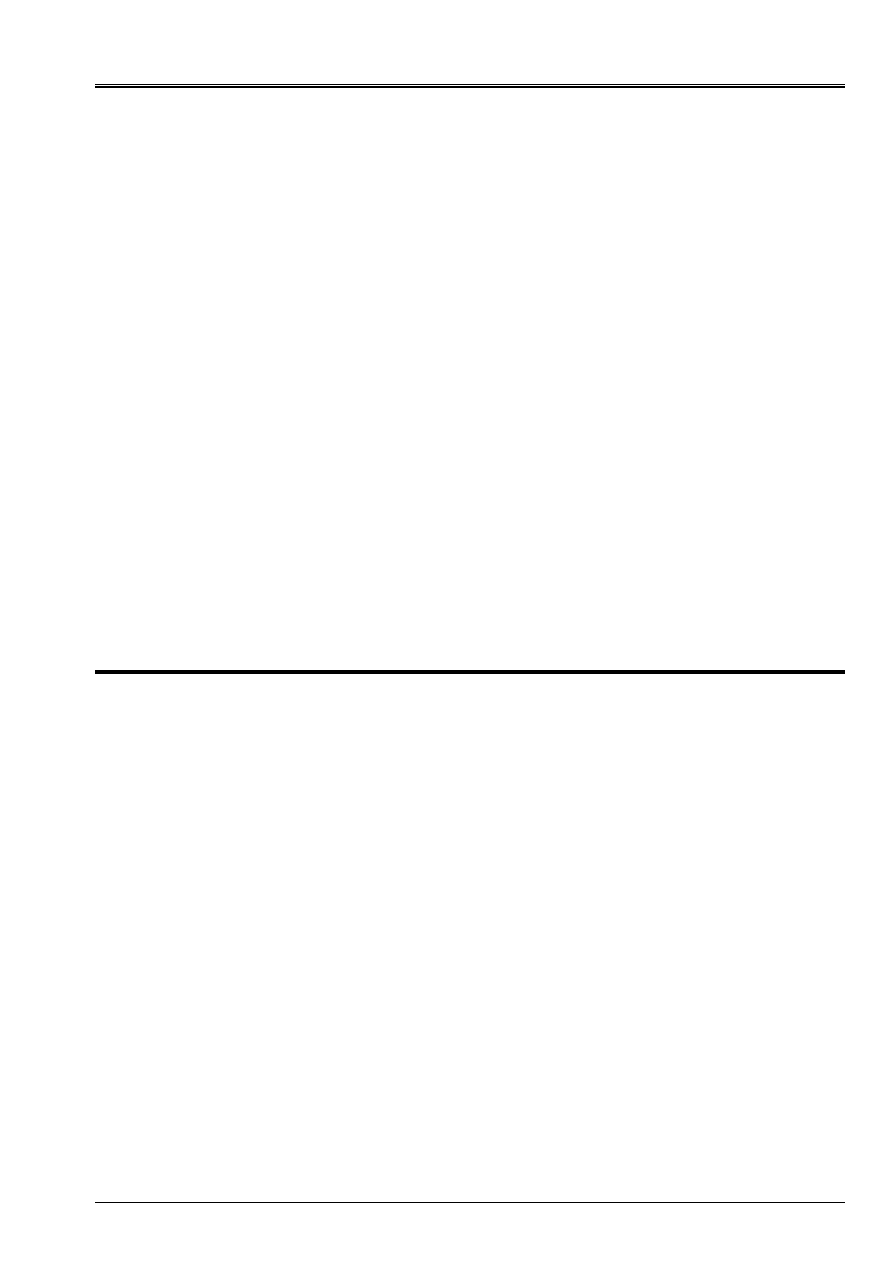

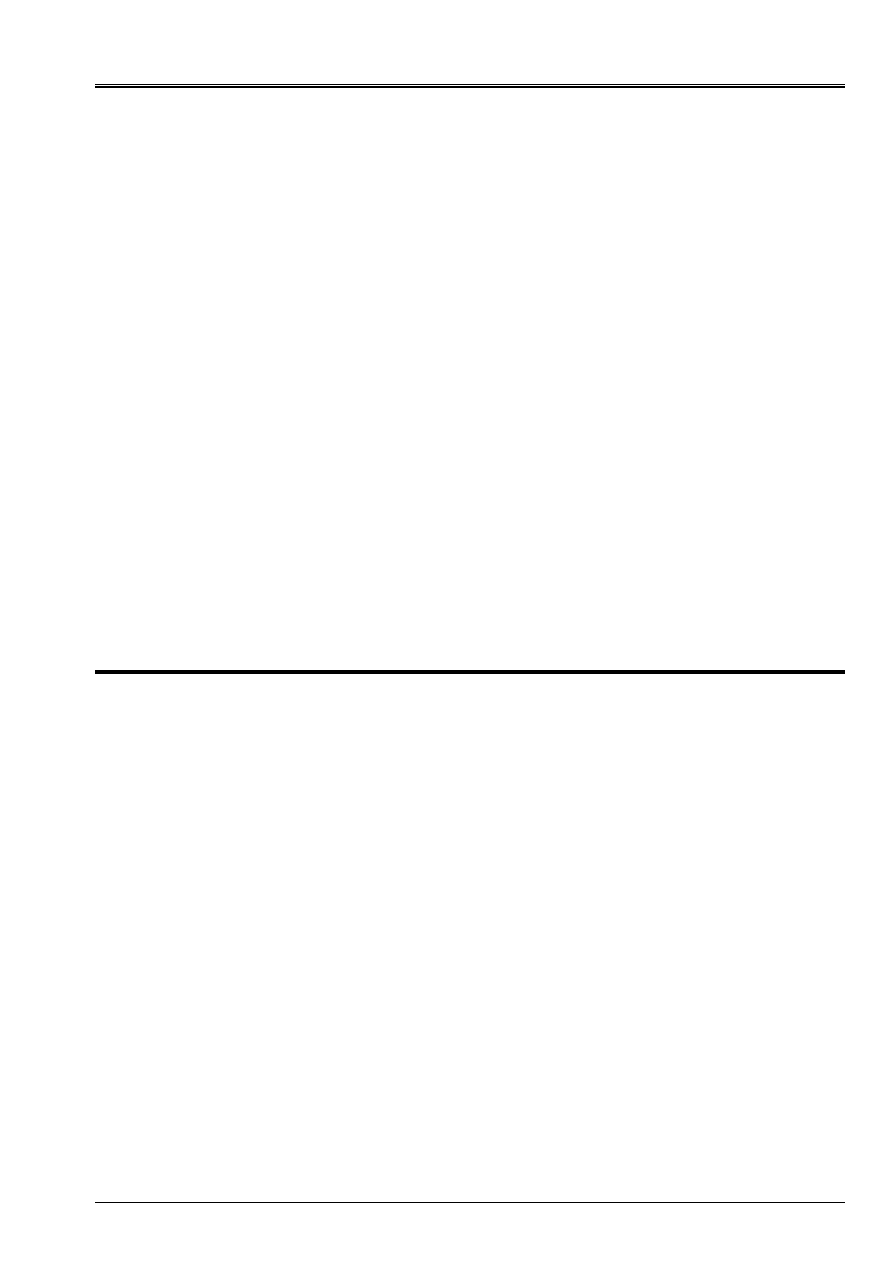

1.1 Geometry

Y

X

X

ref.

30°

NO3

NO4

NO1

NO2

1

2

3

X

Y

Z

E

E

E

X

ref.

X

ref.

- 20°

- 75°

X

ref.

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

3/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

1.2

Properties of materials

Solid 1

1

1

=

E

;

7

1

10

-

=

G

;

0

1

=

;

1

1

1

=

=

T

L

; offsetting = +0,01; épaisseur=0,01

Solid 2

2

2

=

E

;

7

2

10

-

=

G

;

0

2

=

;

1

2

2

=

=

T

L

; offsetting = 0,00; épaisseur= 0,01

Solid 3

3

3

=

E

;

7

3

10

-

=

G

;

0

3

=

;

1

3

3

=

=

T

L

; offsetting = - 0,01; épaisseur= 0,01

1.3

Boundary conditions and loadings

Embedded side NO1-NO4.

