Code_Aster

®

Version

8.2

Titrate:

DEMO006 Optimization of the radius of curvature of a bent piping

Date:

05/09/05

Author (S):

J. LAVERNE, F. LEBOUVIER

Key:

V3.03.131-A

Page:

1/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/05/005/A

Organization (S):

EDF-R & D/AMA, DeltaCAD

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

V3.03.131 document

DEMO006 Optimization of the radius of curvature

of a bent piping

Summary:

This test of demonstration illustrates the use of the language python in Code_Aster.

The objective of this case-test is to optimize the value of the radius of curvature of a piping via a loop python.

The radius of curvature is modified repeatedly. The optimal value is obtained when the maximum stress

of Von Mises is lower than a threshold.

The language python, in this case-test allows repeatedly:

·

to modify the file describing the geometry of the elbow,

·

of launching GMSH in order to net the elbow,

·

to recover the maximum stress of Von Mises,

·

to evaluate a criterion of stop of the iterations,

·

of launching GMSH to carry out an interactive postprocessing.

This case-test takes again the problem of the case-test forma01f: bent piping, made up of an elastic material

linear, subjected to a force applied at its end, modelized by elements of hulls DKT.

Note:

To have the interactive functions of visualization, to put interactive = 1 at the beginning of the file of

order.

Code_Aster

®

Version

8.2

Titrate:

DEMO006 Optimization of the radius of curvature of a bent piping

Date:

05/09/05

Author (S):

J. LAVERNE, F. LEBOUVIER

Key:

V3.03.131-A

Page:

