Code_Aster

®

Version

7.2

Titrate:

SSLS128 - Validation of the option

CRIT_ELNO_RUPT

of

CALC_ELEM

Date:

05/03/04

Author (S):

J.M. PROIX

Key

:

V3.03.128-A

Page:

1/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/04/005/A

Organization (S):

EDF-R & D/AMA

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

Document: V3.03.128

SSLS128 -

CALC_ELEM

: Validation of the option

CRIT_ELNO_RUPT

Summary:

This option allows, in the case of the multi-layer hulls to calculate in a layer the stresses in

identify the aforementioned as well as the corresponding criterion of Tsai-Hill.

Code_Aster

®

Version

7.2

Titrate:

SSLS128 - Validation of the option

CRIT_ELNO_RUPT

of

CALC_ELEM

Date:

05/03/04

Author (S):

J.M. PROIX

Key

:

V3.03.128-A

Page:

2/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/04/005/A

1

Problem of reference

1.1 Geometry

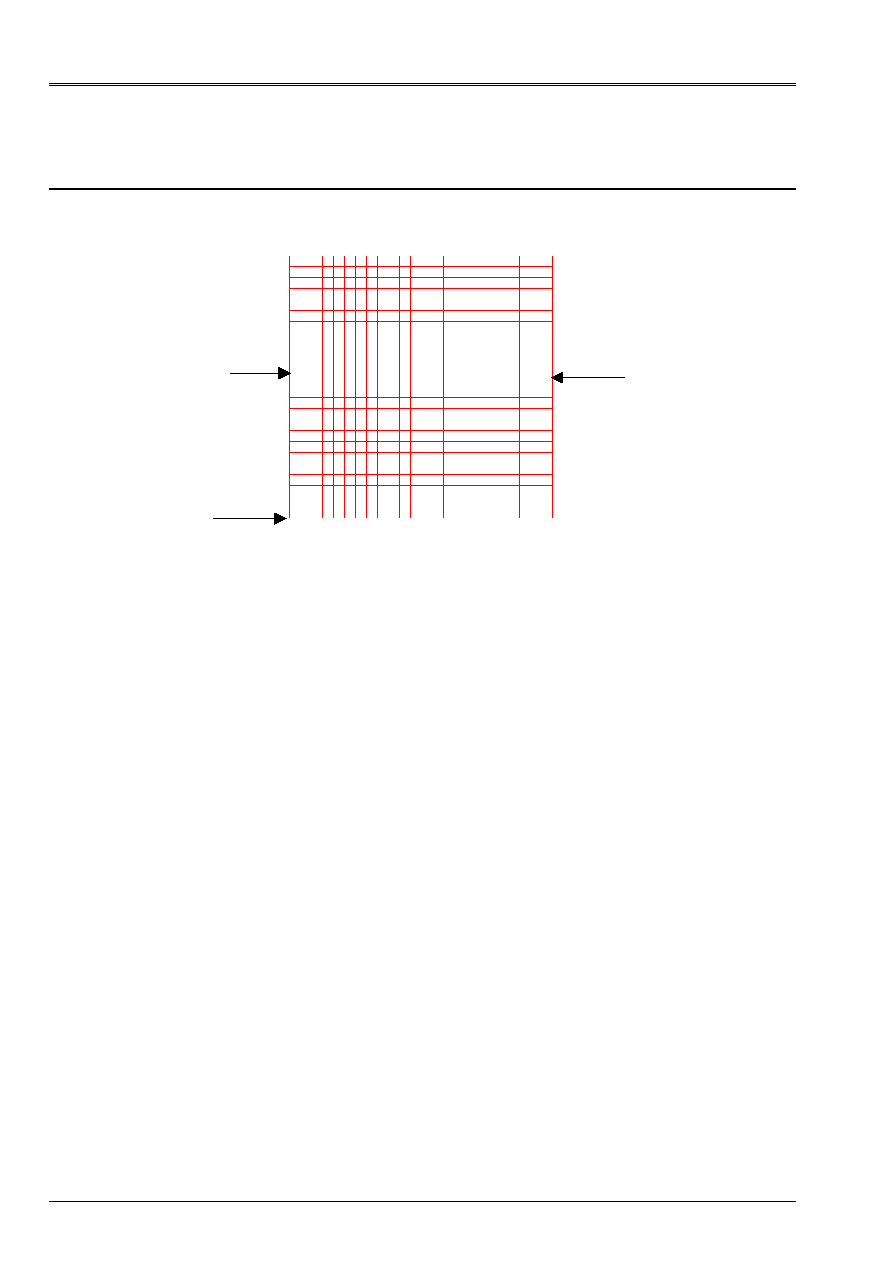

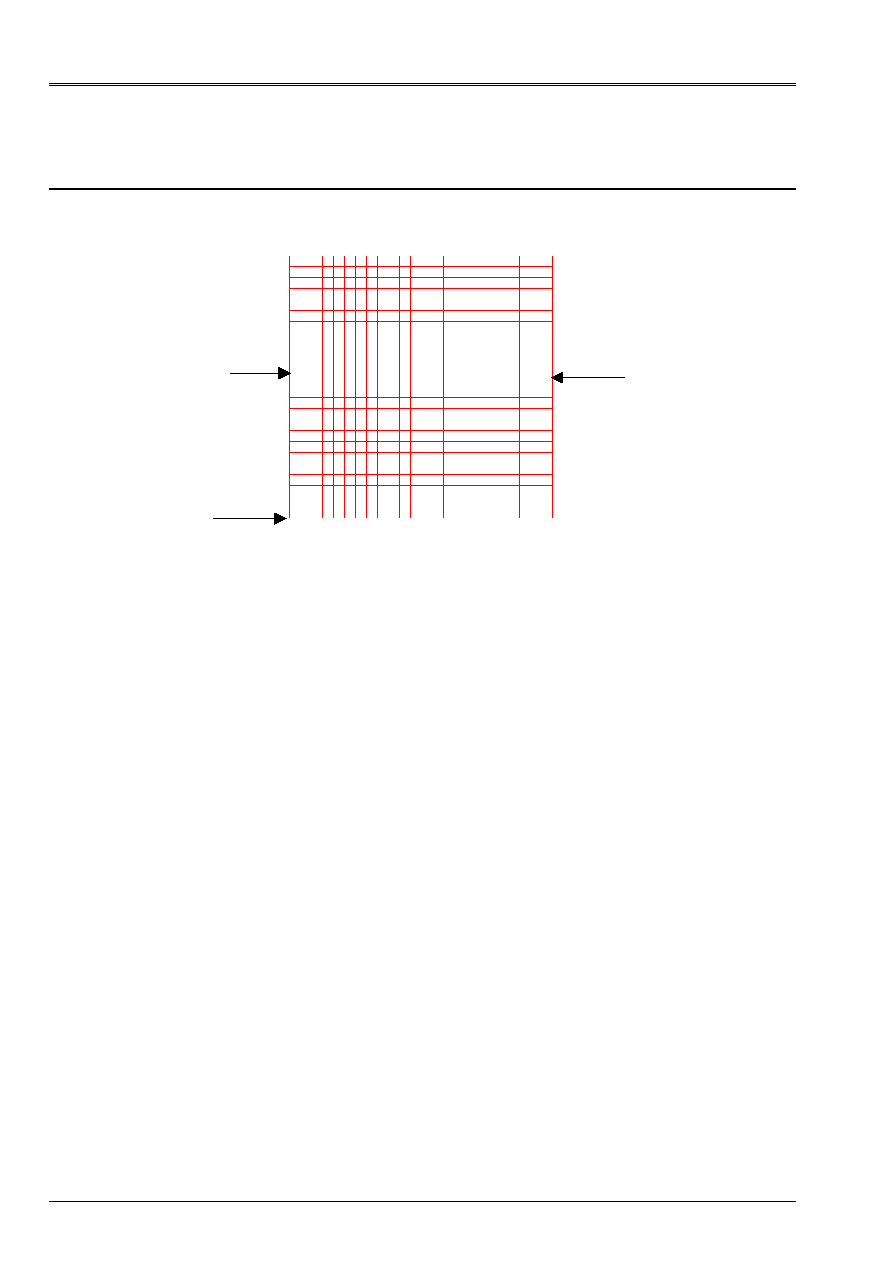

It is about a composite material made up of 16 superimposed layers of the same material and of

fiber directions different forming plate a 4.48 m thickness. The longitudinal direction or

feel fibers of each layer is defined by the first direction of orthotropism.

