Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

1/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

Organization (S):

EDF/AMA, DeltaCAD

Instruction manual

U2.02 booklet: Elements of structure

Document: U2.02.01

Note of use of the elements plates and hulls

Summary:

This document is a note of use for modelings plates and hulls.

The elements of hulls and plates play a part in the numerical modeling of the mean structures with

surface average, planes (modeling plates) or curve (modeling hulls).

They are usable in or not linear linear mechanics and thermics.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

2/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

Count

matters

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

3/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

4/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

1 Introduction

The elements of hulls and plates are particularly used to modelize structures

thin where the relationship between dimensions (characteristic thickness/length) is much lower than

1/10 (thin hulls) or about 1/10 (thick hulls).

These modelings are usable in linear and nonlinear mechanics, under assumption of

small deformations and small displacements or many assumptions of great displacements and of

great rotations, according to modelings. A mean modeling of hull is also

available in transitory linear thermics.

Two categories of thin elements of structures are described in this document:

·

The elements of plates, which are plane, therefore the curvature of the structure to be represented is not

ideally not taken into account and it is necessary to use a great number of elements of

way to approach correctly the geometry of the structure (aspect breakages).

·

The elements of hulls, which are curved, therefore the geometry of the structure is better

approached.

Concerning the nomenclature and the reference materials associated with each one of

modelings:

·

the plane elements of plates triangle and quadrangle are gathered under modelings,

(reference material [R3.07.03]):

-

DKT: net TRIA3 element DKT, mesh QUAD4 elements DKQ (linear geometrical);

-

DST: net TRIA3 DST element, mesh QUAD4 element DSQ (linear geometrical);

-

Q4G: net QUAD4 element Q4G (linear geometrical);

·

the elements of curved hulls resulting from models 3D with a kinematics of hull are

gathered under modelings:

-

COQUE_3D: net TRIA7 and QUAD9, structure 3D with unspecified geometry ([R3.07.04]

into linear geometrical, [R3.07.05] into linear geometrical and [R3.03.07] with

following pressures);

-

COQUE_AXIS: net SEG3, hulls with symmetry of revolution around the axis

0Y ([R3.07.02] into linear geometrical);

-

COQUE_C_PLAN or COQUE_D_PLAN: net SEG3, hulls with invariant geometry it

length of axis OZ ([R3.07.02] into linear geometrical).

A characteristic: for studies on reinforced concrete structures, elements of plates

specific were developed to represent the tablecloths of reinforcement made up of two

metal reinforcements with 90° one compared to the other (the most general case for the concrete structures

armed). They are elements of orthotropic plates DKT to 3 nodes offset compared to the layer

means out of concrete. This last is modelized by elements of plates DKT or DST with 3 nodes. One

for the tablecloths of reinforcement a modeling defines ROASTS which uses the elements of plates DKT

with 3 usual nodes. The reinforced concrete structure is then represented by the superposition of

modelings ROASTS and of that used for the concrete (DKT or DST).

