Sliding bearings are those in which two or more elements in the bearing assembly slide over one another. The properties of the bearing are determined by the coefficient of friction of the two materials upon one another and the loads transferred to the bearing. These properties can be aided by the use of lubricants, generally oil or grease. The lubrication does not totally eliminate contact between the surfaces, and this is the distinguishing hactor between sliding-contact and non-contact bearings.

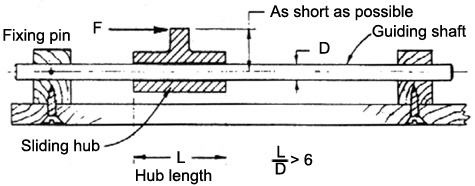

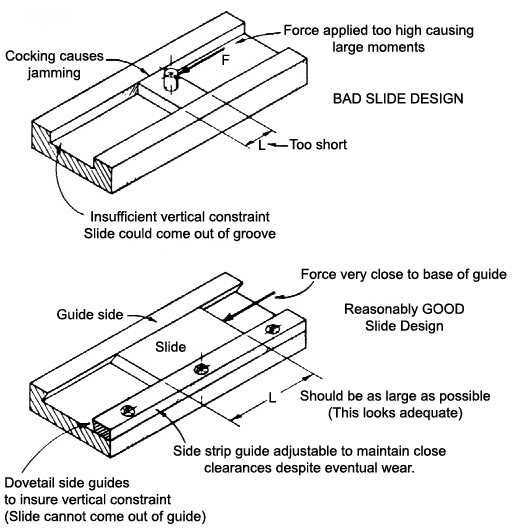

Among all the mechanical motions this is the trickiest and most potentially unreliable. It should not be attempted without adequate materials and fabrication techniques. Guided sliding members tend to cock and jam. Wear causes the situation to become increasingly worse. Guiding members should be very smooth, hard, and preferably even sized cylindrical shafts. Sliding hubs should have closely fitting bores with just enough clearance for lubrication (0.001" per inch of shaft diameter). Materials should be steel for shafts, and either steel or hard brass for the bores. NEVER USE ALUMINUM OR WOOD for sliding members. Both materials cause stick-slip performance and frequently tend to jam, wear badly, and seize easily.

For lubrication use dry lubricants such an graphite. Soft pencil lead ground and smeared over the shafts is advisable for prototypes (could be somewhat messy) but effective. Whenever possible, straight linear motions should be controlled through multiple simultaneous driving at critical points to maintain alignment and prevent cocking.

The difficulties of insuring reliable sliding motions can never be emphasized enough. The failure of most mechanical functions can often be traced to sliding linear members.

There are no hard and fast rules for the design of slides such as the one shown above. Materials, lubrication, maintenance, etc. can affect the proportions in any given design. In general, the longer the slide, the better.

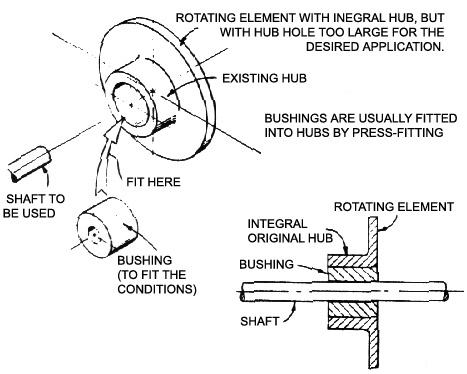

A bushed bearing (also called a plain, sleeve or journal bearing) is a type of sliding-contact bearing that is commonly used for rotating shafts. The shaft rotates in the bushing, which is usually made of a low-friction material such as Teflon.Whenever a shaft of a small diameter has to be inserted into a larger hole it is necessary to fill-in the radial space by using a bushing. Bushings are therefore hollow cylindrical elements. The outside diameter of the bushing is intended to fit the diameter of the larger hole where the shaft to be inserted, while the diameter of the hole in the bushing is to match the diameter of the shaft that it is intended to support.

The term bushing is usually applied to the cases where there is to be no motion between the original hole and the shaft; in other words, where the shaft, bushing, and original hub, do not rotate relative to each other but are rigidly attached.

Sleeve bearings, properly called journal bearings, are mounted inside suitable hub holes by press-fitting, or bonding, but they are not fixed to the mounting shafts. Instead, they are intended to permit the free sliding between the inside of the bearing and the surface of the shaft, therefore allowing free rotation. Journal bearings must be provided with adequate lubrication to prevent excessive wear.

Note - The materials provided with the kits are to be considered as basic raw materials, regardless of their originally intended function.

Think of them as chunks of materials to be remade into whatever is needed. . .

In the configurations shown above, if the shaft is to be fixed to the rotating element, either a key and keyway could be used or a cotter pin could be inserted. If the shaft is to be allowed to rotate freely into the bushing, then the latter should be called a journal bearing and must be lubricated. Some axial fixation must also be provided to prevent wandering along the shaft.