2/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/05/005/A

1

Problem of reference

1.1 Geometry

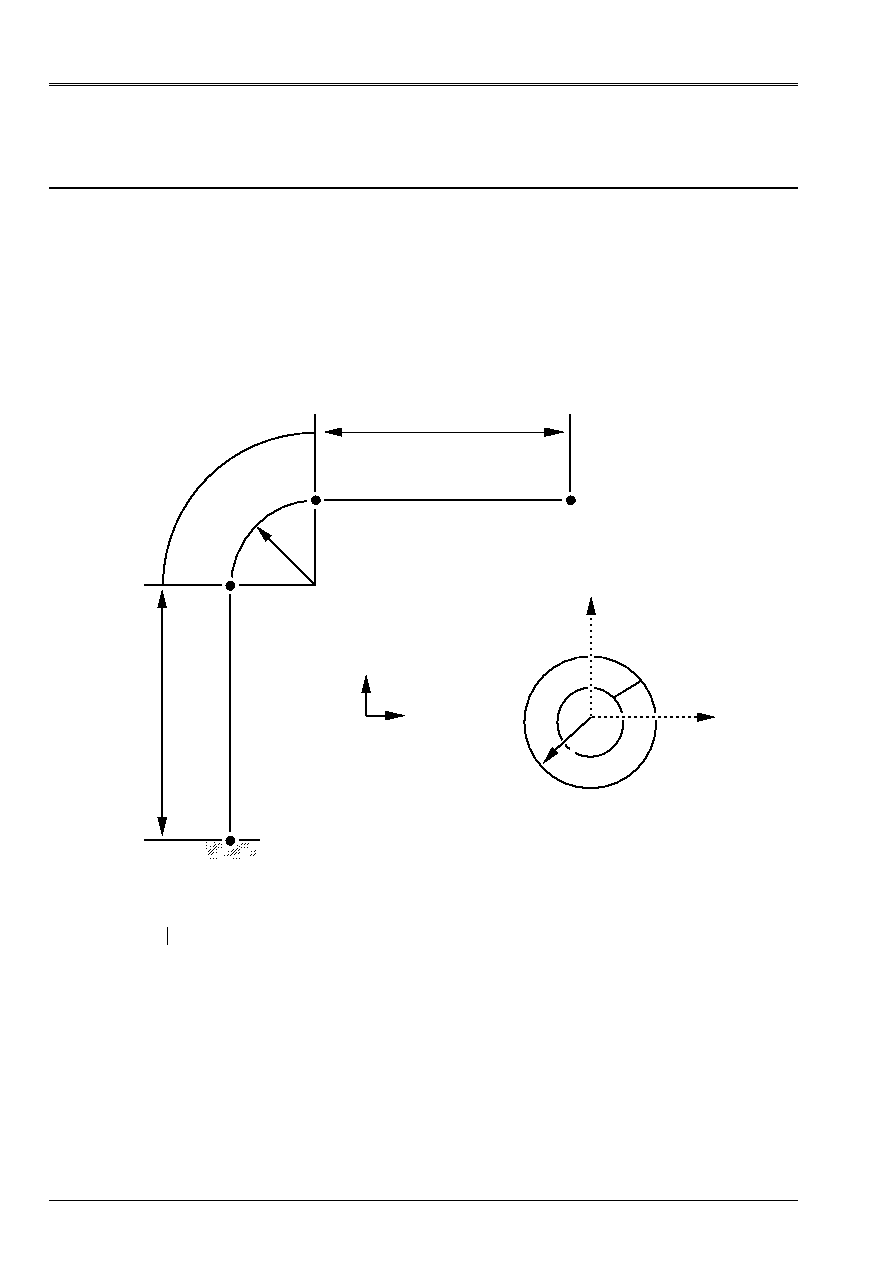

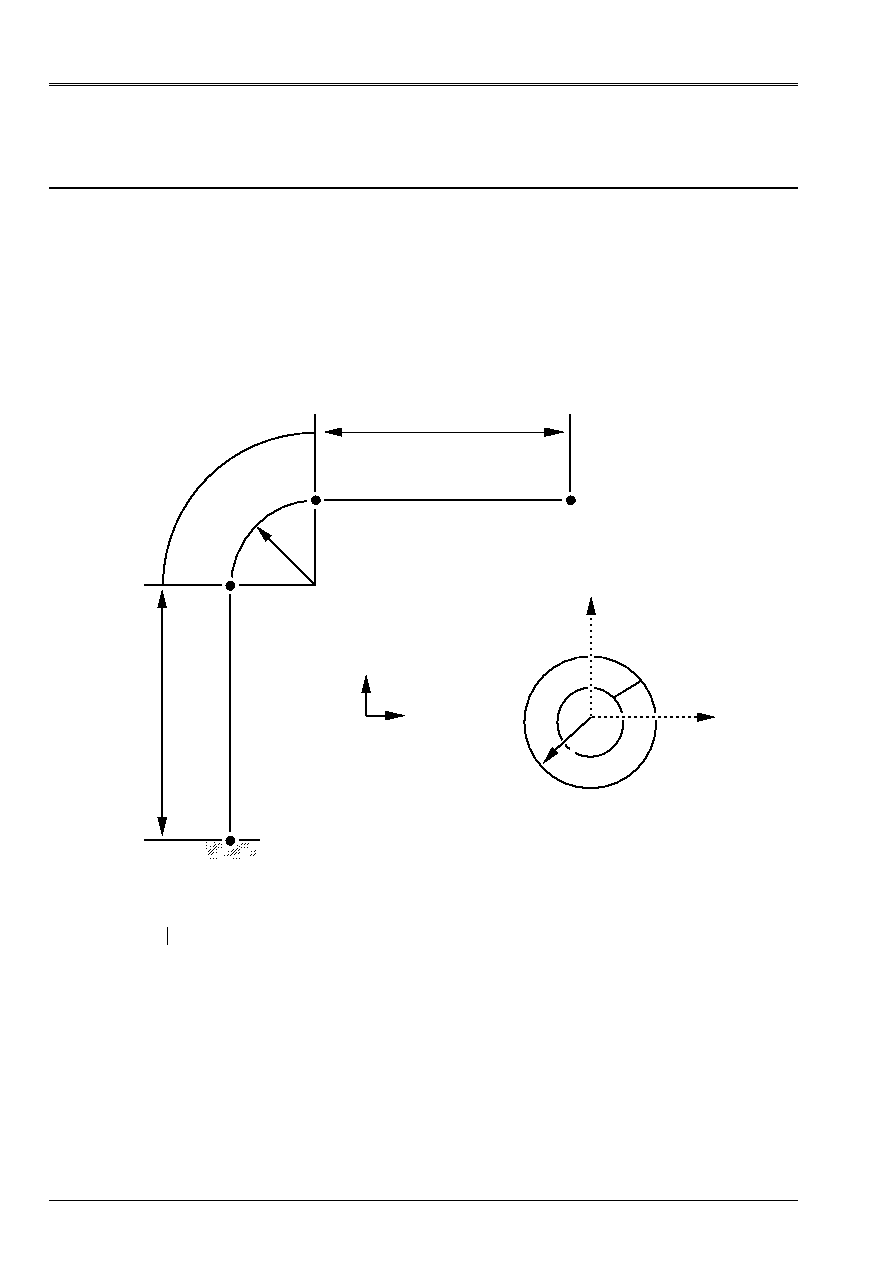

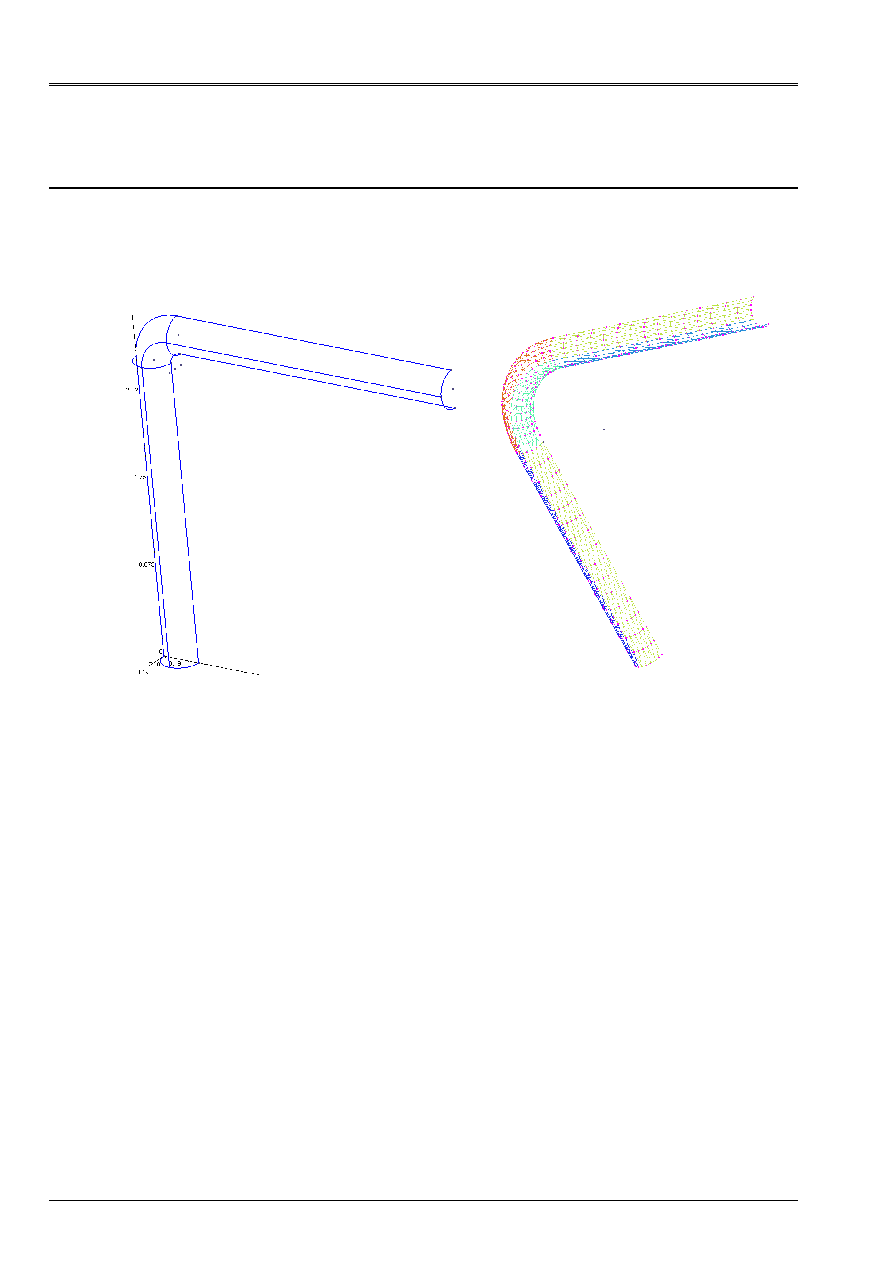

The study relates to a piping including/understanding two right pipes and an elbow [Figure 1.1-a].

The geometrical data of the problem are as follows:

·

the length L

G

the two right pipes is 3 m,

·

initial the Rc radius of the elbow is 0.3 m,

·

the angle

elbow is 90 degrees,

·

the thickness of the right pipes and the elbow is 0.02 m,

·

and the radius external Re of the right pipes and the elbow is of 0.2 Mr.