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

5/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2 Mechanics

2.1

Capacities of modeling

2.1.1 Recall of the formulation

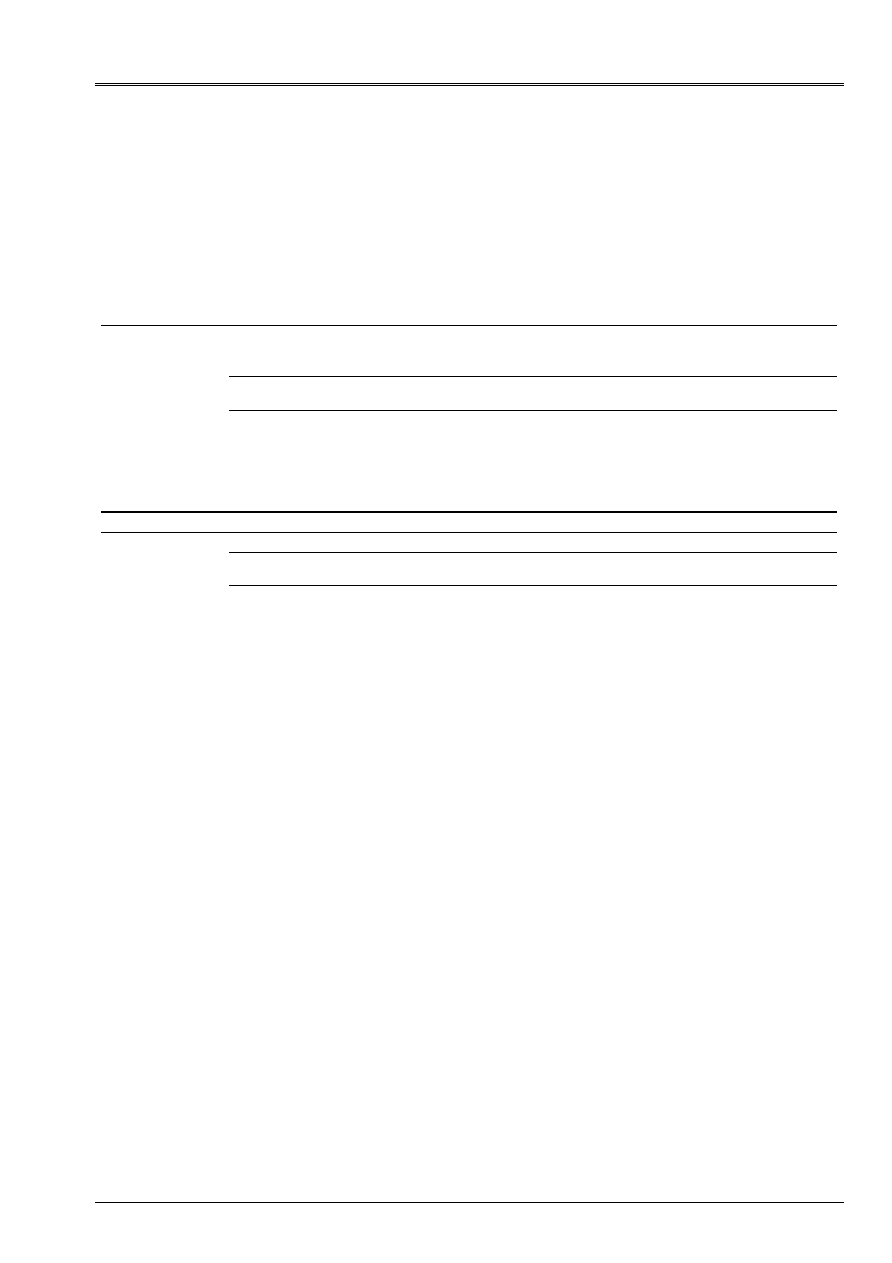

2.1.1.1 Geometry of the elements plates and hulls

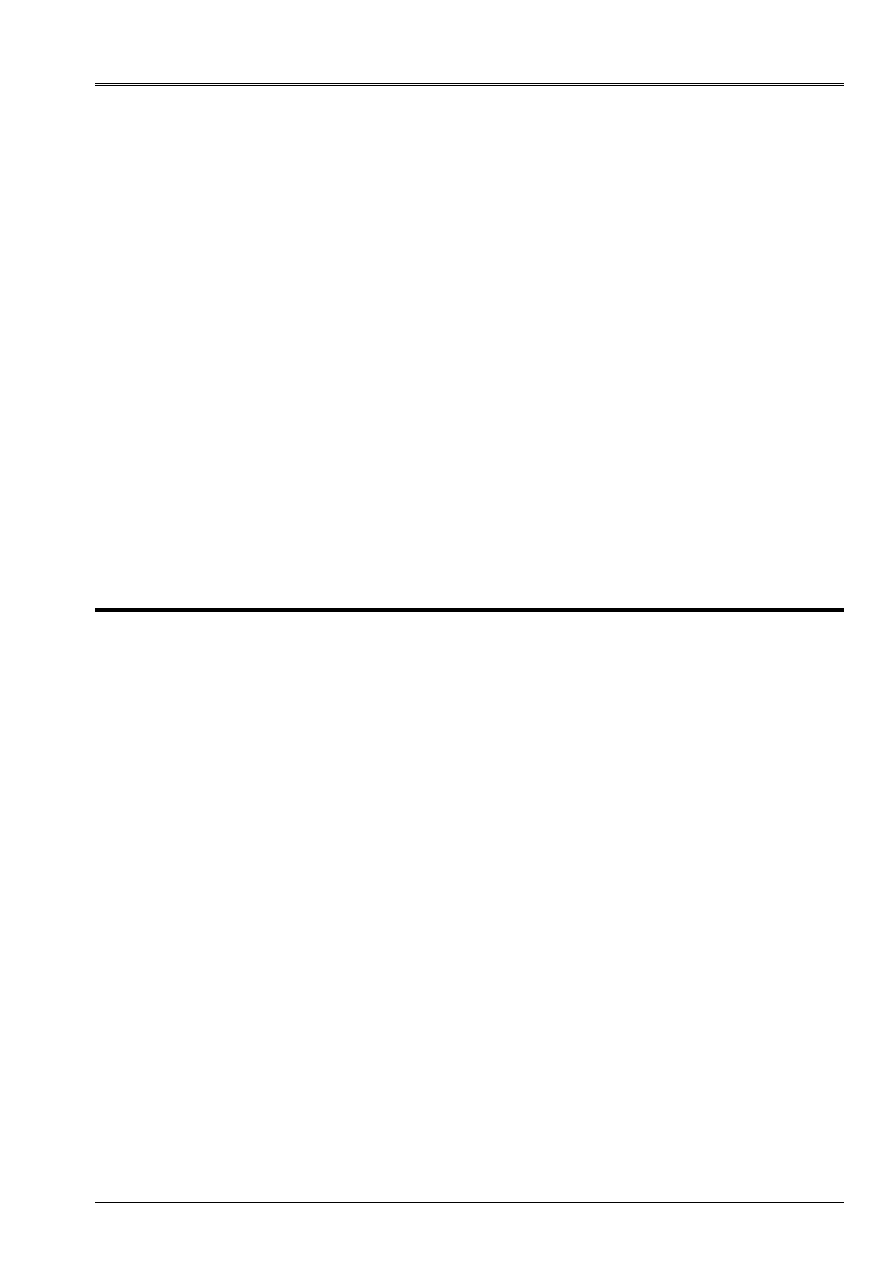

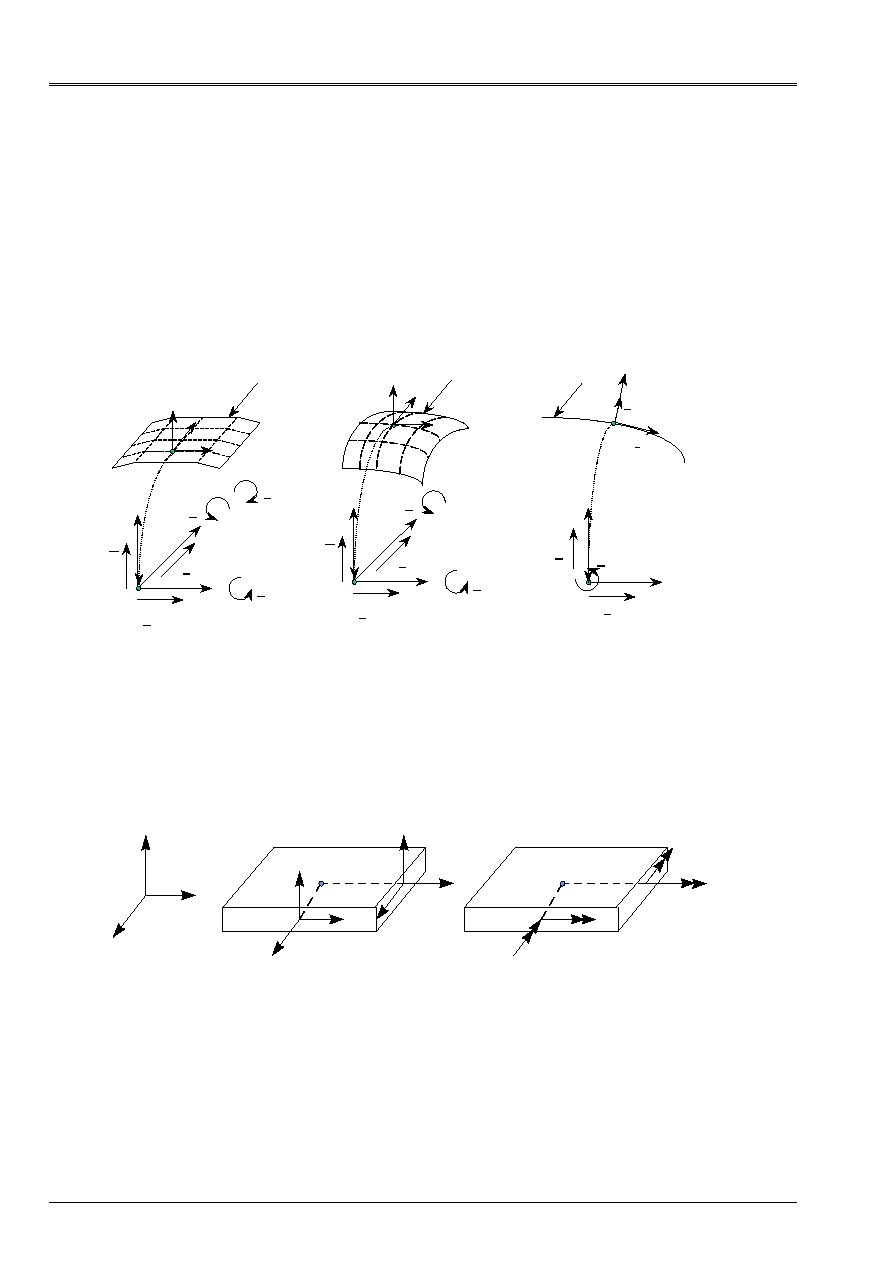

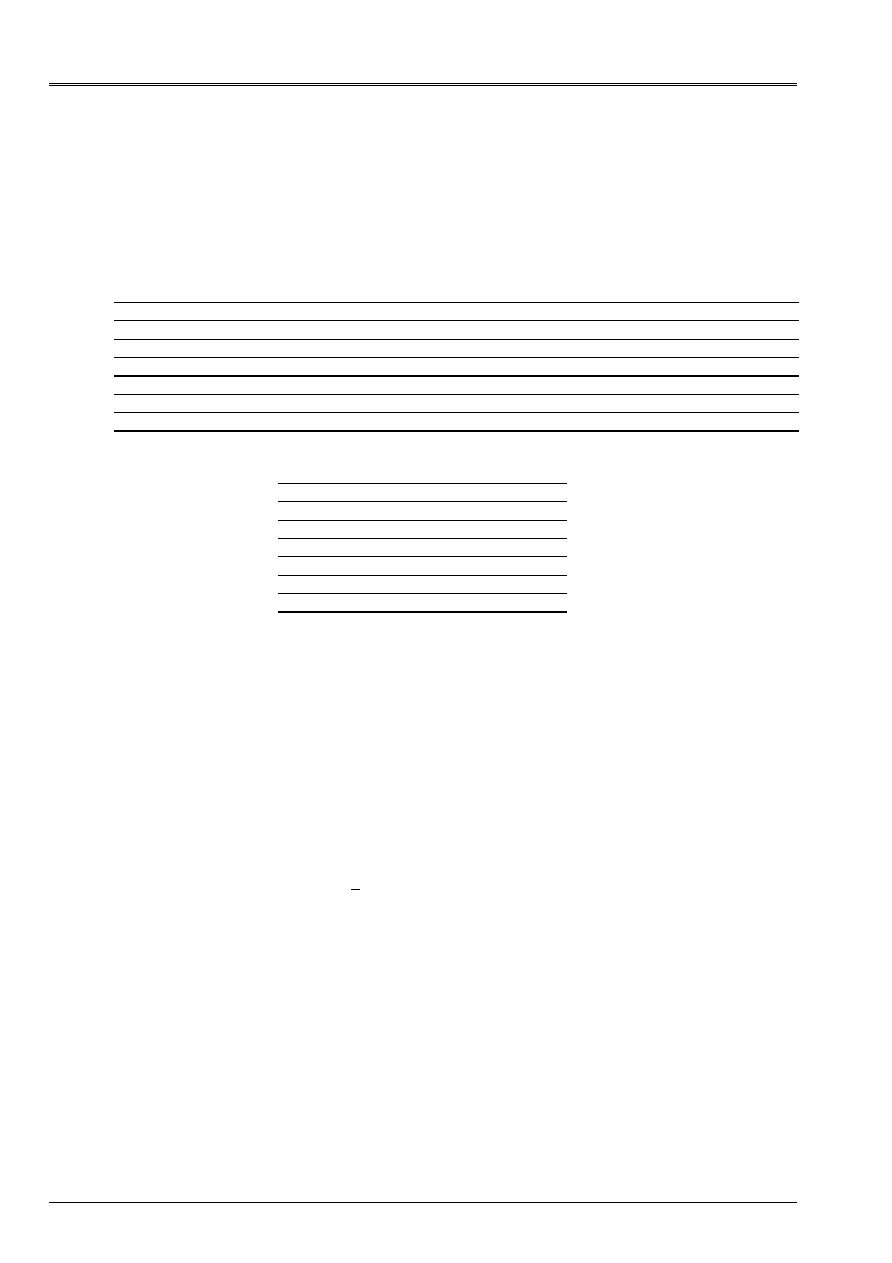

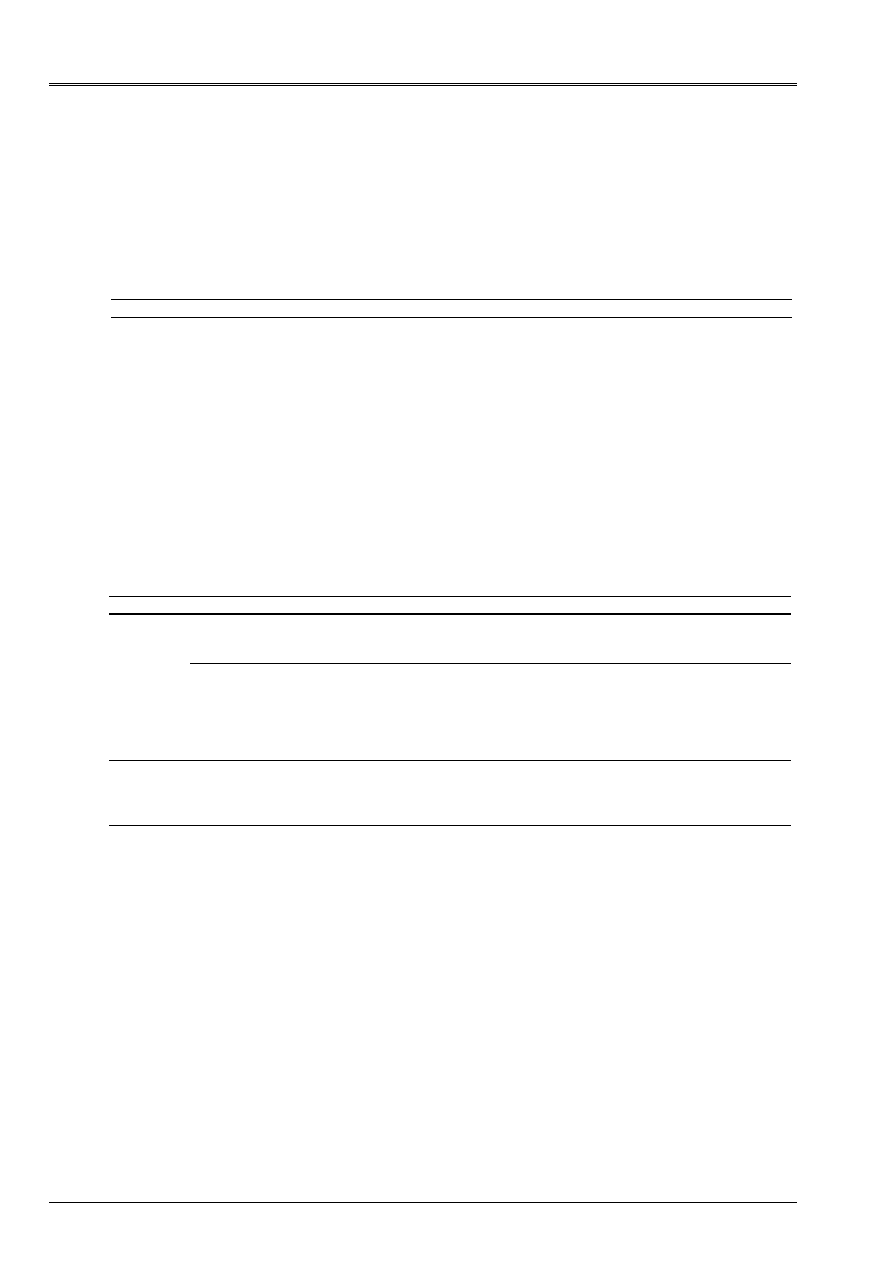

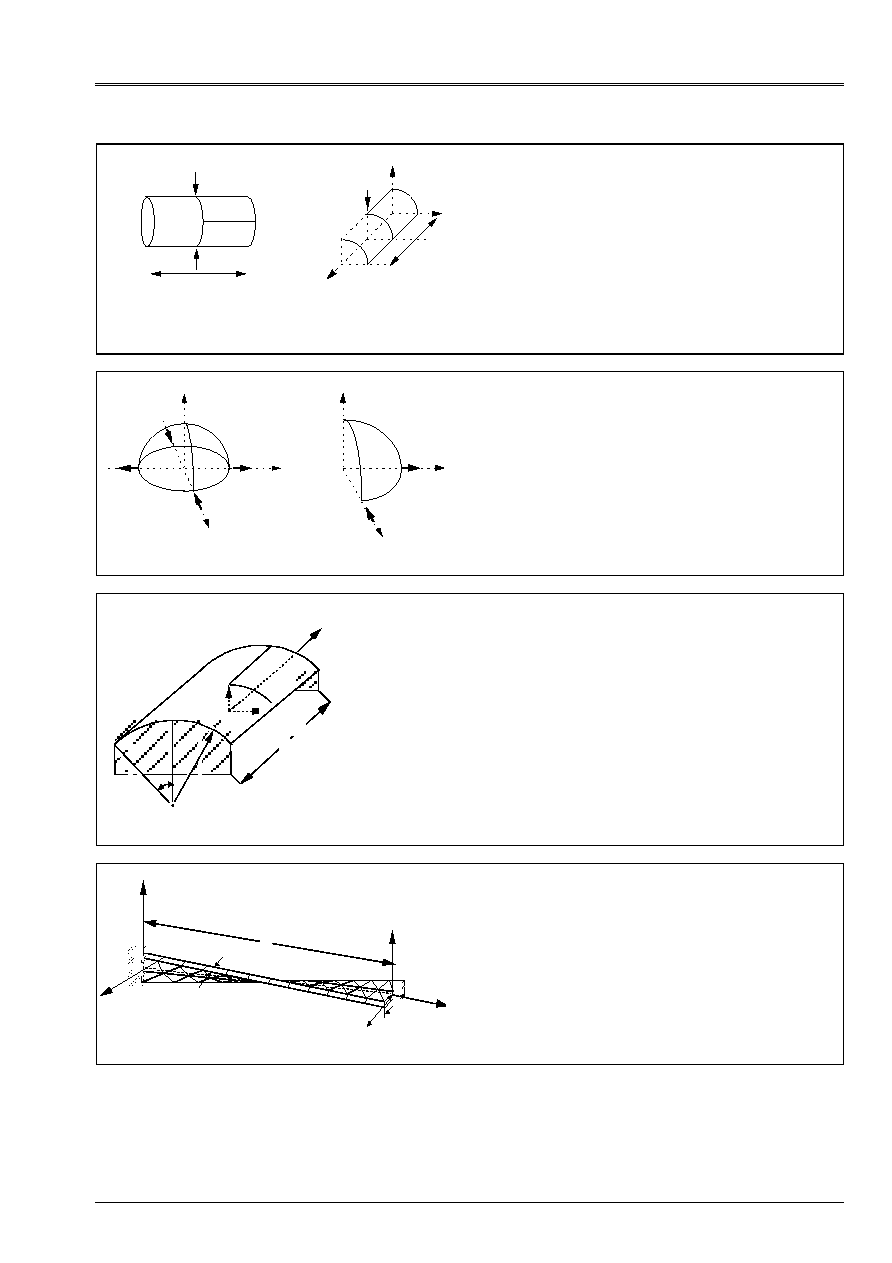

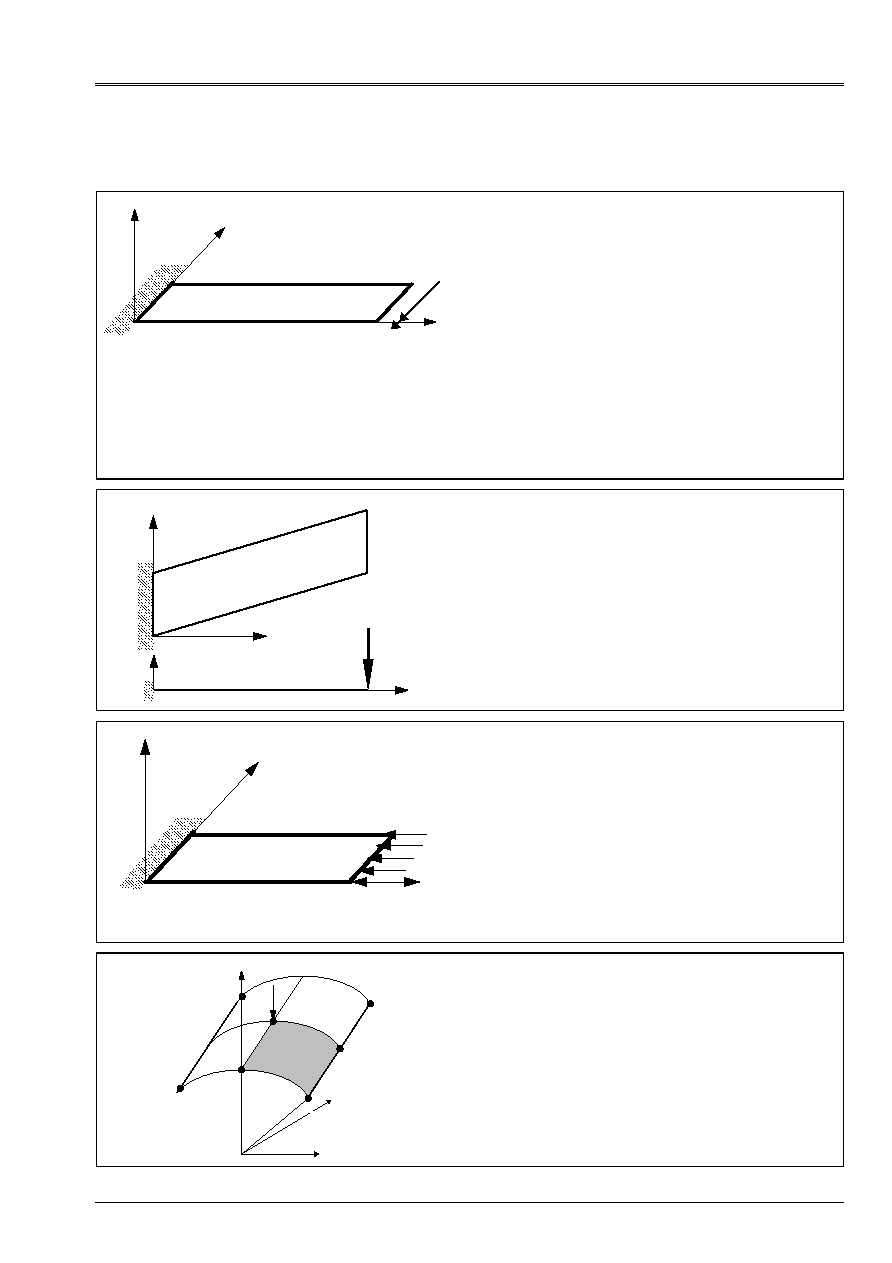

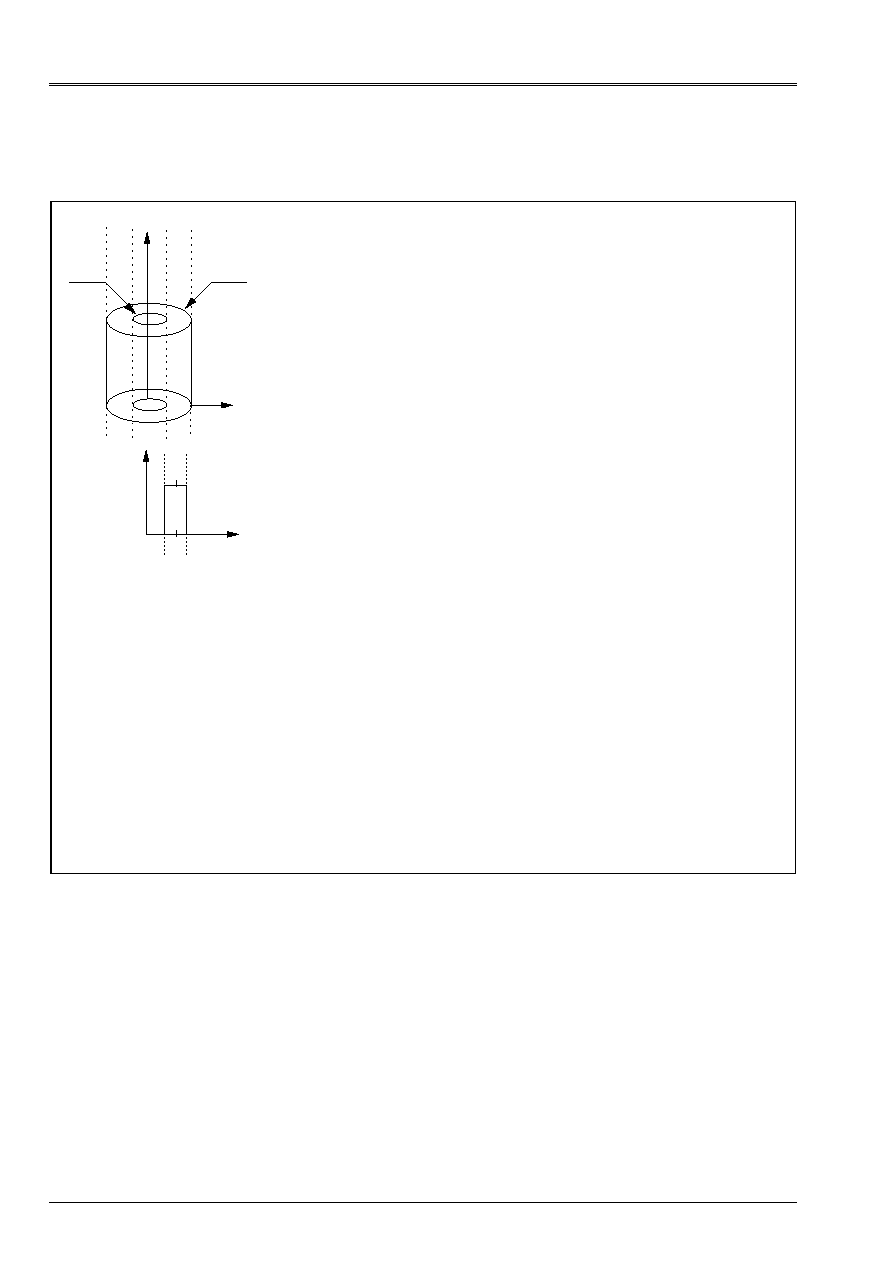

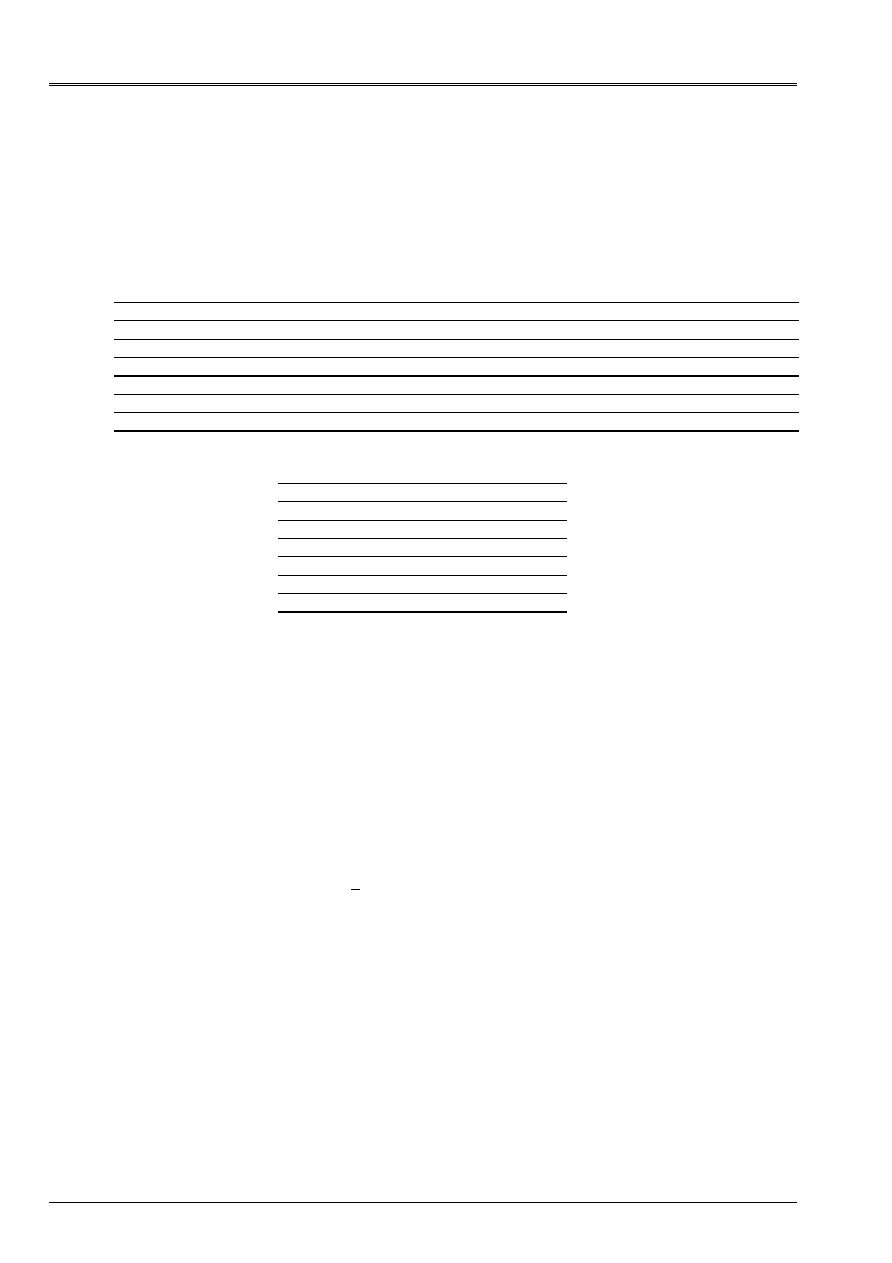

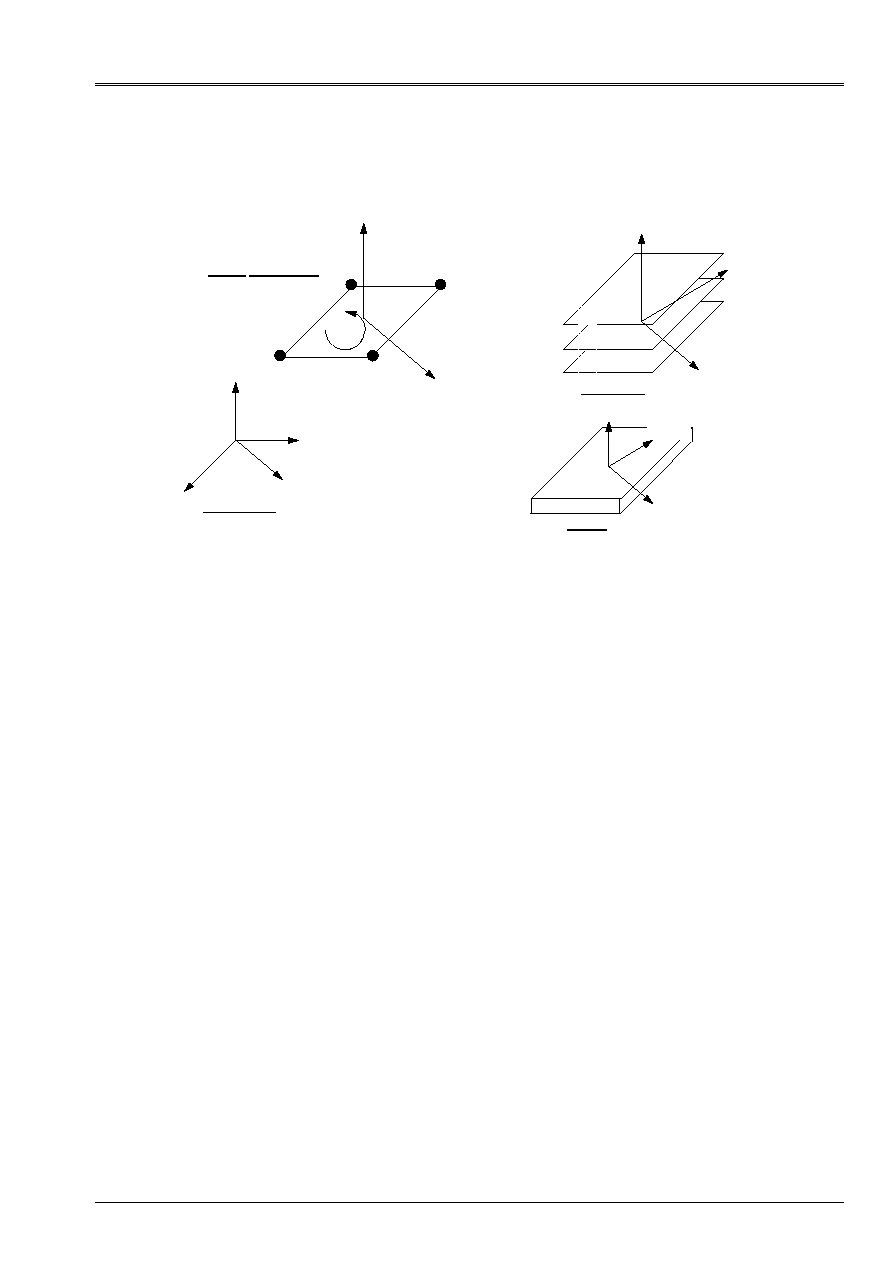

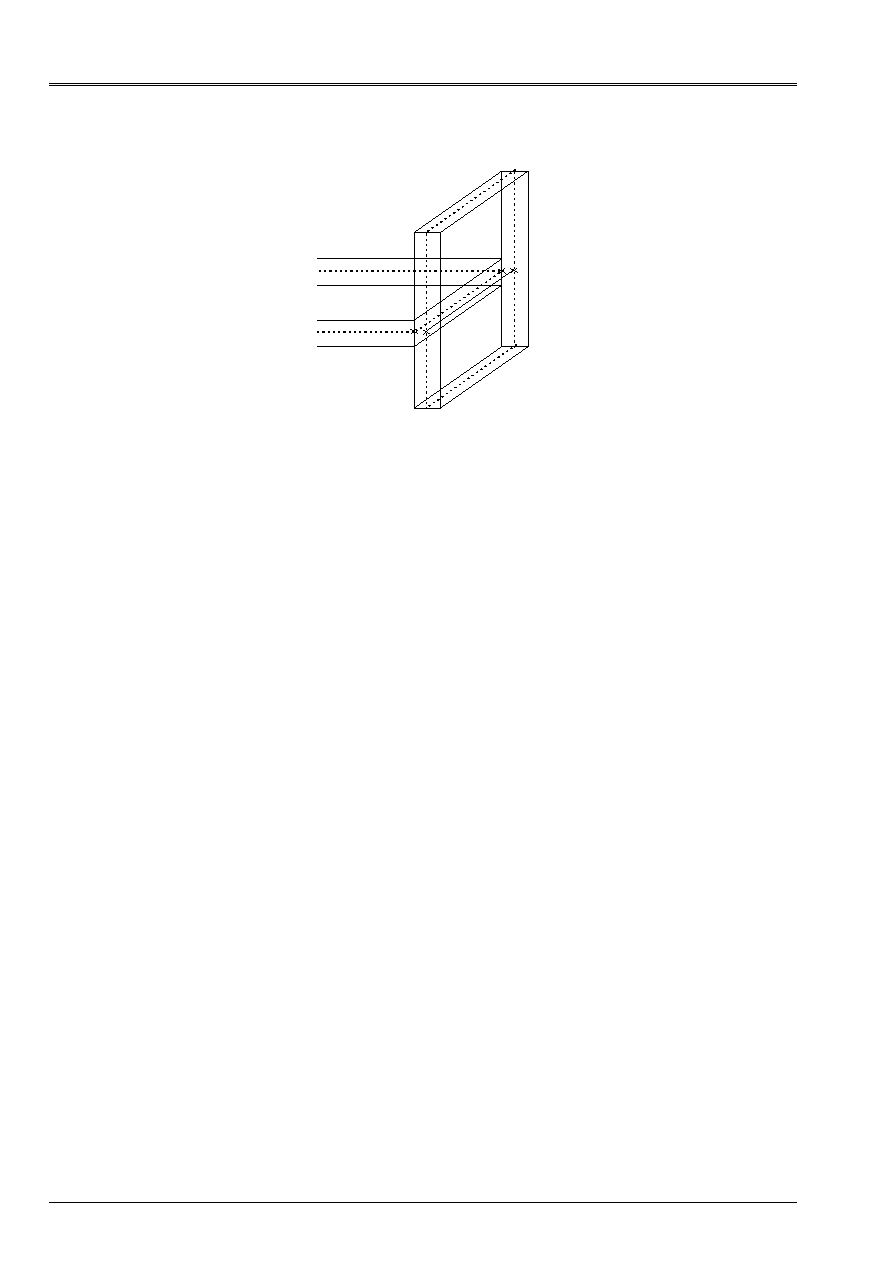

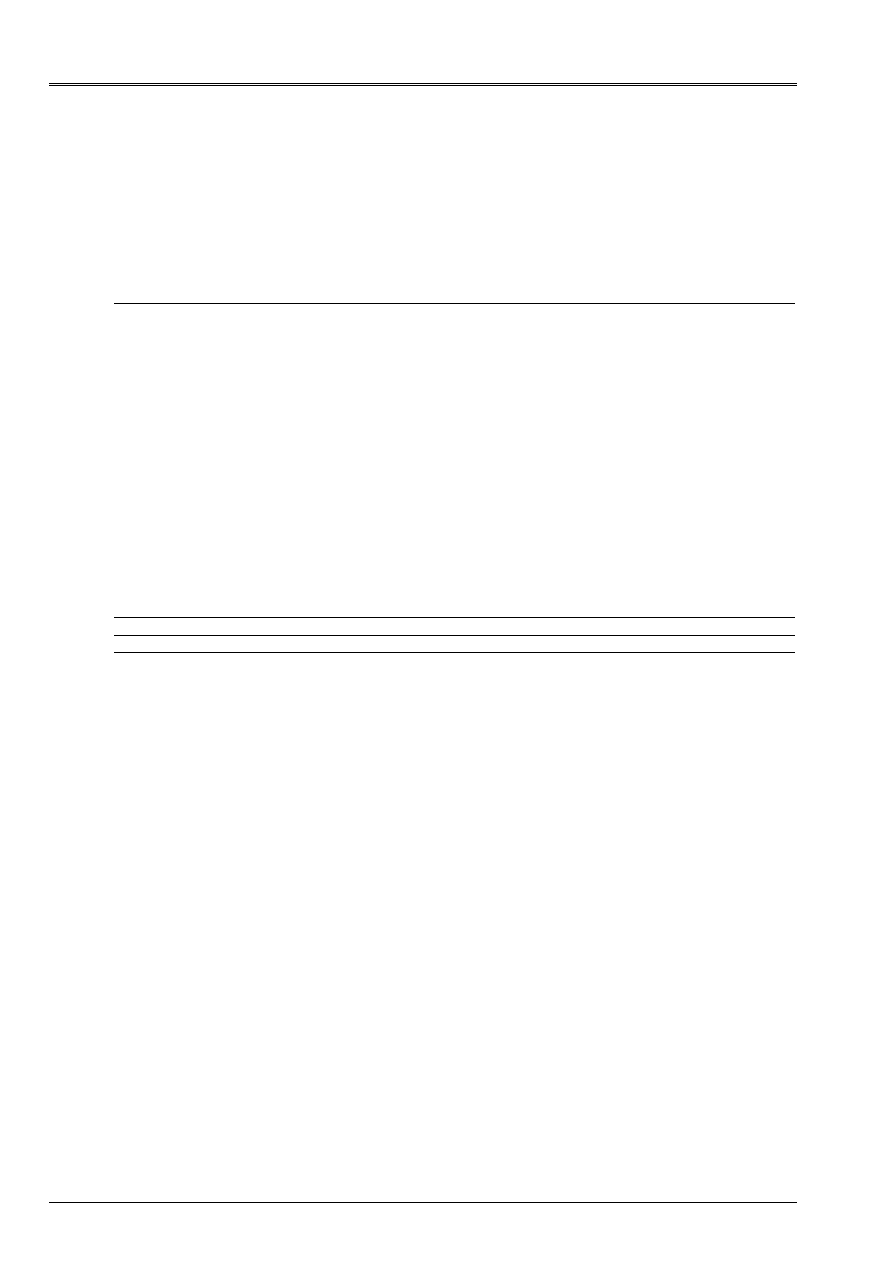

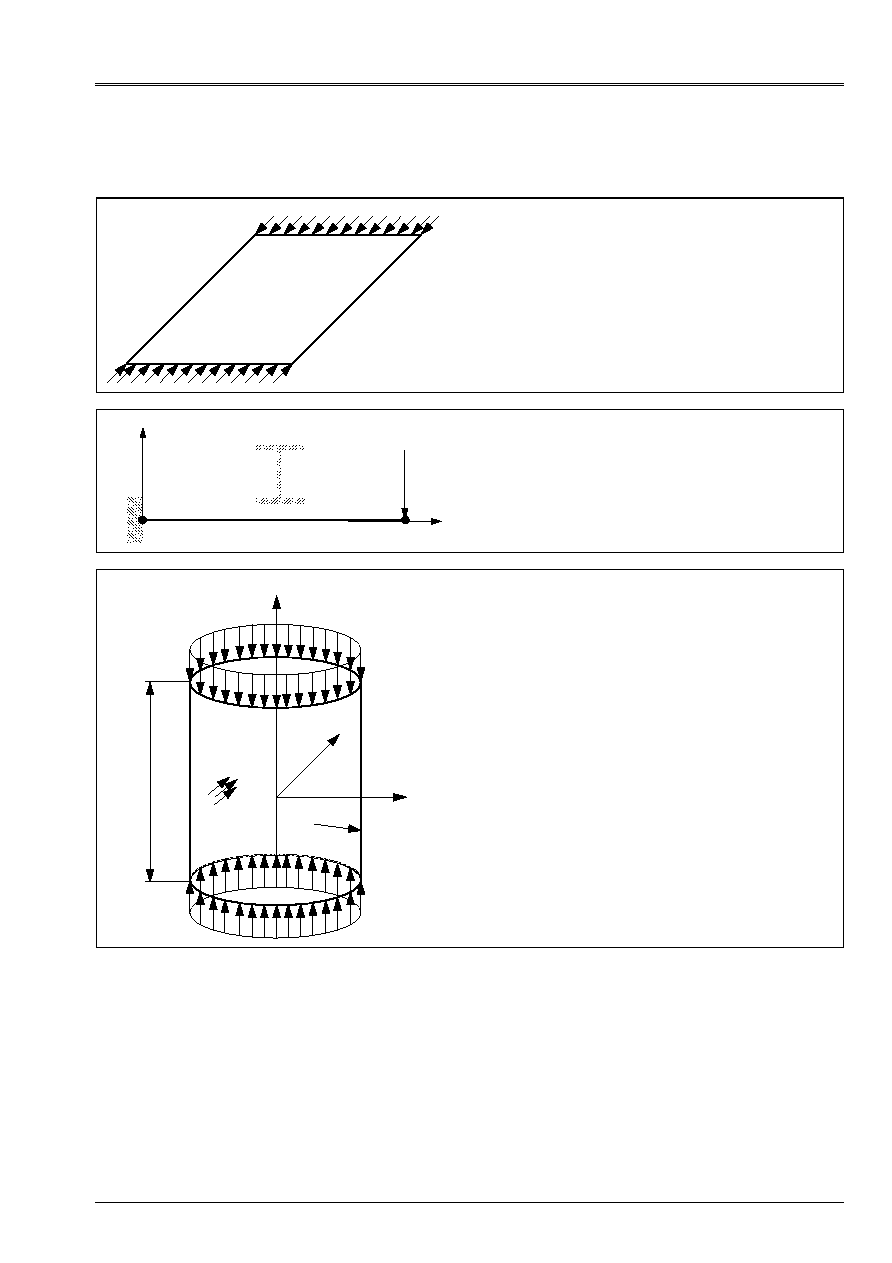

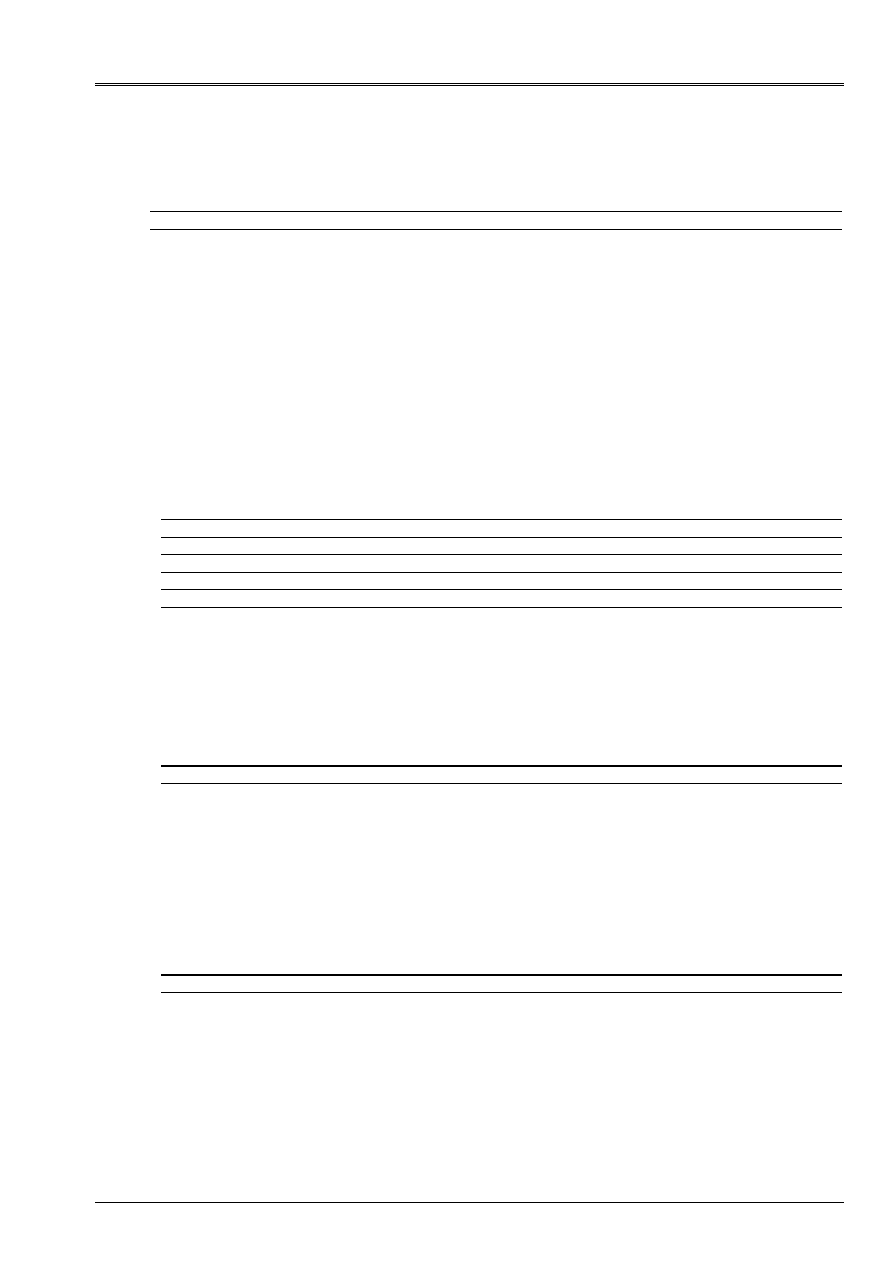

For the elements plates and hulls one defines a surface of reference, or surfaces average, plane

(plan X y for example) or curve (X and define a whole of curvilinear co-ordinates in it) and one

thickness H (X, y). This thickness must be small compared to other dimensions of the structure with

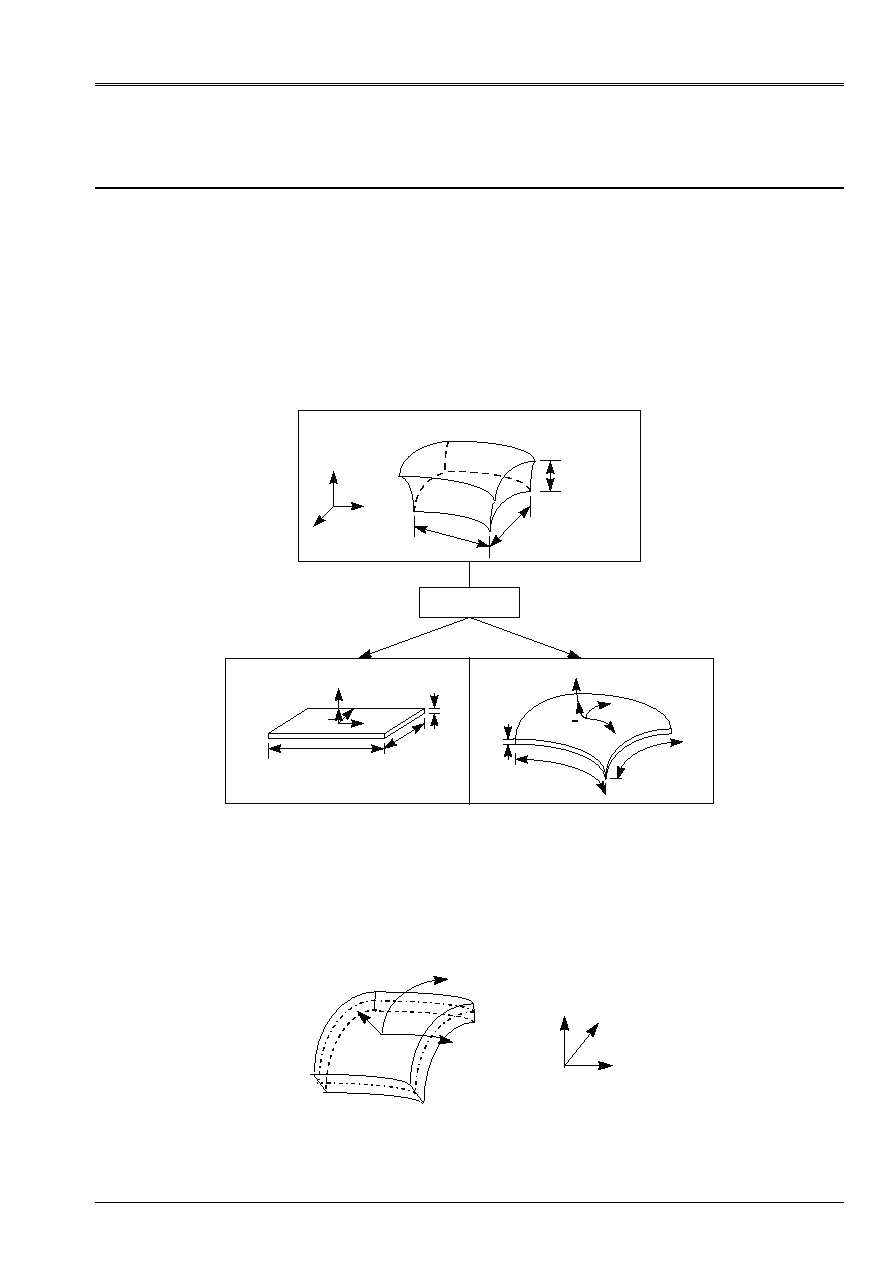

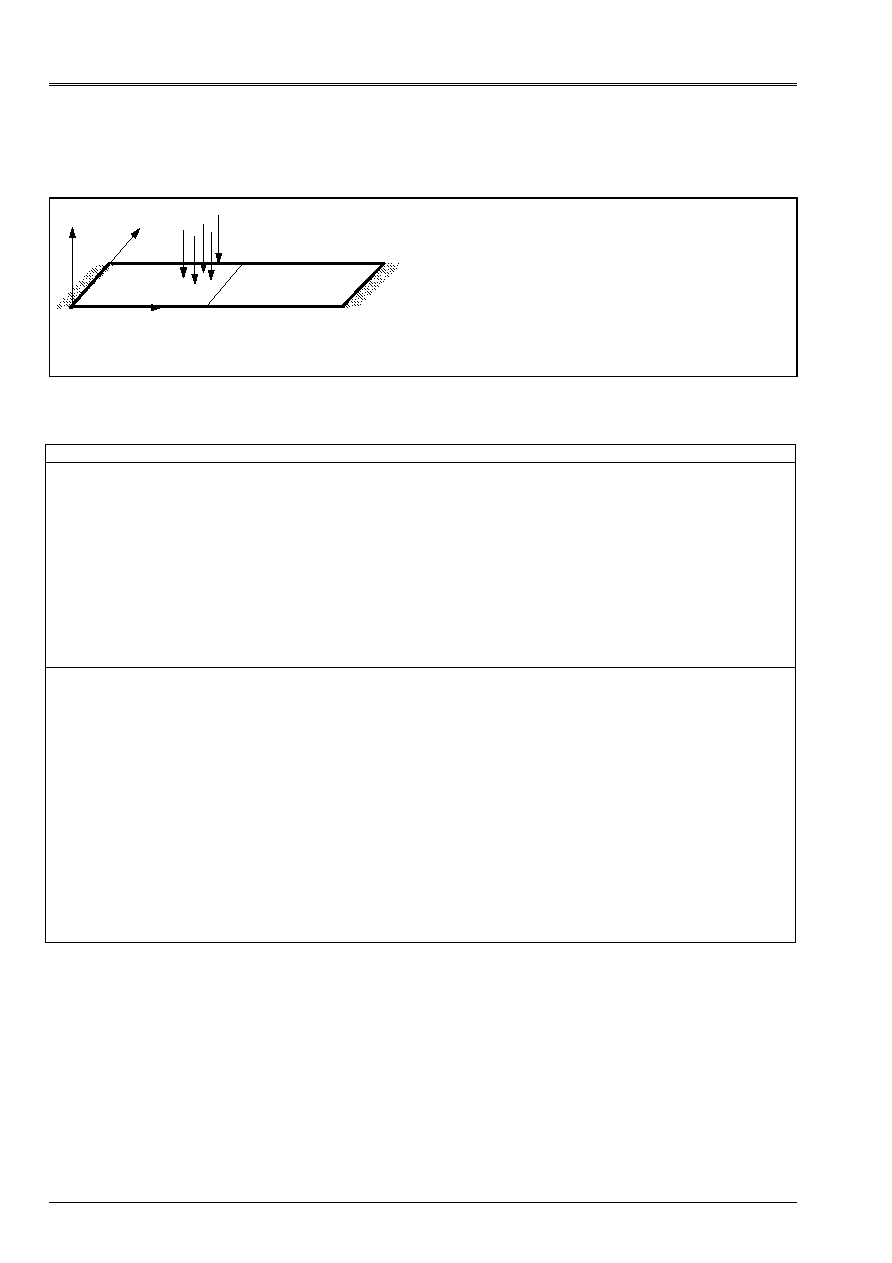

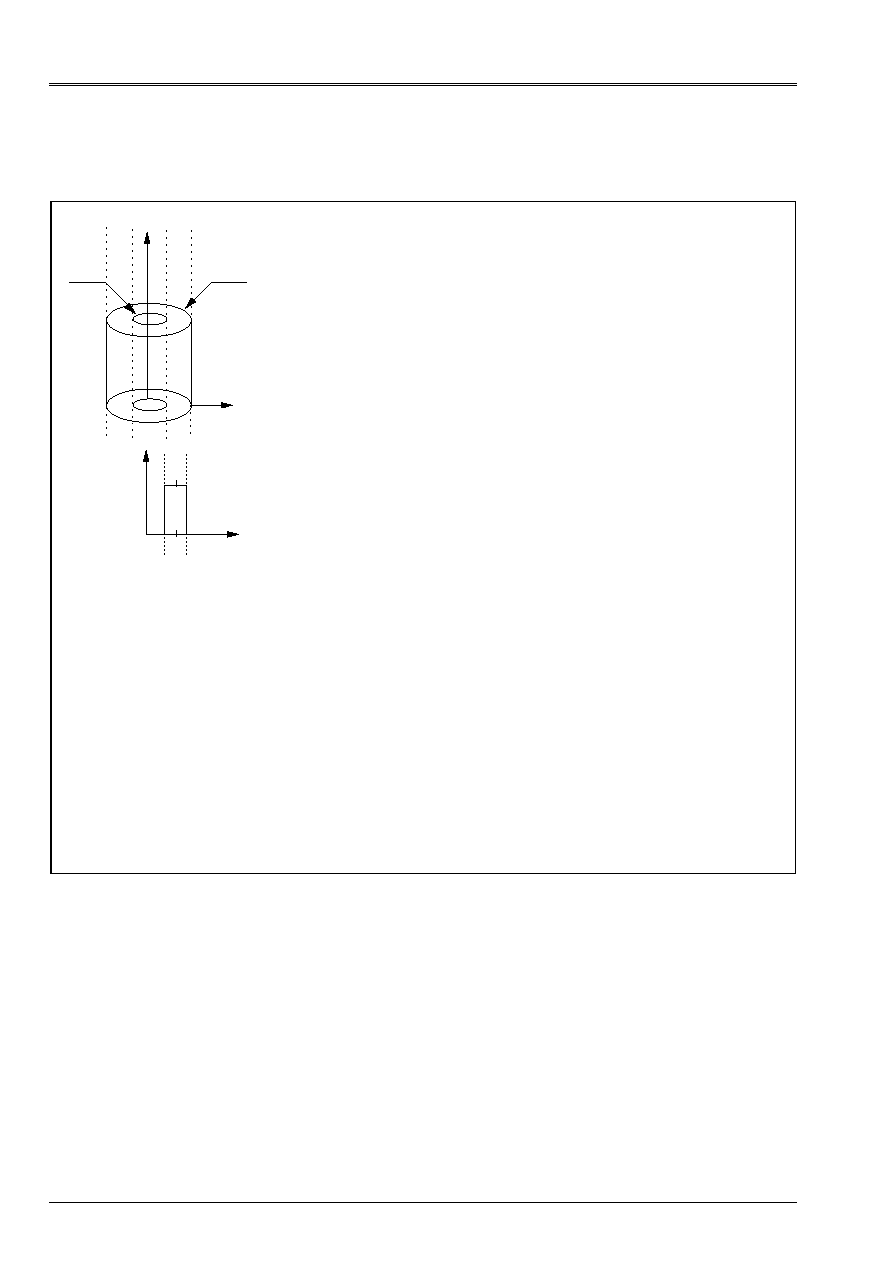

to modelize. The figure below illustrates these various configurations.

