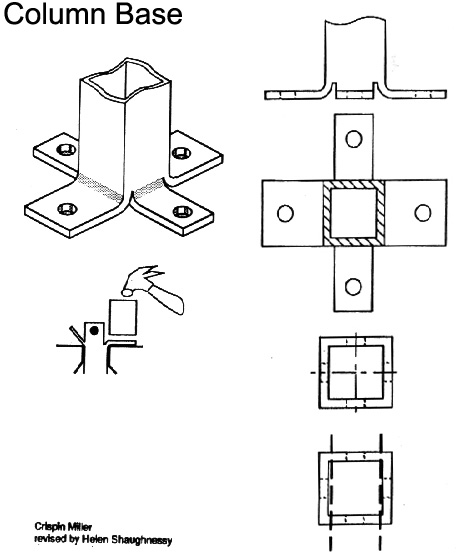

Design Cookbook: Column Base

Cookbook Index

This column base is a useful design which provides a sturdy attachment that resists tilting moments in all directions.

Material:

Square extruded aluminum box extrusion, length as desired.

Procedure:

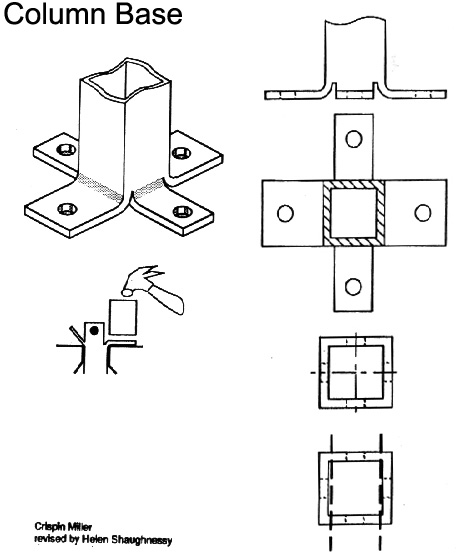

- Draw bending lines on the aluminum stock. The bending lines should be located approximately the width of the square section from the end of the stock (eg. 1" for 1" cross section).

- Drill holes completely through the end of the stock in both directions to create holes in all four sides. The drill size is determined by the bolt used to fasten the base to a machine.

- Make any cuts or holes needed along the length of the extrusion, as it is easier to machine the stock when it is still bar shaped.

- Make saw cuts slightly deeper than the width of the section just inside two parallel faces, so as to separate these faces from the other two.

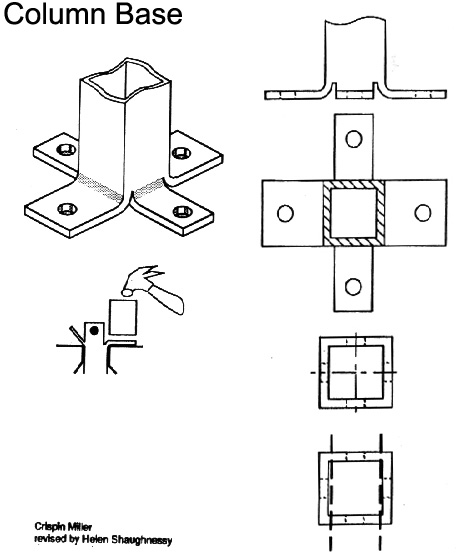

- Bend out these tabs from the four separated faces. Be sure to make all the bends at the bend line. (The extra bit of saw cut is to reduce the risk of tearing at the ends of the cuts, which can happen if the bends are done too close to them.) Use a hammer, vise, and woodblock to bend.