L

G

L

G

R

C

section B

section D

section C

section A

O

Y

X

Z

Re

X

Z

E

C

D

B

With

Appear 1.1-a

Note:

The geometry of the problem has a symmetry compared to the plan (A, X, Y).

1.2

Material properties

Isotropic linear elastic material. The properties of material are those of A42 steel:

·

the Young modulus:

E = 1.8 10

11

AP,

·

the Poisson's ratio:

= 0.3,

Code_Aster

®

Version

8.2

Titrate:

DEMO006 Optimization of the radius of curvature of a bent piping

Date:

05/09/05

Author (S):

J. LAVERNE, F. LEBOUVIER

Key:

V3.03.131-A

Page:

3/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/05/005/A

1.3

Boundary conditions and loadings

· Boundary conditions: embedding on the level of section A,

· Loading: force constant FY directed according to the axis Y and applied to the section B.

The value of FY is calculated to leave:

of the average radius:

19

.

0

=

RMOY

,

of the total force applied:

2

/

500000

m

NR

FTOT

=

,

Its expression is as follows:

(

) (

)

8

.

418828

2

=

RMOY

FTOT

FY

· The limiting stress of Von Mises is 2.0E+09 NR/m ²

2

Reference solution

2.1

Method of calculation used for the reference solution

The reference solution is obtained numerically. It is thus only about one test of not

regression.