Thickness H < L, B

Solid 3D

X

Y

Z

H

L

B

Plate

L

B

H

X

y

Z

N

Hull

Z

X

y

N

L

B

H

Appear 2.1.1.1-a: Assumption in theory of the plates and hulls

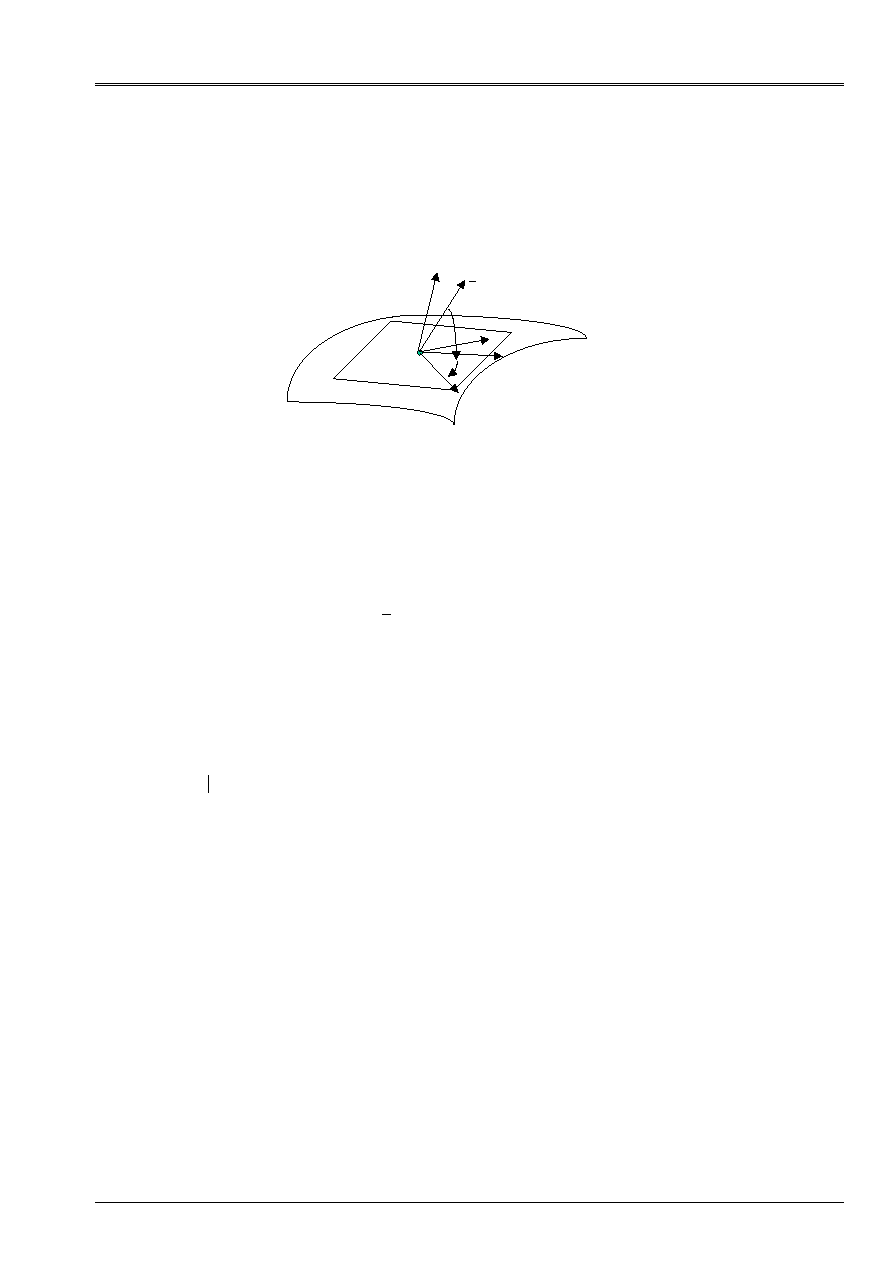

One attaches to average surface

a local reference mark Oxyz different from total reference mark OXYZ. The position

points of the plate or hull is given by the curvilinear co-ordinates (

1

,

2

) of surface

average and front elevation

3

compared to this surface. For the plates the frame of reference

curvilinear is a local Cartesian frame of reference.

O

Y

Z

N,

3

2

X

1

, X

, y

, Z

_

Appear 2.1.1.1-b: Definition of an average surface

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

6/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

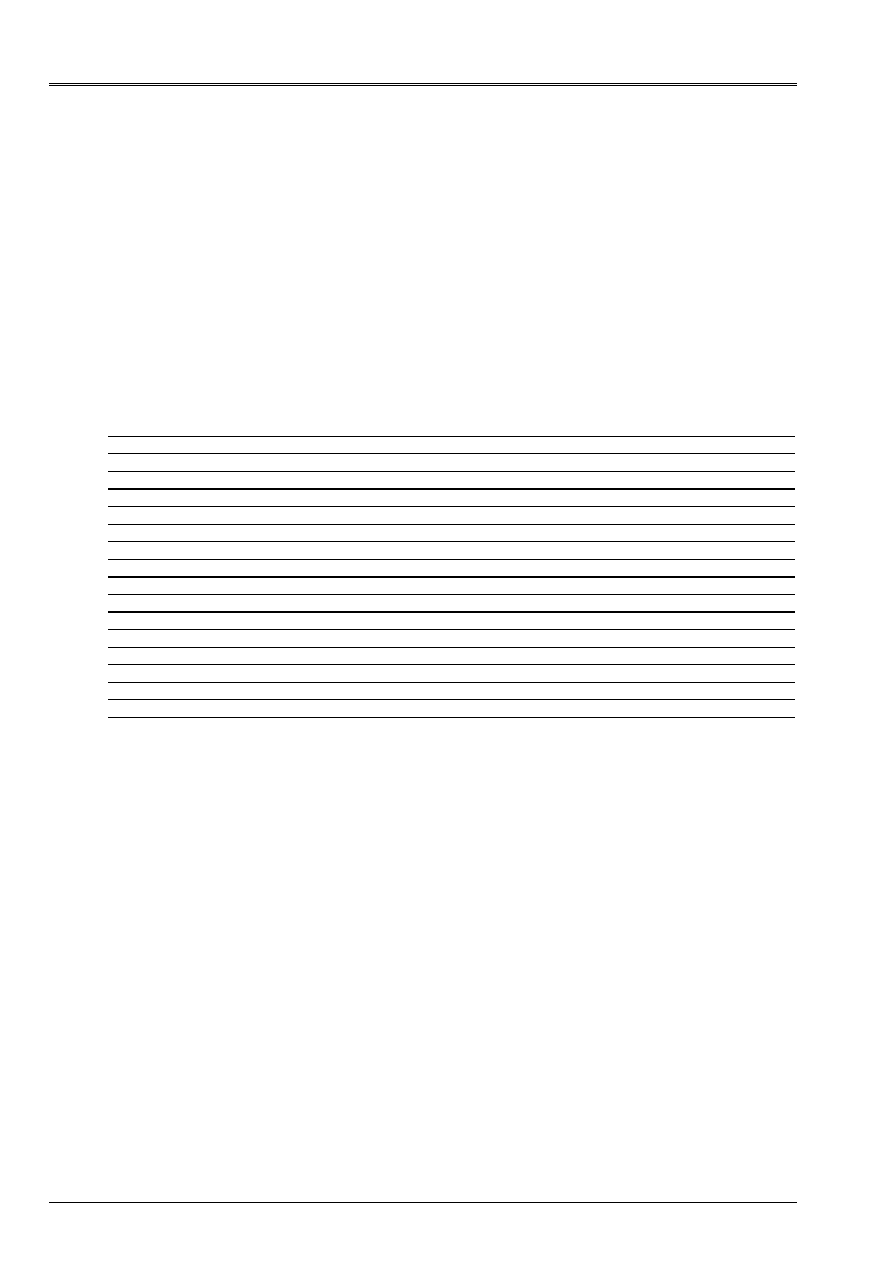

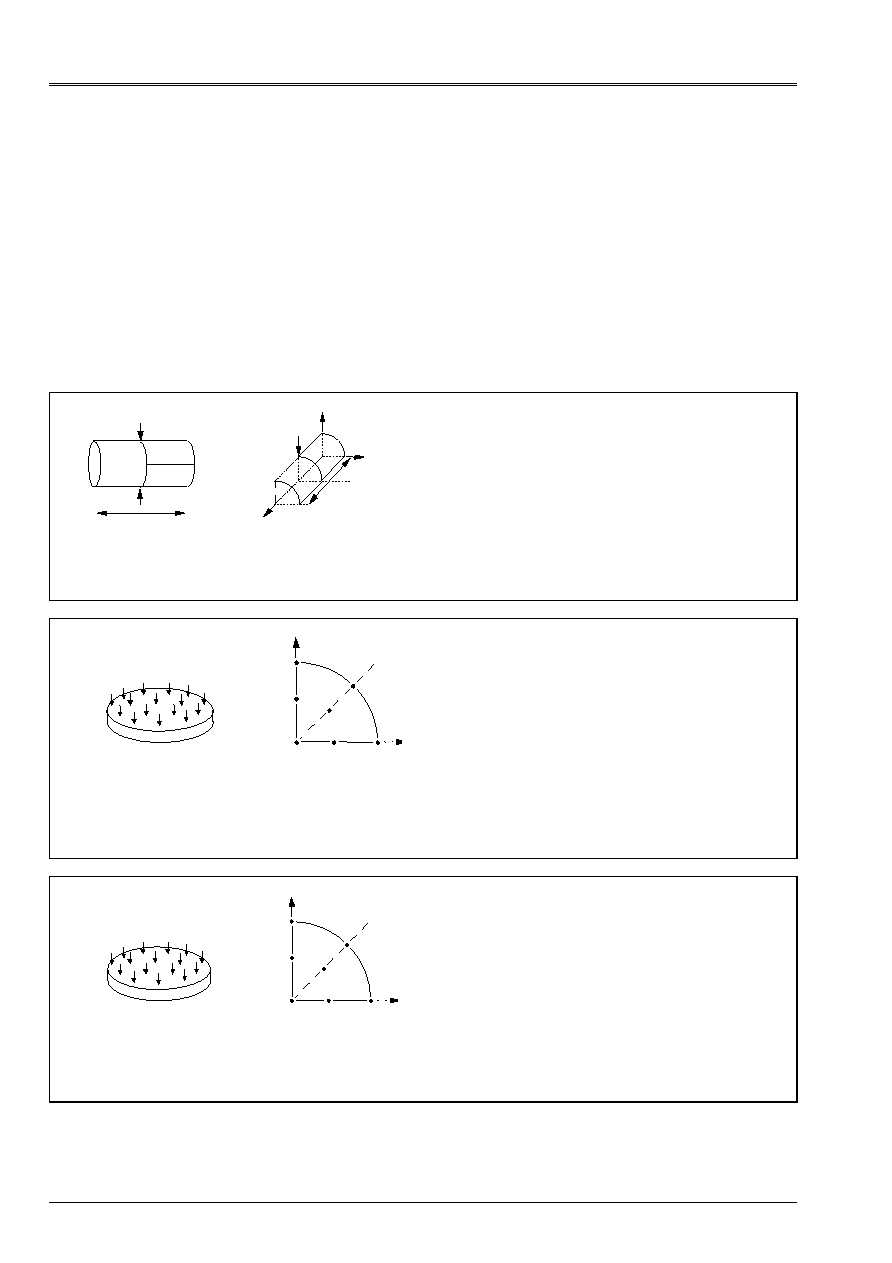

To represent hulls with symmetry of revolution around an axis (COQUE_AXIS) or hulls

with invariant geometry by translation (COQUE_C_PLAN in plane stresses or COQUE_D_PLAN in

plane deformations), the knowledge of the section of revolution or the trace of surface

average is sufficient, as the figure [Figure 2.1.2.1-a] shows it to us. These hulls rest on

a linear mesh and in a point

m

average surface one defines a local reference mark (

N

,

T

,

E

Z

)

by:

T

= Om

, S

Om

, S

;

N

T = E

Z

.

