Retractable Roof Design Challenge

Introduction

Cambridge Athletic FC's adventurous plans for the future include the building of a modern super-stadium with a deployable/retractable roof.

Your task, working via the internet in a virtual learning environment (VLE) with all the other members of your team with an assigned member of the Cambridge University Engineering Department (CUED) acting as an adviser, is to design/draw that roof, together with a suitable supporting framework, using the computer-aided design (CAD) package specified. You and your team will then come to Cambridge for a day to build and test a working model of the design with the components/materials supplied/made by the CUED workshops.

Task Description

NAGTY project guidelines for participants

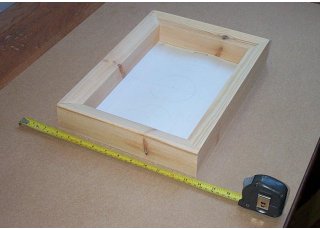

A photograph of the stadium model for which your roof is to be designed is shown below. (Overall dimensions, 38cm x 27.5cm x 5.5cm)

Getting started

We have assembled a range of support materials in the VLE to help your team undertake this challenge. The amount of information may seem overwhelming at first. Therefore we would suggest that you focus initially on learning about Project Management and the Engineering Design Process.

To help you generate your own ideas for possible solutions to this problem we have provided some general information about Deployable Structures, some information about existing Retracting Roof Stadia and some advice about how to approach the Design of Retracting Roofs.

We have also provided a range of information to support the detailed design of your model roof. Real-world engineering project teams are usually multidisciplinary with engineers with different areas of expertise (Mechanical Engineers, Structural Engineers etc.) contributing to the design process. Rather than expecting every member of your team to take in all the information provided, you may find it more effective to allocate responsibility for different aspects of your design to individual team members.

The materials and standard components you have to work with are detailed in the Kit List. A decision your team will have to make quite early on is whether to use the electric motors or the pneumatic actuators provided to deploy/retract your roof.

Submission of Drawings

As part of this challenge your team has to produce manufacturing drawings for your design using the CAD package provided. These drawings have to be submitted to us by 22 December 2005 accompanied by a short document explaining how your design is intended to work to help us interpret the drawings.

We will provide feedback on your design by 6 January 2006. You will then have the opportunity to modify your design in the light of this feedback. Final CAD drawings for your design have to be submitted by 13 January 2006.

Manufacture of Components

Using the drawings you have submitted our technicians will manufacture the metal components in your design in our workshops. Alternatively, if you have access to suitable workshop facilities at school/college or at home, you can opt to manufacture some or all of these components yourself. If you do opt to make components yourself, please remember to bring them with you when you come to Cambridge for the finale.

Components of your model made from flexible materials (simulating canvas or cable) will be manufactured by your team when you assemble your design at the finale of the challenge.

Finale

In the finale of this challenge you will come to CUED on either 28 January 2006 or 4 February 2006 to meet the rest of your team and your adviser face-to-face, to assemble and fine-tune your design, and then formally test it. The timetable for the day is:

10.00 - Arrival and registration

10.15 - Teams assemble, test and fine-tune designs

13.15 - Lunch break

14.00 - Tinkering time

15.00 - Formal test of each design

15.30 - Tour of the Deployable Structures Lab

16.15 - Presentation about real-world stadium construction by guest lecturer

17.00 - Participants depart

Post-mortem

After the finales we will assess your designs through discussion (to which all can contribute) in the VLE. The aspects of the designs to be considered will include aesthetics, ingenuity, the success of the deployment/retraction system, structural integrity, the ability to withstand additional loads (wind, snow etc.). Discussion will also cover issues related to scaling the models up to full-size, such as cost, power consumption etc.

Summary of Challenge Calendar

31 October 2005 - Teams announced, challenge starts

22 December 2005 - Deadline for submitting initial design drawings

6 January2006 - Feedback on designs

13 January 2006 - Deadline for submission of final design drawings

28 January2006 - First Challenge Finale in Cambridge (4 teams)

4 February 2006 - Second Challenge Finale in Cambridge (4 teams)