One imposes a tensile load on side NO2-NO3: FX = 2

2

Reference solution

2.1 Solution

formal

Model DEFI_COQU_MULT of Code_Aster (modeling A) makes it possible to validate the model

“GRID” proposed (modeling B).

2.2

Numerical values of reference

Values of:

U, v, W,

X

and

y

with node NO2,

membrane deformation:

xy

yy

xx

,

,

in solid 1 calculated with node NO2,

variation of curvature:

xy

yy

xx

,

,

in solid 1 calculated with node NO2,

stresses 3D:

xy

zz

yy

xx

,

,

,

in solid 1 calculated with node NO2.

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

4/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

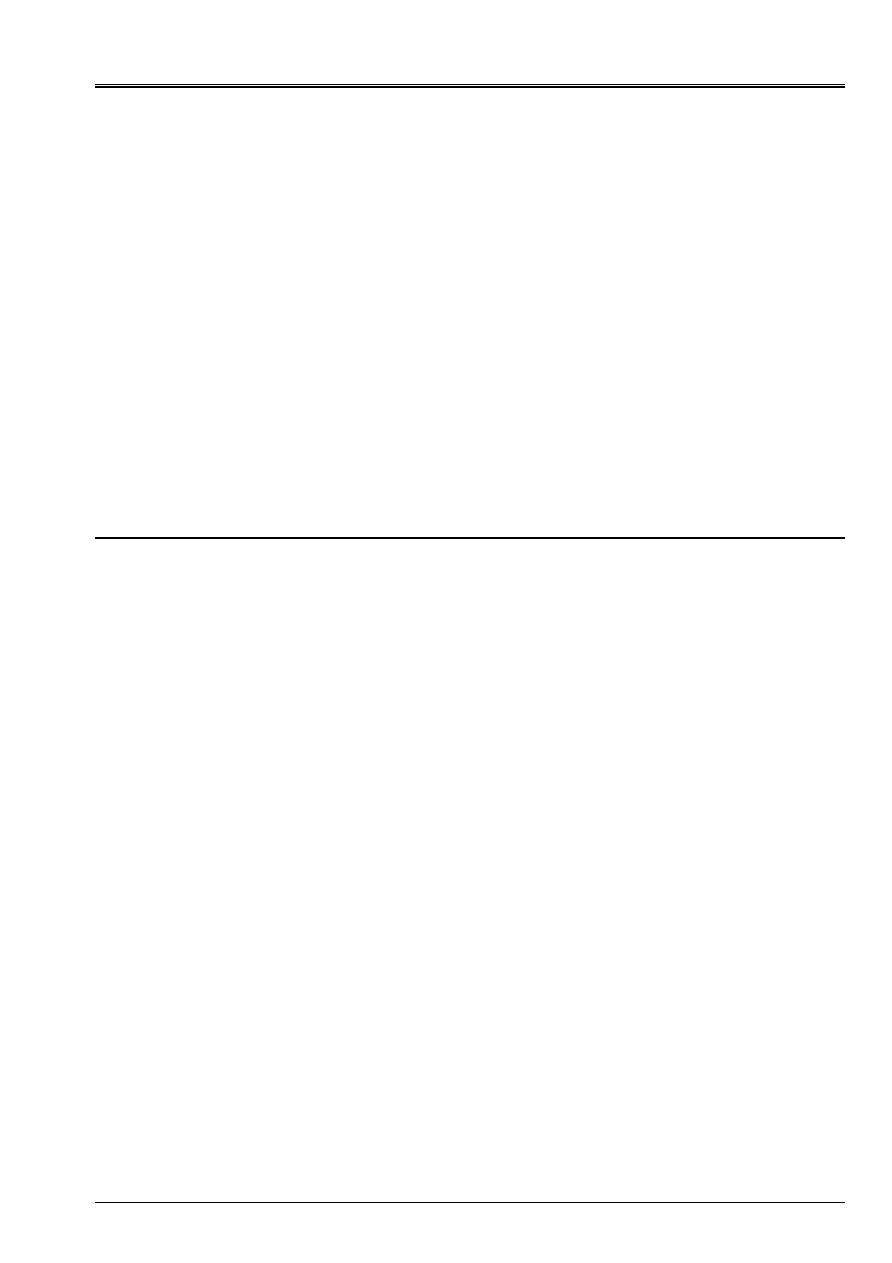

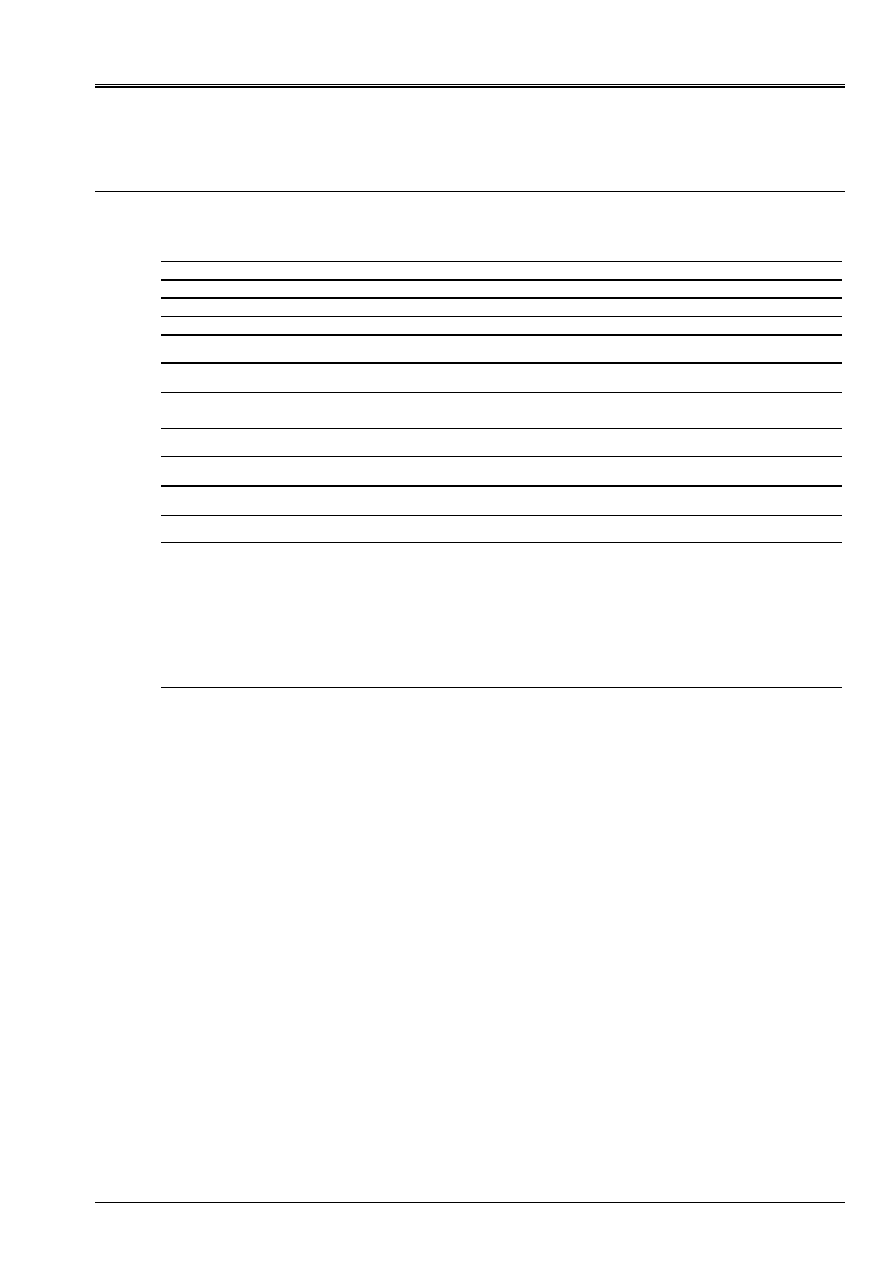

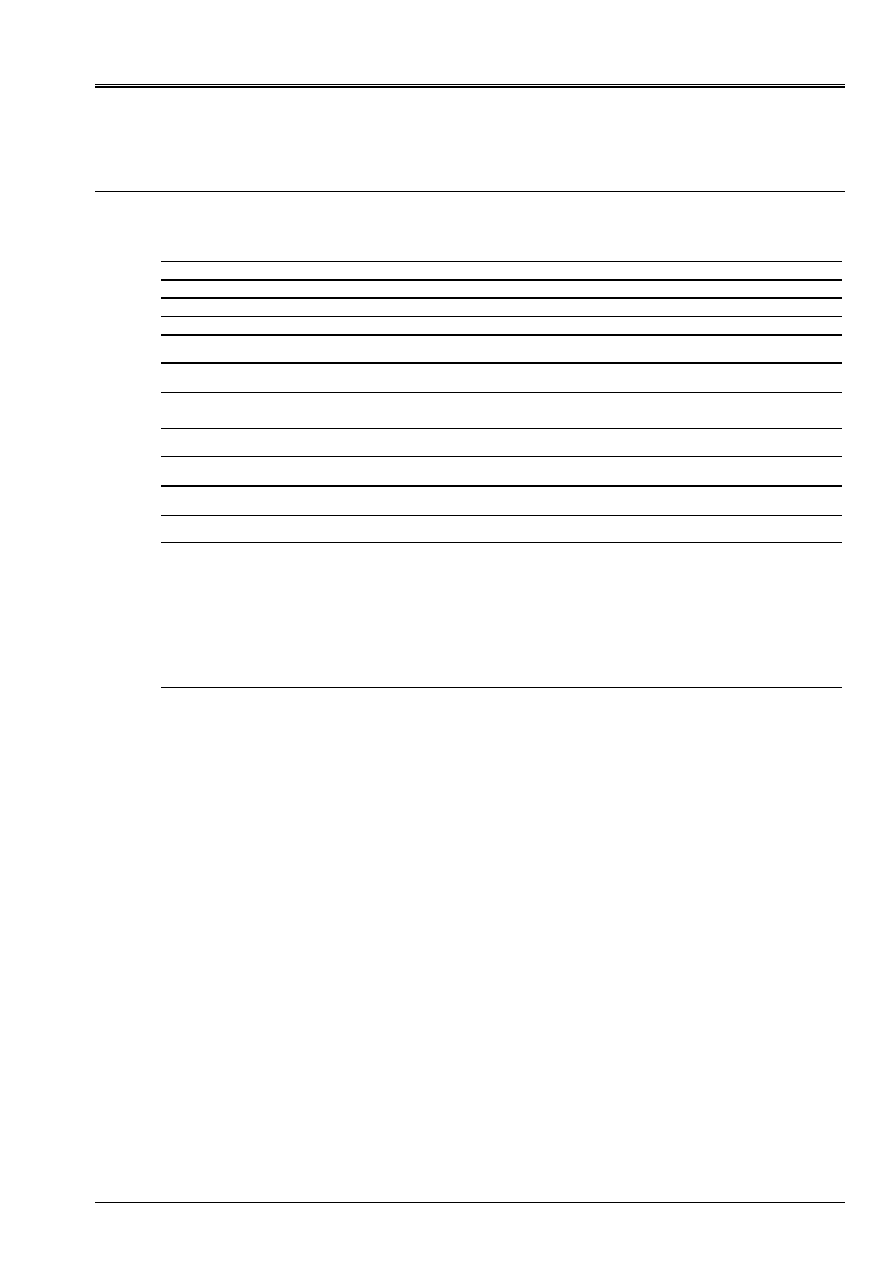

3 Modeling

With

3.1

Characteristics of modeling