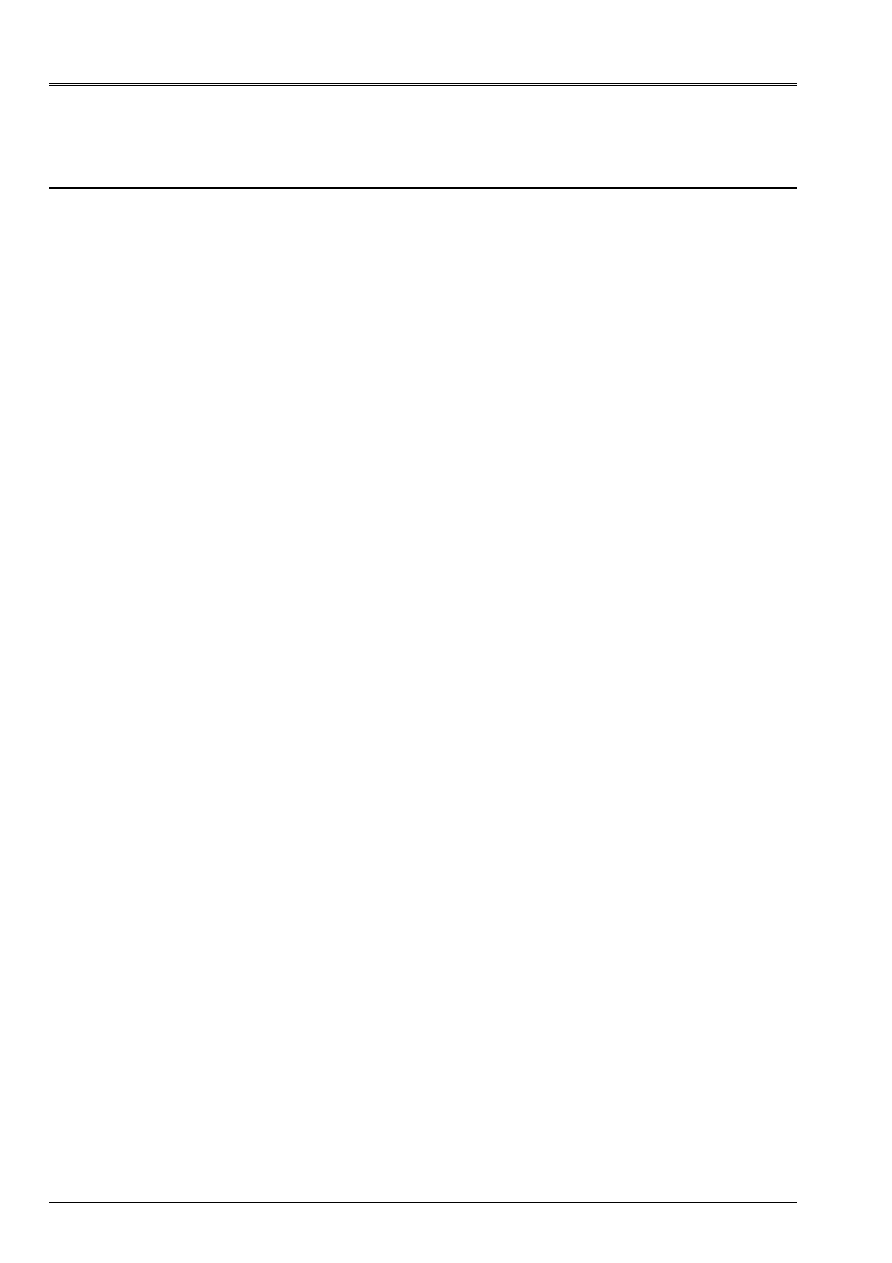

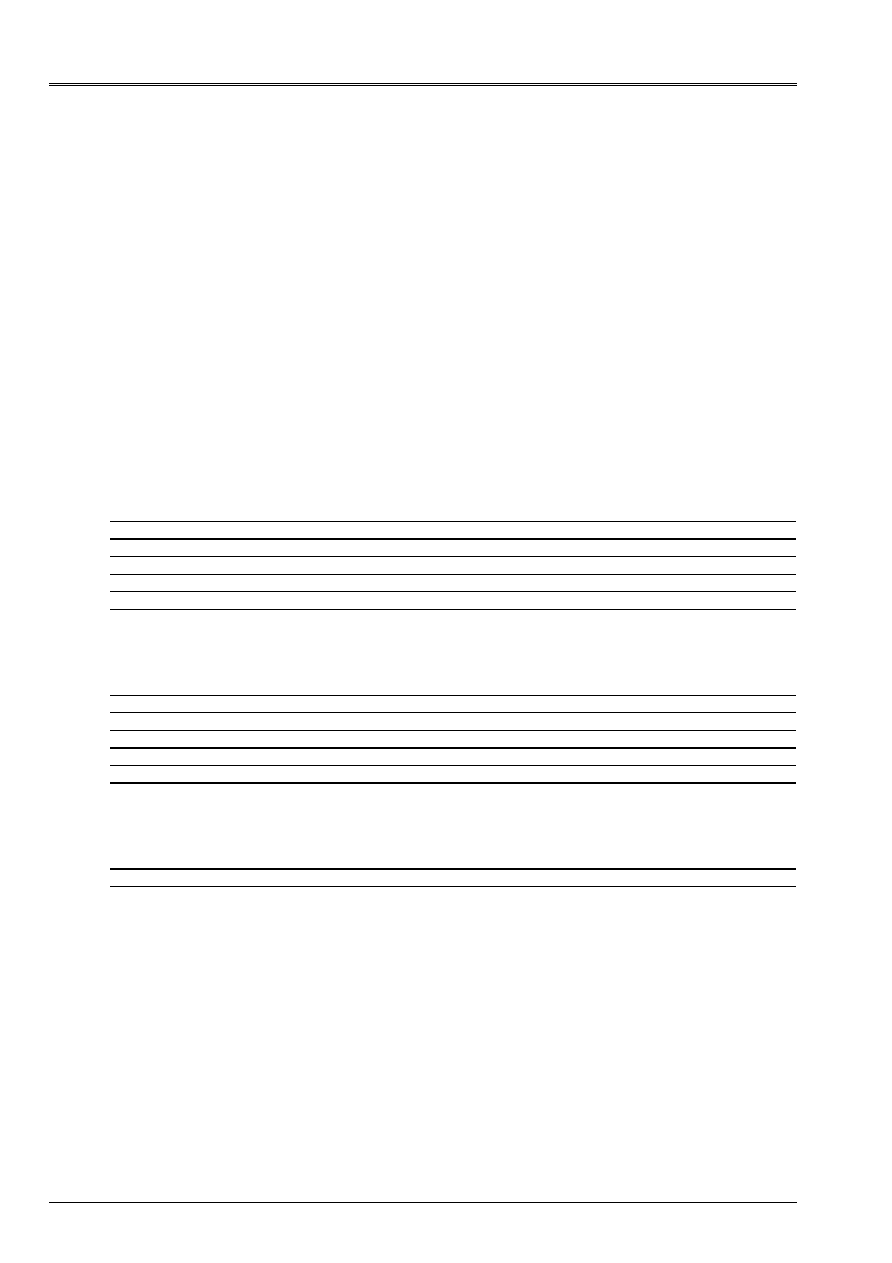

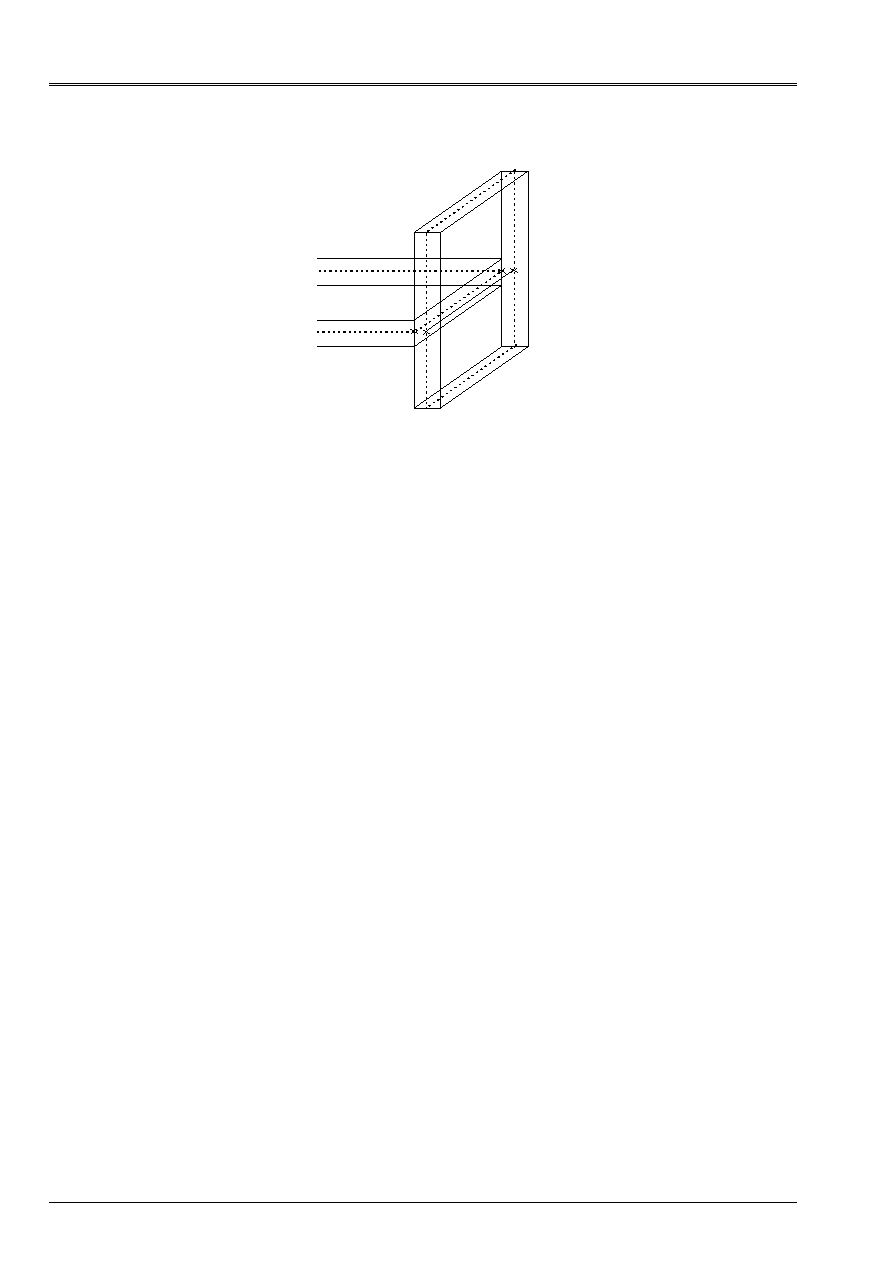

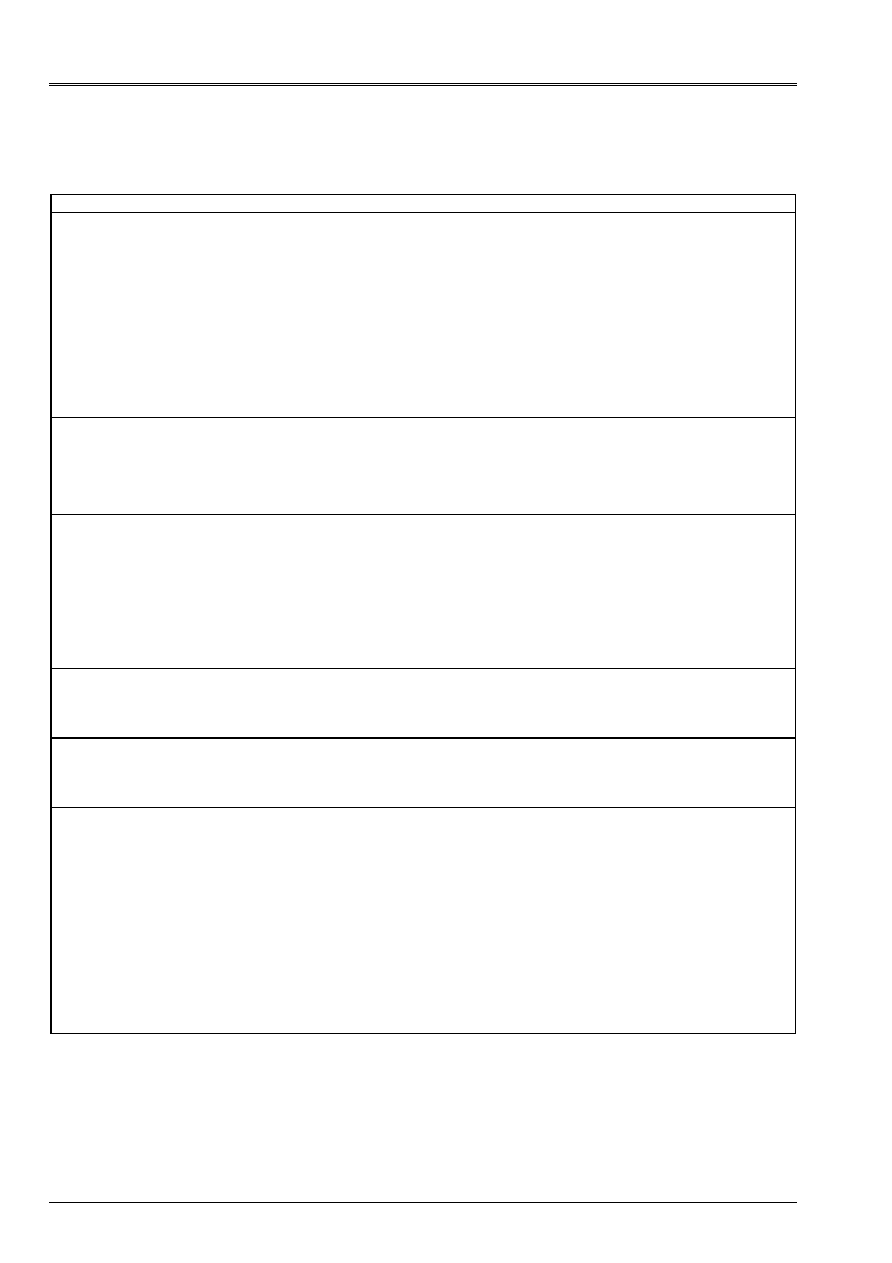

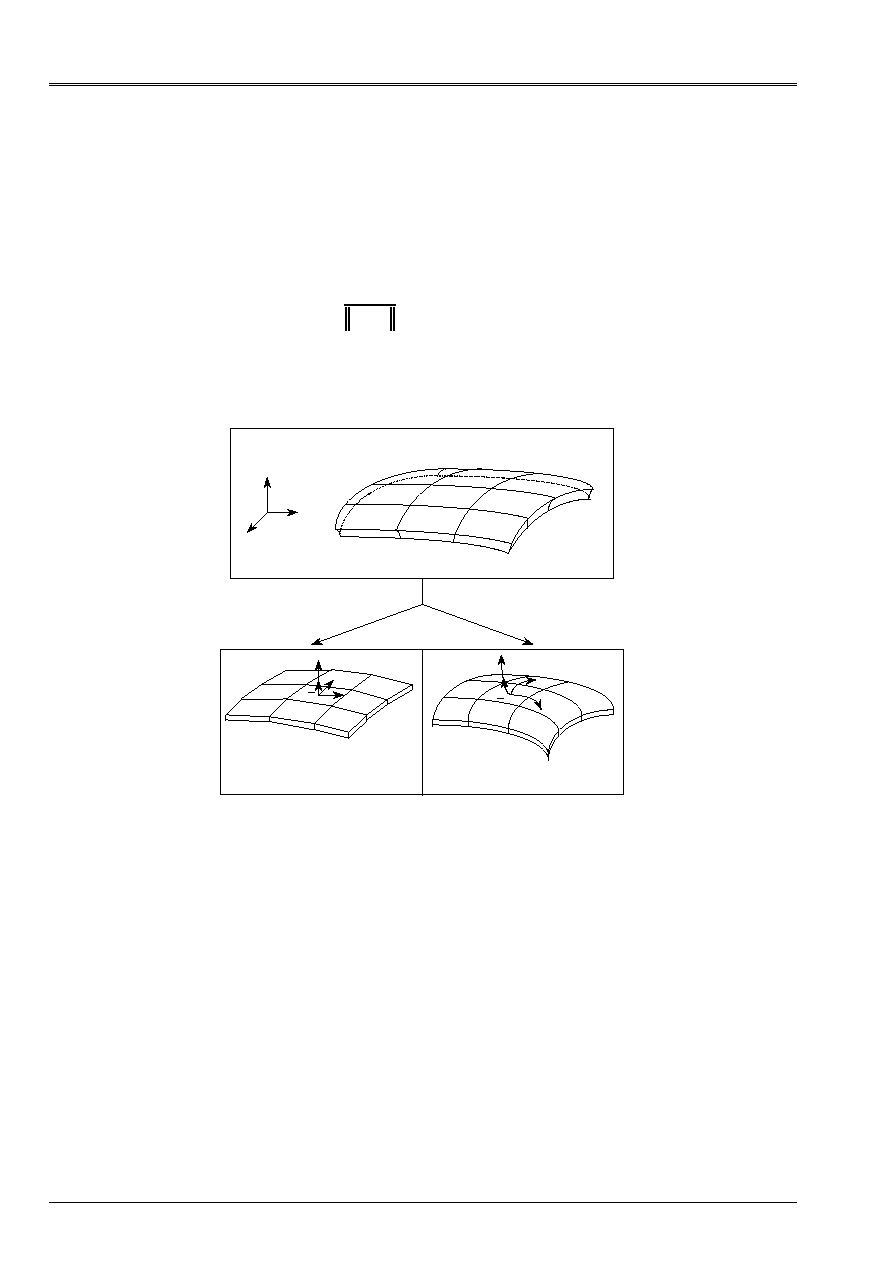

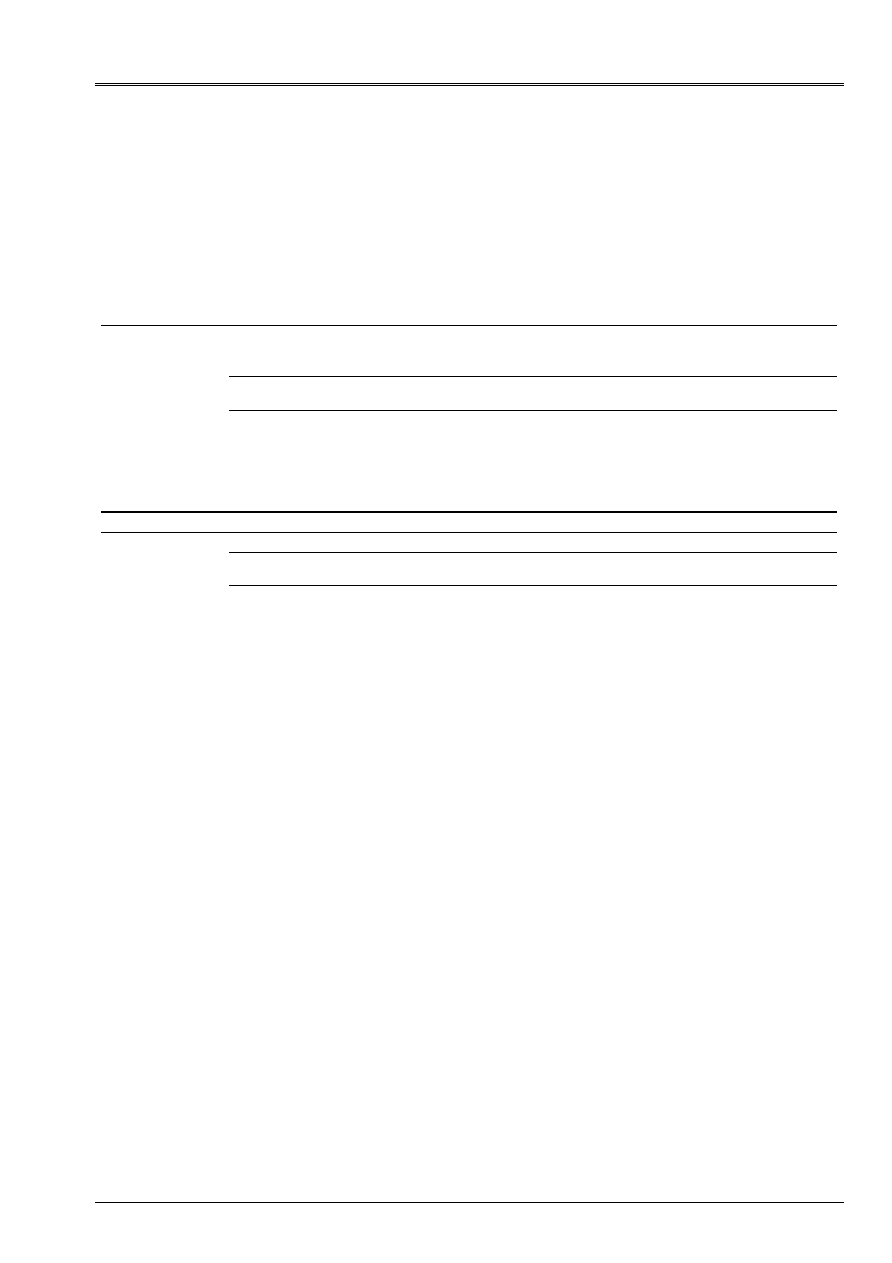

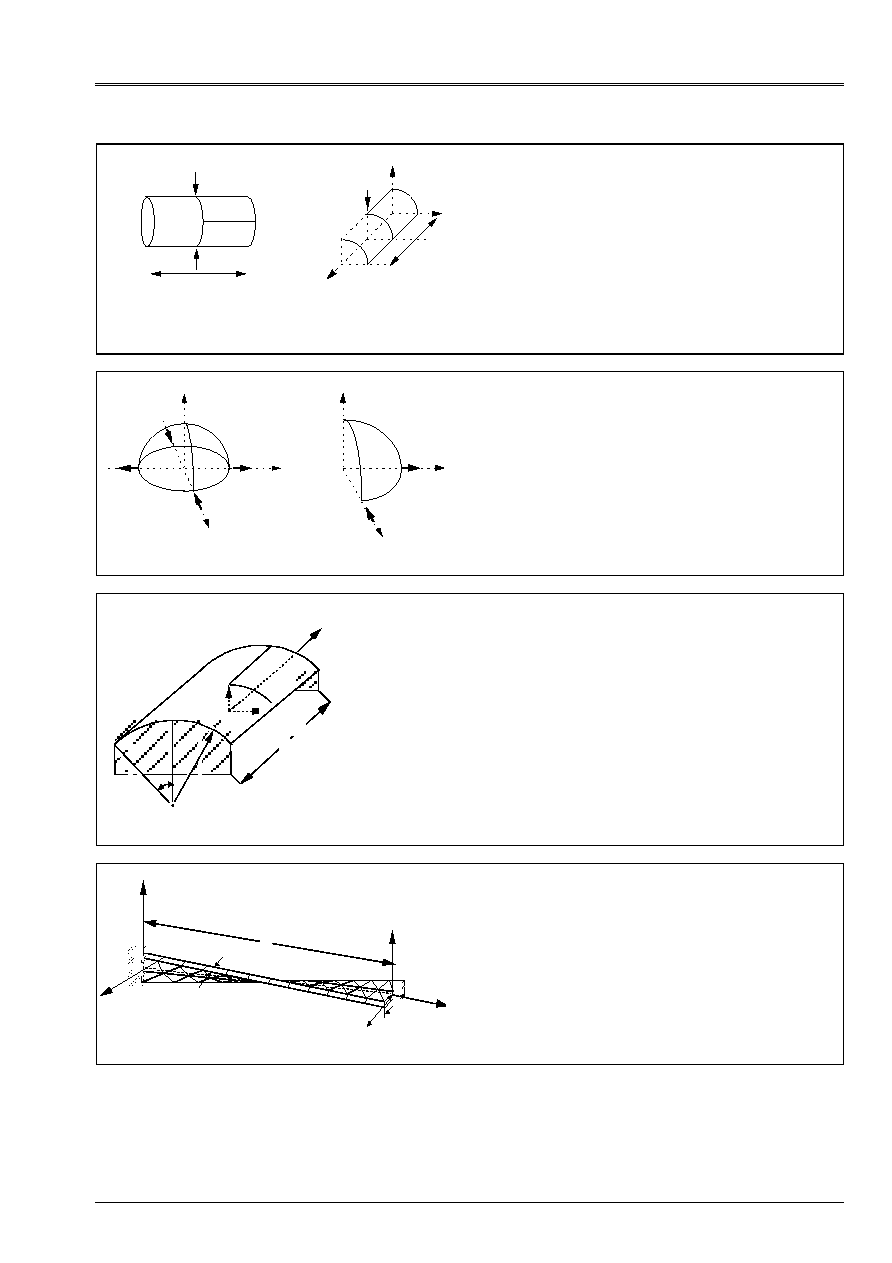

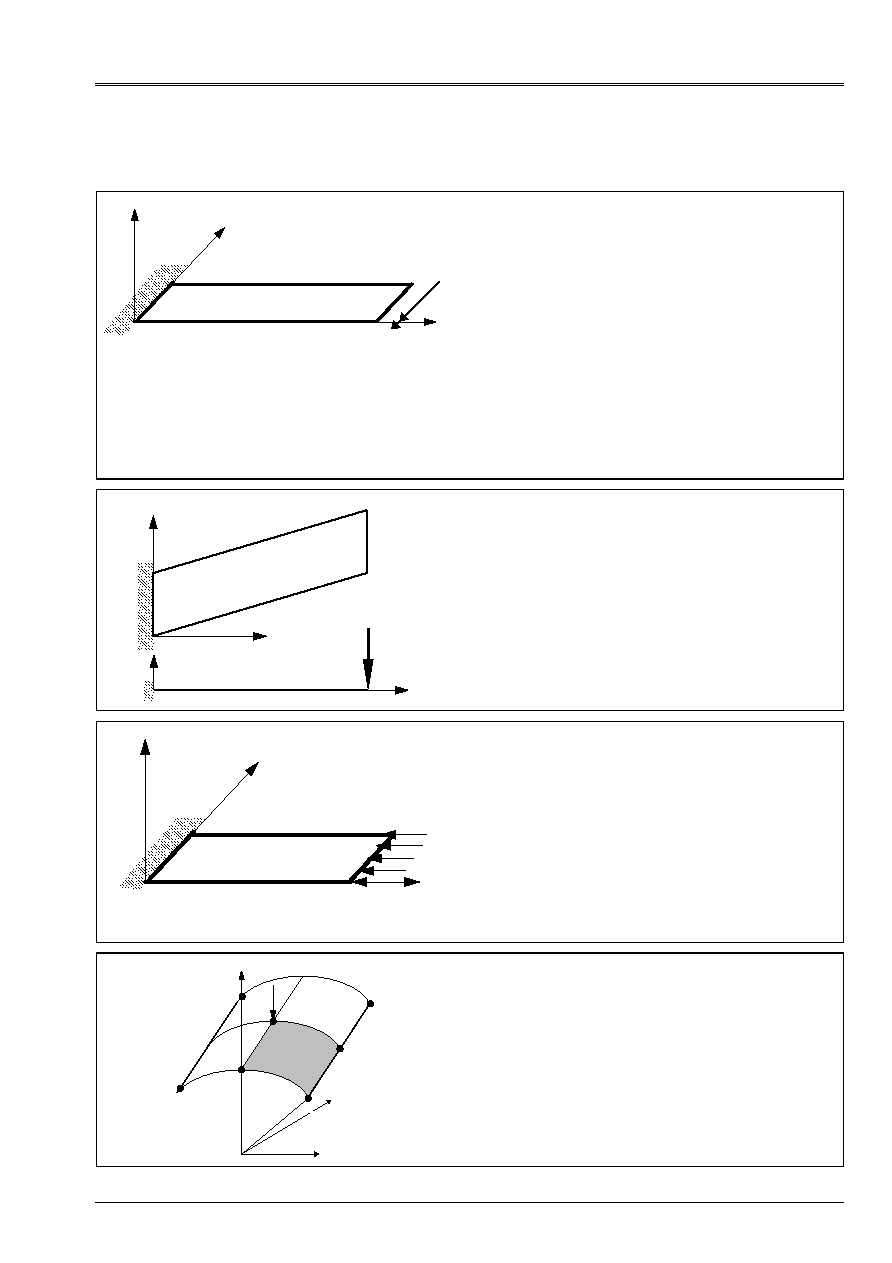

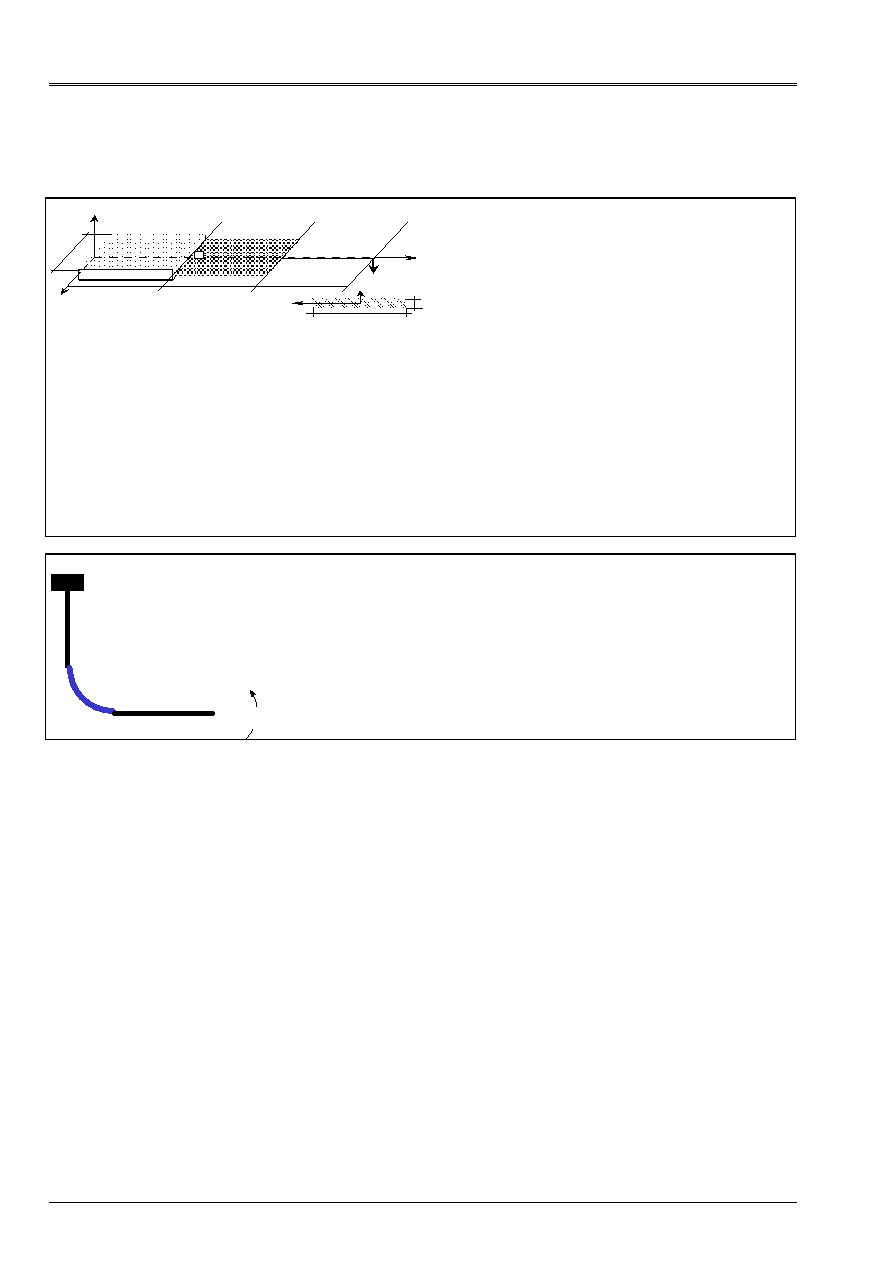

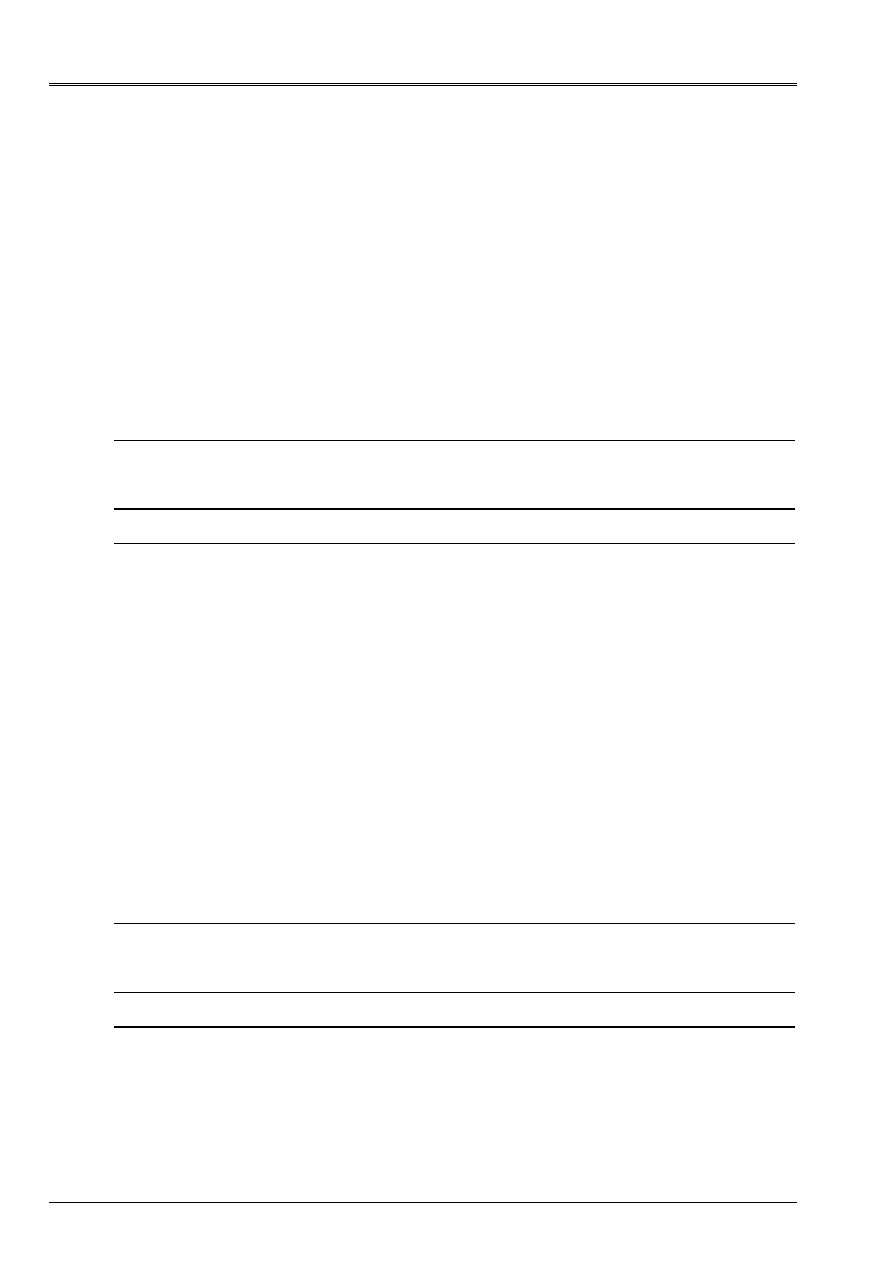

When one wishes to modelize a solid of an unspecified form (not plan), one can use

elements of hulls to account for the curvature, or many elements of plates. In it

last case, the geometry is approximated by a network of breakages.

Solid complete 3D

X

Y

Z

Elements of plates: breakages

X

y

Z

N

X

y

Z

N

Elements of hulls

Z

X

y

N

Z

X

y

N

Appear 2.1.1.1-c: Modeling of an unspecified solid 3D by elements of plates or hulls

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

7/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.1.2 Formulation of the elements plates and hulls

2.1.2.1 Formulation into linear geometrical

In this formulation, one supposes that displacements are small, one can thus superimpose

initial geometry and deformed geometry. These elements are based on the theory of the plates according to

which:

·

the cross-sections which are the sections perpendicular to the surface of reference remain

straight lines; material points located on a normal at not deformed average surface

remain on a line in the deformed configuration. It results from this approach that them

fields of displacement vary linearly in the thickness of the plate or of

hull. If one indicates by U, v and W displacements of a point Q (X, y, Z) according to X, y and Z, one

has as follows:

+

=

0

)

y

,

X

(

)

y

,

X

(

Z

)

y

,

X

(

W

)

y

,

X

(

v

)

y

,

X

(

U

)

Z

,

y

,

X

(

W

)

Z

,

y

,

X

(

v

)

Z

,

y

,

X

(

U

y

X

The associated tensor of deformation is written then:

)

y

,

X

(

Z

)

y

,

X

(

)

y

,

X

(

)

Z

,

y

,

X

(

E

+

+

=

.

first term E includes/understands the deformations of membrane (for an element of plate it

are the deformations in the plan of the element), the second

those of shearing

transverse, and third Z

deformations of bending, associated the tensor of

curvature

. For the thick plates or hulls transverse shearings are taken

in account following the formulation suggested by Reissner, Hencky, Bollé, Mindlin. This

formulation includes the approach without transverse shearing, where the tensor

is null,

developed by Kirchhoff for the thin plates or hulls according to which points

hardware located on a normal N at not deformed average surface remains on

normal on the deformed surface.

·

the transverse stress

zz

bus is null regarded as negligible compared to

other components of the tensor of the stresses (assumption of the plane stresses).

·

one does not describe the variation thickness nor that of the transverse deformation

zz

that one

can calculate by using the preceding assumption of plane stresses.

·

the taking into account of transverse shearing depends on given factors of correction has

priori by energy equivalences with models 3D, so that rigidity

in transverse shearing of the model of plate is nearest possible to that defined

by the theory of three-dimensional elasticity. For the homogeneous plates, the factor of

transverse correction of shearing based on this method is k=5/6.

Note:

The determination of the factors of correction rests for Mindlin on equivalences of

Eigen frequency associated the mode of vibration by transverse shearing. One obtains then