1.2

Property of material

The properties of material are:

·

longitudinal Young modulus: E_L = 59000 MPa

·

transverse Young modulus: E_T = 59000 MPa

·

modulus of rigidity in plan LT: G_LT = 3700 MPa

·

Poisson's ratio in plan LT:NU_LT = 0.08

·

criterion of rupture in traction in the longitudinal direction: XT = 560 MPa

·

criterion of rupture in compression in the longitudinal direction: TESTSTEMXÇS = - 475 MPa

·

criterion of rupture in traction in the transverse direction: YT = 560 MPa

·

criterion of rupture in compression in the transverse direction: TESTSTEMYÇS = - 475 MPa

·

criterion of rupture in shearing in plan LT: S_LT = 48 MPa

The orientation of the first layer is 0° compared to the reference mark of reference, for the second layer

45°, for the third 0° and so on.

1.3

Boundary conditions and loadings

·

N1

DY=0, DZ=0, DRX=0, DRY=0, DRZ=0

·

LEFT

DX=0

·

STRAIGHT LINE

FX= - 784 NR

LEFT

STRAIGHT LINE

N1

Code_Aster

®

Version

7.2

Titrate:

SSLS128 - Validation of the option

CRIT_ELNO_RUPT

of

CALC_ELEM

Date:

05/03/04

Author (S):

J.M. PROIX

Key

:

V3.03.128-A

Page:

3/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/04/005/A

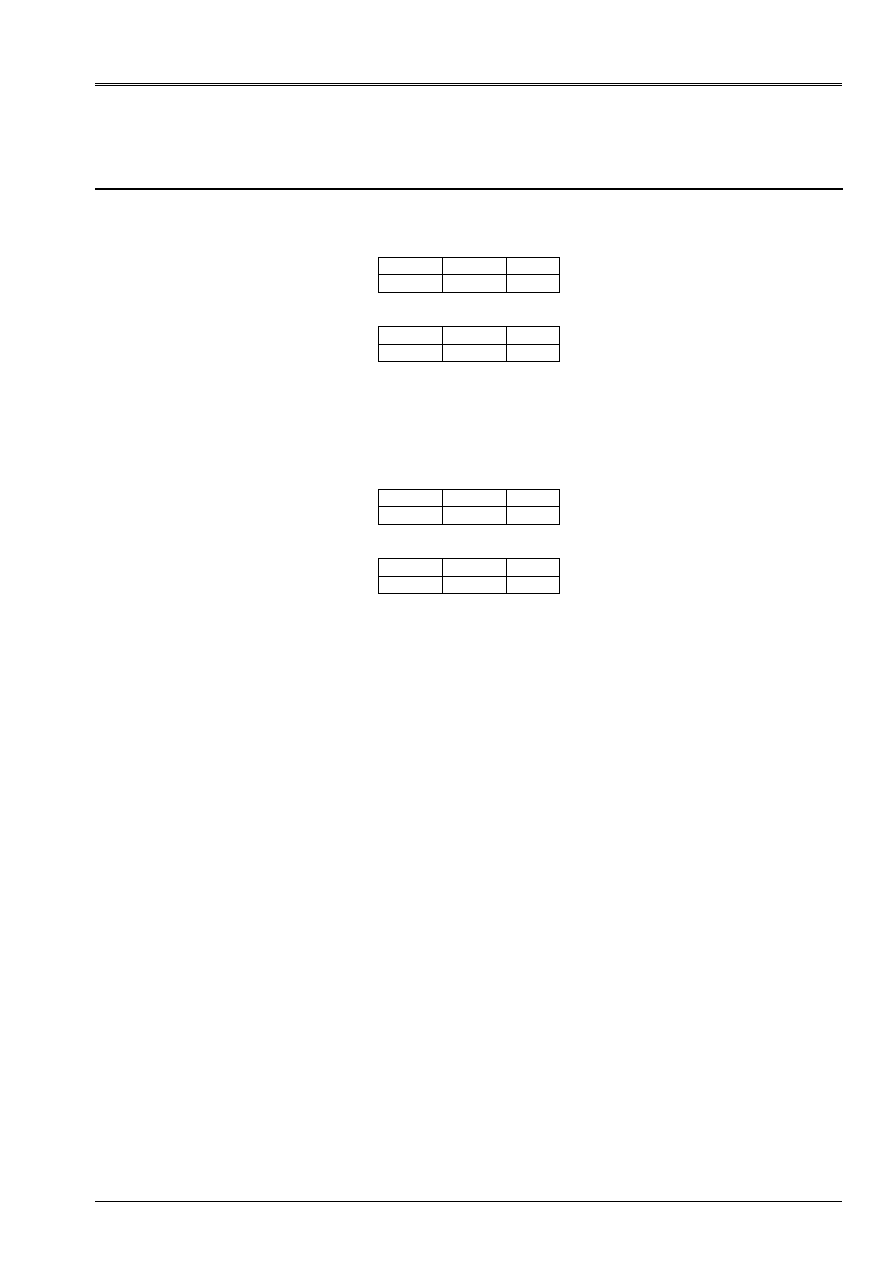

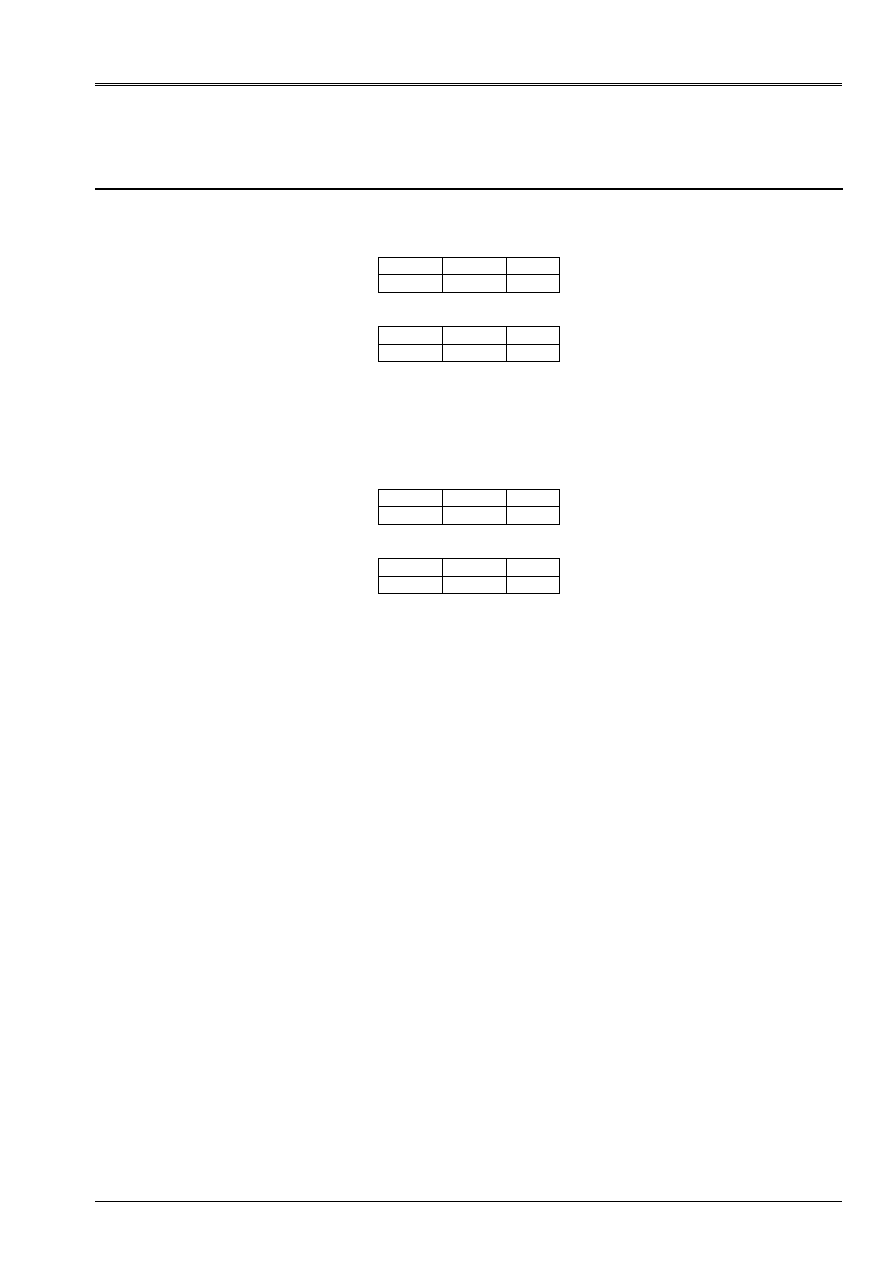

2

Reference solution given by the software “Plates”

In the first layer with 0°

Sxx Syy Szz

- 242 - 67 0

Stresses in the reference mark of the plate

SSL ST

SLT

- 242 - 67 0

Stresses in the reference mark of the layer

Criterion of Tsai-Hill

TH

C

= 0.344

In the second with 45°

Sxx Syy Szz

- 108 - 67 0

Stresses in the reference mark of the plate

SSL ST

SLT

- 88 - 88 21

Stresses in the reference mark of the layer

Criterion of Tsai-Hill

TH

C

= 0.223

SSL is the stress in the first direction of orthotropism of the layer, ST the second and SLT

shear stress.

Sxx, Syy, Szz are the stresses in the reference mark of the user.

Code_Aster

®

Version

7.2

Titrate:

SSLS128 - Validation of the option

CRIT_ELNO_RUPT

of

CALC_ELEM

Date:

05/03/04

Author (S):

J.M. PROIX

Key

:

V3.03.128-A

Page:

4/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/04/005/A

3 Modeling

With

3.1

Characteristics of modeling

The hull is modelized by elements DKT. Its characteristics are defined in

AFFE_CARA_ELEM

:

·

thickness: 16 X 0.28 = 4.48 m

·

identify reference of the hull defined by

ANGL_REP

= 0.

The various layers are defined by the operator

DEFI_COQU_MULT

who gives for each

its thickness, its material and its orientation compared to the reference mark of reference sleep defined in

AFFE_CARA_ELEM

.

