Design Cookbook: Pulley Drives

Cookbook Index

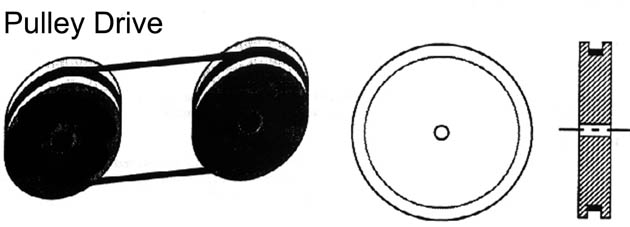

Pulley drives are useful as they transmit rotational motion and torque

from one location to another. Pulleys

of different size can be used to achieve

a desired angular velocity ratio. The belt

can be crossed to reverse the rotation.

Materials:

- 1/4" plastic sheet (eg. Polycarbonate)

- 1/16" diameter braided cord

- small rubberband

Procedure:

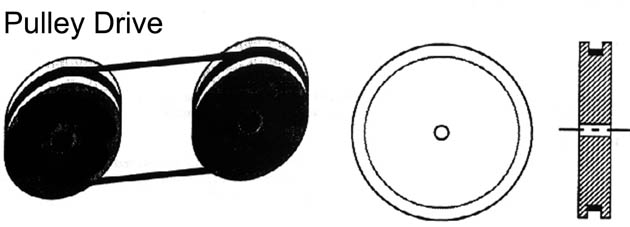

- Use a hole saw on a large drill press to cut a disk slightly larger then the finished size of

the pulley.

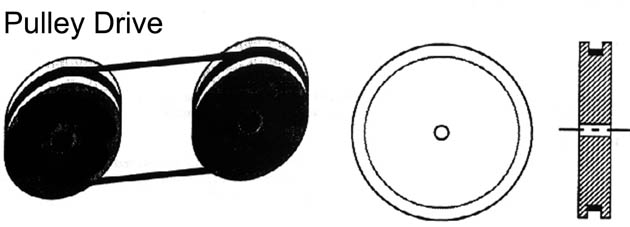

- Drill ahole in the center of the disk. The size of the hole should at least fit 0.25 inch or 6 mm bolt.

- Put a bolt through the hole in the disk, then put a nut on the bolt and tighten. This

bolt will act as a spindle to allow you to mount the disk in a lathe safely.

- Place this assembly in a lathe chuck. A three jaw chuck can easily grip three faces on

the nut.

- Turn the pulley to the appropriate outer diameter.

- Use a cut-off tool to cut a groove 0. 100" deep in the edge of the disk.

- Remove pulley from the lathe.

- Carefully place the small rubberband into the groove so that it is not twisted.

- Attach the pulley to shafts or wheels as shown in other sections of the cookbook. The distance between the

pulleys should be adjustable to allow tensioning of the belt.

- To make a continuous loop belt from braided cord, heat the two ends of the cord with

a soldering iron until the ends melt. Ouickly press the ends together and roill between your

fingers to make a smooth joint.