K =

2

12

/

, value very close to 5/6.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

8/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

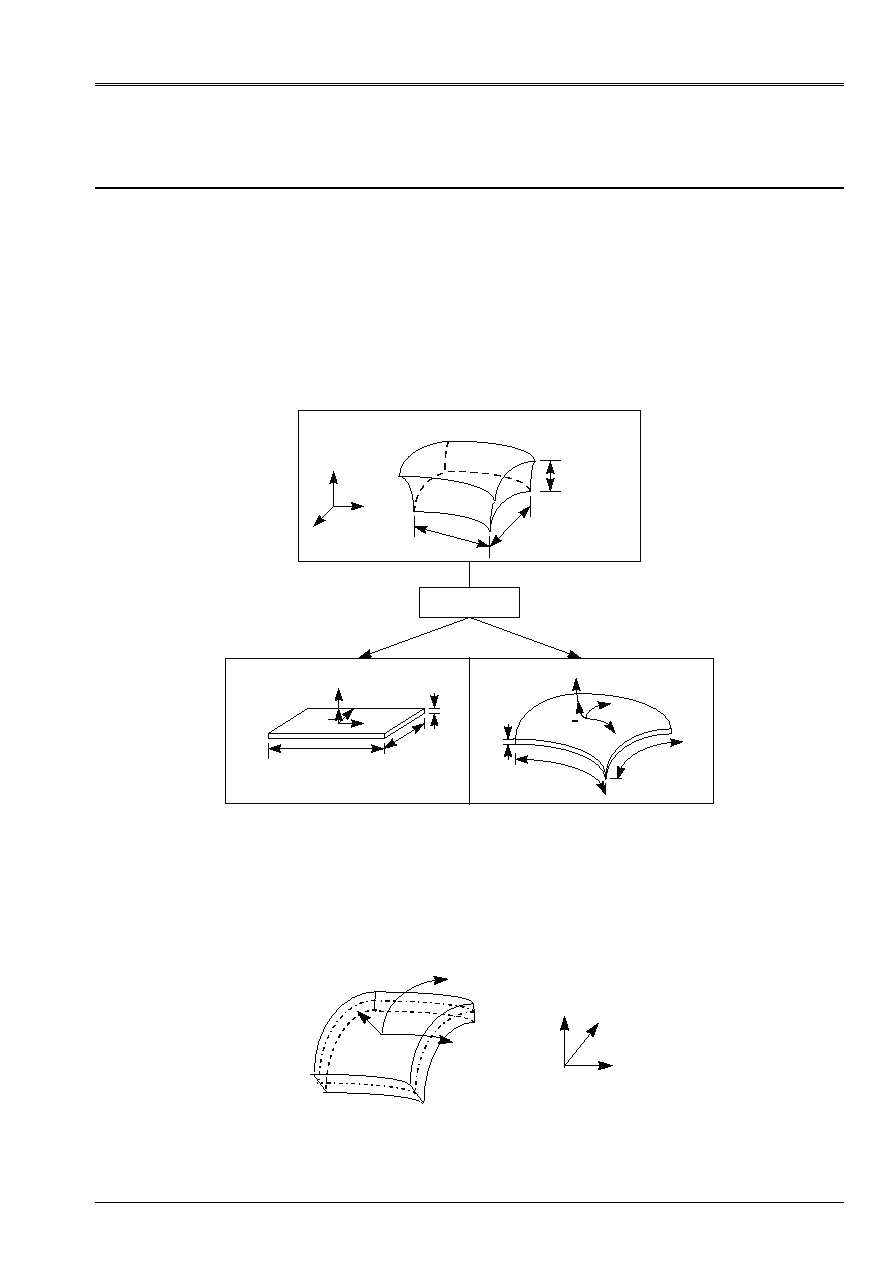

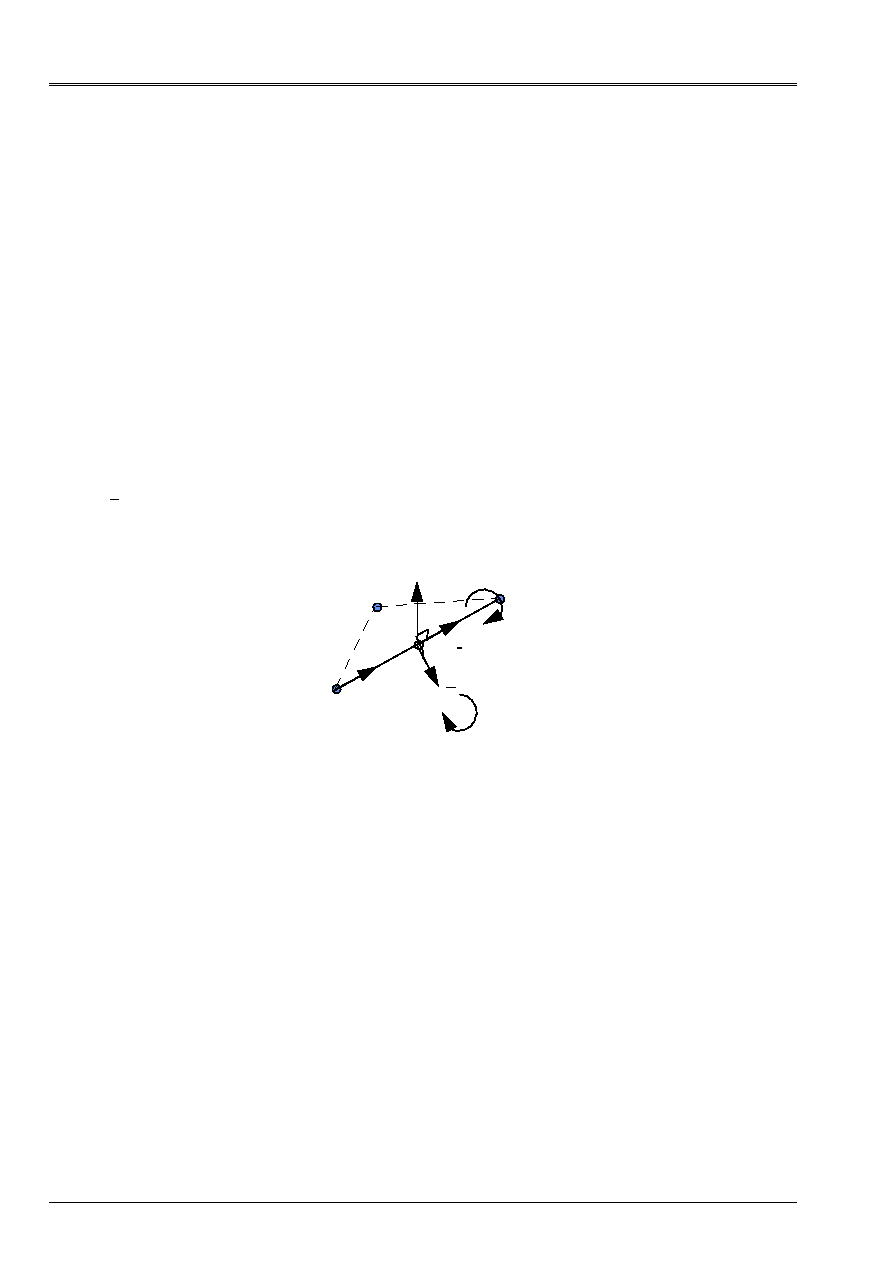

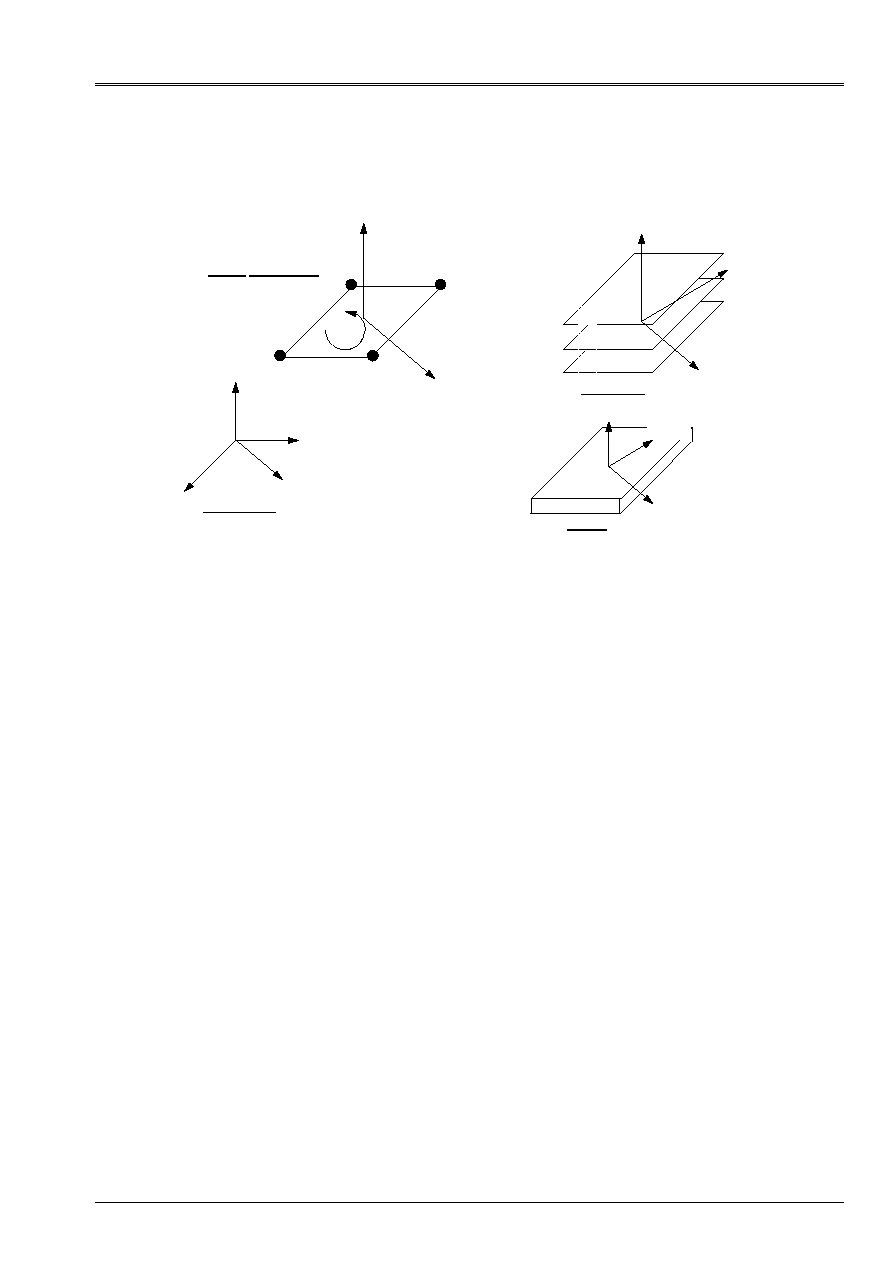

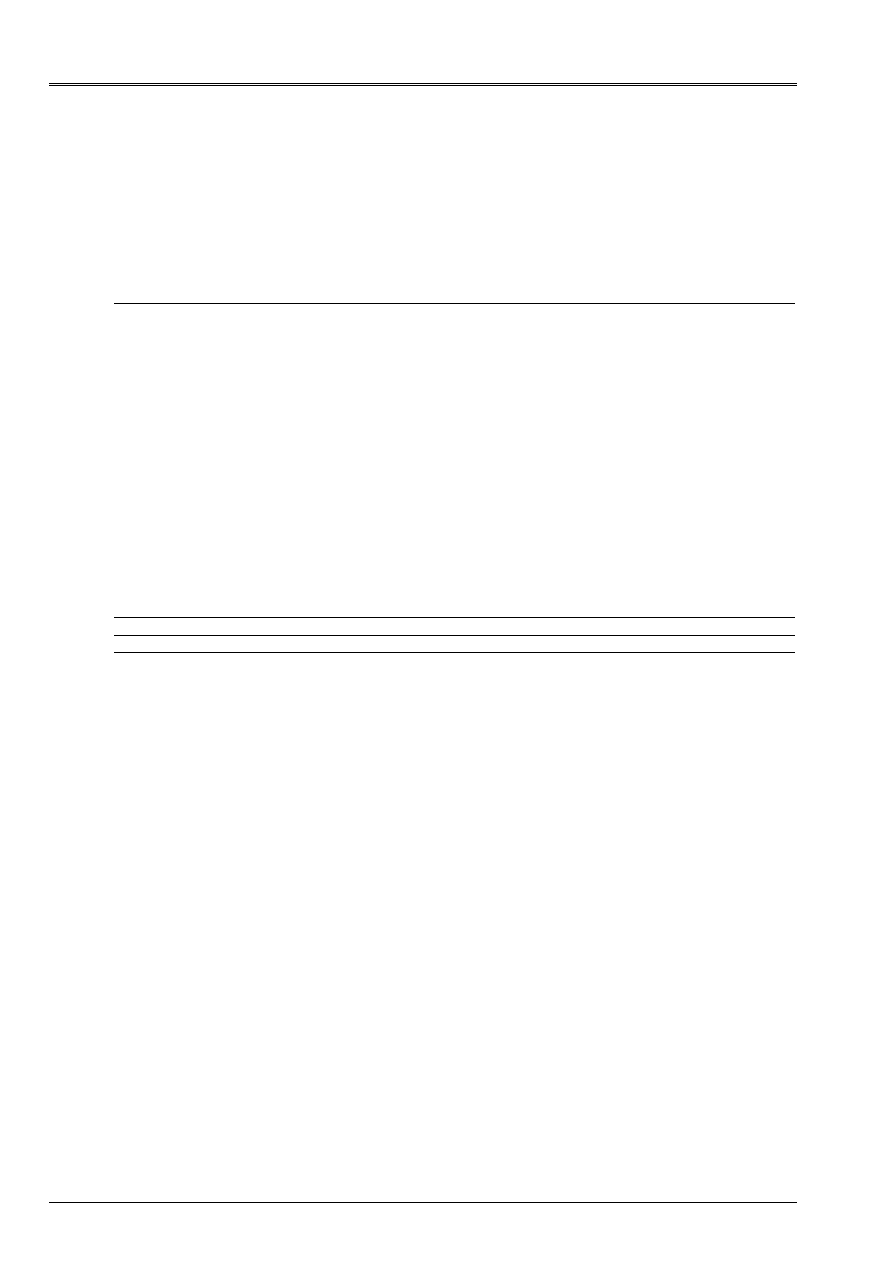

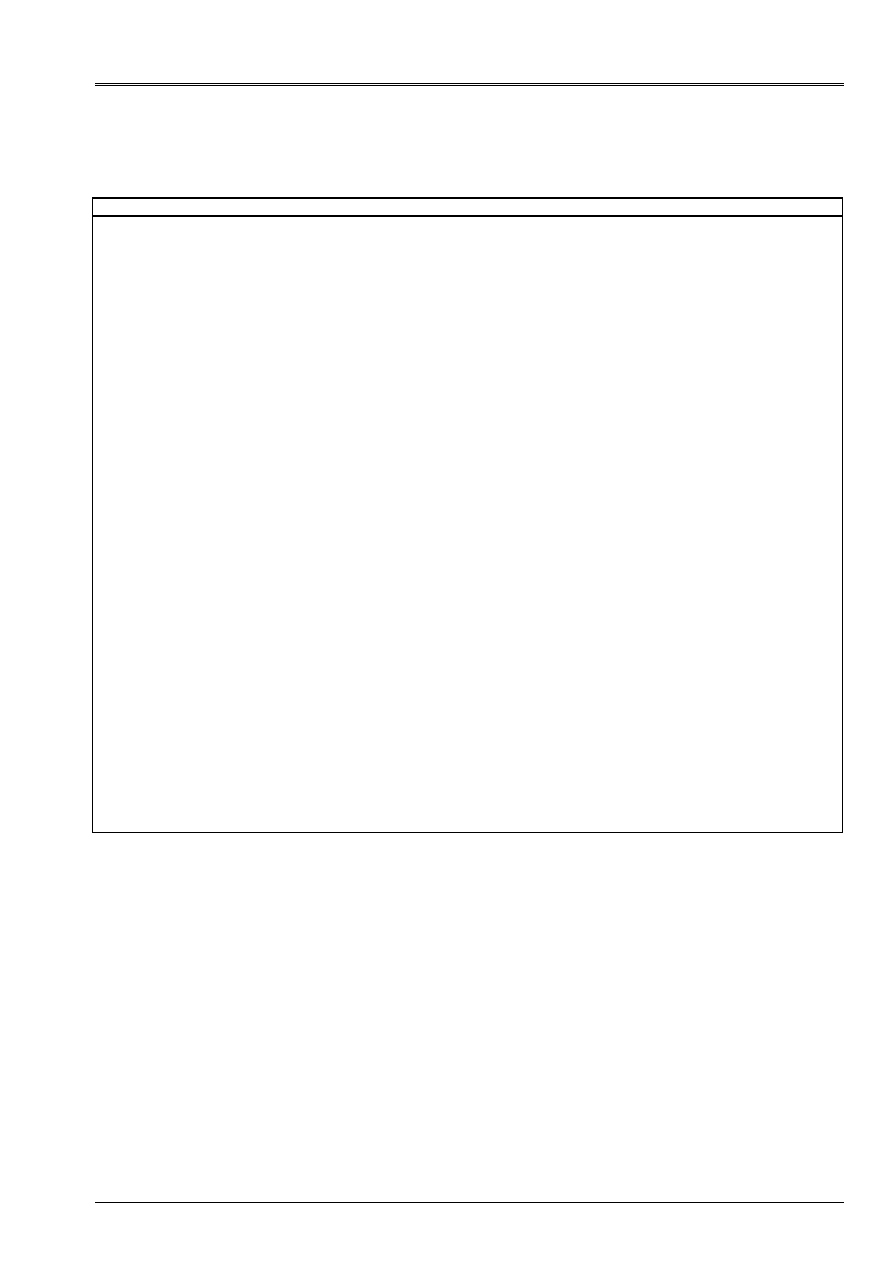

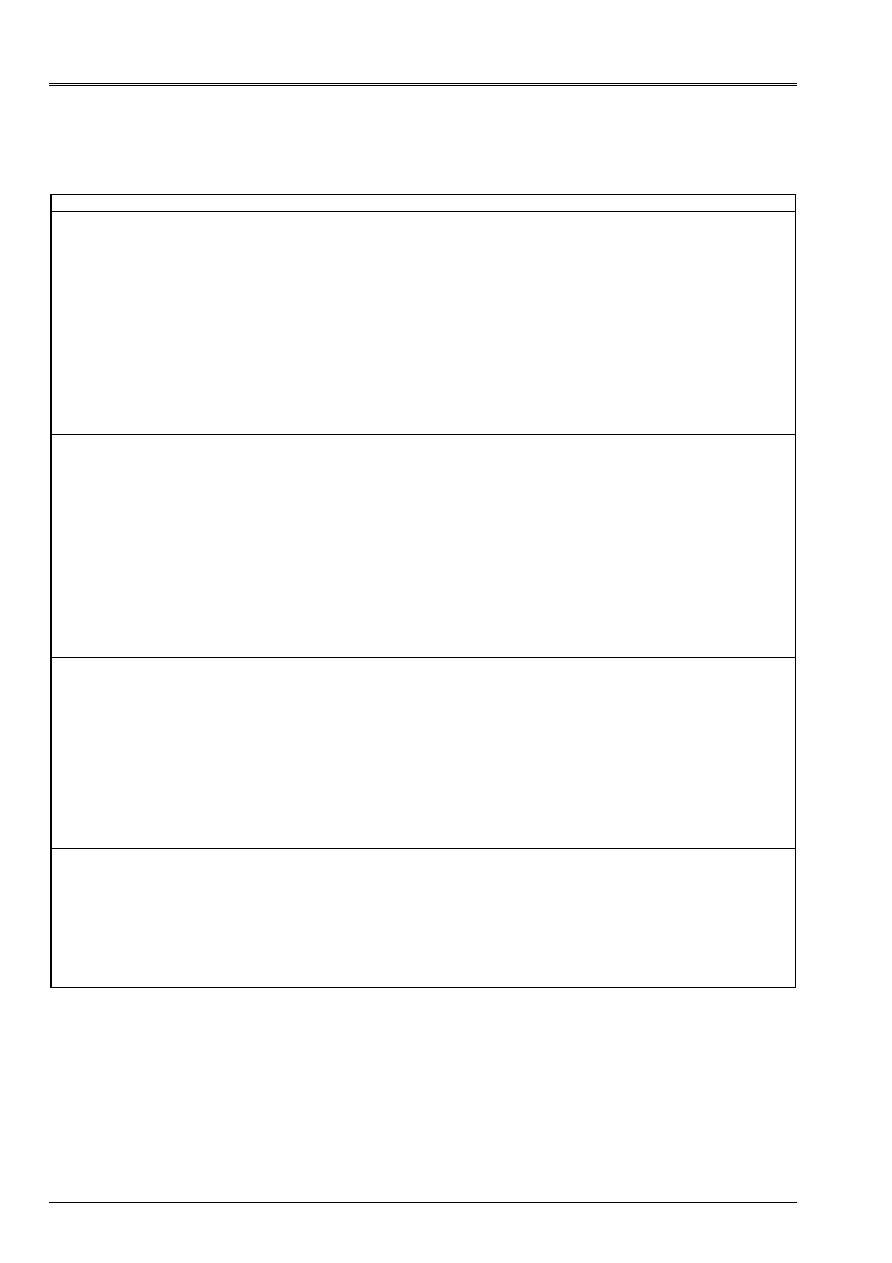

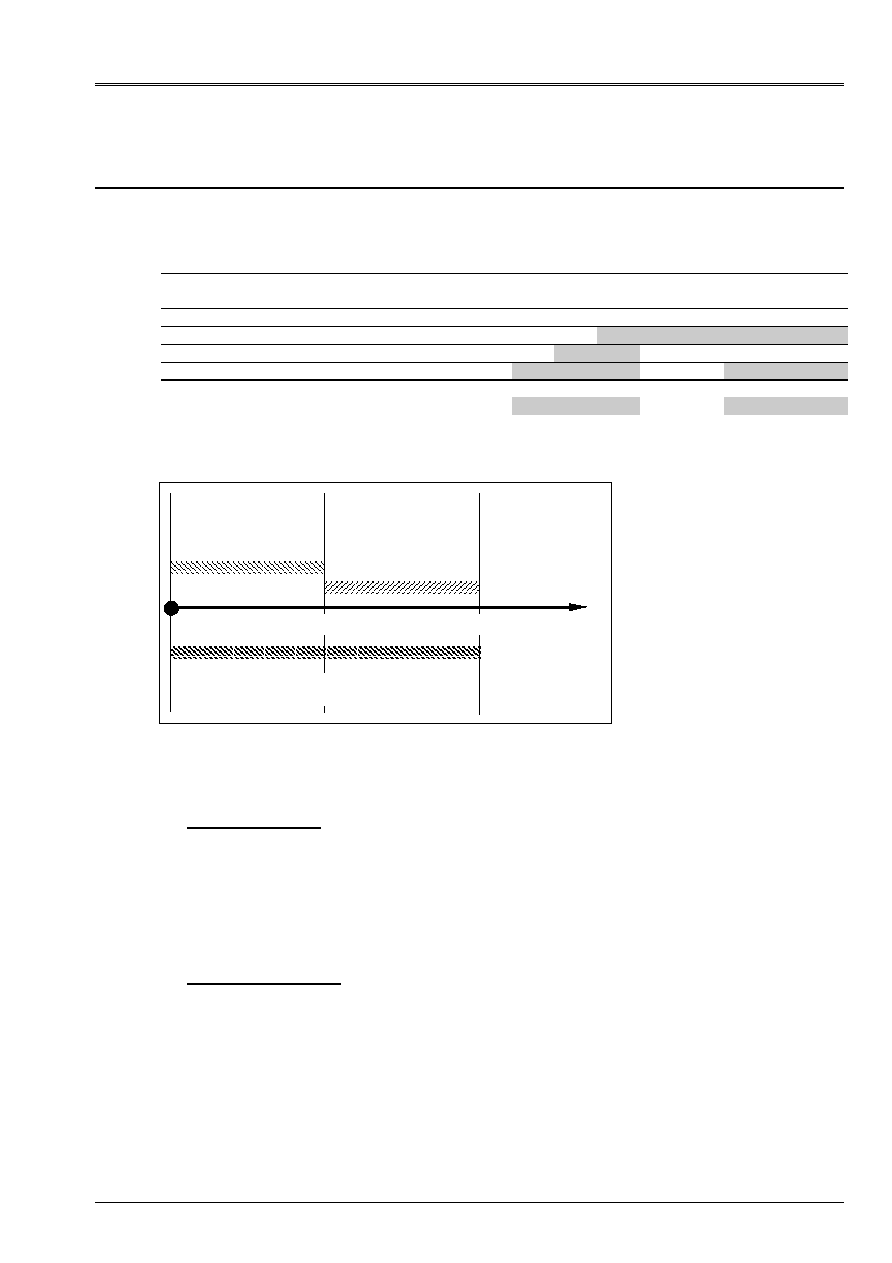

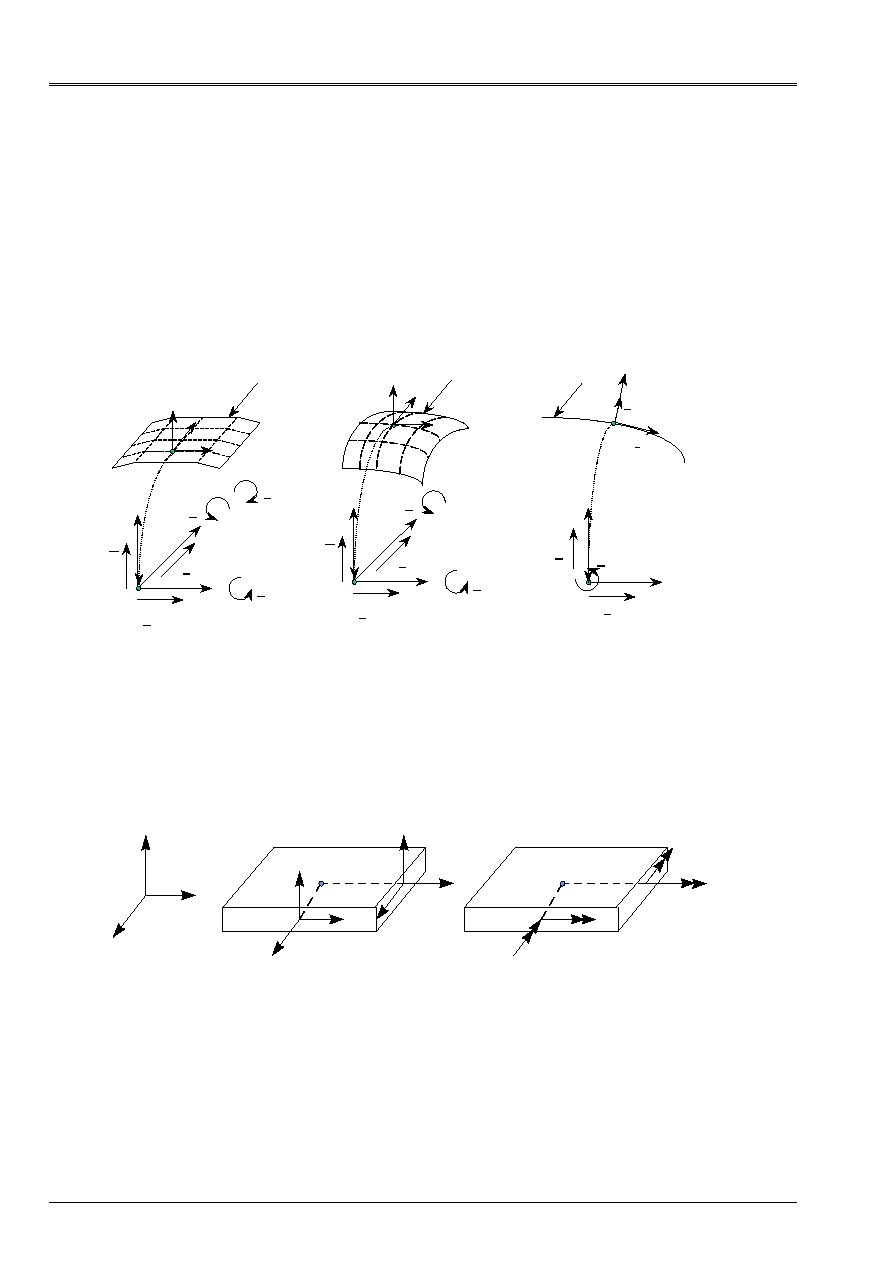

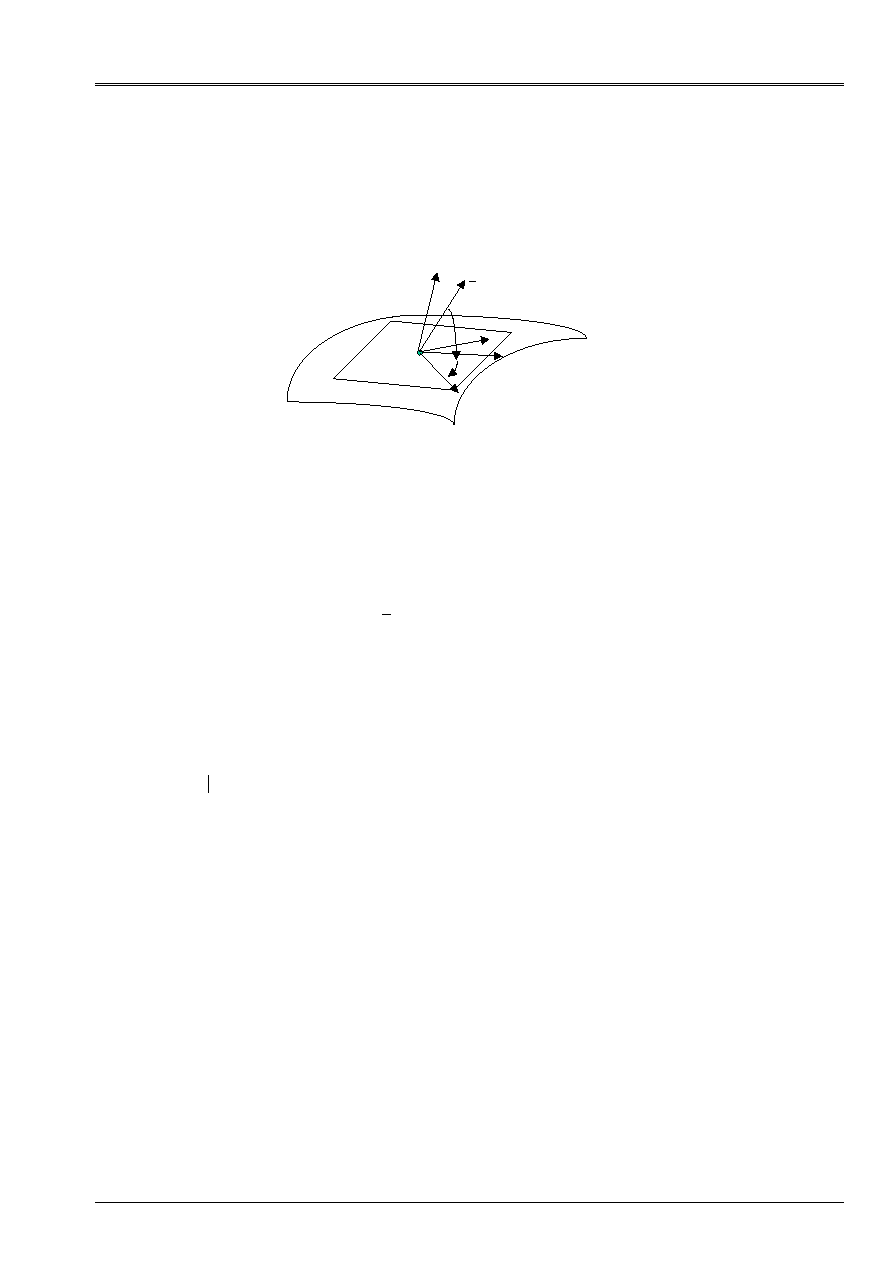

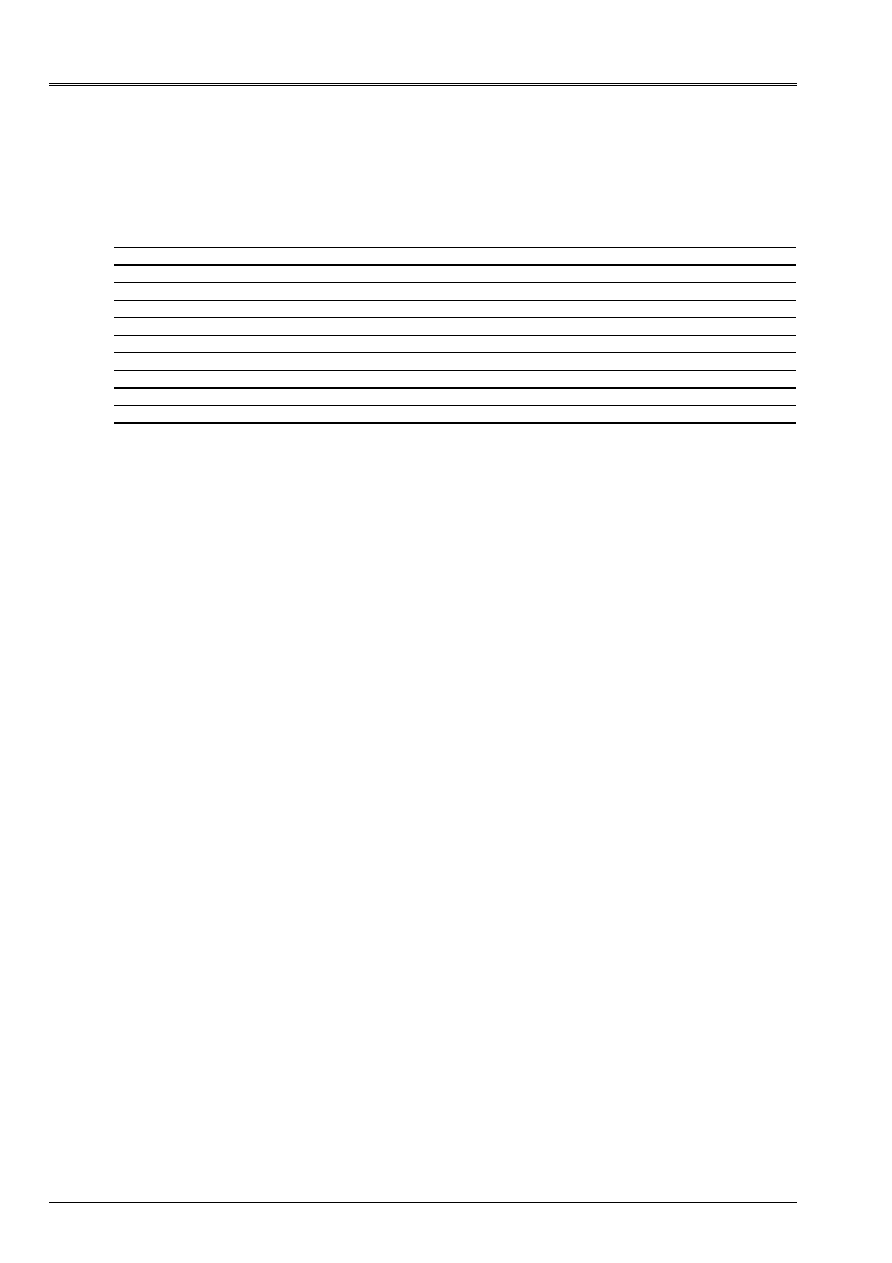

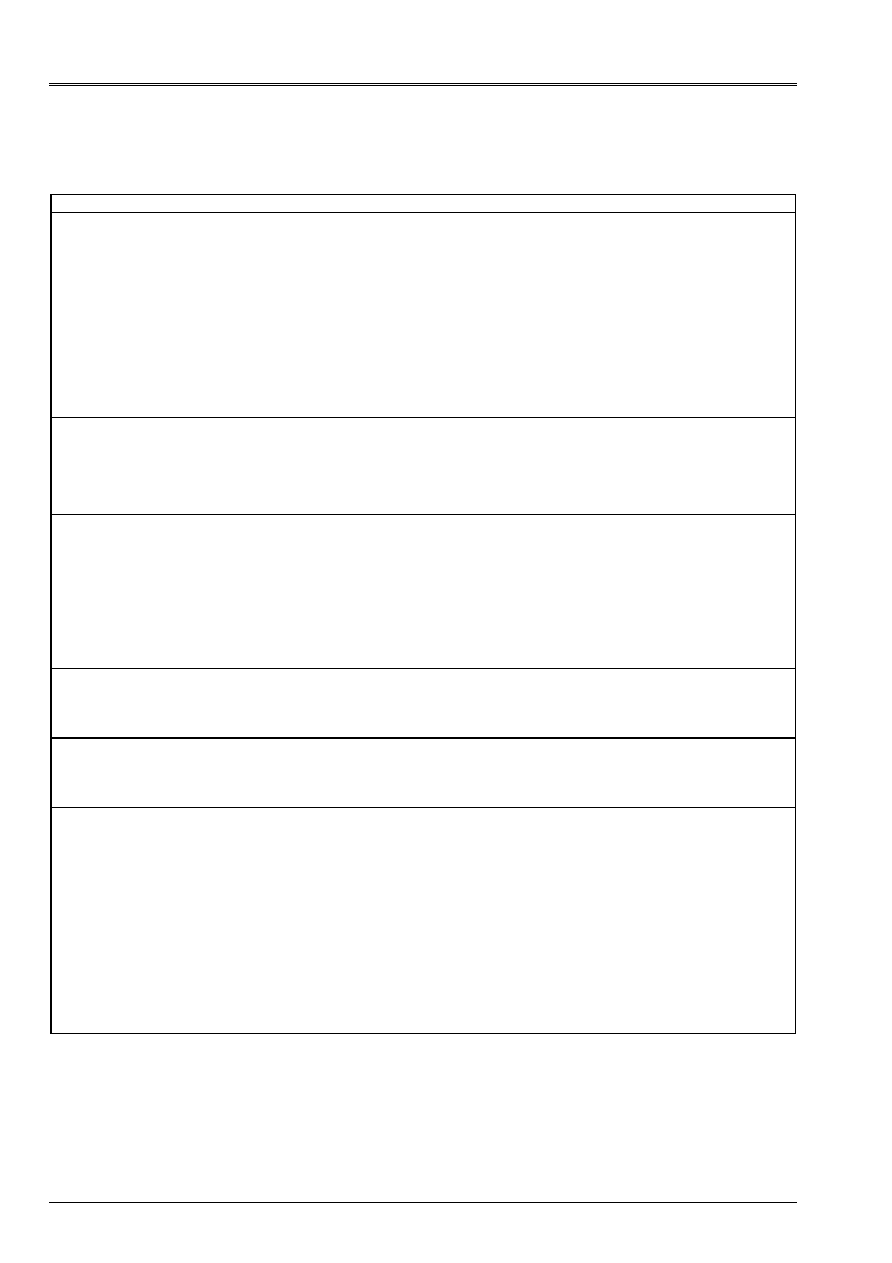

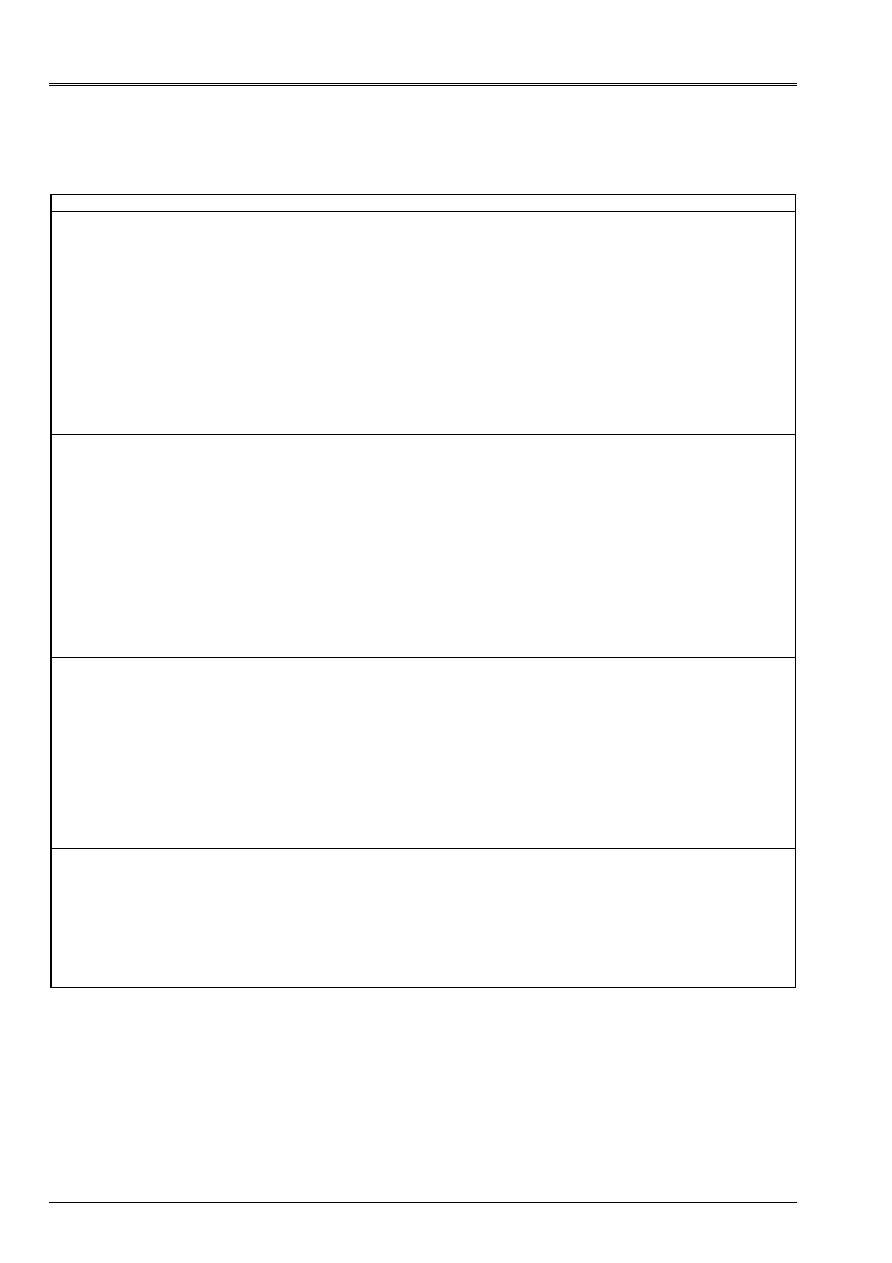

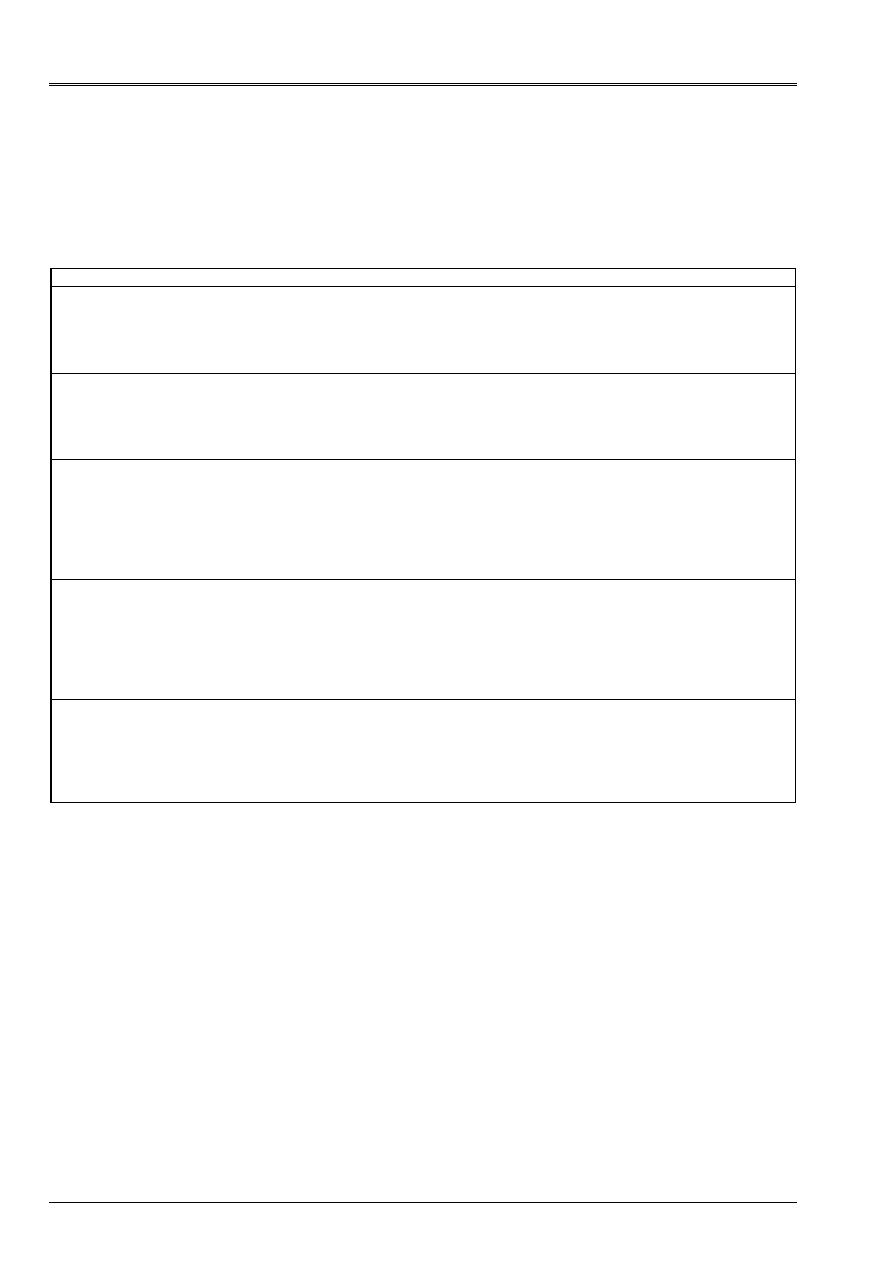

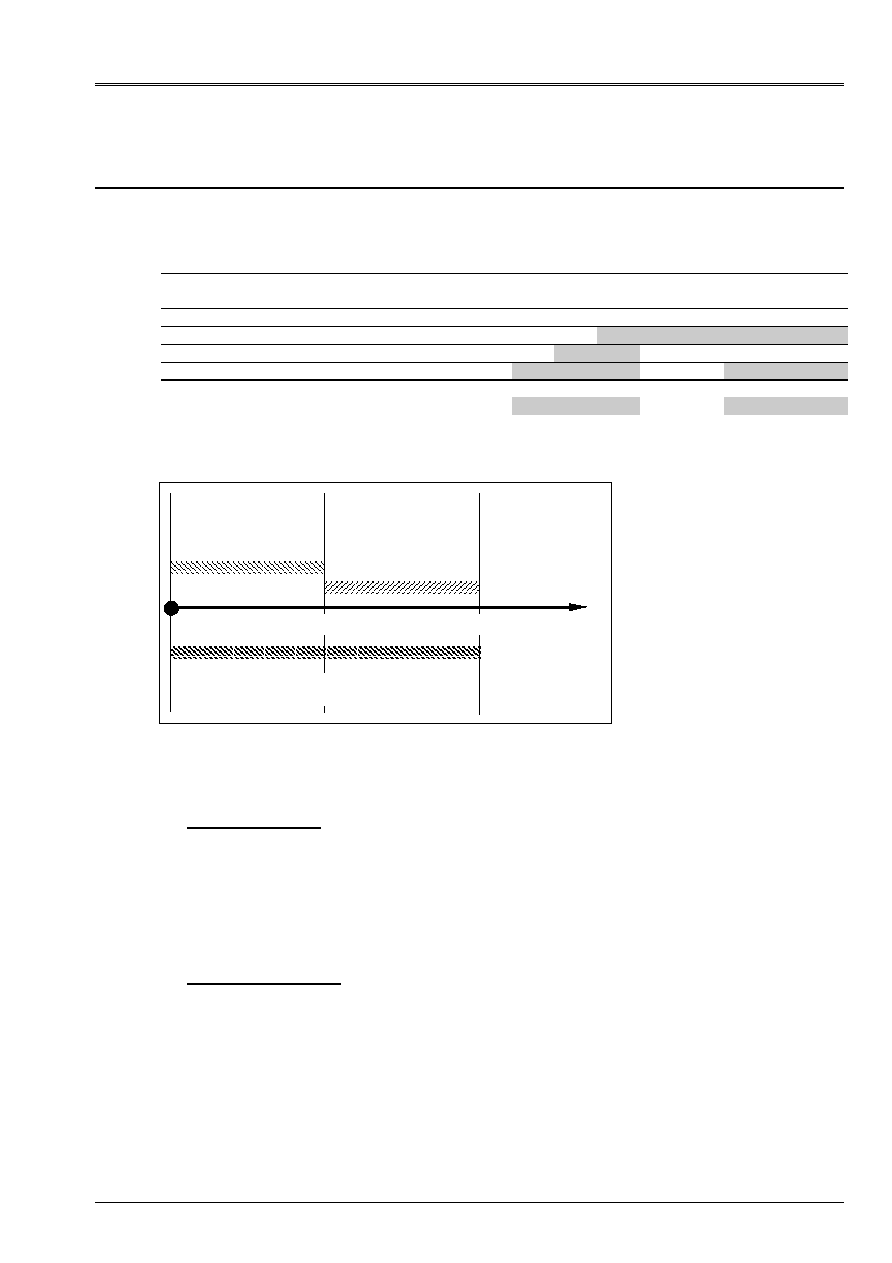

These elements utilize locally:

·

five variables kinematics for the elements plates and hulls unspecified;

displacements of membrane U and v in the datum-line z=0, transverse displacement

W and rotations

X

and

y

normal on the average surface in the yz plans and xz

respectively.