3.2

Characteristics of the mesh

A number of nodes: 624

A number of meshs and types: 48 SEG2 and 576 QUA4

3.3 Functionalities

tested

Controls

THICK DEFI_COQU_MULT

MATER

ORIENTATION

CALC_ELEM SIGM_ELNO_DEPL

CRIT_ELNO_RUPT

4

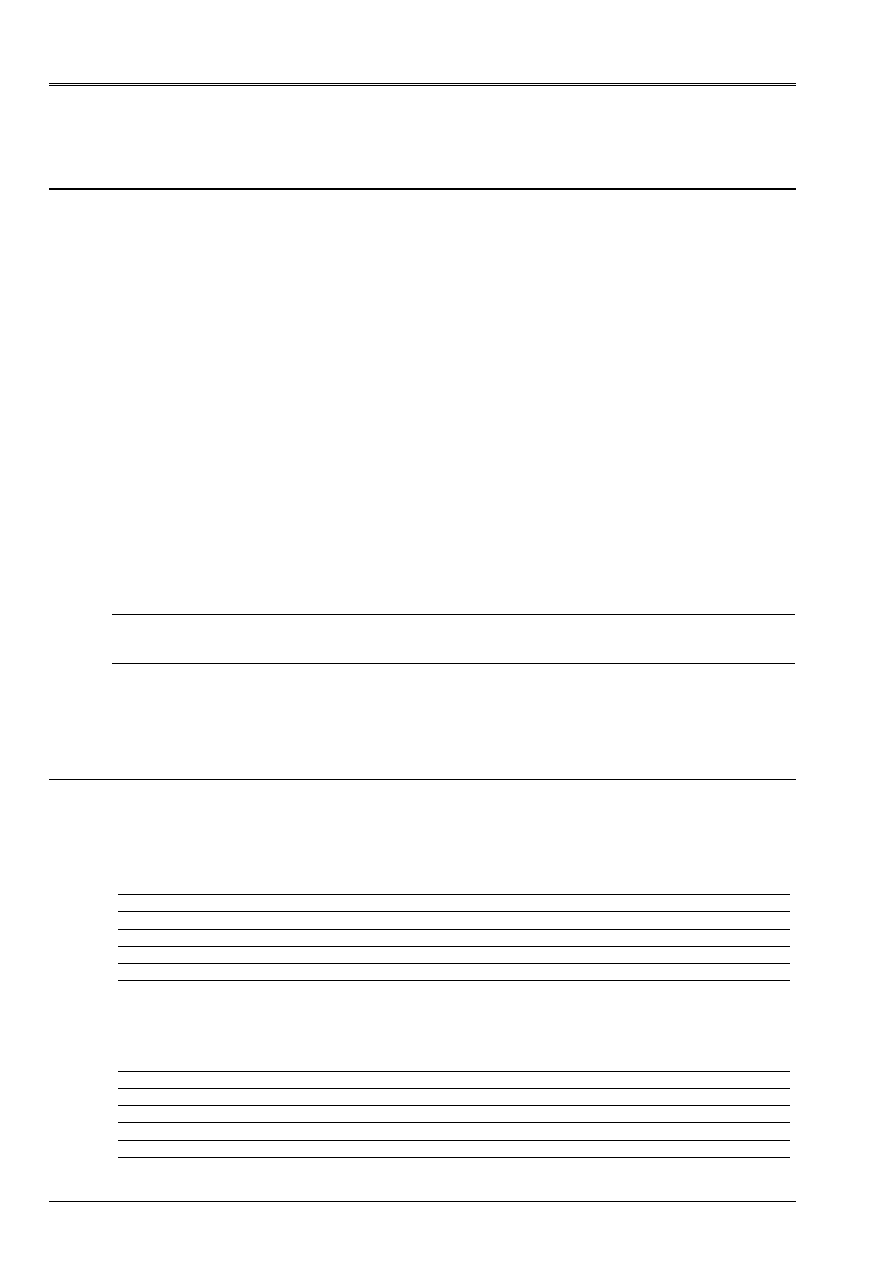

Results of modeling A

4.1 Values

tested

For the layer with 0°

Identification Reference

Aster %

difference

Sxx - 242 - 2.41623E+02

0.15

Syy 67

6.66229E+01

0.56

SSL - 242

- 2.41623E+02

0.15

ST 67

6.66229E+01

0.56

|SLT| 0

2.82232E-12

0

CTH 0.344

3.44256E-01

0.06

For the layer with 45°

Identification Reference

Aster %

difference

Sxx - 108 - 1.08377E+02

0.35

Syy - 67

- 6.66229E+01

0.56

SSL - 88

- 8.75000E+01

0.57

ST - 88

- 8.75000E+01

0.57

|SLT| 21

2.08771E+01

0.58

CTH 0.223

2.23106E-01

0.05

Code_Aster

®

Version

7.2

Titrate:

SSLS128 - Validation of the option

CRIT_ELNO_RUPT

of

CALC_ELEM

Date:

05/03/04

Author (S):

J.M. PROIX

Key

:

V3.03.128-A

Page:

5/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/04/005/A

5 Synthesis

The results obtained are satisfactory. The maximum of difference is approximately 0.6% and it is due to

fact that the results resulting from the software “Plate” are given with little precision.

Code_Aster

®

Version

7.2

Titrate:

SSLS128 - Validation of the option

CRIT_ELNO_RUPT

of

CALC_ELEM

Date:

05/03/04

Author (S):

J.M. PROIX

Key

:

V3.03.128-A

Page:

6/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/04/005/A

Intentionally white left page.