Safety

The safety precautions for machining plastic materials are the same as those required for machining metals.

Good ventilation is essential due to the unpleasant and often harmful fumes given off when some plastic materials are heated.

General

Use metal working tools and machines for all machining operations and:

- keep cutting edges very sharp

- keep tool cool, particularly when cutting thermoplastics using compressed air blast or continuous flow of cutting fluid or water

- use fast speed and fine feed. If chattering occurs reduce the speed

- use high speed steel (HSS) or tungsten carbide tipped tools.

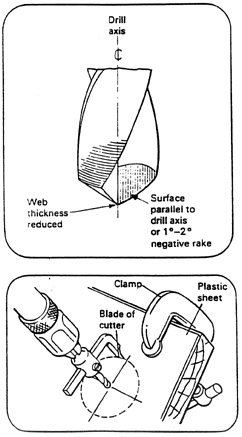

Drilling

For drilling plastics use standard twist drills having wide flutes and quick spiral.

Grind a zero or 1 *-20 negative rake on the cutting face and reduce the web thickness.

Clear the drill frequently.

Keep the drill cool.

Use a pilot drill, maximum 10 mm diameter, for large holes and progressively use larger drills, or alternatively a boring bar.

Note - Ensure that the work is firmly clamped during drilling operations. Insert suitable packing under clamp jaws to protect finish of plastic sheet.

Threading

Use normal taps and dies which must be sharp to avoid tearing or chipping.

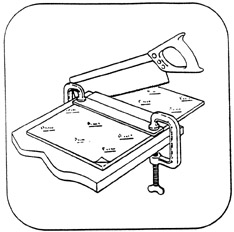

Hand Sawing

- Clamp plastic sheet firmly to bench.

- Cut along cutting line with a fine toothed saw using smooth even strokes.

Note: Take care to avoid splintering the material by too vigorous use of the saw.

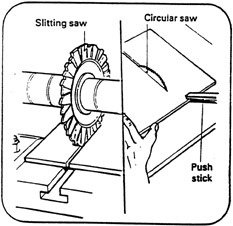

Machine Sawing

Circular hollow ground saws can produce a smooth cut with teeth up to 10 mm pitch and zero or very small rake at speeds of 3000 rpm with 200-250 mm diameter blades.

Safety

Use a push stick when cutting on a circular saw and band saw.

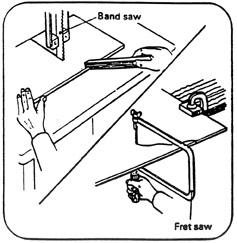

Band Saws

Band saws with a metal cutting blade having very little set will produce a rough cut.

Intricate shapes can be cut using a jigsaw or fretsaw. Saw blades with 5-6 teeth per cm are usually satisfactory.

Note: Avoid the build up of excessive heat during cutting and feed the material slowly and steadily.