·

three variables kinematics for the linear elements; displacements U and v in

datum-line z=0 and rotation

N

normal on the average surface in the xy plan.

Surface average

Trace average surface

Plane elements or of plates

Curved elements or of hulls

Linear elements for the hulls

invariant by translation

and axisymmetric hulls

X

y

Z

U

v

W

X

y

X

y

Z

U

v

W

X

y

X

y

Z

X

y

X

y

U

v

N

N

y

Average plan

X

y

Z

Average plan

X

y

Z

T

Appear 2.1.2.1-a: Variables kinematics for the various elements of plates and hulls

·

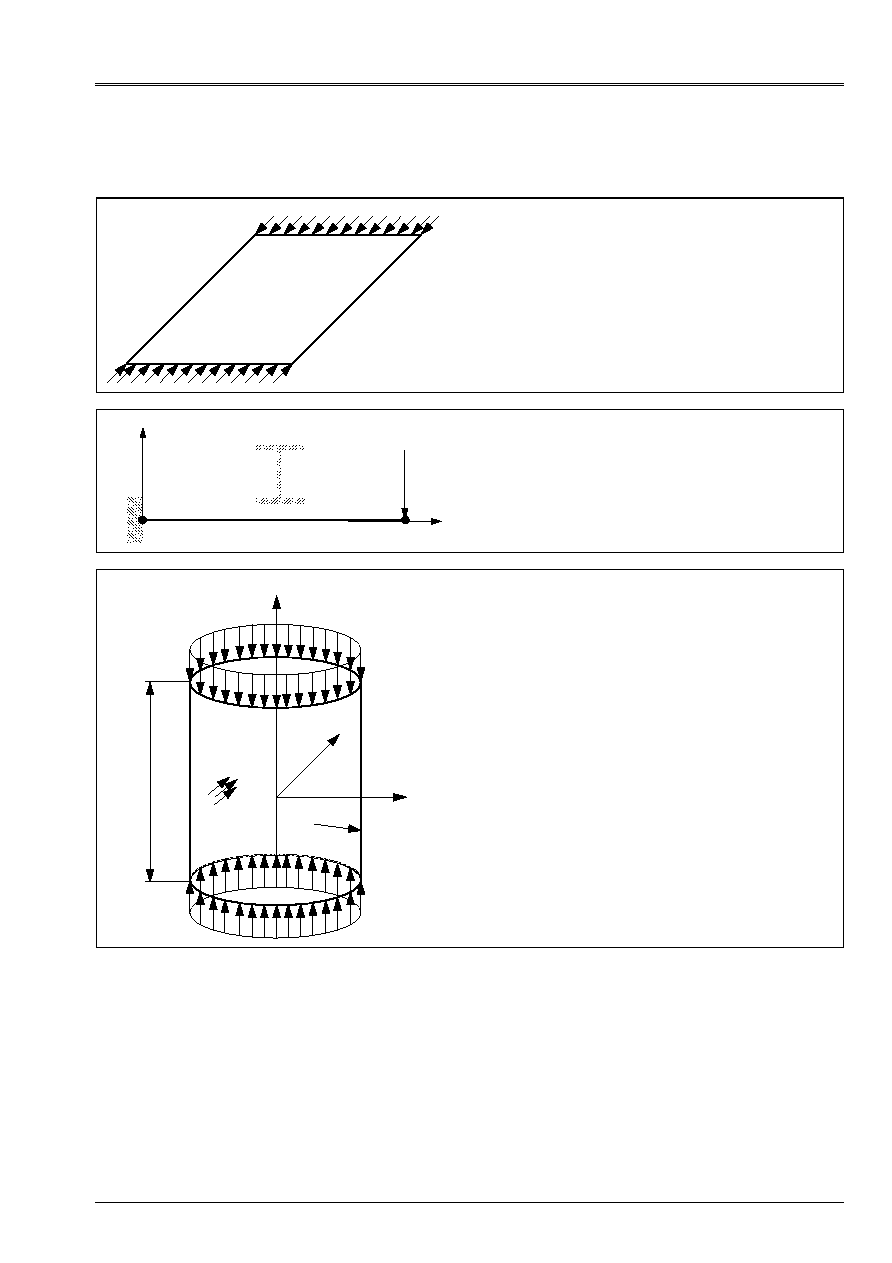

three efforts resulting from membrane noted Nxx, Nyy, Nxy and three noted moments bending

Mxx, Myy, Mxy whatever the element of plate or hull; two noted sharp efforts

Vx and Vy in the case of elements of plates and unspecified hulls.

y

Z

X

NR

xx

NR

xy

V

X

P

NR

yy

V

y

NR

yx

M

xy

M

xx

P

M

yx

M

yy

Appear 2.1.2.1-b: Efforts resulting for an element from plate or hull

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

9/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.1.2.2 Formulation into non-linear geometrical, Buckling of Euler

In the formulation into non-linear geometrical, one is in the presence of great displacements and of

great rotations, one cannot superimpose the initial geometry and the deformed geometry.

The formulation, described in the reference material [R3.07.05], is based on an approach of

continuous medium 3D, degenerated by the introduction of the kinematics of hull of the type

Hencky-Mindlin-Naghdi in plane stresses in the weak formulation of balance. The measurement of

deformations selected is that of Green-Lagrange, vigorously combined with the stresses of

Piola-Kirchhoff of second species. The formulation of balance is thus a formulation

Lagrangian total. Transverse shearing is treated same manner as in the case

linear [R3.07.04].

The element retained into non-linear is a voluminal element of hull (COQUE_3D) of average surface

curve as presented at the preceding paragraph, whose meshs supports are QUAD9 and

TRIA7.

It is possible to apply to these elements of the following pressures, whose formulation is described

in the reference document [R3.03.07]. This loading with the characteristic to follow the geometry of

the structure during its deformation (for example, the hydrostatic pressure always remains

perpendicular with the deformed geometry).

Linear buckling also called buckling of Euler, described in the reference material

[R3.07.05], is presented in the form of a particular case of the geometrical non-linear problem. It is based

on a linear dependence of the fields of displacements, strains and stresses by

report/ratio on the level of load.

The element retained in linear buckling is the voluminal element of hull (COQUE_3D) of surface

curved average as presented at the preceding paragraph, whose meshs supports are QUAD9

and of the TRIA7.

2.1.3 Comparison enters the elements

2.1.3.1 Differences between the elements plates and hulls

The elements of hull are curved elements whereas the elements of plates are plane.

variation of metric of the geometry (i.e. its radius of curvature) according to sound

thickness is taken into account for the elements of hulls but not for the elements of plates.

This variation of metric implies a coupling between the effects of membrane and bending for

nonplane structures which cannot be observed with elements of plate plan for one

homogeneous material (see [bib1]).

The choice of the functions of form for the discretization of these elements is different bus the elements

curved hulls have a more significant number of degrees of freedom. Thus, elements of plates

are linear elements out of membrane whereas the elements of hulls are quadratic.

2.1.3.2 Differences between the elements plates

One distinguishes the elements with transverse shearing (DST, DSQ and Q4G) from the elements without

transverse shearing (DKT and DKQ). Elements DST and DKT have triangular meshs support with

3 nodes (3x5 =15 ddl) and elements DKQ, DSQ and Q4G of the quadrangular meshs supports to 4

nodes (4x5 =20 ddl).

Important remark:

For the elements of plate with 4 nodes (DSQ, DKQ and Q4G), the 4 nodes must be

coplanar so that the theory of the plates can be validated. This checking is

carried out systematically by Code_Aster, and the user is alarmed if one

elements of the mesh does not observe this condition.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

10/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

In the case of elements with transverse shearing, to avoid the blocking of the elements in

transverse shearing (over-estimate of rigidity for very low thicknesses), a method

consist in building fields of constant shearing of substitution on the edges of the element,

whose value is the integral of shearing on the edge in question. In Code_Aster, the elements

of plate and hull with transverse shearing use this method in order not to lock

in transverse shearing. This blocking in shearing comes owing to the fact that elastic energy from

shearing is a term proportional to H (H being the thickness of the plate or the hull) much more

large that the elastic term of energy of bending which is proportional out of H

3

. When the thickness

becomes weak in front of the characteristic length (the ratio H/L is lower than 1/20), for some

functions of form, the minimization of the dominating term out of H leads to bad

representation of the modes of pure bending, for which the arrow is not calculated any more correctly

(see [bib1] page 295 with H/L=0.01).

Element Q4G is a quadrilateral element with four nodes without blocking in transverse shearing,

with bilinear functions of form in X and to represent W there,

X

and

y

. It is the same for

elements DST and DSQ. The difference between DSQ and Q4G (DST modeling, [bib1]) comes owing to the fact that

one uses for the latter of the quadratic functions of form to discretize on each edge

rotation

S

in the sz plan where S is the co-ordinate along the sides. Rotation

N

in the nz plan where

N is the normal at the side directed towards the outside of the element remains discretized with functions of

form bilinear (see it [Figure 2.1.3.2-a]).

I (X

I

, y

I

)

J (X

J

, y

J

)

K

Z

N

K

T

K

S

s=0

s=L

K

S

N

Appear 2.1.3.2-a: Element of plate with transverse shearing

2.1.3.3 Differences between the elements hulls

One distinguishes the linear elements of hulls COQUE_C_PLAN, COQUE_D_PLAN and axisymmetric

COQUE_AXIS of the elements of COQUE_3D.

The first are used to modelize invariant structures according to axis OZ or of revolution

of axis OY and seconds in all the other cases. In the case of invariant hulls according to

direction Z, one distinguishes the free hulls in Z (forced plane COQUE_C_PLAN) from the hulls

locked in Z (plane deformations COQUE_D_PLAN). For these elements of hulls, meshs

supports are linear with 3 nodes. The number of degrees of freedom of these elements is 9.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

11/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

The unspecified elements of hulls COQUE_3D have triangular meshs support with 7 nodes or

quadrangular with 9 nodes:

·

In the case of triangular meshs, the number of degrees of freedom for the translations is 6

(the unknown factors are displacements with the nodes nodes and on the mediums on the sides of

triangle) and that of rotations are the 7 (unknown factors are 3 rotations at the preceding points

and in the center of the triangle). The number of degrees of freedom total of the element is thus of

Nddle=3x6+3x7=39.

·

In the case of quadrangular meshs with 9 nodes, the number of degrees of freedom for

translations is the 8 (unknown factors are displacements with the nodes nodes and on

mediums on the sides of the quadrangle) and that of rotations is the 9 (unknown factors are the 3

rotations at the preceding points and the center of the quadrangle). The number of degrees of freedom

total of the element is thus of Nddle=3x8+3x9=51. These elements thus have about two

time more degrees of freedom than the elements of plate of corresponding family DKT.

Their cost in time, with an equal number, in a calculation will be thus more important.

The elements of COQUE_3D automatically take into account the correction of metric between

surface average and the surfaces upper and lower. For the linear elements, this correction

must be activated by the user (see the paragraph 14). The correction of metric brings one

contribution out of H/L to the stress and in (H/L)

2

in displacement (see [V7.90.03]). For the plates this

correction is without object.

For the elements of hulls the coefficient of correction of shearing K in isotropic behavior

can be modified by the user. This coefficient of correction of shearing is given in

AFFE_CARA_ELEM under key word A_CIS. By defect, if the user does not specify anything in

AFFE_CARA_ELEM that amounts using the theory with shearing of REISSNER; the coefficient of

shearing is then put at k=5/6. If the coefficient of shearing K is worth 1 one places within the framework

theory of HENCKY-MINDLIN_NAGHDI and if it becomes very large (

10

6

H/L) one approaches

the theory of LOVE_KIRCHHOFF.

In practice it is advised not to change this coefficient. Indeed, these elements provide one

physically correct solution, that the hull is thick or thin, with the coefficient K = 5/6.

2.2

Controls to be used

2.2.1 Space discretization and assignment of a modeling

: operator

AFFE_MODELE

In this part, one describes the choice and the assignment of one of modelings plates or hulls thus

that degrees of freedom and associated meshs. The majority of described information are extracted

documentations of use of modelings ([U3.12.01]: Modeling DKT - DST - Q4G,

[U3.12.02]: Modelings COQUE_C_PLAN, COQUE_D_PLAN, COQUE_AXIS).

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

12/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.2.1.1 Degrees of freedom

The degrees of freedom of discretization are in each node of the mesh support the components of

displacement with the nodes of the mesh support, except indication.

Modeling

Degrees of freedom (with each node)

Remarks

COQUE_3D

DX DY DZ DRX DRY DRZ

DRX DRY DRZ with the central node the nodes belong to the layer

means of the hull

DKT

DX DY DZ DRX DRY DRZ

The nodes belong to the breakage

tangent with the average layer of the hull

DST

DX DY DZ DRX DRY DRZ

The nodes belong to the breakage

tangent with the average layer of the hull

Q4G

DX DY DZ DRX DRY DRZ

The nodes belong to the breakage

tangent with the average layer of the hull

COQUE_C_PLAN DX DY DRZ

The nodes belong to surface

average of the hull

COQUE_D_PLAN DX DY DRZ

The nodes belong to surface

average of the hull

COQUE_AXIS

DX DY DRZ

The nodes belong to surface

average of the hull

ROAST

DX DY DZ DRX DRY DRZ

The nodes belong to the breakage

tangent with the average layer of the hull.

2.2.1.2 Meshs support of the matrices of rigidity

Modeling Nets

Element

finished

Remarks

COQUE_3D TRIA7

QUAD9

MEC3TR7H

MEC3QU9H

Meshs not presumedly plane

DKT TRIA3

QUAD4

MEDKTR3

MEDKQU4

Plane meshs

DST TRIA3

QUAD4

MEDSTR3

MEDSQU4

Plane meshs

Q4G QUAD4

MEQ4QU4

Plane meshs

COQUE_C_PLAN SEG3 METCSE3 Meshs not presumedly plane

COQUE_D_PLAN SEG3 METDSE3 Meshs not presumedly plane

COQUE_AXIS SEG3

MECXSE3 Meshs not presumedly plane

ROAST TRIA3

MEGRDKT

Plane meshs

Modeling ROASTS used to modelize the reinforced concrete structures has the same ones

characteristics of mesh that modeling DKT with triangles. For the moment, this modeling

is available only for mesh TRIA3.

Note:

In a mesh, to transform meshs TRIA7 into meshs QUAD9, one can use

operator MODI_MAILLAGE.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

13/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.2.1.3 Meshs support of the loadings

All the loadings applicable to the breakages of the elements used here are treated by discretization

direct on the mesh support of the element in displacement formulation. Pressure and other forces

surface as well as gravity are examples of loadings applying directly to

breakages. No special mesh of loading is thus necessary for the faces of the elements

plates and hulls.

For the applicable loadings on the edges of the elements, one a:

Modeling Nets

Element

finished

Remarks

COQUE_3D SEG3

MEBOCQ3

DKT SEG2

MEBODKT

DST SEG2

MEBODST

Q4G SEG2

MEBOQ4G

COQUE_C_PLAN POI1

Meshs support stub to 1 point

COQUE_D_PLAN POI1

Meshs support stub to 1 point

COQUE_AXIS POI1

Meshs support stub to 1 point

ROAST

Forces distributed, linear, of traction, shearing, the bending moments applied to

edges of structures hull are included in this category of loadings.

2.2.1.4 Model

:

AFFE_MODELE

The assignment of modeling passes through operator AFFE_MODELE [U4.41.01].

AFFE_MODELE

Remarks

AFFE

PHENOMENON:

“MECHANICAL”

MODELING “COQUE_3D”

“DKT”

“DST”

“Q4G”

“COQUE_C_PLAN”

“COQUE_D_PLAN”

“COQUE_AXIS”

“GRID”

Note:

It is advisable to check the number of affected elements.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

14/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

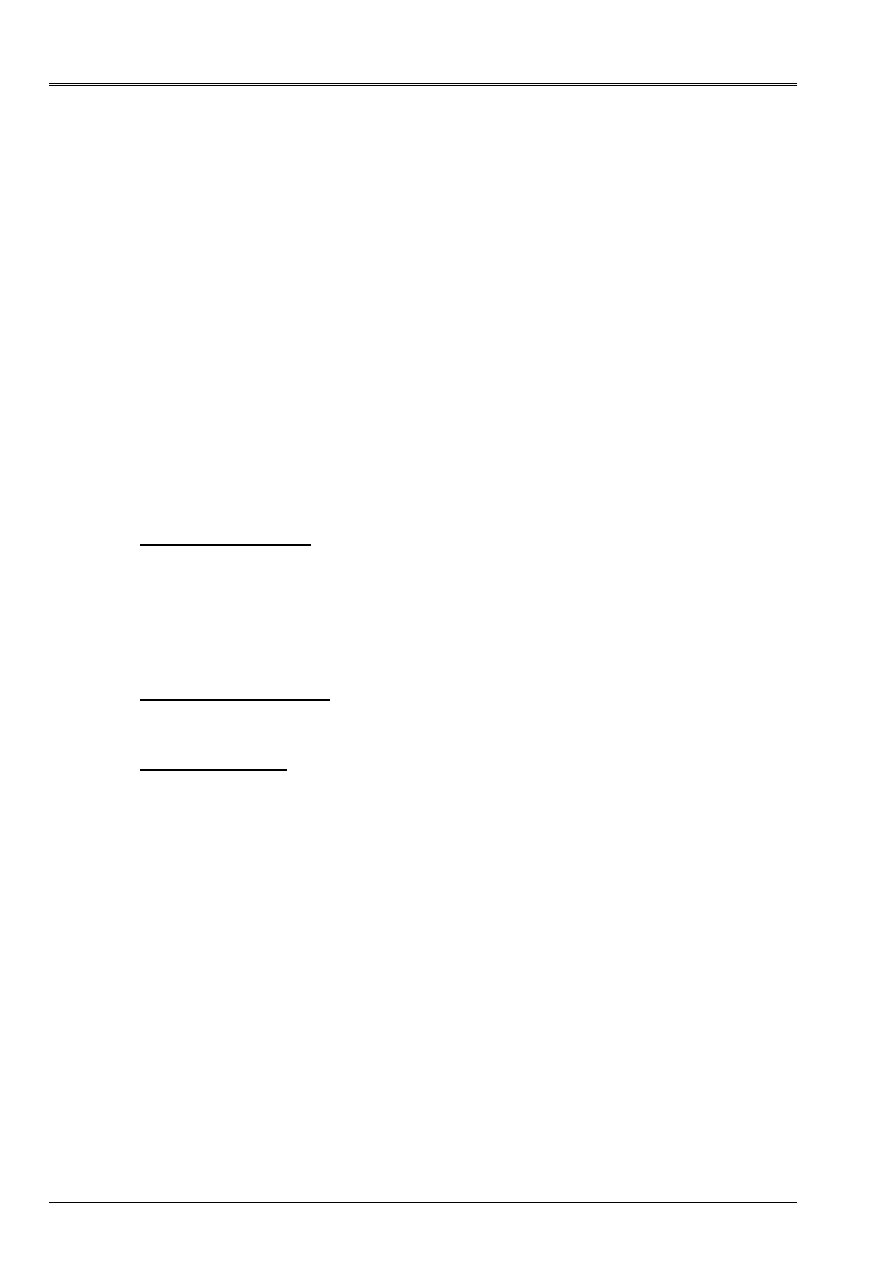

2.2.2 Elementary characteristics: AFFE_CARA_ELEM

In this part, the operands characteristic of the elements of plates and hulls are described.

The documentation of use of operator AFFE_CARA_ELEM is [U4.42.01].

AFFE_CARA_ELEM COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

HULL

·

·

·

·

·

THICK

· · · ·

·

ANGL_REP

· · · ·

A_CIS

·

·

COEF_RIGI_DRZ

· · · ·

·

OFFSETTING

·

·

·

INER_ROTA

·

·

·

MODI_METRIQUE

·

·

AFFE_CARA_ELEM

ROAST

ROAST

·

THICK

·

ANGL_REP ·

OFFSETTING

·

ANGL_L

·

POUR_CENT_L

·

POUR_CENT_T

·

SECTION_L ·

The allocatable characteristics on the elements of plate or hull are:

·

the thickness

THICK

constant on each mesh, since the mesh represents only it

average layer.

·

the coefficient of correction of transverse shearing

A_CIS

for the curved hulls

isotropic.

·

the taking into account of the correction of metric

MODI_METRIQUE

between average surface

and surfaces upper and lower (effective only for the COQUE_C_PLAN,

COQUE_D_PLAN, COQUE_AXIS).

·

a direction of reference D defined by two nautical angles given in the total reference mark,

by the key word

ANGL_REP

. The projection of this direction of reference on the tangent level to

the hull fixes X1, the first direction of the local reference mark. The normal in the tangent plan in fixed one

second and the vector product of the two associated vectors makes it possible to define the local trihedron.

necessary to the supply of the characteristics nonisotropic material and for the analysis of the efforts

generalized, of the state of stress or the generalized and three-dimensional deformations.

The user will have to take care that the selected reference axis is not found parallel with

normal of certain meshs of the mesh. By defect, this direction of reference is axis X

total reference mark of definition of the mesh.

·

a functionality of DEFI_GROUP makes it possible to create a group of meshs automatically

of which it normal is included/understood in a given solid angle, of axis direction of reference.

This control can be used in preprocessing to affect data material not

isotropic or in postprocessing after a calculation of hull.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

15/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

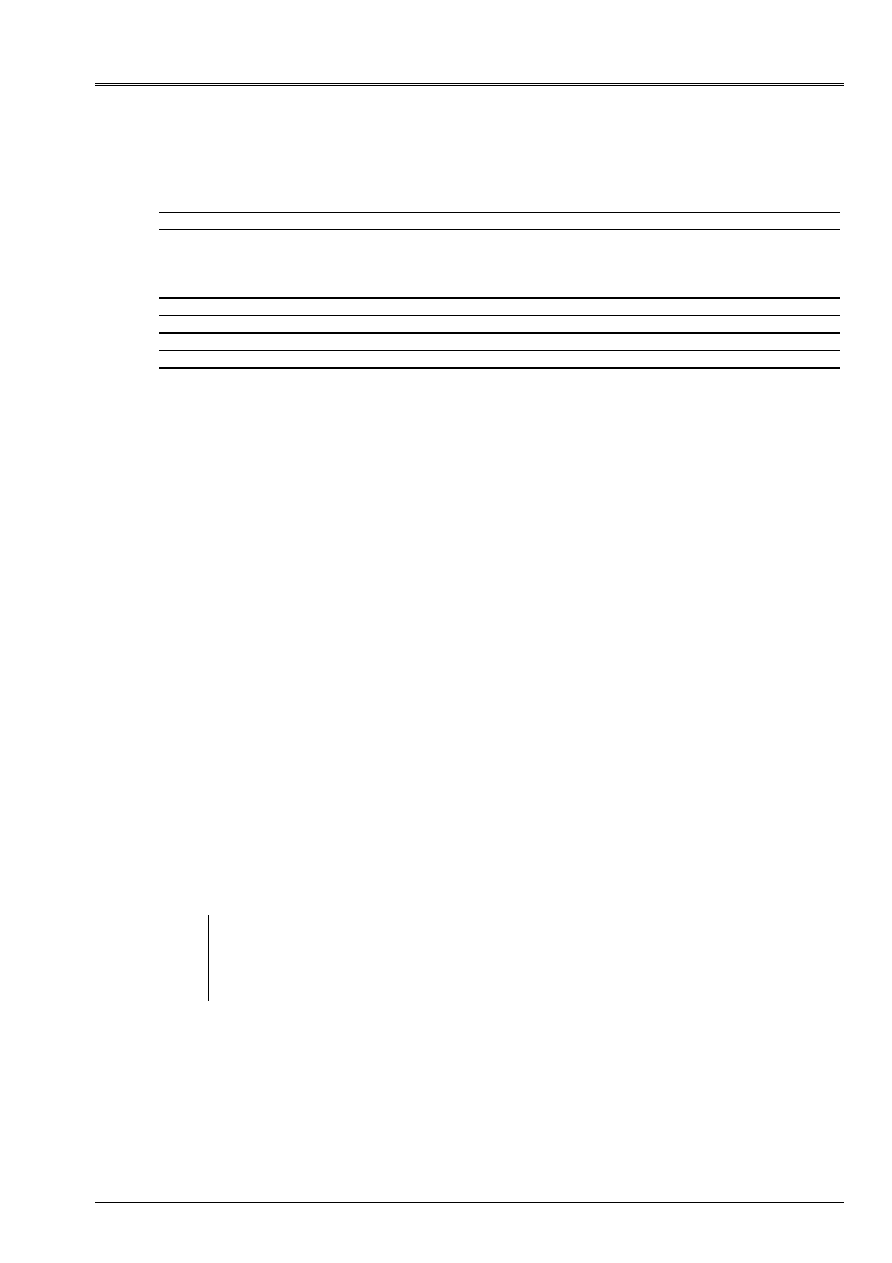

·

offsetting (constant for all the nodes of the mesh)

OFFSETTING

of each one

they compared to the mesh support. This distance is measured on the normal of the mesh

support. In the excentré case inertias of rotation are obligatorily taken into account

and

INER_ROTA

is put at

YES

.

plan

tangent

X

D

Z

y

X

1

The total xy plan is not

parallel in the tangent plan

Appear 2.2.2-a: Identifies total and plane tangent

For modeling ROASTS, the following geometrical data are necessary to modelize them

tablecloths of reinforcements (see [3]):

·

offsetting (constant for all the nodes of the mesh)

OFFSETTING

of each one

they compared to the mesh support. This distance is measured on the normal of the mesh

support which, in practice, is superposable with that of the concrete.

·

direction of reference D defined previously by

ANGL_REP

.

·

direction of the reinforcements compared to the X1 vector of the tangent plan. One of the directions

ANGL_L

is enough because the grid consists of orthogonal reinforcements between them.

·

percentages of section of reinforcement in direction 1

POUR_CENT_L

and direction 2

POUR_CENT_T

who is orthogonal for him.

·

the sum of the sections of reinforcements per unit of width in direction 1

SECTION_L

.

Important remark:

Orientation of the elements of plates and hulls

The direction of the normals to each element is a recurring problem concerning the use of this type

of element, for example when loadings of the pressure type are applied, or to define

a offsetting or a local reference mark.

By defect for the surface elements the orientation is given by the vector product 12^13 for

a triangle numbered 123 (DKT,…) or 1234567 (COQUE_3D) and 12^14 for a numbered quadrangle

1234 (DKQ,…) or 123456789 (COQUE_3D). For linear hulls N is given by the formula of

paragraph 2.1.1.1 with T directed in the direction of course of the mesh on the level of the mesh.

Generally, these data are accessible while looking in the file from mesh, which is not

very practical for the user. Moreover it is necessary that it checks the coherence of its mesh and to ensure itself

that all the meshs have the same orientation well.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

16/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

The user can automatically modify the orientation of the elements of the mesh by imposing one

direction of normal, for a mesh or part of using mesh of modelings of hull

and whatever the type of modeling. The reorientation of the elements is done by the means of

the operator

ORIE_NORM_COQU

control

MODI_MAILLAGE

[U4.12.05]. The principle is it

according to: one defines under

ORIE_NORM_COQU

a direction by the means of a vector and a node

belonging to the group of meshs to be reorientated. If the introduced vector is not in the plan of the mesh

selected by

MODI_MAILLAGE

, one automatically deduces a direction from it from normal obtained

like the vector less given its projection in the field of the mesh. All meshs of the group

related with those initially selected will then have the same orientation of normal

automatically. In addition an automatic checking of the same orientation of the meshs

related is carried out by the means of the operator

VERI_NORM

control

AFFE_CHAR_MECA

[U4.25.01].