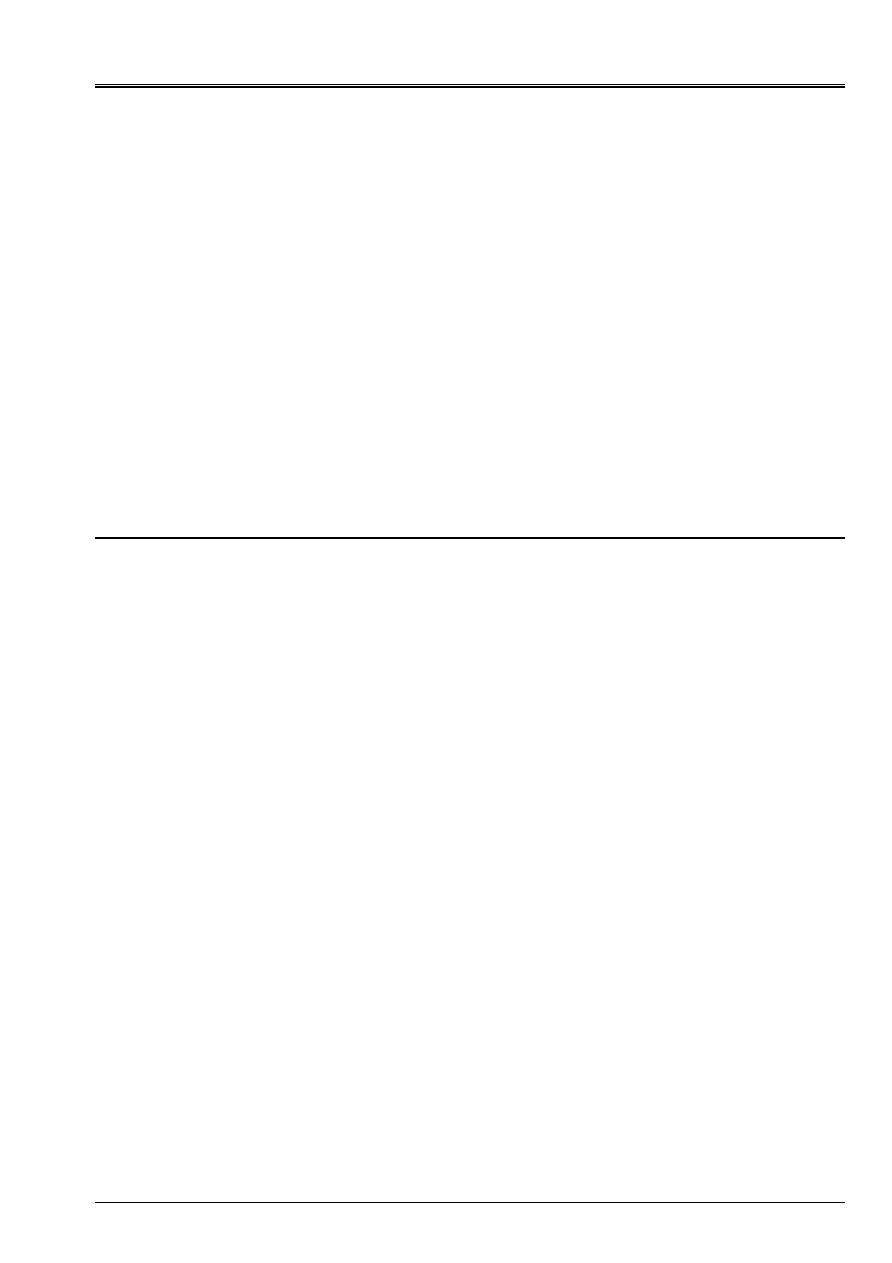

The test-tube is with a grid with four elements “DKT”

1

1

1

1

NO1

NO2

NO3

NO4

NO5

X

Y

Mesh:

A number of nodes: 5

A number of meshs and type: 4 meshs TRIA3

The mesh is symmetrical in order to avoid the parasitic modes of deformations.