2.2

Results of modeling

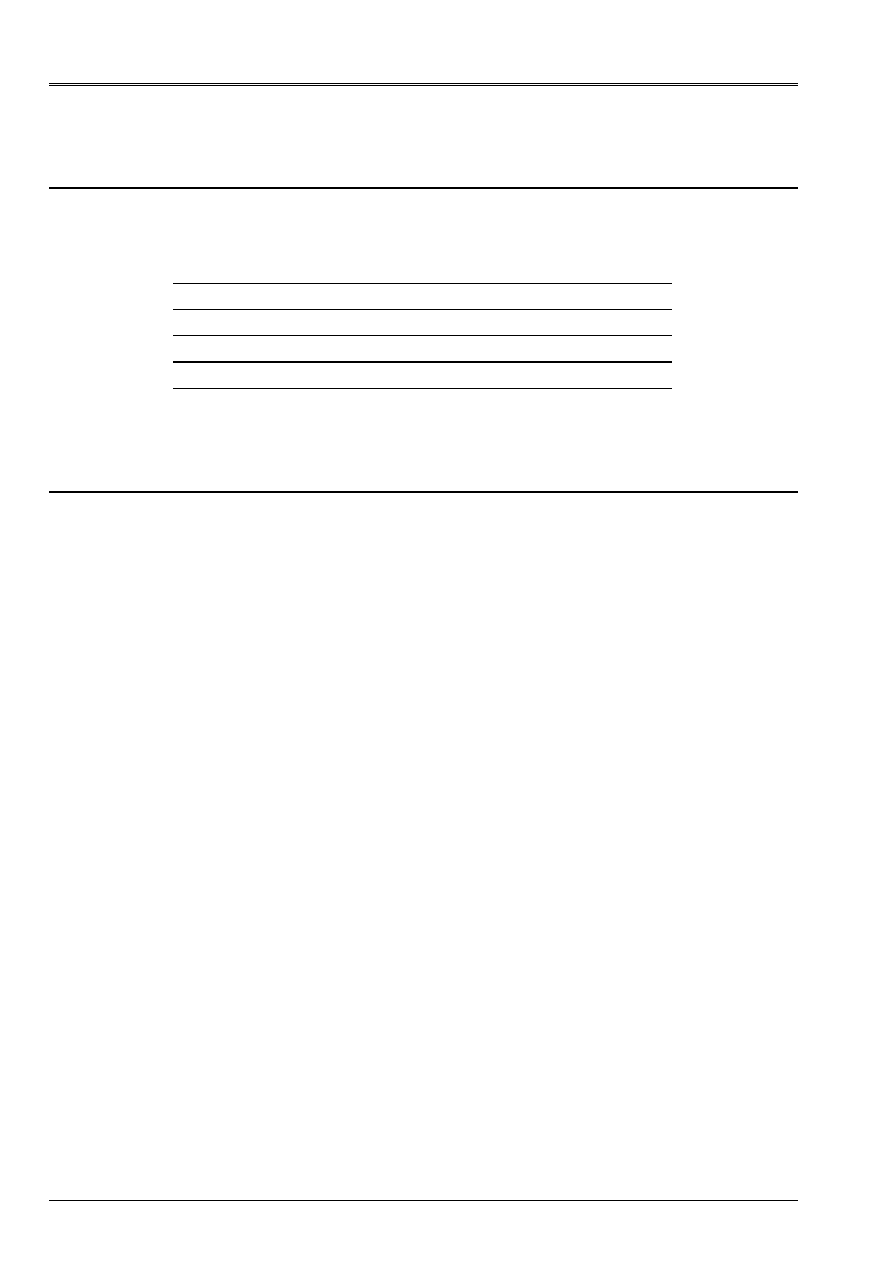

The optimal value of the radius of curvature, respecting the criterion

settings

< 2.10

9

N.m

- 2

is of 1.1m,

obtained after 5 iterations. With each iteration the radius of curvature is increased by 0.2m.

Iterations

Radii of

curvature

Stress max of

Von Mises

1

0.3 m

3.3315 E+09 NR/m ²

2

0.5 m

2.7647 E+09 NR/m ²

3

0.7 m

2.4256 E+09 NR/m ²

4

0.9 m

2.1727 E+09 NR/m ²

5

1.1 m

1.9670 E+09 NR/m ²

2.3

Uncertainty on the solution

Solution of nonregression.

Code_Aster

®

Version

8.2

Titrate:

DEMO006 Optimization of the radius of curvature of a bent piping

Date:

05/09/05

Author (S):

J. LAVERNE, F. LEBOUVIER

Key:

V3.03.131-A

Page:

4/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/05/005/A

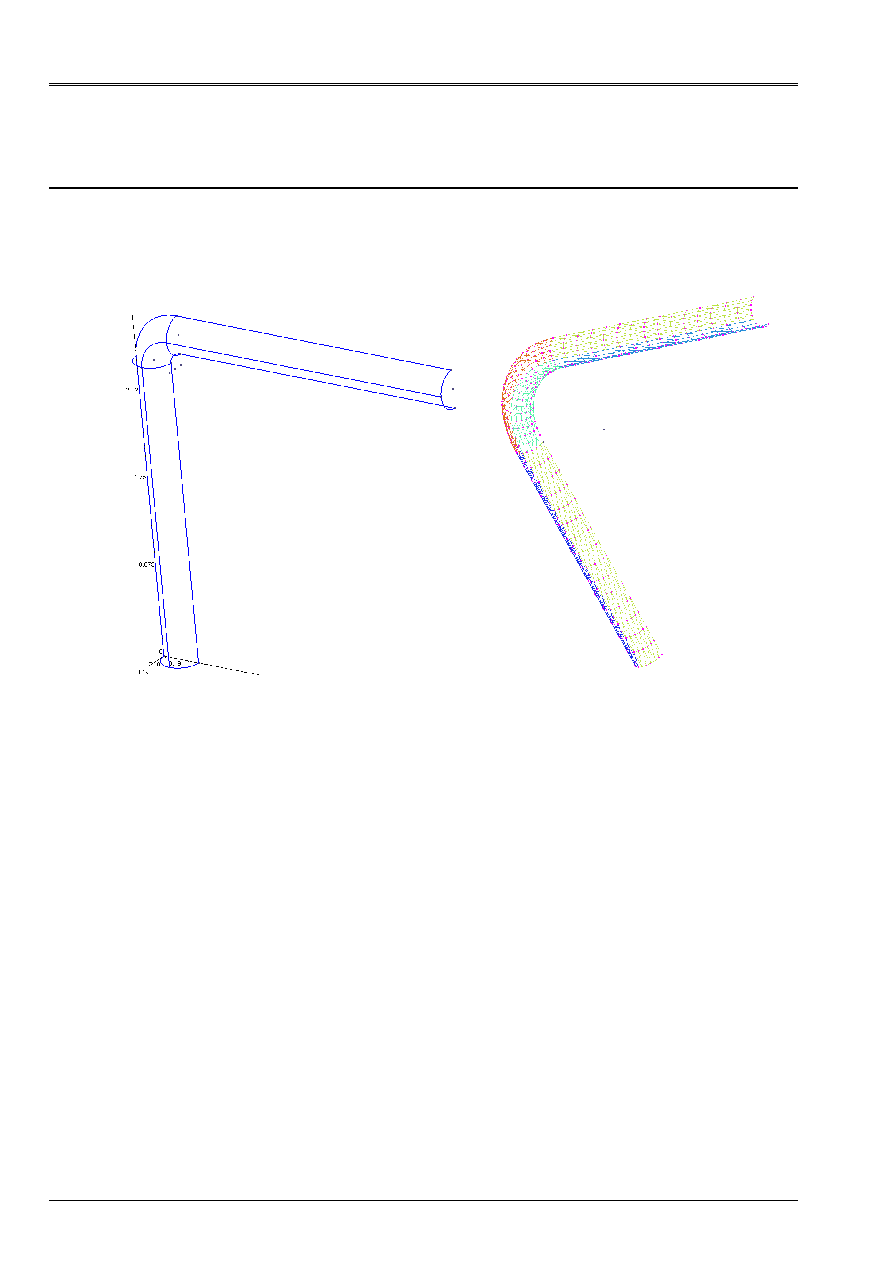

3 Modeling

With

3.1

Characteristics of modeling

Modeling in elements hulls (DKT).

Appear 3.1-a: geometry and mesh of the half rolls (initial RC)

3.2

Characteristics of the mesh

The mesh is regenerated with each iteration because of the amendment of the radius of curvature of

geometry. However the topological characteristics of the mesh are unchanged:

·

1013 meshs (900 TRIA3, 110 SEG2, 3POI3)

·

507 nodes.