2.2.3 Materials

:

DEFI_MATERIAU

The definition of the behavior of a material is carried out using operator DEFI_MATERIAU

[U4.43.01].

DEFI_MATERIAU COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

COMP. LINEAR

ELAS

· ·

·

·

·

·

ELAS_FO

· ·

·

·

·

·

ELAS_ORTHO

· ·

·

·

ELAS_COQUE

·

·

·

ELAS_COQUE_FO

·

·

·

DEFI_MATERIAU COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

COMP. NONLINEAR

TRACTION

· ·

·

ECRO_LINE

· ·

·

ECRO_LINE_FO

· ·

·

CHABOCHE

· ·

·

DEFI_COQU_MULT

·

·

·

DEFI_MATERIAU COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

BY LAYER

All comp.

C_PLAN

· ·

·

The materials used with the whole of the elements plates or hulls can have

elastic behaviors in plane stresses whose linear characteristics are constant or

functions of the temperature. The nonlinear behaviors in plane stresses are available

for modelings DKT and hulls. For more information on these nonlinearities one can

to defer to the paragraph [§2.3.2].

The mean composite material structures can be treated currently only by

modelings plates, by using DEFI_COQU_MULT with material characteristics

homogenized. One can also directly introduce the coefficients of rigidity of the matrices of

membrane, bending and shearing with ELAS_COQUE. These coefficients are given in the reference mark

room of the element defined by ANGL_REP. It should be noted that the terms of shearing are not taken in

take into account behavior ELAS_COQUE that for elements DST and Q4G. They are not taken in

take into account elements DKT.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

17/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

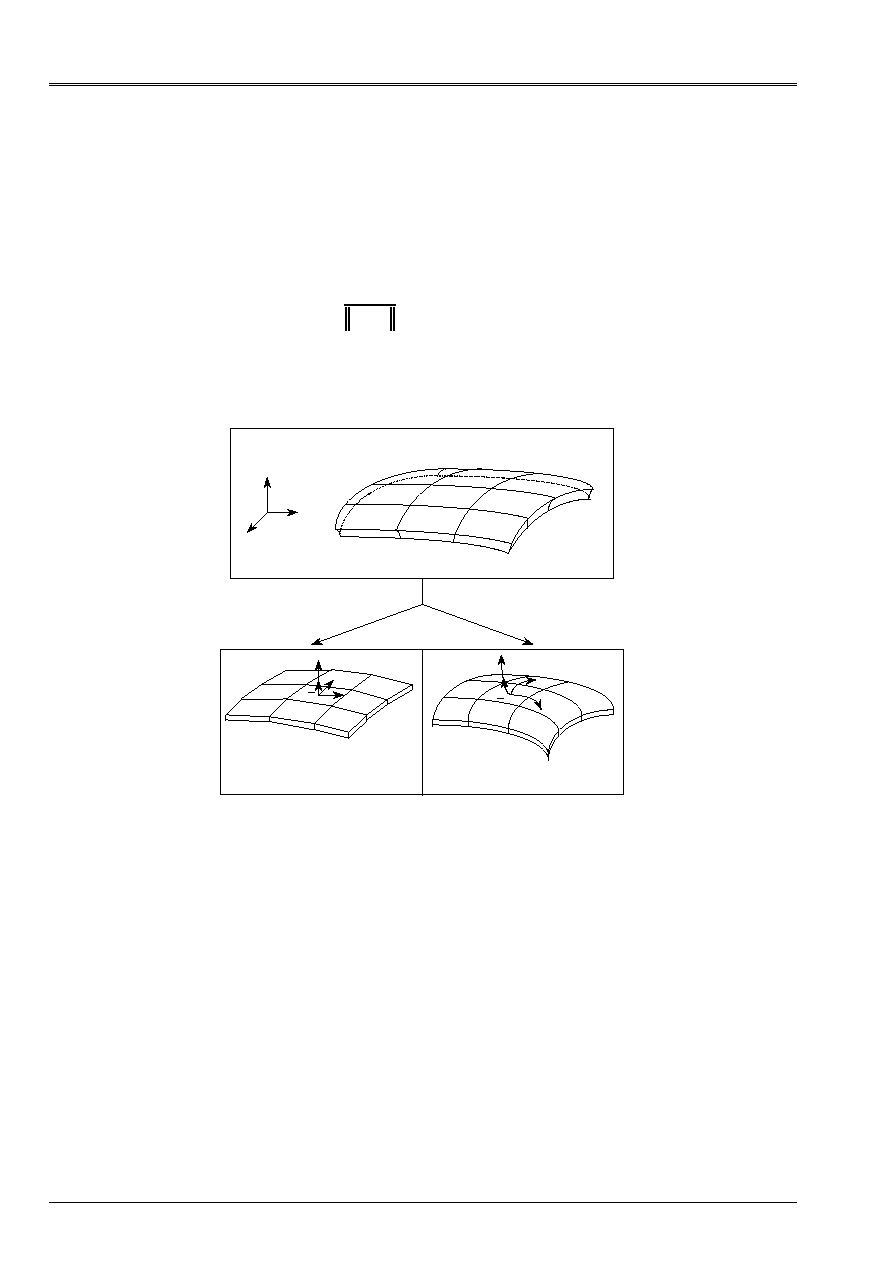

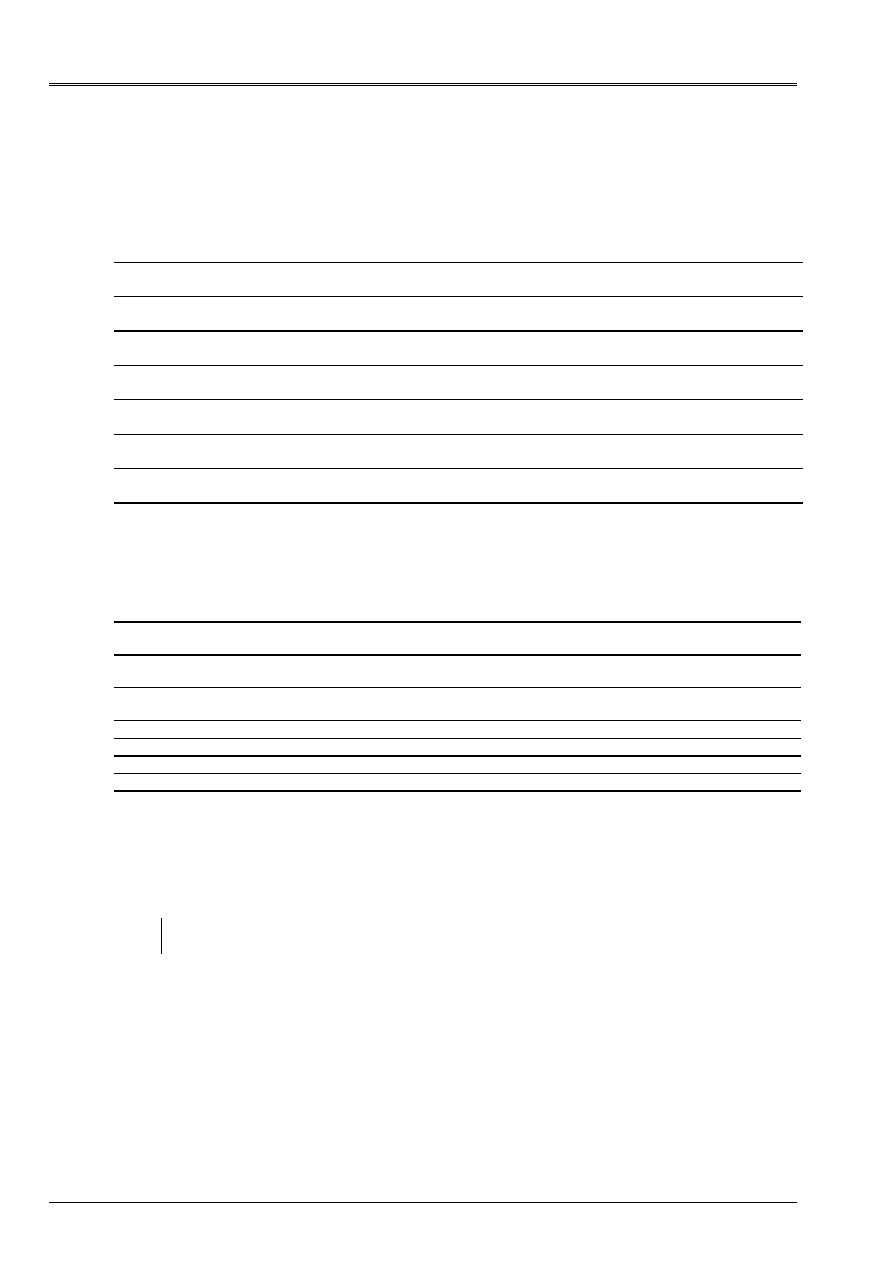

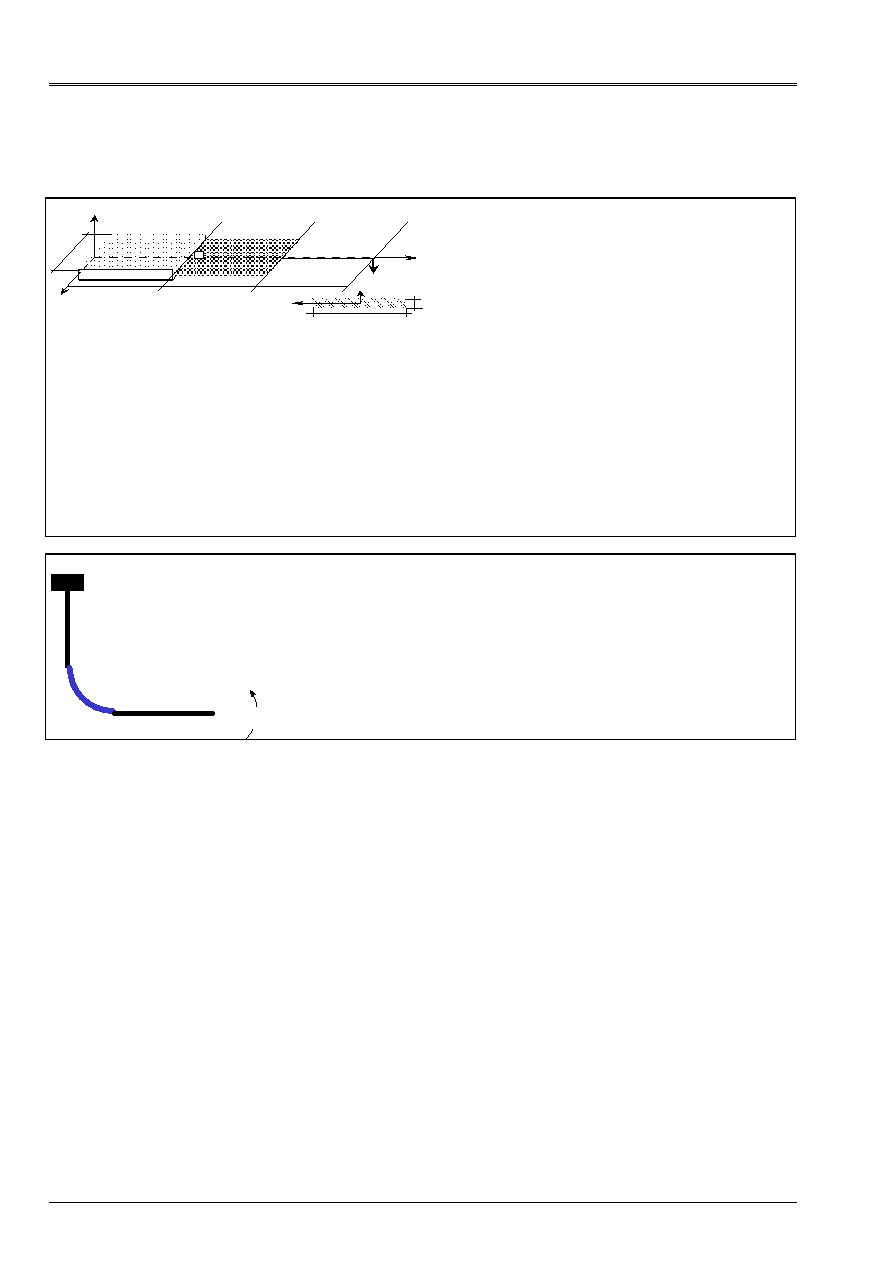

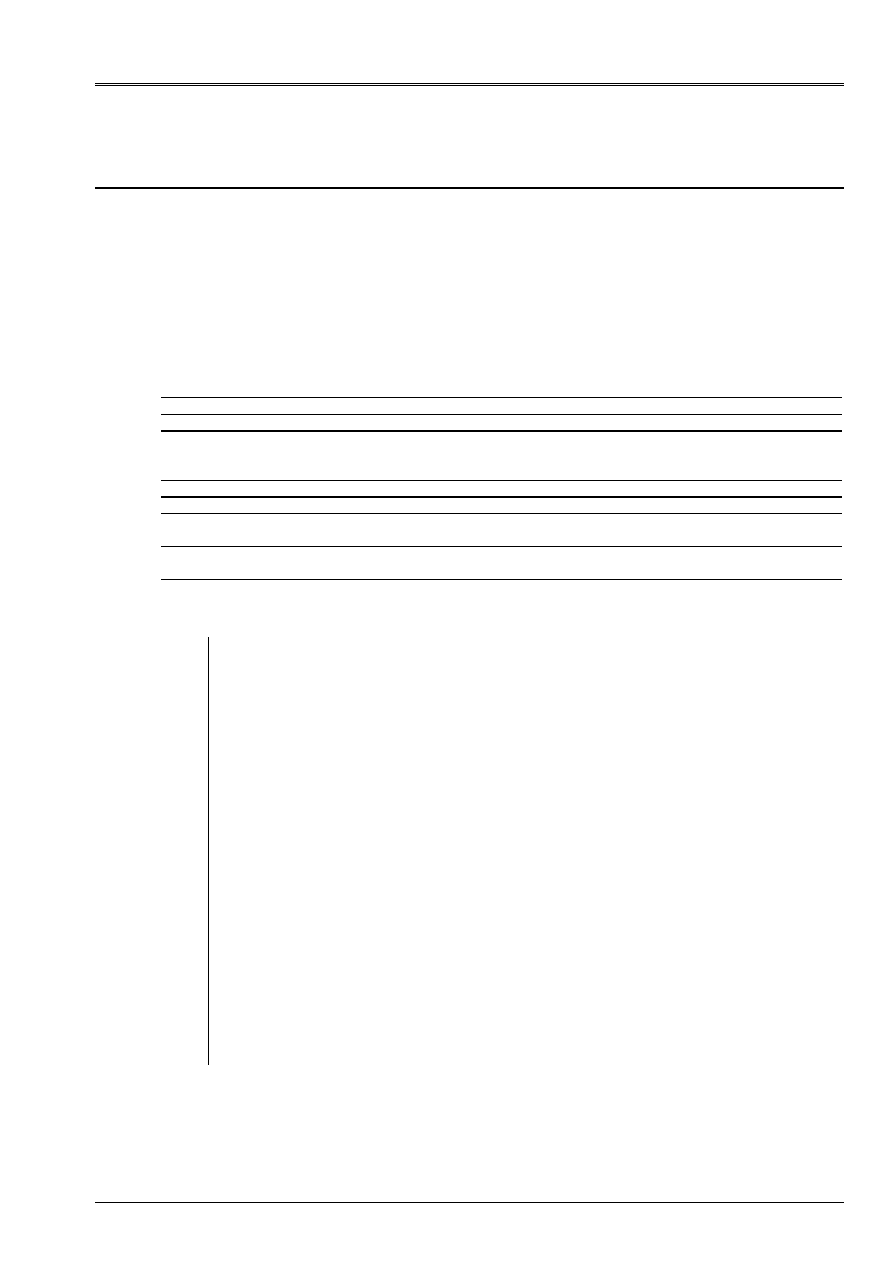

In order to facilitate comprehension, we represented on the figure below the different ones

reference marks used.

X

Y

Z

X ortho

1

4

3

2

X

ortho

Z

ortho

Z

ortho

normal

Skin “SUP”

Skin “INF”

1

3

2

X

ortho

Total reference mark

Identify orthotropism

y

ortho

Z

ortho

X

ortho

y

ortho

Skin MOY'

Stacking

Sleep

Defined layer by layer

Appear 2.2.3-a: Reference marks used for the definition of material

The following example is extracted from case-test SSLS117B and illustrates the syntax of DEFI_COQU_MULT:

MU2=DEFI_COQU_MULT (COUCHE=_F (EPAIS=0.2,

MATER=MAT1B,

ORIENTATION=0.0,),);

In this example, one defines a multi-layer composite thickness 0.2, the material being defines by

MAT1B, and the angle of the 1ère direction of orthotropism (longitudinal direction or direction of fibers) being null. One

will refer to documentation [U4.42.03] for more details concerning the use of

DEFI_COQU_MULT.

2.2.4 Limiting loadings and conditions: AFFE_CHAR_MECA and AFFE_CHAR_MECA_F

The assignment of the loadings and the boundary conditions on a mechanical model is carried out with

the aid of operators AFFE_CHAR_MECA, if loadings and boundary conditions mechanical

on a system are actual values depending on no parameter, or

AFFE_CHAR_MECA_F, if these values are functions of the position or the increment of loading.

The documentation of use of AFFE_CHAR_MECA and AFFE_CHAR_MECA_F is [U4.44.01].

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

18/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.2.4.1 List key words factor of AFFE_CHAR_MECA

AFFE_CHAR_MECA COQUE_3D

DKT DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

DDL_IMPO

· ·

·

·

·

·

FACE_IMPO

· ·

·

·

·

·

LIAISON_DDL

· ·

·

·

·

·

LIAISON_OBLIQUE

· ·

·

·

·

·

LIAISON_GROUP

· ·

·

·

·

·

CONTACT

· ·

·

·

·

·

LIAISON_UNIF

· ·

·

·

·

·

LIAISON_SOLIDE

· ·

·

·

·

·

LIAISON_ELEM

· ·

·

·

LIAISON_COQUE

· ·

·

·

·

·

FORCE_NODALE

· ·

·

·

·

·

DDL_IMPO

Key word factor usable to impose, with nodes or groups of

nodes, one or more values of displacement.

FACE_IMPO

Key word factor usable to impose, with all the nodes of a definite face

by a mesh or a group of meshs, one or more values of

displacements (or certain associated sizes).

LIAISON_DDL

Key word factor usable to define a linear relation between degrees of

freedom of two or several nodes.

LIAISON_OBLIQUE key Word factor usable to apply, with nodes or groups of

nodes, the same component value of displacement definite per component

in an unspecified oblique reference mark.

LIAISON_GROUP

Key word factor usable to define linear relations between some

degrees of freedom of couples of nodes, these couples of nodes being obtained

while putting in opposite two lists of meshs or nodes.

CONTACT

Key word factor usable to notify conditions of contact and of

friction between two assemblies of meshs.

LIAISON_UNIF

Key word factor allowing to impose the same value (unknown) on

degrees of freedom of a whole of nodes.

LIAISON_SOLIDE

Key word factor allowing to modelize an indeformable part of one

structure.

LIAISON_ELEM

Key word factor which makes it possible to modelize the connections of a hull part with

a beam part or of a hull part with a pipe part (see

paragraph 2.2.4.5).

LIAISON_COQUE

Key word factor making it possible to represent the connection enters of the hulls to

means of linear relations.

FORCE_NODALE

Key word factor usable to apply, with nodes or groups of

nodes, of the nodal forces, definite component by component in

TOTAL reference mark or in an oblique reference mark defined by 3 nautical angles.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

19/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

AFFE_CHAR_MECA

private individuals

COQUE_3D

DKT DST Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

FORCE_ARETE

· ·

·

·

FORCE_COQUE

total

near

tangent room

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

GRAVITY

· ·

·

· ·

·

PRES_REP

· ·

·

· ·

ROTATION

·

·

TEMP_CALCULEE

· ·

·

· ·

·

EPSI_INIT

·

·

·

·

FORCE_ARETE

Key word factor usable to apply linear forces to an edge

of an element of hull. For the linear elements the equivalent returns to

to apply a nodal force to the nodes supports of the element. There is not thus

no the particular dedicated term. On the other hand, it requires elements of

edges.

FORCE_COQUE

Key word factor usable to apply surface efforts (pressure by

example) on elements defined on all the mesh or one or

several meshs or of the groups of meshs. These efforts can be given

in the total reference mark or a reference mark of reference defined on each

net or groups meshs; this reference mark is built around the normal with

the element of hull and a fixed direction (see paragraph 2.2.2).

GRAVITY

Key word factor usable for a loading of the gravity type.

PRES_REP

Key word factor usable to apply a pressure to one or more

meshs, or of the groups of meshs.

ROTATION

Key word factor usable to calculate the loading due to the rotation of

structure.

TEMP_CALCULEE

Allows to recover the thermal loading resulting from a thermal calculation

linear or not linear. This functionality is useful for the chainings

thermomechanical, not which will be approached in paragraph 4.

EPSI_INIT

Key word factor usable to apply a loading of deformation

initial.

Note:

The efforts of pressure being exerted on the elements of plates can apply is by

FORCE_COQUE (near) is by PRES_REP. The user will have to thus pay attention (in

version 5) not to twice apply the loading of pressure for the elements

concerned, especially whenever modelings of plates would be mixed with

other modelings using PRES_REP.

In addition it should be noted that efforts of pressure, whether it is with FORCE_COQUE (near) or

PRES_REP are such as a positive pressure acts in the contrary direction with that of the normal with

the element. By defect, this normal is dependant on the direction of course of the nodes of an element, it

who is not always very easy for the user. Moreover it is necessary that the aforementioned makes sure that all these

elements are directed same manner. One thus advises to impose the orientation of these

elements by the means of the operator

ORIE_NORM_COQU

control

MODI_MAILLAGE

(see

paragraph [§2.2.2]).

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

20/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.2.4.2 List key words factor of AFFE_CHAR_MECA_F

The key words factor Generals of operator AFFE_CHAR_MECA_F are identical to those of

operator AFFE_CHAR_MECA introduced above.

AFFE_CHAR_MECA_F

private individuals

COQUE_3D DKT DST Q4G COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

FORCE_ARETE

· ·

·

·

Total FORCE_COQUE

near

tangent room

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

·

The loadings of pressure functions of the geometry can be indicated by the means of

FORCE_COQUE

(near)

.

2.2.4.3 Application of a pressure: key word FORCE_COQUE

The key word factor FORCE_COQUE makes it possible to apply surface efforts to elements of the type

hull

(DKT

,

DST

,

Q4G

,…) defined on all the mesh or one or more meshs or of the groups

meshs. According to the name of the operator called, the values are provided directly

(

AFFE_CHAR_MECA

) or via a concept

function

(

AFFE_CHAR_MECA_F)

.

AFFE_CHAR_MECA

AFFE_CHAR_MECA_F

Remarks

FORCE_COQUE

:

·

ALL:

“YES”

NET

GROUP_MA

·

Place of application of the loading

Identify

total

FX

FY

FZ

MX

MY

MZ

·

Provided directly for

AFFE_CHAR_MECA, in the form of

function for AFFE_CHAR_MECA_F

PLAN “MOY”

“INF”

“SUP”

“MALL”

·

Allows to define a torque of efforts on

the average, lower, higher plan or of

mesh (elements DKT and DST)

Identify

room

CLOSE F1

F2

F3

MF1

MF2

·

Provided directly for

AFFE_CHAR_MECA, in the form of

function for AFFE_CHAR_MECA_F

We return in the paragraph corresponding to key word FORCE_COQUE of the document of use

operators

AFFE_CHAR_MECA

and

AFFE_CHAR_MECA_F

.

2.2.4.4 Limiting conditions: key words DDL_IMPO and LIAISON_ *

The key word factor DDL_IMPO makes it possible to impose, with nodes introduced by one (at least) of the words

keys: ALL, NODE, GROUP_NO, MESH, GROUP_MA, one or more values of displacement (or of

certain associated sizes). According to the name of the operator called, the values are provided

directly (AFFE_CHAR_MECA) or via a concept function (AFFE_CHAR_MECA_F).

The operands available for DDL_IMPO, are listed below:

·

DX DY DZ

Blocking on the component of displacement in translation

·

DRX DRY DRZ

Blocking on the component of displacement in rotation

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

21/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

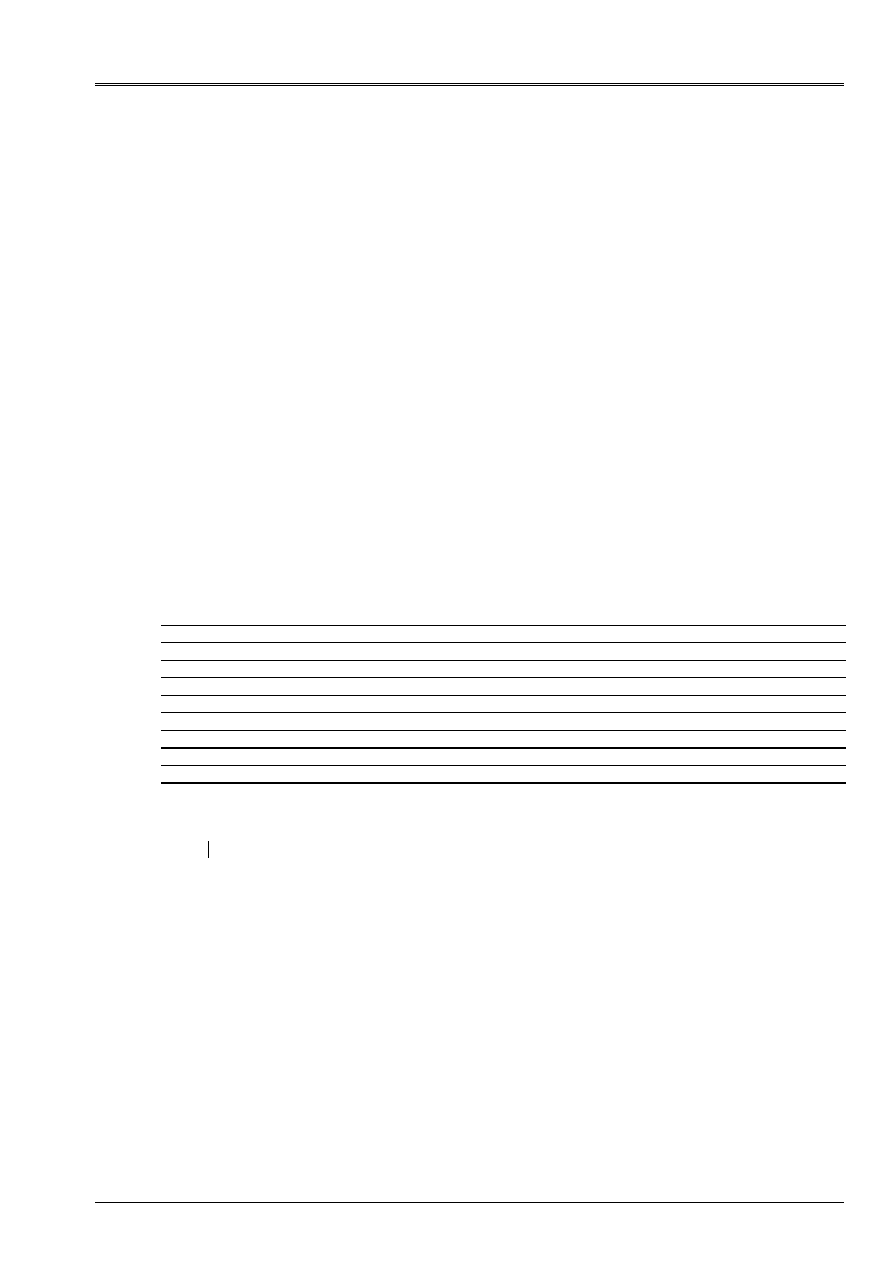

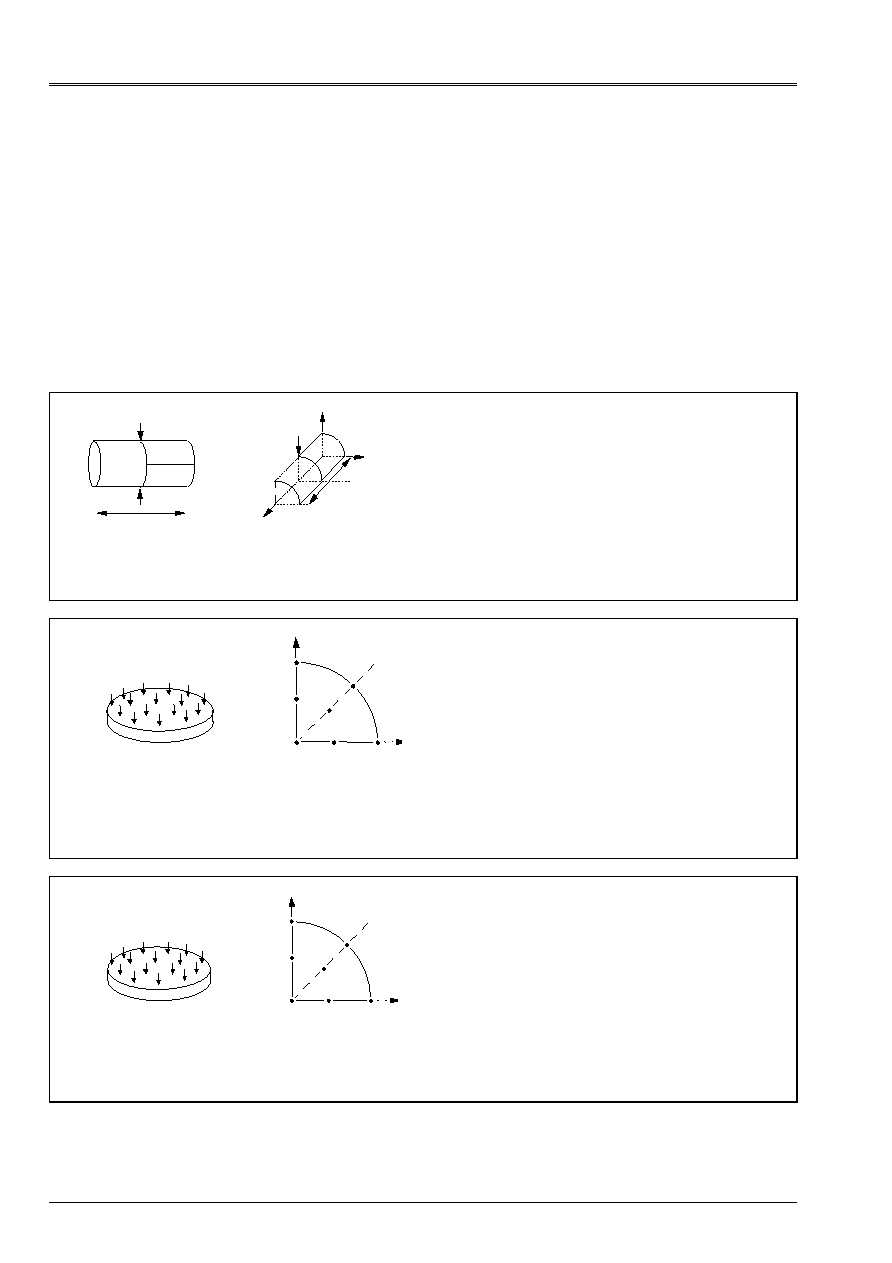

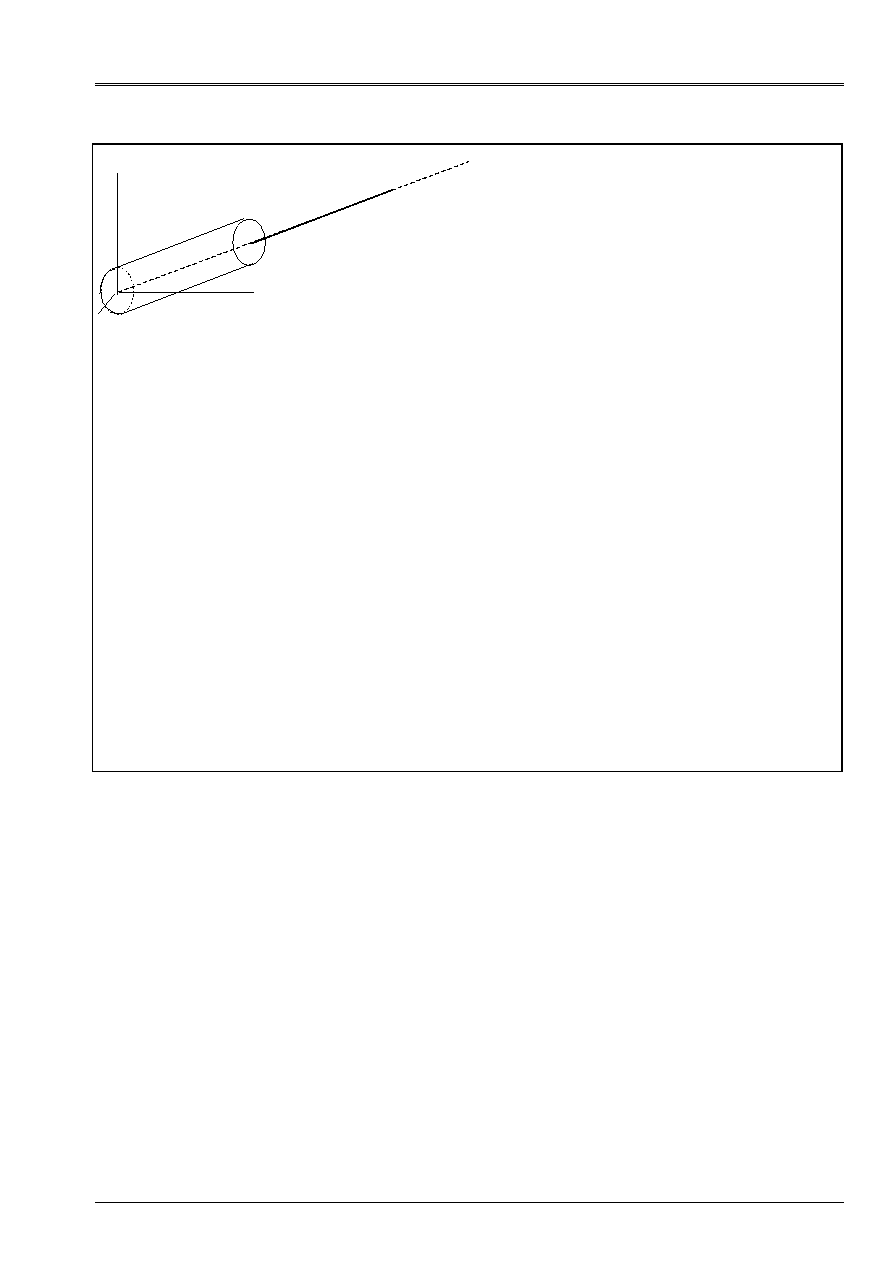

2.2.4.5 Connections hulls with other machine elements

These connections must meet the requirements established in [bib4] and that one finds in particular

in the connection 3d-BEAM in [R3.03.03].

