Problems are often specified rather imprecisely because the client does not understand exactly what's required, or because complete clarification requires initial exploratory work. An imprecise specification should not prevent a start being made on the problem, but it is important that designer and client communicate at the earliest opportunity - and continue to communicate throughout the design process - to make sure that they are both on the same wavelength regarding what has to be done.

It is all too easy for a poorly briefed designer to go off at a tangent. It is the designer's responsibility - not the client's - to initiate communication and to clear up any misunderstanding.

Specifications, for D&B competitions in particular, are often misinterpreted simply because they are not read with enough attention to detail. There is no place for loose interpretation. Each and every clause must be isolated, put under the microscope and examined critically to deduce its ongoing implications. Especial care must be taken to . . . .

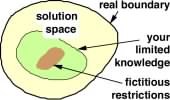

The solution space for a problem must always be finite and further constrained by the designer's limited knowledge. Extreme care must be taken to avoid tighter artificial constraints. These are fictitious restrictions which are not intrinsic to the problem but which are introduced incorrectly and usually unwittingly by the designer.

-

In the SLAMDUNK competition, students had to design and build a device to pick up a ball from a rest position on the ground, transport it to a vertical pipe 3m away, and drop it into the end of the pipe 1m

above ground - the accent was on minimising the run-time from pickup to drop. Most students divided this task into two components :

above ground - the accent was on minimising the run-time from pickup to drop. Most students divided this task into two components :

- carry the ball 3m horizontally, and

- lift the ball 1m vertically.

- A pressure vessel is used to store a pressurised fluid. It usually consists of a cylinder with end closures and with attached pipes through which fluid enters and leaves the vessel. Students were asked to design such a vessel with a 'pipe diameter of 500mm'. They took this to mean that the pipe's bore (inside diameter) was 500mm, but in fact this dimension referred to the pipe's 'nominal diameter' - a different thing entirely. By introducing this artificial constraint the students' optimum vessel was in fact some 25% unnecessarily expensive and would not have gotten past first base in a real-life tendering situation.

The detailed logic of why this fictitious bound led inexorably to a cost blow-out need not concern us here, but the point which must be made is that slack interpretation of the specification was the root cause of the blow-out - exactly the sort of thing that Somerville warned against.

Try to define a less specific problem which encompasses the given problem, thereby increasing the potential advantages of a successful solution. My poser is a case in point - rather than pussy-foot around adjusting my car's timing in an effort to reduce fuel costs and improve my finances, I am likely to be substantially more satisfied by posing and solving a broader problem.

Broadening is not always so attractive as it was in this example: it depends on the context. The client may not wish it broadened; you may be given a very specific design task to carry out - no frills, no fancy ideas, just solve the problem! While you do not have much option under these circumstances, attempts to broaden the issue - if only for your own enlightenment - will assist your understanding and solution of the specific problem.

Completion is a very detailed exercise, and in order to prevent its inhibiting creativity it should generally be left until after the bank of solution candidates has been generated.

During the problem statement therefore, completion should consist only of identifying folk who are likely to be affected by, and who must be satisfied by the design. Their agenda will be examined in detail under 'constraints and criteria' below.

Sometimes a problem lends itself to splitting into sub-problems which are each easier to solve than the original problem. For example if the problem were to collect a pile of grain at ground level and deliver it to a bin 3m high and some metres distant horizontally, then separate sub-problems might be posed :

- how to collect the grain and lift it off the ground ?

- how to elevate the grain to a height of 3m ?

- how to transport the grain some metres horizontally ?

- how to energise these various transportation components ?

- how to control these various transportation components ?

- from what materials should a device be constructed ? etc. etc.

- If you think about the problem too critically with a view to subdivision then your mind may be pre-configured into the critical mode, to the detriment of subsequent ideation.

- If subdivision leads to a plethora of problems then you might unconsciously throw in the towel - the prospect of having to solve so many problems is just too daunting.

- Subdivision of the problem may obscure unified solutions. For example if each grain transporter sub-problem were individually addressed, then it would be more difficult to come up with solutions in the form of a large industrial vacuum cleaner (answering sub-problems i-v in one fell swoop), or a couple of guys equipped with wheelbarrows and shovels (answering all the above).

- Sub-problems are seldom of equal difficulty. You must learn to distinguish between those which are relatively difficult and those which are not, putting most of your energy into solving the former. For example in D&B competitions the question of materials is often quite minor compared to the difficulty of figuring out a mechanism to carry out the required task - so the choice of materials might advisedly be left until later detailing.

Look out when you are asked to improve an existing solution! An improvement is often sought because someone else's design is less than perfect, and by sticking to the letter of your instructions you may automatically retain drawbacks which are inherent in the existing solution - recall John's oven and the inevitable limitations of retro-fixes.

Another class of 'improvement' brief arises when an existing solution must be adapted to conditions which differ from those for which it was designed in the first place - conditions for which it may be totally unsuited. Appendix A describes an unfortunate request for improvements to a computer workstation.