Click the photos to enlarge them.

Cylinders in the form of tubes, pipes, tanks and pressure vessels clearly play a crucial role in this plant - as they do in most processing plant.

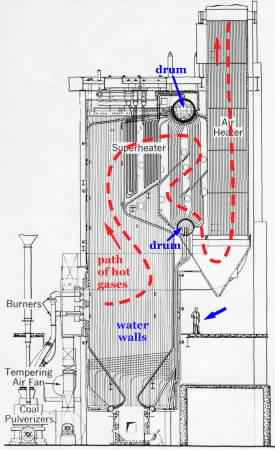

The layout of a medium sized coal-fired boiler is sketched - the arrowed man gives an idea of the boiler size.

Pulverised coal is transported in a continuous jet of air through each burner and burns in the combustion chamber ( the large chamber between burners and the man in the sketch ). The hot gaseous combustion products then follow a tortuous path produced by baffles, giving up their heat generally in counterflow to the steam, water and combustion air before exhausting through the boiler stack ( not shown ).

The boiler is constructed mainly of interconnected cylinders such as the superheater tubes, the generating tubes which completely cover the walls of the combustion chamber ( the 'water walls' ), various larger diameter headers ( not identified ), and the large drums. Water and steam circulate by natural convection through the tube network, the steam finally collecting in the upper ( steam ) drum, from whence it is drawn off for use.

click the sketch to enlarge it

This is a view inside a boiler similar to the above during manufacture.

This shows a gas pass downstream from the combustion chamber. Again cylinders are featured - water/steam tubes completely cover the walls of the passage so that the gases cannot give up heat unless it's transferred to the water/steam.

The tradesperson is applying insulation to selected areas of the wall.

This photograph shows the combustion chamber of an operating boiler similar to the above.

The pulverised coal-air mixture is pouring continuously out of the burners and commences to burn immediately it enters the combustion chamber.

The water wall in which the burners are mounted is clearly shown - the arduous conditions under which the high pressure cylindrical tubes operate can be appreciated. Some ash build-up on the tubes is apparent.

This sketch is of a pair of angular contact ball bearings mounted back-to-back.

This sketch is of a pair of angular contact ball bearings mounted back-to-back.

The fits of each bearing's inner race on the shaft and outer race in the housing are critical to the smooth operation of the bearing.

If fits are too loose then the bearing is sloppy and cannot offer the guidance it's designed to provide.

If there is too much interference then the balls are tightly constricted - ball loads, friction and noise all increase, and wear life decreases.

Each bearing race is a cylinder, as are the shaft ( albeit probably a solid cylinder ) and the housing ( a cylinder of large OD ). The compound cylinder theory presented later in this chapter is necessary to understand how these statically indeterminate mating cylinder pairs behave on assembly.