The connections available with the elements of plates and hulls are as follows:

·

Connection Beam-Hull: it is a question of establishing the connection between a node end of an element of

beam and a group of meshs of edge of elements of hulls. Theories of beam and of

plate know only normal cuts with fiber or the average surface.

connections can take place only according to these average fibers or surfaces. The connection

beam-hull is realizable for beams whose neutral fiber is orthogonal with

normals with the breakages of the plates or the hulls. To extend to other configurations

(a beam arriving perpendicular to the plan of a plate for example) request one

feasibility study because the elements of plate or hull do not have rigidity associated with

a rotation in the plan perpendicular to the normal on the average surface. The connection is

usable by using key word LIAISON_ELEM: (OPTION: “COQ_POU”) of

AFFE_CHAR_MECA.

·

Connection Hull-Pipe: it is a question of establishing the connection between a node end of an element of

pipe and a group of mesh of edge of elements of hulls. The formulation of the connection

hull-pipes is presented in the reference document [R3.08.06]. Theories of pipe

and of plate, know only normal cuts with fiber or the average surface.

The connections can take place only according to these average fibers or surfaces. The connection

hull-pipe is realizable for pipes whose neutral fiber is orthogonal with the normals

with the breakages of the plates or hulls. The connection is usable by using the key word

LIAISON_ELEM: (OPTION: “COQ_TUYAU”) of AFFE_CHAR_MECA.

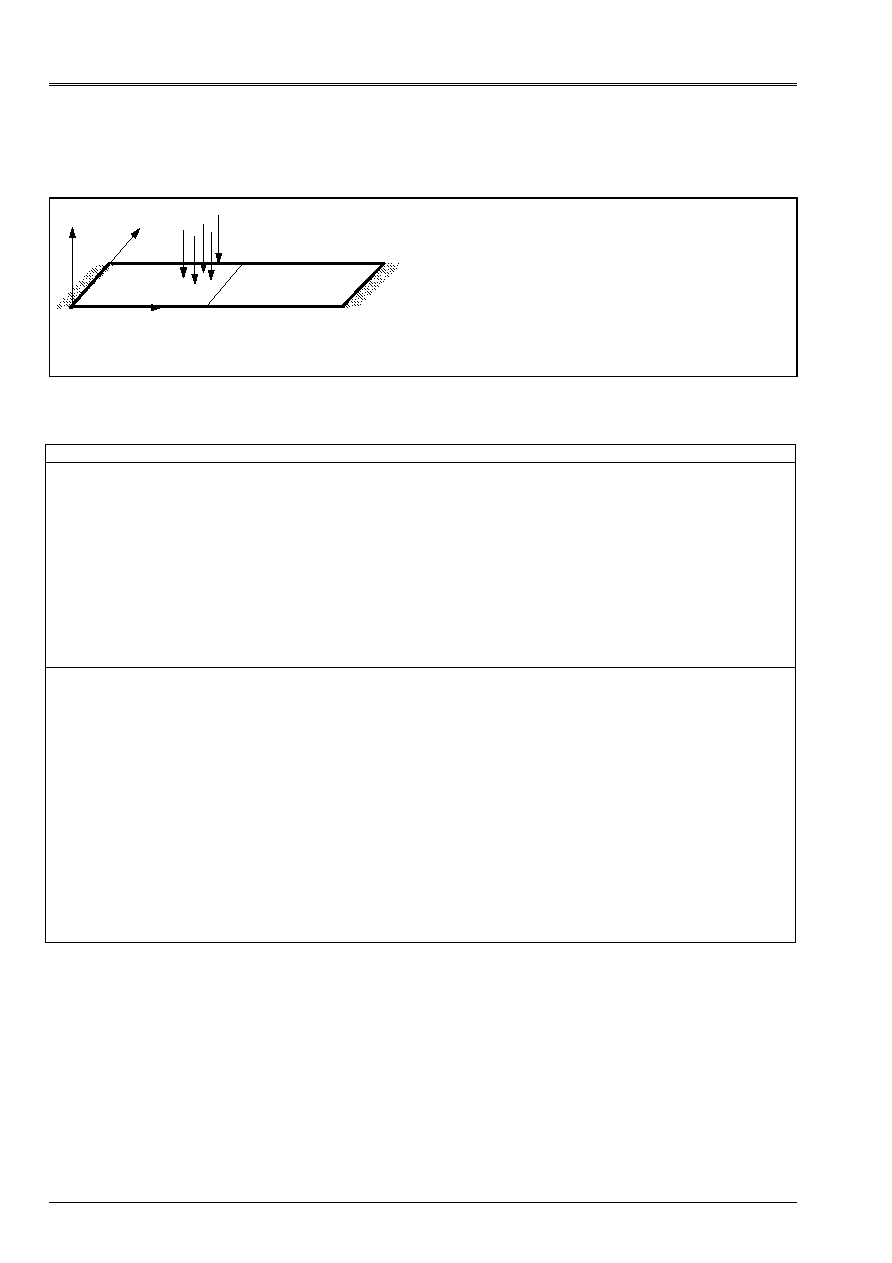

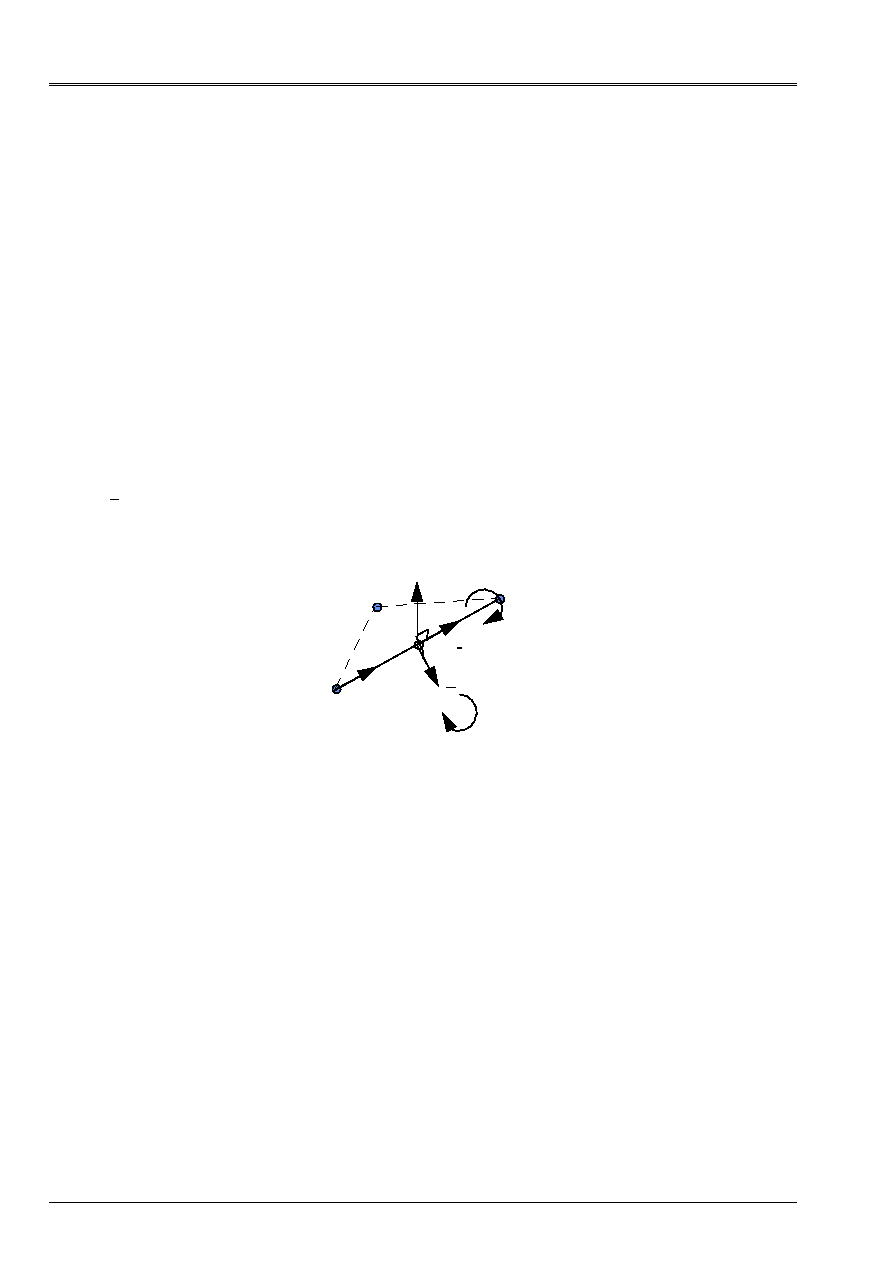

Connection plates or hull - beam

N

N

N normal with the breakage of the hull = tangent to the beam

Connection hull - pipe

Appear 2.2.4.5-a: Connections hulls with other machine elements

·

Connection Hull massive 3D: the connection massive hull-3D is being studied but it will be limited

initially with the cases where the normal with the solid is orthogonal with the normal with the one

breakages of the element of plate or hull (see [bib4]).

·

Connection between elements of Hulls: to connect two elements of hulls between them,

one uses key word LIAISON_COQUE of AFFE_CHAR_MECA (_F) (documentation [U4.44.01]).

This connection is carried out by means of linear relations. The conventional approach admits that 2

plans with a grid in hulls are cut according to a line which belongs to the mesh of

structure. In order to prevent that the volume which is the intersection of the 2 hulls is counted twice,

one stops the mesh of a hull perpendicular to a hull given to the level of the skin

higher or lower of the latter. On [Figure 2.2.4.5-b], the connection between the 2

hulls is done by connections of solid body between the nodes in with respect to segments A

1

With

2

and B

1

B

2

.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

22/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

With

1

B

1

B

2

With

2

Appear 2.2.4.5-b: Connection between elements of hulls

Case-tests making it possible to validate these connections are available in the section examples,

2.3 Resolution

2.3.1 Linear calculations: Linear MECA_STATIQUE and other operators

Linear calculations are carried out in small deformations. Several linear operators of resolution

are available:

·

MECA_STATIQUE:

resolution of a problem of static mechanics linear

([U4.51.01]);

·

MACRO_ELAS_MULT:

calculate linear static answers for various cases of

loads or modes of Fourier. ([U4.51.02]).

·

MODE_ITER_SIMULT: calculation of the values and vectors clean by methods of under

spaces. ([U4.52.03]).

·

MODE_ITER_INV:

calculation of the values and vectors clean by the method of iterations

opposite ([U4.52.04]).

·

MODE_ITER_CYCL:

calculation of the clean modes of a structure with cyclic symmetry

([U4.52.05]);

·

DYNA_LINE_TRAN:

calculation of the transitory dynamic response to an excitation

temporal unspecified ([U4.53.02]);

·

DYNA_TRAN_MODAL:

calculation is carried out by modal superposition or by under

structuring ([U4.53.21]);

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

23/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.3.2 Nonlinear calculations: STAT_NON_LINE and DYNA_NON_LINE

2.3.2.1 Behaviors and assumptions of deformations available

Following information is extracted from the documentation of use of the operator

STAT_NON_LINE: [U4.51.03].

COQUE_3D DKT DST Q4G COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

RELATION

All relations

available in stresses

plane

· ·

·

The relations 3D while using:

ALGO_C_PLAN:“DEBORST”

· ·

·

COMP_INCR

(small

deformations)

DEFORMATION:

“GREEN_GR”

Coque_3D into large

displacements and large

rotations available with

incrémentaux behaviors

nonlinear, but into small

deformations

·

RELATION ELAS

DEFORMATION:'

GREEN_GR'

·

COMP_ELAS

(large

deformations)

TYPE_CHARGE:'

SUIV'

Following pressure

·

All the mechanical nonlinear behaviors of plane stresses of the code are accessible.

One distinguishes the incremental relations of behavior (key word factor COMP_INCR) from the relations

nonlinear elastic behaviors (key word factor COMP_ELAS). The relation of behavior

connect the rates of deformation to the rates of stresses.

For modeling ROASTS reinforced concrete structures, the nonlinear behaviors

correspond to particular incrémentaux behaviors in

STAT_NON_LINE

(COMP_INCR)

:

·

GRILL_ISOT_LINE

for plasticity with isotropic work hardening,

·

GRILL_ISOT_CINE

for plasticity with kinematic work hardening linear Bi,

·

GRILL_PINTO_MEN

for the behavior of Pinto Menegotto.

Moreover, the behavior of the average concrete layer is given by a law of the type NADAI_B.

The concept RESULT of STAT_NON_LINE contains fields of displacements, stresses and

variables intern at the points of integration always calculated at the points of gauss:

·

DEPL: fields of displacements.

·

SIEF_ELGA: Tensor of the stresses by element at the points of integration (COQUE_3D and

DKT) in the local reference mark. For each layer, one stores in the thickness and for each

thickness on the points of surface integration. Thus if one wants information on one

stress for layer NC, on level NCN (NCN = - 1 so lower, NCN = 0 if medium, NCN

= +1 so higher) for the surface point of integration NG, it will be necessary to look at the value

data by the point defined in the option NOT such as

: NP = 3 * (NC-

1) * NPG+ (NCN+1) * NPG+NG where NPG is the total number of points of surface integration of

the element of COQUE_3D (7 for the triangle and 9 for the quadrangle) and of element DKT.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

24/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

·

VARI_ELGA: Field of variables intern (DKT and COQUE_3D) by element at the points

of surface integration. For each point of surface integration, one stores them

information on the layers while starting with the first, level “INF”. The number of

variables represented is worth thus 2 * NCOU * NBVARI where NBVARI represents the number of

internal variables.

It can be enriches by the following fields, calculated in postprocessing by operator CALC_ELEM:

·

SIEF_ELNO_ELGA: activate the calculation of the tensor of the efforts generalized by element with

nodes (membrane efforts, bending moments, sharp efforts), in the reference mark

user (defined in the paragraph [§2.2.2]).

·

VARI_ELNO_ELGA: activate the calculation of the field of internal variables by element with the nodes

in the thickness (by layer SUP/MOY/INF in the thickness except indication).

2.3.2.2 Detail on the points of integration

For non-linear calculations the method of integration for the elements of plate and hulls is

a method of integration by layers, of which the number is defined by the user. For each

sleep, except modeling

ROAST

, one uses a method of Simpson at three points of integration, with

medium of the layer and in skins higher and lower of layer. For NR layers the number of

points of integration in the thickness is of 2N+1.

To treat non-linearities material, one advises to use from 3 to 5 layers in the thickness for

a number of points of integration being worth 7, 9 and 11 respectively. For tangent rigidity, one calculates

for each layer, in plane stresses, the contribution to the matrices of rigidity of membrane, of

bending and of coupling membrane-bending. These contributions are added and assembled to obtain

the matrix of total tangent rigidity. For each layer, one calculates the state of the stresses and

the whole of the internal variables, in the middle of the layer and in skins higher and lower of

sleep. This information is available in VARI_ELGA and SIEF_ELGA. The behavior

plastic does not include/understand the transverse terms of shearing which are treated in an elastic way,

because transverse shearing is uncoupled from the plastic behavior.

For modeling ROASTS reinforced concrete structures, it has only one point of integration there by

sleep.

2.3.2.3 Geometrical non-linear behavior

Calculations into non-linear geometrical (great displacements and great rotations), available with

modeling COQUE_3D, are carried out using operator STAT_NON_LINE, by using it

key word COMP_ELAS, as illustrated in the following example:

STAT_NON_LINE (

COMP_ELAS (RELATION: “ELAS”

COQUE_NCOU: 3

DEFORMATION: “GREEN_GR”)

)

or by using an incremental behavior (key word COMP_INCR) in small deformations.

It is possible to apply to the elements of COQUE_3D, of the following pressures. This loading has

the characteristic to follow the geometry of the structure during its deformation (for example:

hydrostatic pressure remains always perpendicular to the deformed geometry). To take in

count this type of loading, it is necessary to specify in operator STAT_NON_LINE information

following:

STAT_NON_LINE (

EXCIT (LOAD: near

TYPE_CHARGE: “SUIV”)

)

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

25/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

The geometrical non-linear behavior of the structures can have instabilities (buckling,

snap-through/snap-back…). The determination and the passage of these limiting points, cannot be

obtained by imposing the loading, however options of piloting of loading “DDL_IMPO”

or “LONG_ARC” of operator STAT_NON_LINE make it possible to cross these critical points.

2.3.2.4 Buckling

linear

Calculations in linear buckling are similar to the search of Eigen frequencies and modes

of vibration. The problem has to solve is expressed in the form:

To find (

, X)

(R, R

NR

) such as AX=

BX

where A is the matrix of rigidity

B

is the geometrical matrix of rigidity (calculated with option RIGI_GEOM of

CALC_MATR_ELEM)

is the critical load

X is the mode of buckling associated with the critical load

Operators MODE_ITER_INV [U4.52.04] and MODE_ITER_SIMULT [U4.52.03] are used

to determine the critical load and the mode of associated buckling.

2.4

Additional calculations and postprocessings

2.4.1 Elementary calculations of matrices: operator CALC_MATR_ELEM

Operator CALC_MATR_ELEM (documentation [U4.61.01]) allows to calculate matrices

elementary, which is then compilable by control ASSE_MATRICE (documentation

[U4.61.22]).

The elementary options of operator CALC_MATR_ELEM are described below:

CALC_MATR_ELEM COQUE_3D

DKT DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

“AMOR_MECA”

· · ·

· ·

·

“MASS_MECA”

· · ·

· ·

·

“RIGI_GEOM”

·

“RIGI_MECA”

· · ·

· ·

·

“RIGI_MECA_HYST”

· · ·

· ·

·

·

AMOR_MECA: Stamp damping of the elements calculated by linear combination of

rigidity and of the mass.

·

MASS_MECA: Stamp of mass.

·

RIGI_GEOM: Stamp geometrical rigidity (for great displacements).

·

RIGI_MECA: Stamp rigidity of the elements.

·

RIGI_MECA_HYST: Hysteretic rigidity (complex) calculated by the product by one

coefficient complexes structural damping of simple rigidity.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

26/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.4.2 Calculations by elements: operator CALC_ELEM

One presents hereafter the options of postprocessing for the elements of plates and hulls. They

correspond to the results which a user can obtain after a thermomechanical calculation

(internal stresses, displacements, deformations, variables, etc…). For the modelized structures

by elements of hulls or beams it is particularly important to know how are

presented results of stresses in order to be able to interpret them correctly. Approach

adopted in Code_Aster consists in observing the stresses in a particular reference mark related to

the element whose reference axis was defined in the paragraph [§2.2.2]. Indeed, for a structure

cylindrical the stresses easiest to interpret are not the stresses in Cartesian reference mark

but stresses in cylindrical co-ordinates. Moreover this approach allows larger

flexibility in use.

OPTIONS COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

“SIEF_ELGA_DEPL”

· ·

·

·

·

·

“SIGM_ELNO_DEPL”

· ·

·

·

·

·

“SIGM_ELNO_CART”

“EQUI_ELNO_SIGM”

· ·

“EFGE_ELNO_DEPL” ·

· ·

·

·

·

“EFGE_ELNO_CART”

“EPSI_ELNO_DEPL”

· ·

·

·

·

·

“DEGE_ELNO_DEPL”

·

·

·

·

·

“EPOT_ELEM_DEPL”

· ·

·

·

·

“ECIN_ELEM_DEPL”

· ·

·

·

·

“VNOR_ELEM_DEPL”

·

MEDKTR3

·

“SIEF_ELNO_ELGA”

· ·

·

“VARI_ELNO_ELGA”

· ·

·

“SIGM_ELNO_COQU”

· ·

·

“VARI_ELNO_COQU”

· ·

·

NUME_COUCHE

· ·

·

·

·

NIVE_COUCHE

· ·

·

·

·

·

SIEF_ELGA_DEPL: Calculation of the efforts generalized by element at the points of integration of

the element starting from displacements (use only in elasticity). Identify user.

·

SIGM_ELNO_DEPL

: Calculation of the stresses by element to the nodes from

displacements in a point the thickness (key word NIVE_COUCHE = INF, SUP or MOY).

Use in elasticity. Identify user.

·

SIGM_ELNO_CART: Expression of the stresses by element to the nodes in the reference mark

total of description of the mesh. Nonavailable for the elements of plates and hulls.

·

EQUI_ELNO_SIGM: Stresses equivalent to the nodes, calculated in a point of

the thickness starting from SIGM_ELNO_DEPL or SIGM_ELNO_COQU:

VMIS: Stresses of Von Mises.

VMIS_SG: Stresses of Von Mises signed by the trace of

.

PRIN_1, PRIN_2, PRIN_3: Main stresses.

·

EFGE_ELNO_DEPL: Calculation of the efforts generalized by element with the nodes from

displacements (use only in elasticity). Identify user.

·

EFGE_ELNO_CART: Expression of the efforts generalized by element with the nodes in

total reference mark of description of the mesh.

·

EPSI_ELNO_DEPL: Calculation of the deformations by element to the nodes from

displacements, in a point the thickness (use only in elasticity). Identify

user.

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

27/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

·

DEGE_ELNO_DEPL: Calculation of the deformations generalized by elements with the nodes to leave

displacements. Identify user.

·

EPOT_ELEM_DEPL: Calculation of the linear elastic energy of deformation per element to be left

displacements.

·

ECIN_ELEM_DEPL: Calculation of the kinetic energy by element.

·

VNOR_ELEM_DEPL: Projection of a field speed on the normal of the elements hull.

·

SIEF_ELNO_ELGA: Option of activation of the calculation of the tensor of the efforts generalized (see

paragraph [§2.3.2]) by element with the nodes, in the reference mark user, by integration of

stresses SIEF_ELGA.

·

VARI_ELNO_ELGA: Option of activation of the calculation of the field of variables intern (see

paragraph [§2.3.2]) by element and layer with the nodes. For each point of integration

surface, one stores information on the layers while starting with the first,

level “INF”. The number of variables represented is worth thus 3 * NCOU * NBVARI where NBVARI

represent the number of internal variables.

·

SIGM_ELNO_COQU: Extraction of the stress field in a point in the thickness by

element and by layer (in skins SUP, MOY and INF) with the nodes. Reference mark defined by the user

with ANGL_REP. This stress fields surface can then be visualized.

·

VARI_ELNO_COQU: Calculation of the field of variables intern in a point thickness (in

skins SUP, MOY and INF, to see the key words

NUME_COUCHE

and

NIVE_COUCHE

). Reference mark defined by

the user with key word ANGL_REP of AFFE_CARA_ELEM.

·

NUME_COUCHE: In the case of a multi-layer material (composite or hull in plasticity),

whole value ranging between 1 and numbers it layers, necessary to specify the layer

where one wants to carry out elementary calculation.

·

NIVE_COUCHE: For layer N, one can specify the ordinate where one wishes to carry out it

elementary calculation. A calculation in internal skin is indicated by “INF”, in external skin by

“SUP” and on the average layer by “MOY” (according to the direction of the normal).

·

PLAN: For option EFGE_ELNO_DEPL one can specify the plan in which one wishes to have it

calculation. This possibility is interesting in the event of offsetting of the elements of plate. One

calculation in the plan of the mesh is indicated by “MALL” (defect), a calculation in internal skin is

indicated by “INF”, in external skin by “SUP” and on the average layer by “MOY”.

2.4.3 Calculations with the nodes: operator CALC_NO

OPTIONS COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

“FORC_NODA”

· ·

·

·

·

·

“REAC_NODA”

· ·

·

·

·

·

_NOEU_

· ·

·

·

·

·

For the elements of plates and hulls, operator CALC_NO (documentation [U4.81.02]) allows

only the calculation of the forces and reactions (calculation of the fields to the nodes by moyennation, option

_NOEU_):

·

starting from the stresses, balance: FORC_NODA (calculation of the nodal forces from

stresses at the points of integration, element by element),

·

then by removing the loading applied: REAC_NODA (calculation of the nodal forces of reaction

with the nodes, the stresses at the points of integration, element per element):

·

REAC_NODA = FORC_NODA - loadings applied,

·

useful for checking of the loading and calculations of resultants, moments, etc

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

28/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

2.4.4 Calculations of the elementary fields: operator CALC_CHAM_ELEM

Operator CALC_CHAM_ELEM (documentation [U4.81.03]) allows to calculate fields

elementary starting from already calculated fields of type CHAM_NO_ * or CHAM_ELEM_ *.

OPTIONS COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

“EFGE_ELNO_DEPL” ·

· ·

·

·

·

·

EFGE_ELNO_DEPL: Calculation of the efforts generalized by element with the nodes from

displacements. Identify user. See the option PLAN for the definition of the plan of calculation.

For the modelings of plates and hulls, only the efforts generalized for a field of

displacement are available.

2.4.5 Calculations of quantities on whole or part of the structure: operator POST_ELEM

Operator POST_ELEM (documentation [U4.81.22]) allows to calculate quantities on all or

part of the structure. The calculated quantities correspond to particular options of calculation of

affected modeling.

OPTIONS Operator

COQUE_3D

DKT

DST

Q4G

COQUE_C_PLAN

COQUE_D_PLAN

COQUE_AXIS

ROAST

“MASS_INER” POST_ELEM

· ·

·

·

·

“ENER_POT” POST_ELEM

· ·

·

·

·

“ENER_CIN” POST_ELEM

· ·

·

·

·

·

MASS_INER: calculation of the geometrical characteristics (volume, center of gravity, stamps

of inertia) for the elements plates and curves.

·

ENER_POT: calculation of the potential energy of deformation due to balance from

displacements in linear mechanics of the continuous mediums (2D and 3D) and in mechanics

linear for the elements of structures, or the energy dissipated thermically with

balance in linear thermics starting from the temperatures (cham_no_TEMP_R).

·

ENER_CIN: calculation of the kinetic energy starting from a field speed or one

field of displacement and a frequency (only for the elements of structure and them

elements 3D).

2.4.6 Values of components of fields of sizes: operator POST_RELEVE_T

Operator POST_RELEVE_T (documentation [U4.81.21]) allows, on a group of nodes, to extract

values or to carry out calculations:

·

to extract from the values of components of fields of sizes;

·

to carry out calculations of averages and invariants:

Moyennes,

Résultantes and moments from vector fields,

Invariants of tensorial fields,

Directional Trace of fields,

Of expression in the reference marks TOTAL, LOCAL, POLAR, USER or

CYLINDRICAL

Code_Aster

®

Version

6.3

Titrate:

Note of use of the elements plates and hulls

Date:

21/06/02

Author (S):

A. ASSIRE, P. MASSIN, F. LEBOUVIER

Key

:

U2.02.01-A

Page

:

29/50

Instruction manual

U2.02 booklet: Elements of structure

HT-66/02/003/A

The produced concept is of type counts.

To use POST_RELEVE_T, it is necessary to define three concepts:

·

a place: the option NODE (example: N01 N045) or option GROUP_NO (example: SUPPORT);

·

an object: with the choice, the option RESULT (SD result: EVOL_ELAS,…) or the option

CHAM_GD (CHAM_NO: DEPL,… or CHAM_ELEM: SIGM_ELNO_DEPL,…) ;

·

a nature: with the choice, the option “EXTRACTION” (value,…) or the “AVERAGE” option

(average, maximum, mini,…).

Important remark:

If one comes from an interface with a maillor (PRE_GIBI, PRE_IDEAS, PRE_GMSH), the nodes

are arranged by numerical command. It is necessary to reorder the nodes along the line of

examination. The solution is to use operator DEFI_GROUP with option NOEU_ORDO.

This option makes it possible to create an ordered GROUP_NO containing the nodes of a whole of

meshs made of segments (SEG2ou SEG3).

TAB_DRZ=POST_RELEVE_T (ACTION=_F (

GROUP_NO = “Of,

ENTITLE = “TB_DRZ”,

RESULT = RESUL,

NOM_CHAM = “DEPL”,

NOM_CMP = “DRZ”,

TOUT_ORDRE = “YES”,

OPERATION = “EXTRACTION”

)

)

The purpose of this syntax is:

·

to extract:

OPERATION = “EXTRACTION”

·

on the group of nodes D:

GROUP_NO = “Of

·

component DRZ of displacement: NOM_CHAM = “DEPL”, NOM_CMP = “DRZ”,

·

for every moment of calculation:

TOUT_ORDRE = “YES”

2.4.7 Impression of the results: operator IMPR_RESU

Operator IMPR_RESU allows to write the mesh and/or the results of a calculation on listing with the format

“RESULT” or on a file in a displayable format by external tools for postprocessing with

Aster: format RESULT and ASTER (documentation [U4.91.01]), format CASTEM (documentation

[U7.05.11]), format ENSIGHT documentation [U7.05.31]), format IDEAS (documentation [U7.05.01]),

format MED (documentation [U7.05.21]) or format GMSH (documentation [U7.05.32]).

Currently this procedure makes it possible to write with the choice:

·

a mesh,

·

fields with the nodes (of displacements, temperatures, clean modes, modes

statics,…),

·

fields by elements with the nodes or the points of GAUSS (of stresses, efforts

generalized, of variables intern…).