The groups of meshs correspond to:

·

GM30 <=> surface of the PIPE

·

GM28 <=> section B (effort)

·

GM31 <=> not A1 (- R, 0, 0)

·

GM27 <=> section A (embedding)

·

GM29 <=> SYMMETRY

Code_Aster

®

Version

8.2

Titrate:

DEMO006 Optimization of the radius of curvature of a bent piping

Date:

05/09/05

Author (S):

J. LAVERNE, F. LEBOUVIER

Key:

V3.03.131-A

Page:

5/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/05/005/A

3.3 Controls

Aster

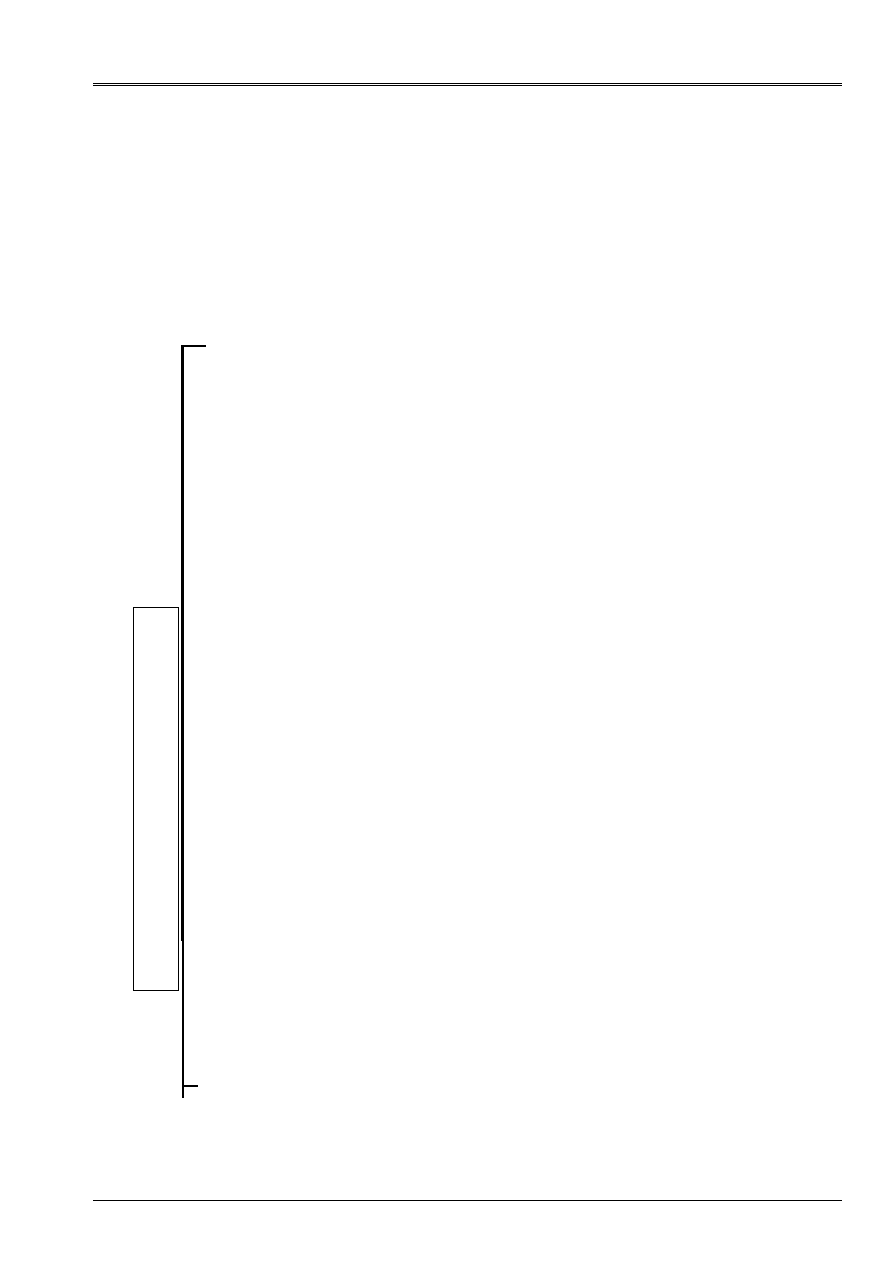

This paragraph describes the algorithm used in the command file and presents the controls

Code_Aster used.