3.2

Stages of calculation and functionalities tested

The main stages of calculation correspond to the functionalities which one wishes to validate:

Controls

AFFE_MODELE AFFE MODELING

“DKT”

AFFE_CARA_ELEM HULL

DEFI_MATERIAU ELAS_ORTH

DEFI_COQU_MULT SLEEP

MECA_STATIQUE

CALC_ELEM

CALC_NO

RECU_CHAMP

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

5/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

4

Results of modeling A

Variables

DEFI_COQU_MULT

(modeling A)

Displacements node NO2

U 81.9373

v 18.6398

W 2098.66

X

1239.88

y

3820.42

Deformations node NO2

(Solid 1)

xx

32.9433

yy

2.33011

xy

34.3522

zz

0

Stresses node NO2

(Solid 1)

xx

42.7252

yy

63.0951

xy

5.88029

zz

0

Curvatures node NO2

(Solids 1, 2 and 3)

xx

531.043

yy

2035.19

xy

2058.44

4.1 Remarks

The results presented are given in the reference mark of reference

)

,

(

ref.

ref.

Y

X

R

R

forming an angle of 30°

compared to

)

,

(Y

X R

R

, concerning the deformations, stresses and curvatures.

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

6/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

5

Modeling B (GRID)

5.1

Characteristics of modeling

The test-tube is with a grid with 12 elements “ROASTS” (4 elements by tablecloth of reinforcements) to three

nodes (thin section: formulation DKT with offsetting compared to the datum-line).

nodes are common to each tablecloth.

1

1

1

1

NO1

NO2

NO3

NO4

NO5

X

Y

Mesh:

A number of nodes: 5

A number of meshs and type: 3x4 meshs TRIA3

The mesh is symmetrical in order to avoid the parasitic modes of deformations.

5.2

Stages of calculation and functionalities tested

The main stages of calculation correspond to the functionalities which one wishes to validate:

Controls

AFFE_MODELE AFFE

MODELING “ROASTS”

PHENOMENON

“MECHANICAL”

DEFI_MATERIAU ELAS

AFFE_CARA_ELEM ROASTS

MECA_STATIQUE

CALC_ELEM OPTION

EPSI_ELNO_DEPL

SIGM_ELNO_DEPL

DEGE_ELNO_DEPL

EFGE_ELNO_DEPL

SIEF_ELGA_DEPL

CALC_NO OPTION

FORC_NODA

RECU_CHAMP

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

7/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

6

Results of modeling B

Variables

Modeling A

Modeling B

% difference

Displacements node NO2

U 81.9373

81.9373

0

v 18.6398

18.6398

0

W 2098.66

2098.66

0

X

1239.88 1239.88 0

y

3820.42 3820.42 0

Deformations node NO2

(Solid 1)

xx

32.9433 32.9433 0

yy

2.33011 2.33011 0

xy

34.3522 34.3522 0

zz

0 0

0

Stresses node NO2

(Solid 1)

xx

42.7252 42.7252 0

yy

63.0951 63.0951 0

xy

5.88029 5.88029 0

zz

0 0

0

Curvatures node NO2

(Solids 1, 2 and 3)

xx

531.043 531.043 0

yy

2035.19 2035.19 0

xy

2058.44 2058.44 0

6.1 Remarks

The results presented are given in the reference mark of reference

)

,

(

ref.

ref.

Y

X

R

R

forming an angle of 30°

compared to

)

,

(Y

X R

R

, concerning the deformations, stresses and curvatures

.

Code_Aster

®

Version

5.0

Titrate:

SSLS109 Plaque in traction made up of three tablecloths of reinforcements

Date

:

21/03/02

Author (S):

C. CHAVANT, O. MERABET, Mr. DJERROUD

Key

:

V3.03.109-A

Page:

8/8

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/02/001/A

7

Summary of the results and remarks general

The results of modeling A are identical to those of modeling B.