·

Initialization of certain variables:

Radius of curvature: Rc = 0.3

Critère of convergence: crit = 2.0E+09 (forced of Von Mises targets)

·

One enters the loop python whose criterion of stop relates to the stress max of Von

Settings. As long as the criterion is not respected, the following instructions are carried out:

Reconstruction of the mesh:

one

redefines

Rc in the geometrical file .geo of GMSH

one launches gmsh via python to generate the file of mesh .msh

Lecture of mesh (PRE_GMSH) and generation of mesh (LIRE_MAILLAGE). One uses

DEFI_GROUP to re-elect the groups of meshs according to the correspondence:

# GM30 <=> PIPE

# GM28 <=> EFOND

# GM31 <=> A1

# GM27 <=> ENCAST

#

GM29

<=>

SYMMETRY

Définition of the finite elements used (AFFE_MODELE). The right pipes and the elbow are

modelized by elements of hull (DKT).

Réorientations of the normals to the elements: one uses MODI_MAILLAGE to direct all

elements in the same way, with a normal turned towards the interior.

Définition and assignment of material (DEFI_MATERIAU and AFFE_MATERIAU).

mechanical characteristics are identical on all the structure.

Affectation of the characteristics of the elements hulls (AFFE_CARA_ELEM): thickness,

vector V defining the reference mark of examination (key word ANGL_REP)

Définition of the boundary conditions and loading (AFFE_CHAR_MECA).

Piping is embedded in its base, on all the nodes located in the Y=0 plan.

Piping presents a symmetry plane Z=0.

One calculates an effort distributed FY directed according to the axis Y and applied to the section B, (the effort

distributed is such as the resultant 2Pi * RMOY. FY = FTOT, FTOT being the total force

that one wishes to apply). To apply the effort to the section B, one will use

FORCE_ARETE

.

Résolution of the linear elastic problem (MECA_STATIQUE).

Calcul of the stress field by elements to the nodes for each loading case

(option “SIGM_ELNO_DEPL”). The stresses are calculated in the definite local reference mark

for each element using the vector V (preceding key word ANG_REP). To use

NIVE_COUCHE

to define the level of calculation in the thickness.

Calcul of the stress field equivalent by elements to the nodes calculated from

stress field (option “EQUI_ELNO_SIGM”).

Calcul of the preceding fields to the nodes (options “SIGM_NOEU_DEPL”,

“EQUI_NOEU_SIGM”)

Impression of results (IMPR_RESU).

Détermination of a table containing calculations of averages of the stress field

equivalent to the nodes.(“POST_RELEVE_T')

Extraction of component VMIS of the preceding table via python.

Test of stop:

If VMIS is higher than CRIT, then one reiterates with Rc=Rc+0.2

If not one leaves the loop python.

Loop python of optimization of the radius of curvature

Code_Aster

®

Version

8.2

Titrate:

DEMO006 Optimization of the radius of curvature of a bent piping

Date:

05/09/05

Author (S):

J. LAVERNE, F. LEBOUVIER

Key:

V3.03.131-A

Page:

6/6

Manual of Validation

V3.03 booklet: Linear statics of the plates and hulls

HT-66/05/005/A

4

Results of modeling A

4.1 Values

tested

Iterations

Radii of

curvature

Stress max of Von

Settings

1

0.3 m

3.3315E+09 NR/m ²

2

0.5 m

2.7647E+09 NR/m ²

3

0.7 m

2.4256E+09 NR/m ²

4

0.9 m

2.1727E+09 NR/m ²

5

1.1 m

1.9670E+09 NR/m ²

5

Summary of the results

The optimal radius of curvature respecting the criterion: stress max of Von Mises < to 2.0E+09 is of

1.1m. It was obtained after 5 iterations, and the maximum stress of Von Mises found is of

1.9670E+09 NR/m ².